This guide shows why a properly engineered underground conveyor belt is central to real underground safety and uptime. It applies only to mines with fire/explosion hazards—coal (methane/coal dust), sulfur/phosphate/oil-shale, and certain chemical/organic operations—and begins with a table clarifying scope. We prove requirements with ISO 340, EN 14973, and MSHA Part 14 thresholds plus factory tests and field cycles (e.g., Indonesia 18–24 months). Expect clear design logic on flame resistance and conductivity, and a practical outlook: selection, splicing, tracking, and maintenance checklists you can use immediately.

Type of Mine | Presence of Flammable or Explosive Substances | Mandatory Use of Flame-Retardant & Anti-Static Belt | Common Belt Type / Standard |

Coal Mine (with methane or coal dust) | ✅ High risk: methane and coal dust are extremely flammable and explosive | ✅ Mandatory by national safety regulations | MT914-2002, MT147, GB16413 |

Metal Mine (iron, copper, lead-zinc, etc.) | ❌ Usually no combustible gas or dust | ❌ Not mandatory (optional) | Standard wear-resistant or heat-resistant belts (GB7984) |

Non-metallic Mine (limestone, granite, gypsum, quartz) | ❌ Low flammability, non-explosive dust | ❌ Not mandatory | EP/NN fabric belts for general use |

Sulfur, Phosphate, Oil Shale Mines | ⚠️ May contain combustible or volatile materials | ⚠️ Recommended or mandatory depending on gas presence | MT/T 1092 and related safety standards |

Salt or Potash Mines | ❌ Non-flammable atmosphere | ❌ Not mandatory | Standard or corrosion-resistant belts |

Underground Chemical / Organic Material Mines | ⚠️ Possible release of flammable gases or vapors | ✅ Recommended flame-retardant & anti-static type | Customized flame-retardant belts |

1.Underground Conveyor Belt: Why Real Mining Safety Starts with Design

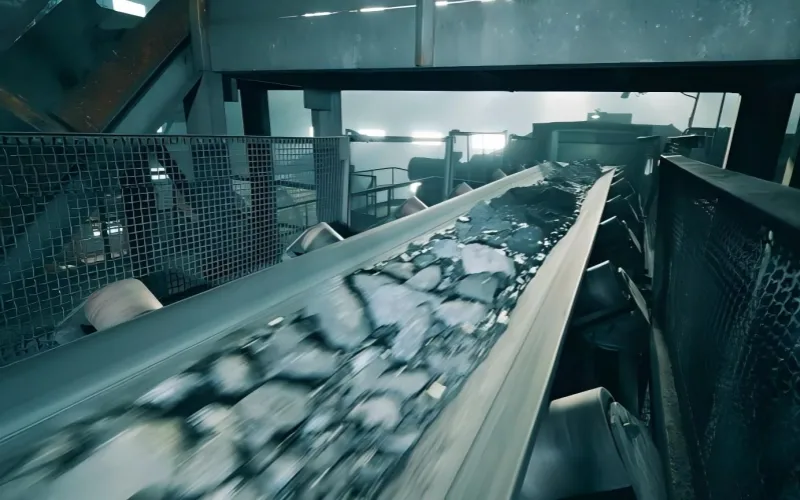

Every minute underground, safety depends on the systems we build to handle extreme pressure. Among them, the underground conveyor belt does far more than transport material — it connects every stage of the mine’s operation. When it fails, everything behind it stops.

The 2014 Soma coal mine disaster in Turkey, which caused over 300 casualties, began near an underground electrical distribution box. Official investigations confirmed the initial ignition was electrical, not mechanical. However, subsequent analyses by independent researchers found that the non flame-resistant conveyor belts accelerated smoke and flame propagation through the tunnels, worsening the impact on trapped workers ( SciELO Study on Conveyor Belt Fire Behavior). The event highlighted one fact that no engineer can ignore: in underground mining, a conveyor belt is not just a piece of equipment — it’s a potential ignition source.

Working conditions underground are unforgiving. High humidity, dust, poor airflow, and flammable gases all combine to create an environment where ordinary belts simply don’t survive. Heat from friction or electrical faults can quickly turn into a fire. According to the U.S. Mine Safety and Health Administration (MSHA), conveyor belt incidents are a top cause of mine emergencies (MSHA – Flame Resistant Conveyor Belts). A related federal study found that roughly 15% of underground coal mine fires were connected to belt systems (GovInfo – Analysis of Fire Data).

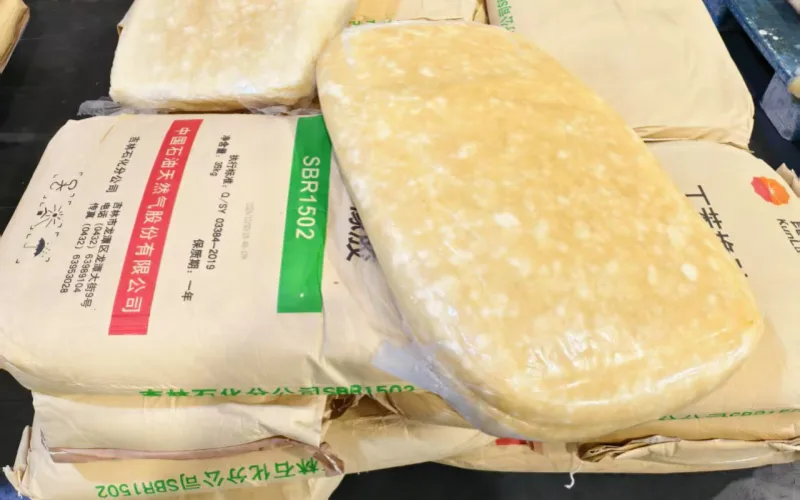

That’s why modern flame resistant conveyor belts are designed differently. Their cover rubber uses compounds such as Polychloroprene (CR) and SBR(Flame retardant needs to be added), which can self-extinguish and resist heat propagation. To prevent static discharge, conductive carbon black and special fibers are embedded into the rubber, forming a reliable anti-static belt that protects against spark formation in gas-rich areas.

Before any belt enters an underground mine, it must pass stringent global certifications — ISO 340, EN 14973, and MSHA Part 14. These standards evaluate flame spread, smoke behavior, and electrical resistance. For safety compliance, the surface resistance must remain below 3×10⁸ Ω. Anything higher can allow dangerous static buildup.

From Soma in Turkey to Aracoma in the U.S., accident investigations point to the same lesson: an underground conveyor belt is as critical to safety as any piece of life-support equipment. When it’s built right, tested right, and maintained right, it doesn’t just move ore — it keeps people alive and operations stable.

2.Underground Conveyor Belt vs Outdoor Conveyor Belt: Designed for Two Different Realities

The underground conveyor belt operates in one of the harshest industrial environments imaginable. Every belt must perform under high humidity, heat, and explosive gases. In contrast, an outdoor conveyor belt — typically used in surface mining or bulk material handling — works in open-air conditions where temperature, ventilation, and maintenance are far easier to control. This environmental gap drives major differences in belt design, materials, and safety performance.

1. Operating Conditions and Risk Factors

In underground mining, even a small friction point or static charge can ignite methane gas or coal dust. Fire spreads rapidly through confined tunnels where air circulation is limited. The U.S. Mine Safety and Health Administration (MSHA) reports that more than 15% of all underground mine fires involve conveyor systems (MSHA – Conveyor Safety Guidelines). Outdoor belts, by comparison, face mechanical risks like wear or slippage. Open air reduces heat buildup and allows faster emergency response.

2. Material Engineering

Underground conveyor belts are made from flame-resistant CR or CR/SBR rubber compounds, which form a self-extinguishing barrier and limit flame spread. To prevent static discharge, conductive carbon black and anti-static fibers are added to the rubber, creating a stable conductive network with surface resistance below 3×10⁸ Ω, ensuring ignition safety in methane or coal-dust environments.

3. Structural Strength and Flexibility

The underground belt must handle stronger tension and tighter pulley diameters, often across long distances. Reinforced EP (polyester-nylon) and steel cord carcasses provide low elongation, excellent adhesion, and fatigue resistance. The underground conveyor belt is designed for continuous operation in confined tunnels where failure is not an option.

In contrast, the outdoor conveyor belt focuses on throughput and maintenance convenience. Because it’s accessible, the internal structure can be lighter. Durability matters, but flame resistance and conductivity control are not mandatory.

4. Safety Standards and Compliance

Every underground conveyor belt must meet global safety certifications: ISO 340, EN 14973, and MSHA Part 14. These standards define flame resistance, smoke density, and surface resistivity. To pass, the belt must self-extinguish within 15 seconds, restrict flame propagation to under 125 mm, and maintain surface resistance below 3×10⁸ Ω. These requirements do not apply to typical outdoor belts.

5. Service Life and Maintenance

Underground belts must operate continuously with minimal access for repairs. Edge sealing, moisture barriers, and specialized bonding technologies improve lifespan by 30–50% compared to outdoor conveyor belts. These design choices prevent delamination and moisture damage — common causes of underground failures.

6. Cost vs Safety

While an outdoor conveyor belt may offer lower upfront costs, the underground conveyor belt provides far higher long-term value. Its safety design prevents fires, downtime, and regulatory violations. As the MSHA data confirms, the cost of one fire underground can exceed years of savings on cheaper materials.

In simple terms, both systems move material — but only the underground conveyor belt is engineered for survival. It’s not just stronger; it’s safer, smarter, and built to protect every life underground.

3.Inside the Underground Conveyor Belt – Structural Design for Harsh Conditions

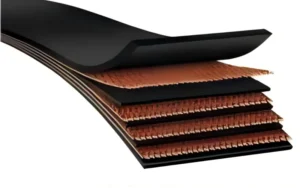

Every underground conveyor belt is more than a moving strip of reinforced rubber — it’s a safety-critical system designed to endure high tension, extreme humidity, abrasive dust, and explosive gases. Its internal design defines how safely and efficiently an underground mine operates. To understand why the right structure matters, let’s look inside the belt—layer by layer—and explore how materials, bonding, and standards turn raw rubber into a lifeline for underground mining.

1. The Core of an Underground Conveyor Belt – Strength Begins at the Center

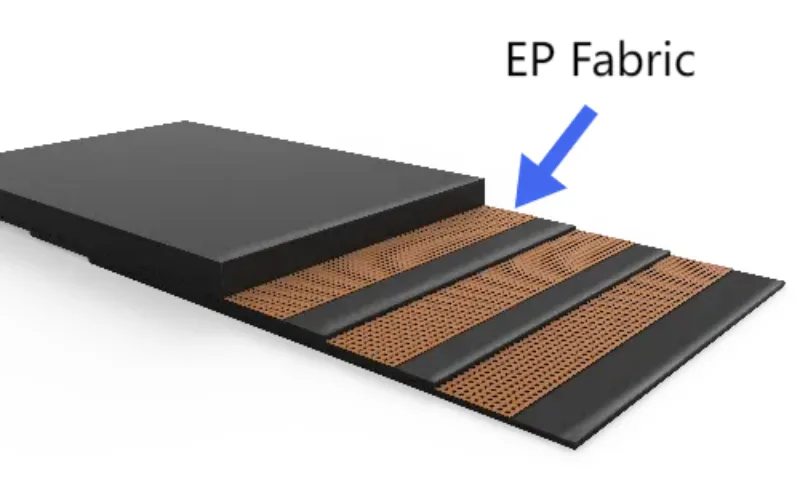

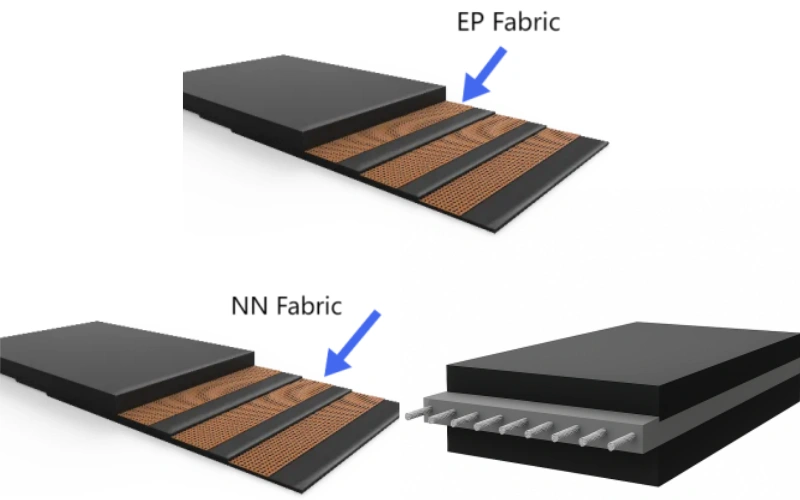

The carcass is the mechanical backbone of every underground conveyor belt. It bears tension, absorbs impact, and provides dimensional stability. The three common reinforcement types—EP, NN, and ST—each serve specific engineering needs.

- EP Belts (Polyester/Nylon):

EP belts combine low elongation (from polyester) with good flexibility and impact resistance (from nylon). They maintain stable tension even in humid tunnels, making them the most widely used carcass structure in underground conveyor belts. Ideal for medium to long-distance conveying, EP belts are easy to splice and maintain precise tension control—critical for multi-drive underground systems. - NN Belts (Nylon/Nylon):

NN carcasses provide excellent impact resistance and shock absorption, making them useful for steep or drop-fed conveyors. However, their higher elongation can complicate tension control in long, enclosed conveyors. In underground mines, NN belts are sometimes used at transfer points or short-distance conveyors where impact loads are high but precision alignment is less critical. Their flexibility is an advantage, but humidity can increase stretch, requiring more frequent tension adjustments. - ST Belts (Steel Cord Type):

For long-haul or high-capacity transport, the steel cord underground conveyor belt is unmatched. Each steel cable runs parallel within the rubber matrix, providing ultra-low elongation (≤0.25%), superior adhesion, and uniform tension distribution. Steel cord belts are standard in main haulage tunnels, where they can exceed several kilometers in length and operate continuously with minimal maintenance.

- EP Belts (Polyester/Nylon):

The takeaway: EP and ST belts dominate underground applications, while NN belts play niche roles where impact resistance outweighs precision needs.

2. Protective Layers of an Underground Conveyor Belt – Where Safety Takes Shape

The outer covers transform structural strength into operational safety. In an underground conveyor belt, the cover rubber protects against heat, flame, static, and abrasion. The formulation depends on the mine’s fire risk, gas content, and mechanical load.

The flame resistant conveyor belt typically uses Polychloroprene (CR) or SBR blend systems, not EPDM. These compounds form a carbonized barrier under heat, cutting off oxygen supply and stopping flame propagation. According to ISO 340 , EN 14973 , and Chinese standard MT147, compliant belts must self-extinguish within 15 seconds, with a flame spread of less than 125 mm.

Static discharge prevention is equally vital. Conductive carbon black and anti-static fibers are integrated into the rubber compound, forming a consistent conductive path. This keeps surface resistance below 3×10⁸ Ω, as defined in ISO 284, ensuring sparks cannot form even under dry, frictional conditions.

3. Typical Rubber Systems in Flame-Resistant and Anti-Static Underground Conveyor Belts

Application | Typical Rubber System | Key Characteristics |

Underground coal mine flame-resistant and anti-static belt | CR or CR + SBR blend | Balances flame retardancy and conductivity; recommended by Chinese standards MT914 / MT147 |

Steel cord anti-static belt (ports, power plants) | NBR + CR blend | Excellent conductivity, oil resistance, and aging stability |

General industrial anti-static fabric belt | SBR + conductive carbon black | Cost-effective for moderate static dissipation needs (e.g., grain, electronics) |

These systems illustrate why CR-based compounds dominate underground designs — they provide a proven balance of flame resistance, static control, and durability under harsh conditions.

4. Bonding Technology in an Underground Conveyor Belt – Hidden Strength Beneath the Surface

More than 60% of underground belt failures originate from weak interlayer bonding. To prevent delamination, modern underground conveyor belts use precision calendering and controlled vulcanization.

In EP and NN belts, adhesion is achieved through optimized skim rubber and multiple calendered plies. In ST belts, brass-coated steel cords chemically bond with sulfur-cured rubber, creating exceptional shear strength. Tiantie Industrial’s production data show that optimized bonding can extend belt life by up to 40–50% under high moisture conditions.

Edge sealing is another vital defense. Sealed edges — using heat-cured rubber or polyurethane coating — block water and chemical ingress, preventing separation and reinforcing mechanical stability in humid mines.

5. Testing and Standards – Proving Safety in Every Underground Conveyor Belt

Every underground conveyor belt must pass standardized tests before shipment. Tensile strength for fabric belts must exceed 10 MPa, and steel cord belts 14 MPa. Adhesion between rubber and carcass follows DIN 22102 and ISO 252.

Flame resistance is verified under ISO 340 and MSHA Part 14, where after-flame time, smoke density, and char length are precisely measured. Static resistance is tested to ensure surface resistivity below 3×10⁸ Ω.

Tiantie Industrial’s laboratory employs DIN abrasion testers, flame chambers, and resistance meters for each production batch. Every belt is traceable by batch number, reinforcing mining safety and accountability.

6. Manufacturing Precision in an Underground Conveyor Belt – From Process to Performance

A modern underground conveyor belt is the result of strict manufacturing discipline.

During calendering, rubber thickness and fabric tension are electronically monitored. Steel cord alignment uses automatic tension correction to ensure even spacing. Vulcanization takes place under controlled temperature and pressure to guarantee consistent bonding across the belt width.

Each flame resistant conveyor belt undergoes batch testing for tensile strength, elongation, flame propagation, and surface resistance before shipment. These procedures transform conveyor belts from industrial components into verified safety products.

7. Why the Structure of an Underground Conveyor Belt Determines Survival

A well-engineered underground conveyor belt doesn’t just move material — it protects lives. From the carcass to the rubber compounds and bonding technology, every layer contributes to long-term safety. EP and steel cord carcasses prevent elongation and failure; CR/SBR covers self-extinguish fires; and conductive additives discharge static electricity before it becomes a spark.

When all these design factors work together, the result is not just a durable belt, but a safety-certified shield for underground mining operations. In this sense, the true strength of an underground conveyor belt lies inside — in the structure you can’t see but rely on every day.

4. Flame Resistance of Underground Conveyor Belts – How Fire-Safe Design Protects the Mine

Flame resistance is the defining property that determines whether an underground conveyor belt can operate safely under extreme conditions. According to the MSHA list of approved flame resistant conveyor belts fewer than 5% of belts submitted for certification fail to meet flame-resistance standards, yet most of those failures stem from uneven bonding or unstable rubber composition. In underground mining, where heat, gas, and friction coexist, a belt that fails to self-extinguish can quickly turn a small spark into an uncontrollable emergency.

1. Why Flame Resistance Matters Underground

Conventional conveyor belts made with NR or SBR rubber are suitable for general industrial use but lack inherent flame resistance. When exposed to heat or frictional sparks, these materials can sustain combustion once ignited because they do not self-extinguish.

By contrast, flame-resistant compounds based on CR or CR/SBR blends form a carbonized insulating layer when heated. This layer blocks oxygen and stops flame propagation — a crucial feature in underground mining, where airflow is limited and even a small ignition can escalate quickly.

A flame resistant conveyor belt behaves differently. It chars on the surface, forming a barrier that blocks oxygen from reaching the reinforcement layers. This self-extinguishing characteristic is the foundation of mining safety, ensuring that a localized heat source does not propagate fire through the entire conveyor system.

2. The Chemical and Mechanical Logic of Flame Resistance

The resistance to flame is achieved through a carefully balanced rubber compound that combines Polychloroprene rubber (CR), styrene-butadiene rubber (SBR), and flame retardant fillers.

- CR contributes chemical stability and inherent flame retardancy; when exposed to heat, it releases small amounts of hydrogen chloride that suppress the combustion chain reaction.

- SBR adds tensile strength and flexibility, allowing the belt to maintain mechanical integrity even after heat exposure.

- Aluminum hydroxide (ATH) and magnesium hydroxide (MDH) decompose endothermically, absorbing heat while releasing water vapor, which dilutes flammable gases and cools the belt surface.

In combination, these mechanisms ensure that the underground conveyor belt resists ignition, limits flame spread, and retains its structure during emergency conditions.

3. Testing and International Certification

No belt can be sold for underground use without proven flame-resistance certification. The major international standards include:

- ISO 340:small-flame test requiring the belt to self-extinguish within 15 seconds, with char length under 125 mm.

- EN 14973:adds low-smoke and low-toxicity criteria for confined airways.

- MSHA Part 14 (30 CFR §14.22): conducts full-scale flame propagation tests under controlled airflow.

- MT 914 (China): combines flame, adhesion, and heat-aging resistance.

At Tiantie Industrial’s testing center, every production batch undergoes a calibrated ISO 340 test. Technicians monitor after-flame time, smoke density, and re-ignition potential. The results are recorded for traceability, ensuring that every flame resistant conveyor belt delivered meets the performance requirements of both MSHA and MT 914 standards.

4. Engineering Effects in Real Operations

In real underground operations, flame resistance brings measurable, practical benefits—not theoretical ones.

- Reduced secondary ignition:When a roller locks up or a belt misaligns, localized heating can create friction burns. Flame-resistant rubber prevents that hot zone from turning into a secondary fire source.

- Cleaner ventilation circuits:Belts that self-extinguish produce far less smoke and soot, maintaining clearer airways and extending filter and fan service life.

- Stable splicing and repair:During hot vulcanization, flame-resistant compounds maintain bonding integrity without producing flammable vapors, lowering the risk during repair in confined spaces.

- Regulatory confidence:Mines that use certified belts simplify safety inspections and compliance documentation under both local and international standards.

These are the engineering realities that matter underground—not theoretical savings, but fewer incidents, safer repairs, and stable ventilation integrity.

5. Material Consistency and Long-Term Stability

Flame resistance can degrade over time if the belt’s composition is inconsistent. Uneven dispersion of flame retardants or poor bonding between plies can create weak zones that ignite earlier than tested samples. Tiantie’s process control focuses on maintaining compound homogeneity across all 20 production lines. Every roll is batch-tested before vulcanization to confirm adhesion and surface resistance. This consistency ensures that a belt’s fire protection remains stable even after months of continuous service in humid or dusty tunnels.

6. A Practical View on Safety

In underground mining, perfection doesn’t mean eliminating risk—it means controlling it. Flame-resistant belts do not prevent heat, dust, or friction, but they prevent these normal stresses from escalating into tragedy. A compliant underground conveyor belt represents more than a certificate; it’s the sum of design precision, verified testing, and material reliability.

At Tiantie Industrial, our approach to flame resistance is simple: build the belt to withstand the worst so that miners never have to face it. That’s not marketing—it’s the reality of safety below the surface.

5. Anti-Static Technology of Underground Conveyor Belts – The Hidden Layer of Safety

In underground mining, electricity doesn’t always come from wires. Sometimes, it’s invisible, silent, and waiting to spark. That’s static electricity — a hidden but serious hazard. Every underground conveyor belt must be built not only to resist flame but also to dissipate static charge safely. Flame resistance stops a fire once it starts; anti-static performance prevents it from starting at all.

1. Why Static Electricity Is a Hidden Risk Underground

A moving conveyor constantly generates static through friction — between the belt, the rollers, and the dry coal dust coating everything. Underground, humidity levels are often below 40%, allowing voltage buildup far above 20 kV on the belt surface.

At that level, a discharge won’t electrocute anyone — but it can ignite a methane-air mixture in milliseconds. That’s why every mine safety regulation, from MSHA Part 14.21 to MT147, mandates surface resistance below 3×10⁸ Ω for conveyor belts used underground.

2. Why 20 kV Static Doesn’t Kill – But Still Destroys Mines

This is a classic misunderstanding: “If static voltage can reach 20,000 volts, why doesn’t it kill people?” The answer lies in the difference between static charge and continuous current.

Static electricity involves high voltage but extremely low charge — usually a few nano- to micro-coulombs — discharged in billionths of a second. The total energy is tiny, often below 0.02 J (about 20 millijoules). That’s enough to ignite coal dust, but not enough to harm human tissue.

Comparison | Electrostatic Discharge (ESD) | Power Supply Voltage (DC/AC) |

Voltage | 10–50 kV | 12–220 V |

Charge (Q) | nC–μC | Continuous current |

Duration | Nanoseconds | Continuous |

Energy | Millijoules (mJ) | Joules–kilojoules (J–kJ) |

Effect | Shock or spark | Potentially lethal |

A static discharge is like a single tap on your hand — sharp but brief. A 36 V DC power source, by contrast, is like someone holding that tap continuously.

The human danger threshold is around 30 mA sustained for 0.1 s, while an electrostatic discharge rarely lasts more than 100 ns.

So, while a 20 kV discharge won’t kill, it carries enough energy to ignite methane or coal dust, whose minimum ignition energy (MIE) can be as low as 20–60 mJ (U.S. Mine Safety and Health Administration Data).

That’s why anti-static belts matter: not to protect humans from shock, but to protect mines from ignition.

3. Designing the Right Conductive System

In conveyor belts, the goal is to maintain resistivity between 10⁶ and 10⁸ Ω — enough to dissipate charge safely, but not so low that the belt overheats or loses flexibility. This “ESD-safe window” ensures charge flows gradually into the grounded structure.

Choosing the right material combination is key:

- CR (Polychloroprene Rubber):Highly polar, stable, and compatible with conductive fillers; ideal for general mining use.

- NBR (Nitrile Rubber):Best for oily or greasy environments; maintains conductivity with oil resistance.

- SBR (Styrene-Butadiene Rubber):Cost-effective and flexible; used in lighter ESD belts.

- EPDM:Non-polar and poor in dispersion; unsuitable unless heavily modified.

CR or CR/SBR blends remain the preferred base for anti-static underground conveyor belts, balancing processability and conductivity stability.

4. Conductive Networks and Layer Design

Conductivity in rubber is achieved through both chemistry and architecture:

- Conductive carbon black (10–20 phr) forms the base conductive network. High-structure blacks like Ketjenblack provide strong charge paths with minimal loading.

- Conductive fibers — carbon or stainless steel — act as macro discharge paths across the belt length.

- Layered design routes charge from the cover to the core: a conductive middle layer links to ground terminals at pulleys and steel-cord anchors, keeping total resistance ≤ 10⁸ Ω.

A well-engineered belt doesn’t just “not spark” — it bleeds charge smoothly through the system, maintaining safety in any humidity.

There is also a simple measure. Many conveyors under mines are suspended with iron chains. In addition to absorbing energy, the biggest use is to ground the iron chains and conduct away excess charge.

5. Testing and Certification

Every anti-static conveyor belt must be certified under specific standards:

- MSHA Part 14.21: Surface resistance ≤ 3×10⁸ Ω.

- MT147: Continuous conductivity with no isolated zones.

- IEC 60079-32-1: Static control in explosive atmospheres.

Testing is performed at 23 ± 2 °C and 60 ± 5% humidity with a surface resistance meter. Tiantie’s internal testing uses five measurement points per sample roll to ensure conductivity uniformity.

6. Real Engineering Practice

In production, formulations depend on working conditions:

- Coal mines:CR/SBR = 60/40 ± 10, 12–18 phr conductive carbon black, plus a central conductive layer and ground terminal.

- Oily sites (ports, power plants):NBR/CR = 70/30 ± 10, 10–16 phr carbon black, using high-acrylonitrile NBR.

- General ESD belts:SBR-based, 10–14 phr carbon black, one longitudinal conductive strip achieving 10⁶–10⁸ Ω.

This engineering control ensures safe discharge performance without compromising tensile strength or flame resistance.

7. Balancing Flame Resistance and Conductivity

A flame resistant belt stops a fire from spreading.

An anti-static belt prevents that fire from starting.

Together, they define what true mining safety means.

A modern underground conveyor belt isn’t just rubber and fabric — it’s a controlled electrical system, grounded, tested, and designed to keep sparks from ever becoming headlines.

6. Performance Testing and Certification of Underground Conveyor Belts

Every underground conveyor belt is more than a strip of rubber — it’s a critical safety component that must perform under heat, tension, humidity, and chemical stress. To ensure that each belt delivers consistent performance, international standards require full laboratory testing before it can be certified for mining use. Flame resistance, anti-static conductivity, tensile strength, adhesion, and wear resistance are not marketing claims; they are measurable, verifiable data points that define the belt’s reliability underground.

1. Why Testing Matters

Underground mines operate under conditions that push materials to their limits. A belt can run over 10 kilometers in a closed loop, exposed to dust, vibration, moisture, and heavy impact. A single layer of delamination or an unnoticed static buildup could result in serious downtime — or worse, ignition. That’s why global regulations from ISO, MSHA, and MT standards require belts to undergo comprehensive performance testing before installation.

Testing ensures not only compliance but also predictability: knowing exactly how the belt behaves under load, heat, and flame means knowing how to prevent accidents.

2. Core Testing Categories

Each underground conveyor belt undergoes five major categories of laboratory testing:

- Tensile and Elongation Testing:Measures strength and deformation under load. Using DIN 22102 or ISO 283 methods, the belt must meet minimum tensile ratings (e.g., EP315/3 means 315 N/mm 3 ply).

- Adhesion Testing:Evaluates bonding strength between layers of fabric and rubber. ISO 252 ensures adhesion values above 4.5 N/mm for cover–ply bonding.

- Flame Resistance Testing:According to ISO 340 and EN 14973, belts are exposed to a controlled flame; self-extinguishing time must be ≤15 s and char length ≤125 mm.

- Anti-Static Testing:As defined in MSHA Part 14.21 and MT147, surface resistance must remain below 3×10⁸ Ω with no isolated high-resistance zones.

- Abrasion and Wear Resistance:Measured by DIN 53516 or ISO 4649, which assess volume loss under 10 N pressure; lower values indicate better wear performance.

These tests collectively determine whether a belt is suitable for continuous underground service.

3. Flame and Static Testing: Dual Certification

For a belt to be accepted in mining operations, it must pass both flame and static tests — one without the other is insufficient.

- Flame resistance ensures that the belt will self-extinguish under ignition, measured by char length and after-flame time.

- Static resistance ensures the belt cannot accumulate or discharge dangerous voltages.

Certification bodies such as MSHA and TÜV Rheinland conduct full-scale tests simulating real mine airflow conditions. In China, MT 914 integrates both requirements, combining flame, anti-static, and mechanical stability testing in one unified protocol.

The result is a globally recognized safety benchmark: if a belt meets these standards, it can be used in coal mines from Shanxi to South Africa without modification.

4. Equipment and Testing Environment

Modern testing facilities are built to replicate underground conditions. Tiantie Industrial’s laboratory includes:

- DIN abrasion tester:simulates wear caused by continuous material loading.

- Flame test chamber (ISO 340 calibrated):monitors flame propagation, after-flame time, and char length.

- Surface resistance meter:verifies anti-static performance under 23 ± 2°C and 60 ± 5% humidity.

- Tensile testing machine:measures breaking load and elongation for each carcass type (EP/NN/ST).

- Peel adhesion tester:checks the bond strength between cover and fabric layers.

All instruments are calibrated according to ISO 17025 laboratory requirements, ensuring test results remain traceable and internationally valid.

5. Data Verification and Certification

After testing, data is validated against the appropriate standards and recorded in a traceable batch report.

- ISO 9001 certification ensures process consistency.

- ISO 14001 covers environmental compliance in test materials and waste handling.

- SGS and TÜV provide independent third-party verification, confirming that all belts meet the claimed ratings.

- MSHA Approval Number(e.g., “14A-XXXX”) identifies belts approved for use in U.S. underground coal mines.

Every roll leaving the factory includes a test code linking back to its laboratory record. This traceability allows customers or auditors to access the original test data at any time — a fundamental requirement under both ISO 340 and MT 914.

6. Why Consistency Matters More Than One-Time Certification

Passing a test once isn’t enough. Real mining safety depends on batch-to-batch consistency. A belt might meet the standard in the lab but fail in production if the compound dispersion or curing profile shifts. To prevent that, Tiantie Industrial applies in-line monitoring across 20 production lines, measuring thickness, adhesion, and electrical resistance during manufacturing.

Consistency builds credibility. It means every meter of belt behaves as predicted — in fire, under tension, and through years of mechanical stress.

7. Certification as a Trust Signal

In modern global supply chains, certification is not bureaucracy — it’s reputation. A certified underground conveyor belt is proof of engineering integrity. For operators, it means less downtime and fewer safety incidents. For regulators, it means confidence that every system meets legal safety thresholds. And for end users, it’s reassurance that their investment carries both strength and safety — verified by international testing.

7. Durability and Wear Resistance in Extreme Conditions of Underground Conveyor Belts

A reliable underground conveyor belt must do more than resist fire or static — it must survive years of mechanical punishment. Underground systems run continuously, carrying sharp, abrasive materials through humid, confined spaces. The challenge is not only resisting surface wear but also preventing internal fatigue and edge degradation over time.

The main wear mechanisms underground include abrasive wear, impact damage, and edge erosion. Coal dust and ore particles act like sandpaper against the belt surface, while misaligned rollers and heavy loading create localized stress. Over time, these micro-damages accumulate, reducing the belt’s effective lifespan. According to DIN 22102 and ISO 4649, the abrasion loss rate directly correlates with expected service hours — every 50 mm³ reduction in volume loss can extend life by 10–15%.

Durability starts with the right cover compound. Heat-, oil-, and wear-resistant rubbers such as SBR, NR, and CR are formulated based on material type and loading conditions. For severe mining environments, belts rated DIN-W or DIN-X provide superior wear resistance, typically reducing surface wear by 30–50% compared with standard belts. In addition, maintaining a balanced cover thickness is essential: too thin shortens life, while too thick increases rolling resistance and power consumption.

Environmental factors also play a major role. High humidity accelerates oxidation and weakens adhesion, while temperature variation induces fatigue in the carcass fabric. To counter this, high-strength EP fabrics and precision calendering ensure uniform stress distribution across the belt width, minimizing delamination and extending operational stability.

8. Integration Within Underground Conveyor Systems – How the Belt Defines System Performance

The underground conveyor belt is the primary mechanical element that links every subsystem in a mine. Its performance determines how the entire conveying line operates — from drive torque to fire monitoring accuracy.

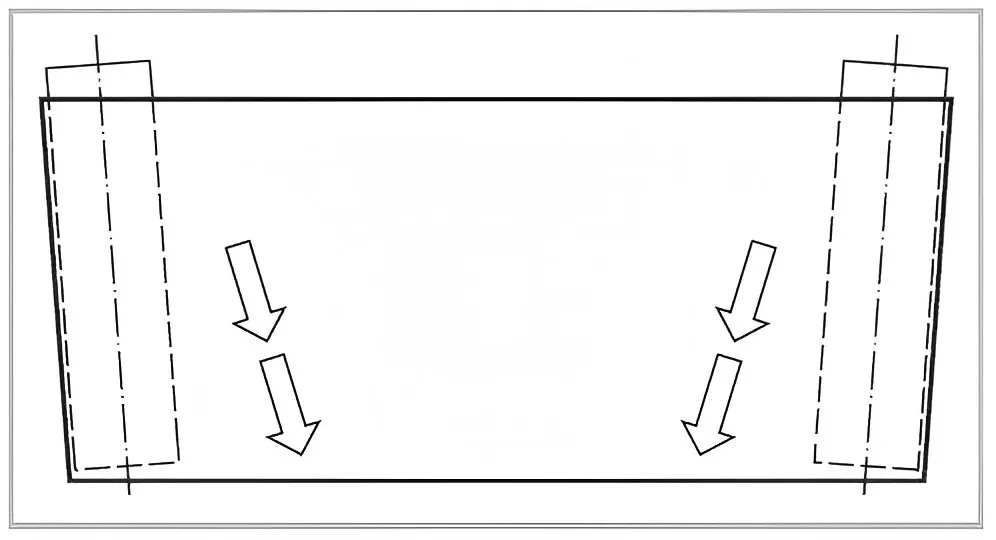

A conveyor system underground has specific mechanical limits: restricted headroom, long center distances, high humidity, and continuous operation. These conditions shape every aspect of belt design. Small pulley diameters require flexible carcasses and strong interlayer adhesion. Long-distance runs demand low-elongation fabrics or steel cords for stable tension. Constant humidity and heat require moisture-resistant rubber and sealed edges to prevent delamination.

Integration begins with mechanical matching.

- The belt stiffnessmust align with pulley diameters to avoid flex fatigue.

- The friction coefficientmust suit drive pulley lagging to prevent slip.

- The elongation valuemust fit the take-up system’s tension range.

A mismatch in any of these factors can cause slippage, tracking errors, or premature joint failure.

System protection also depends on the belt’s electrical and thermal properties. Flame sensors and heat detectors require a belt that doesn’t interfere with infrared monitoring. Anti-static and conductive layers maintain proper signal grounding for misalignment switches, speed sensors, and emergency stop circuits. These elements only work when the belt provides a stable electrical pathway throughout the loop.

The bending radius and tensioning zone design determine how the belt interacts with pulleys and return idlers. Belts with low flex modulus can negotiate tighter curves, reducing installation footprint in narrow tunnels. Proper alignment reduces friction, lowering system energy consumption by up to 8–10% compared with misaligned installations (source: Energy.gov Conveyor Efficiency Study).

Modern systems use integrated monitoring — sensors track belt tension, temperature, and alignment in real time. Predictive maintenance software detects abnormal patterns and prevents breakdowns before they stop production. But all this technology depends on a stable, mechanically consistent belt.

In an underground conveyor system, the belt defines how efficiently and safely the system performs. It carries material, transfers energy, grounds static, and stabilizes sensors — making it the functional core of the entire mine transport network.

9. Splicing, Maintenance, and Safety Practices for Underground Conveyor Belts

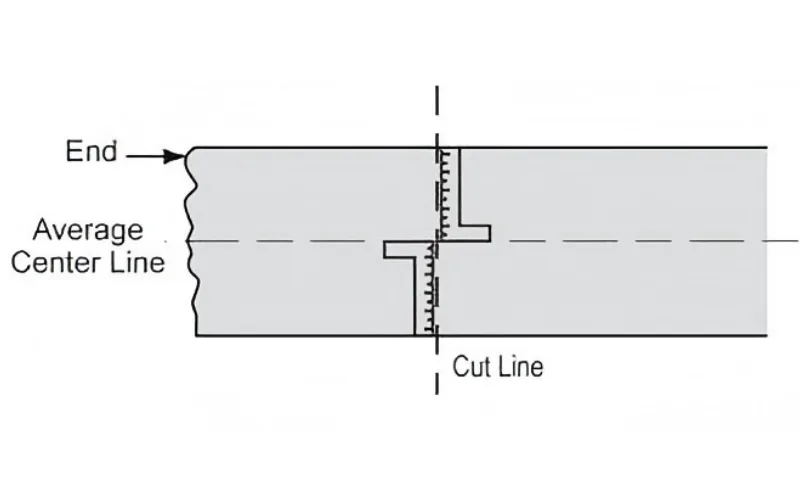

When you manage an underground conveyor belt, the first thing you should understand is that the splice controls the system’s reliability. Every failure I have investigated underground started from improper joint work or missed inspection. The splice is not just a connection; it’s a structural transition zone under continuous stress.

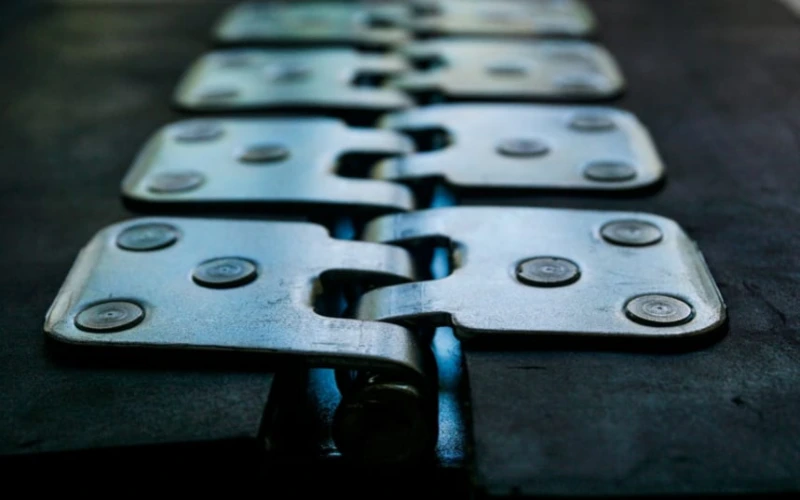

1. Selecting the Right Splicing Method

For underground applications, I always recommend hot vulcanized splicing. It provides consistent bonding and restores over 90% of the belt’s tensile strength. The process uses controlled heat and pressure, avoiding open flames and eliminating spark risk — essential in methane or coal dust environments.

Cold splicing has its place for short sections or quick repair. However, humidity and dust interfere with adhesive curing, and long-term performance drops quickly.

Mechanical fasteners are rarely acceptable underground. They create metal-to-metal contact, localized stress, and possible ignition points. Their use should be limited to temporary emergency repairs under controlled supervision.

2. Maintenance and Inspection Routine

During inspection, I start with the splice. I look for uneven surface, delamination, or hardening. Small cracks at the joint edge often signal tension imbalance or contamination between layers. Temperature should be checked with an infrared thermometer — a rise above 60°C usually means slippage or misalignment.

Tracking, tension, and pulley alignment must remain within tolerance. Inconsistent tension increases load on the splice and accelerates fatigue. Monitoring systems such as belt speed sensors and thermal cameras help, but manual inspection remains the most accurate verification.

3. Safe Working Practices

Before any splicing or repair, the conveyor must be locked out and tagged out. Verify isolation physically — not visually. Use MSHA-approved vulcanizing presses, conductive adhesives, and anti-static tools. Avoid any cutting, grinding, or heating methods that could generate sparks. Always maintain clear access to emergency stop lines and pull cords during maintenance.

Consistent inspection, proper tensioning, and controlled splicing procedures extend belt life and prevent unexpected downtime. In underground conditions, reliability depends less on replacement speed and more on process discipline.

10. Common Failure Modes and Troubleshooting of Underground Conveyor Belts

When you operate an underground conveyor belt, failures rarely appear without a cause. Most start small — a slight vibration, a temperature rise, or an uneven sound. Once you understand how each failure develops, you can stop problems before they force an unplanned shutdown.

1. Delamination and Layer Separation

Delamination often begins at the splice or belt edge when adhesion is weak or moisture contaminates the joint. Dust intrusion makes it worse with every cycle. The only real solution is full hot re-splicing with controlled pressure and curing time. Patch repairs only delay failure.

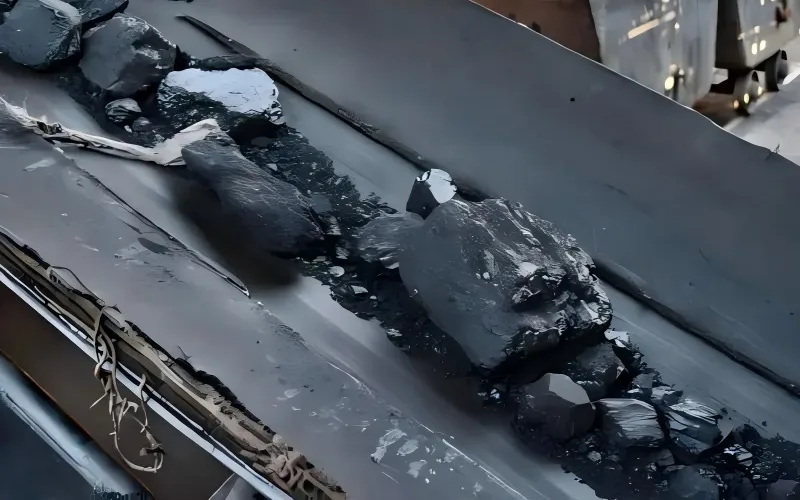

2. Surface Burn and Friction Damage

If you notice dark spots or hardened rubber, the belt is overheating. This usually results from drive slippage or misaligned pulleys. Always check tension first — low tension or worn lagging are common triggers. When belt surface temperature exceeds 80°C, the compound starts to degrade, shortening service life significantly. Clean, re-tension, and recalibrate before restarting.

3. Edge Cracking, Conveyor Belt Alignment, and Tracking Issues

Edge cracking almost always connects to conveyor belt alignment or tracking errors. When the belt drifts to one side, it rubs against frame components and generates localized heat. Over time, this leads to side wear and delamination.

After every splice or pulley adjustment, I always run a conveyor belt tracking check to ensure proper alignment across the full loop. Tracking sensors and misalignment switches help, but visual inspection remains essential.

If you need deeper calibration details, I’ve written a dedicated conveyor belt alignment and tracking guide with adjustment methods and monitoring setup.

4. Static Damage and Electrical Marks

When you see small burn dots on the surface, static discharge is the cause. This means the belt’s surface resistance has exceeded the 3×10⁸ Ω safety limit. Clean, measure again, and replace any sections with unstable readings.

5. Troubleshooting Workflow

My process is simple: isolate power, inspect visually, verify with instruments, and document findings. Repeated faults in the same section usually point to system design issues — not operator error.

A reliable underground conveyor belt doesn’t just survive wear; it stays aligned, grounded, and predictable because you correct minor tracking issues before they become major failures.

11. Life Expectancy and Cost Efficiency of Underground Conveyor Belts

When you manage an underground conveyor belt, you quickly learn that cost efficiency has little to do with the purchase price. The real question is how predictably the belt performs and how often you need to replace it. In underground systems, reliability and planning matter more than squeezing out another few months of service life.

1. Realistic Belt Lifespan

Based on field data and direct client feedback, the typical service life for an underground belt is between 10,000 and 18,000 operating hours, or roughly 18 to 24 months of continuous duty.

One of our long-term customers in Indonesia follows this exact replacement cycle — not because their belts fail early, but because they run proactive maintenance schedules tied to production plans. The mine operates in a humid tropical environment, and after two years, even a small loss of adhesion or tracking precision can increase downtime risk.

This kind of fixed-cycle replacement is common practice across Asia and South America. It allows operators to keep performance consistent and avoid sudden shutdowns that disrupt output and worker safety.

2. Cost Efficiency in Real Terms

A flame-resistant underground conveyor belt typically costs 15–25% more upfront than a standard belt, but it easily recovers that cost. A single unplanned shutdown underground can cost several thousand dollars per hour, not counting the risk of heat buildup or splicing under pressure.

Belts with higher adhesion strength, sealed edges, and stable tensioning systems extend maintenance intervals by 300–500 hours, cutting annual repair labor by 30–40%.

3. The Total Cost Perspective

When calculating the total cost of ownership (TCO), always include:

- Splicing and installation labor

- Planned downtime and replacement hours

- Energy consumption from friction and alignment losses

- Waste handling and recycling costs

The most efficient underground conveyor belt isn’t the cheapest — it’s the one that stays predictable within your maintenance cycle, runs safely, and aligns with your production plan. That’s how real cost control works in underground mining.

12. Case Studies and Innovation in Underground Conveyor Belting

When you look at how an underground conveyor belt performs over years of operation, nothing proves quality better than real data from the field. I’ll share two cases that show how modern material design and system integration have changed what’s possible underground.

1. Case 1 – Indonesian Coal Mine

One of our long-term customers in Indonesia runs a high-humidity coal operation with temperatures exceeding 35°C and fine dust throughout the tunnels. Their belts run 18–24 months per cycle under continuous duty, handling over 3,000 tons per hour.

We switched their previous SBR-based flame-resistant belt to a CR/SBR hybrid with sealed edges and conductive adhesive splicing. After two years, the replacement frequency dropped by 28%, and hot-spot readings fell below 55°C — well within MSHA Part 14 flame-safety limits. More importantly, their team now plans maintenance proactively rather than reacting to wear failures.

2. Case 2 – Chilean Copper Mine

At a copper mine in northern Chile, the environment is completely different: high elevation, low humidity, and long transport runs over 2 km. There, the challenge wasn’t fire risk but fatigue and delamination caused by temperature cycling. We replaced standard EP belts with a heat- and wear-resistant FR-D EP315/3 compound. Over 18 months of operation, splice failure rates dropped by 35%, and belt replacement intervals extended by nearly 500 operating hours.

3. Innovation and Future Trends

Today’s underground conveyor belts are not only stronger but smarter.

New LSZH (Low-Smoke, Zero-Halogen) formulations reduce toxic emissions during fire events — already compliant with EN 14973 Category C1.

Some mines have adopted digital-driven monitoring that tracks belt temperature, tension, and tracking deviation in real time. These systems predict faults up to 72 hours in advance, allowing maintenance teams to act before shutdown occurs.

Sustainability is also shaping belt production — using partially recyclable compounds and optimizing curing to reduce CO₂ emissions.

As an ISO certified manufacturer, I believe real progress in underground belting comes from one idea: safety and sustainability must evolve together. The belts of the future won’t just last longer — they’ll think faster, run cleaner, and keep your entire system one step ahead.

13. The Belt That Keeps the Mine Alive

From our experience as a rubber conveyor belt manufacturer, we’ve seen how the right design can completely change underground operations. An underground conveyor belt is not just a moving component — it’s the core element that defines how safely and efficiently the entire system performs.

In underground environments, every technical detail matters. The rubber compound determines resistance to flame and heat. The adhesion system affects splice life and bonding integrity. The anti-static layer ensures safe discharge in methane or dust-prone tunnels. And precise belt alignment and tracking directly influence power efficiency and long-term wear.

When these elements work together, a belt becomes a stable and predictable system component — not a maintenance concern. That’s why our factory focuses on material optimization, sealed-edge technology, and quality-controlled vulcanization processes to maintain performance over every operating cycle.

We’ve also learned through continuous field cooperation — from Indonesia’s humid coal mines to Chile’s dry copper shafts — that a consistent maintenance rhythm is key. Most mines now replace belts every 18–24 months as part of planned safety cycles, not because they fail early, but because prevention saves both time and cost.

Our goal is simple: to produce flame-resistant and anti-static rubber conveyor belts that run longer, safer, and cleaner underground.

When you select the right belt for your system and maintain it within the designed cycle, you don’t just extend lifespan — you build reliability into the entire mining operation.

At Tiantie Industrial, that’s what we mean when we say:

the belt doesn’t just move the mine — it keeps it alive.

14. FAQ – Expert Answers to Uncommon Questions About Underground Conveyor Belts

Q1: What makes a rubber underground conveyor belt more reliable for mining operations?

From my experience, it’s all about mechanical strength and stability under stress. A rubber underground conveyor belt—especially those built with CR/SBR or NBR compounds—maintains flexibility, tensile strength, and flame resistance even after thousands of hours of continuous loading.

Unlike lighter materials, rubber belts can absorb shock, handle misalignment, and resist delamination under wet and abrasive conditions. That’s why they remain the standard choice for serious mining operations.

Q2: What’s the real difference between a flame-resistant belt and a FRAS-certified belt?

A flame-resistant belt self-extinguishes when exposed to fire. A FRAS belt (Flame-Resistant and Anti-Static) meets both flame and conductivity standards simultaneously. In underground coal or methane-rich mines, static discharge can be just as dangerous as open flame. FRAS belts, certified under MSHA Part 14, ISO 340, or EN 14973, are mandatory where explosion risks exist.

Q3: How does humidity underground affect belt life and performance?

Humidity is one of the biggest silent killers of belt performance. It gradually weakens bonding layers and increases the risk of delamination.

In tropical mines, such as our clients in Indonesia, I’ve seen that sealed edges and moisture-resistant adhesion systems can extend service life from 12 months to over 20 months without major structural fatigue. Proper vulcanization and storage are just as important as the compound itself.

Q4: Why do some belts lose anti-static performance over time?

The loss of conductivity often comes from surface oxidation or contamination by dust and oil. Once the surface resistance exceeds 3×10⁸ Ω, static can accumulate. The fix isn’t just cleaning—you need to recondition the conductive layer or recoat the bottom cover with carbon-loaded rubber during scheduled maintenance. Keeping proper grounding across the conveyor line is also essential.

Q5: What causes re-spliced joints to fail in underground conditions?

I’ve seen many re-splices fail because the curing temperature or dwell time didn’t match the compound. Flame-resistant rubbers like CR and NBR require strict heat control during vulcanization. If the splice is under-cured, adhesion drops; if it’s over-cured, elasticity is lost. Always use certified conductive adhesives, maintain even pressure, and follow the curing profile recommended for that specific belt type.