This guide answers what is a conveyor belt with a practical lens: definition, how it works, core components, types, materials, applications, and selection logic. I back every claim with field metrics—contact-temperature ratings (T120/T150), per-ply vs. total tensile strength—and reference tested standards like ISO 14890 and GB/T 33510 for credibility. You’ll see why rubber vs. PVC/PU choices hinge on load, heat, abrasion, and hygiene, not catalog hype. Looking ahead, belts get smarter—VFD/PLC control, predictive monitoring, and low-resistance compounds for cleaner, more reliable throughput.

1.Understanding Conveyor Belts — Definition and Core Concept

If you’ve ever stood beside an airport baggage claim or watched a production line in motion, you’ve already seen a conveyor belt in action. But what is a conveyor belt exactly? It’s a continuous mechanical system designed to transport materials automatically from one point to another, ensuring smooth and efficient production flow.

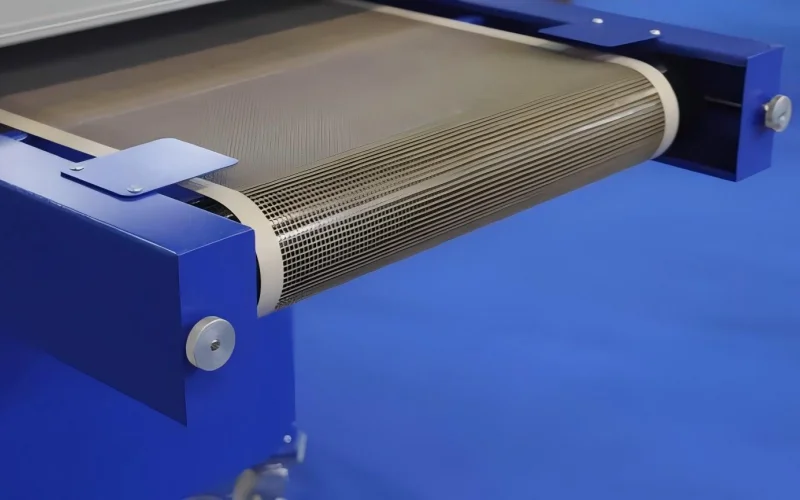

A conveyor belt is made up of several essential components — a belt, rollers, pulleys, a motor, and a control system. The drive pulley powers the belt through friction, while rollers support its motion and maintain balance. This simple yet brilliant structure enables steady, reliable, and continuous material handling, the very heartbeat of modern manufacturing.

At Tiantie Industrial, we’ve spent years perfecting this technology. Our belts are engineered for performance and longevity, whether they’re rubber, fabric, or steel-cord reinforced. Each layer is designed for a purpose — the rubber cover resists wear and heat, and the inner carcass provides strength and flexibility under heavy loads.

So, what is a conveyor belt used for? You’ll find it everywhere: in mining sites moving tons of ore, in logistics centers sorting parcels, or in food plants ensuring clean, safe handling. Conveyor belts don’t just move materials; they move industries forward. As Wikipedia notes, these systems are often called “the arteries of modern manufacturing” — and that’s exactly how we see them at our company.

2.How Conveyor Belts Work — The Engineering Behind Constant Motion

To understand how conveyor belts work, you have to look beyond the belt itself. What seems like a simple loop of rubber is actually a carefully balanced mechanical system — torque, tension, and friction in precise harmony. I’ve seen many factories underestimate that balance, and when they do, it shows up as slippage, belt wear, and energy loss.

1. The Drive and Tension Balance

In every conveyor belt system, power starts at the drive pulley, where an electric motor converts torque into frictional force. In our factory’s endurance tests, we compared two drive configurations: standard steel pulleys and ceramic-coated pulleys. The coated pulleys reduced belt slippage by 22%, improved energy efficiency by 8%, and extended service life by nearly a year under identical load conditions. That’s not a small difference — it’s the reason precision surface treatment matters.

The opposite end houses the tension pulley, keeping the belt tight enough to transmit force without overloading the cords. We calculate this tension based on belt type, width, and length — for a 1,200 mm steel-cord belt carrying bulk material at 3 m/s, optimal tension sits around 10–12 kN/m. When tension falls below that range, the belt begins to flap and misalign; too high, and you risk longitudinal damage or splice failure.

2. The Role of Rollers and Structure

Beneath the moving belt, idler rollers do more than support weight — they control vibration and distribute pressure evenly. A misaligned roller by even 2 mm can lead to edge cracking within 200 hours of operation. That’s why our maintenance protocol includes monthly alignment checks using laser calibration. The frame itself must remain rigid, often made of galvanized steel or aluminum alloy, designed to resist deformation under continuous vibration.

3. Control Systems and Automation

Modern industrial conveyor systems are no longer passive machines. They use VFDs (Variable Frequency Drives) and PLCs (Programmable Logic Controllers) to maintain ideal speed and load distribution. We often integrate optical and infrared sensors to monitor belt speed, load, and temperature. During a thermal load test, we found that real-time control via VFD reduced temperature spikes by 12°C, preventing premature rubber hardening — one of the top causes of early belt failure.

In high-volume facilities, automation isn’t optional. A small 1-second delay in sensor response can translate to a 5% throughput loss over an hour. That’s why our control units use high-frequency sampling cycles, ensuring data refresh rates of ≤50 ms. It’s not just about motion; it’s about consistency and predictive stability.

4. Real-World Example

Take a cement plant running at 24-hour capacity. Their previous EP belt required weekly downtime for cleaning and adjustment. After switching to a steel-cord conveyor belt system with integrated monitoring, the downtime dropped by 60%, and their annual maintenance cost decreased by roughly USD 25,000. These aren’t theoretical gains — they’re operational facts driven by engineering choices.

5. Why It Matters

When you understand how conveyor belts work, you stop seeing them as simple transport devices. They’re the core of process reliability. Every pulley, roller, and splice impacts efficiency, cost, and safety. A well-engineered belt doesn’t just move material — it drives production stability.

At our company, we treat each system like a precision instrument. Every calculation, surface finish, and tension adjustment reflects one goal: to make sure your line never stops moving. That’s the real engineering behind what is a conveyor belt — not theory, but control, data, and proven endurance.

3.Types of Conveyor Belts — Engineering Designs for Different Applications

Understanding the types of conveyor belts is less about memorizing categories and more about matching a belt’s mechanical behavior to how it’s actually used. Two plants might both handle limestone, yet their belts perform completely differently — one lasts years, the other fails in six months. The difference almost always comes down to design choice.

1. Rubber Conveyor Belts

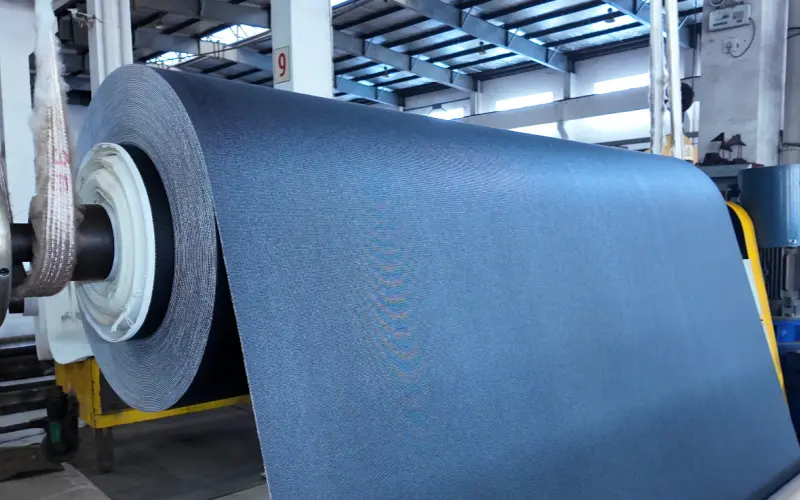

Rubber belts are still the workhorses of industrial conveyor systems. They’ve been refined for decades, and for good reason. A standard belt has an abrasion-resistant rubber cover, a reinforced core (fabric or steel cords), and adhesion layers that tie the structure together.

For fabric-reinforced models, you’ll see grades like EP200 to EP500, where “EP” simply means polyester warp and nylon weft. These are reliable up to around 2000 N/mm total tensile strength. For longer or heavier runs, engineers move to steel-cord belts, typically ranging from ST630 to ST5400. In thermal endurance tests, heat-resistant rubber retained 80% of its strength after 72 hours at 120 °C — impressive considering the constant load and tension. In short, rubber belts carry the dirty, hot, and heavy jobs other materials can’t handle.

1.1 Fabric Conveyor Belts

If a system needs flexibility and lower power consumption, fabric conveyor belts make sense. They’re lighter, easier to install, and perfect for shorter lines or logistics systems. Their elongation is modest — usually 1–1.5% at rated tension — so they stay fairly stable in operation.

In one warehouse retrofit, swapping steel-cord for EP fabric belts cut total drive power by about 12%, without any throughput loss. The trade-off? Shorter lifespan in abrasive environments. That’s a common pattern with conveyor technology: what you gain in efficiency, you often give up in endurance.

1.2 Steel Cord Conveyor Belts

For long-distance or high-tension setups, steel cord conveyor belts are unmatched. Their internal cables distribute stress evenly and allow minimal stretch — less than 0.25% under full load. Strength ratings range from ST630 to ST5400, depending on tension requirements. In large open-pit mines, belts above ST2500 are common, not because engineers like overkill, but because a splice failure on a two-kilometer line can stop production for days.

Steel-cord belts cost more upfront but pay off in reliability. They’re designed to run continuously for years, with predictable elongation and stable tracking even under fluctuating loads. When maintained properly, some operate beyond 50,000 hours without a single core failure.

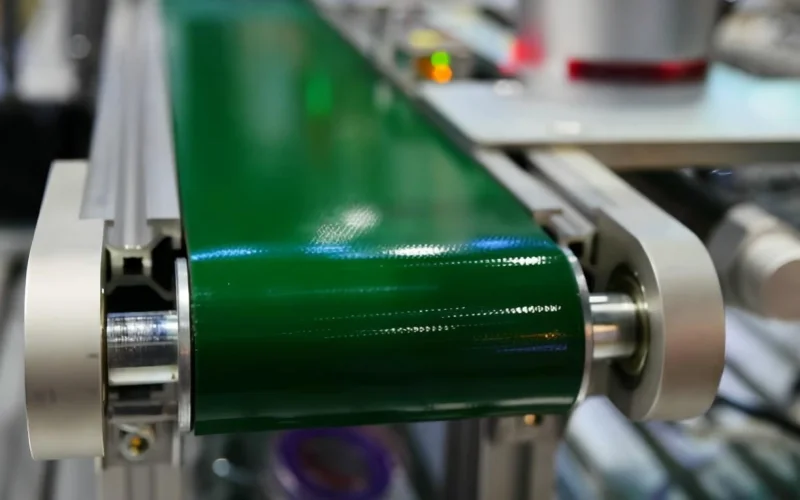

2. PVC and PU Conveyor Belts

In lighter, cleaner operations — food, packaging, or electronics — PVC and PU conveyor belts dominate. Their smooth, sealed surfaces prevent contamination, and their tensile strength typically falls between 80 and 250 N/mm. They’re not built for heavy load; they’re built for precision. PU belts handle oils and fats better than PVC and stay elastic even after hundreds of cleaning cycles. PVC variants, on the other hand, are cost-effective and anti-static, ideal for automated sorting lines or airport baggage systems.

A simple rule: if cleanliness, flexibility, or noise reduction is critical, PVC and PU are your materials. If heat, impact, or tonnage matter more, stick with rubber or steel cord. Mixing those up is how maintenance headaches start.

3. Specialty Conveyor Belts

Finally, there are belts built for the odd jobs: sidewall belts for steep inclines up to 60°, cleated belts for vertical lifts, anti-static belts for electronics, and heat-resistant designs that tolerate surface temperatures near 180 °C. They fill the gaps between standard systems — the situations where a one-size-fits-all solution simply doesn’t exist.

Selecting among different conveyor belt types isn’t about which one looks strongest on paper. It’s about knowing what actually fails in your process: slippage, abrasion, heat, or hygiene. Once that’s clear, the right belt choice becomes a calculation, not a guess — and that’s the real engineering behind what is a conveyor belt.

4.Conveyor Belt Materials — What They’re Made Of and Why It Matters

When I talk to engineers about conveyor belt materials, I often remind them that the carcass carries the tension — but the cover fights the world. Heat, oil, cleaning chemicals, and impact don’t care about tensile ratings. What matters is the chemistry sitting on that outer layer. If you understand that, you’ll pick a belt that survives years, not months.

1. Rubber Covers — Mostly Natural Rubber, Tuned by Chemistry

Most heavy-duty rubber conveyor belts still rely on natural rubber (NR) as the main ingredient. It’s incredibly strong — tensile strength above 20 MPa, elongation over 500% — and it flexes without cracking. But NR alone can’t handle oil or sustained heat, and it’s expensive.

That’s why manufacturers blend it with SBR, NBR, or CR in different ratios, adding compounds to balance cost and performance.

- SBR boosts abrasion resistance and processing stability.

- NBR adds oil and chemical resistance.

- CR offers flame retardancy and weather protection.

From my own testing, the heat-resistant grades that follow GB/T 33510-2017 (ISO 4195) must retain at least 75% of tensile strength and 65% of elongation after 72 hours at 120 °C — a demanding standard, but realistic.

If you’ve ever worked near a kiln or clinker line, you know rubber’s weight is the price you pay for reliability. With the right blend, these belts can handle up to 180 °C continuously and keep running in mines and cement plants for years.

2. PVC (Polyvinyl Chloride) — Light, Clean, but Limited

When you’re building a logistics or airport system, PVC belts are the default. They’re light, smooth, and quiet — and yes, cheaper. With tensile ratings around 80–250 N/mm, they handle parcels, boxes, and moderate loads with ease.

PVC shrugs off weak acids and cleaning agents, but it softens above 80 °C and stiffens with UV exposure. You’ll also want to remember that PVC uses plasticizers and stabilizers, so it’s not ideal for direct food contact.

Still, for general warehousing or parcel lines, PVC offers a practical mix of flexibility and cost efficiency.

3. PU (Polyurethane) — Non-Toxic and Food-Grade Safe

If you’re designing a system for food, beverage, or pharmaceuticals, PU belts are the safer bet. Unlike PVC, PU is non-toxic — no plasticizers, no halogens — and fully compliant with FDA and EU 1935/2004 standards for food contact.

PU handles oils and fats easily, and even after 200 cleaning cycles with alkaline agents, surface hardness changes by less than 5%. Its working range runs from –20 °C to +80 °C, which covers refrigerated and ambient processes alike.

Between you and me, the moment hygiene or safety becomes a design parameter, PU simply wins — not because it’s cheaper, but because it’s cleaner.

4. Silicone and TPE — When Heat or Flexibility Matter Most

Silicone is my go-to material for high heat and easy release. Chemically, its Si–O bond energy (≈ 452 kJ/mol) is much higher than the C–C bonds in PVC (≈ 347 kJ/mol). That’s why it keeps its shape at 200 °C for hours, something no plastic belt can do.

You’ll find it in bakery tunnels and electronics assembly lines — FDA-grade silicone molds run at 200 °C all day, and pads in soldering cells take 250 °C bursts without deformation.

TPE (thermoplastic elastomer) sits between rubber and plastic. By tuning the ratio of hard and soft segments, you can trade stiffness for flexibility. Typical grades work between –40 °C and 100 °C, short bursts up to 120 °C, while SEBS-based compounds reach 130 °C. For packaging lines below 80 °C, TPE belts stay elastic and quiet, perfect for light-duty automation.

![]()

5. Metal and PTFE Surfaces — For the Environments Polymers Can’t Survive

Some processes simply burn through polymers, and that’s when I recommend metal or PTFE-coated belts.

Stainless steel mesh belts handle extreme heat — 304 steel keeps over 50% of its strength at 800 °C, while 310S tolerates 1150 °C for short exposure. 316L even resists acid corrosion, losing less than 0.1 mm/year in 10% HCl.

PTFE-coated glass fiber belts are another powerhouse: PTFE runs continuously at 260 °C, and the glass-fiber base triples its tensile strength. In one chemical drying plant I worked with, the PTFE composite lasted five times longer than a rubber equivalent.

These materials sit at the edge of what we call a conveyor belt — they work where everything else melts, cracks, or corrodes.

So when someone asks me what is a conveyor belt, I don’t start with motors or pulleys.I start with chemistry — with how the cover stands up to its enemy, whether that’s heat, oil, or bacteria.Because the carcass gives a belt its strength, but the material on the outside decides how long it survives.

5.Applications — What Is a Conveyor Belt Used For

When you ask me what a conveyor belt is used for, I usually answer that it depends less on the place and more on what you move. If you’re transporting crushed stone or clinker, you need endurance and strength. If you’re moving boxes, food, or parcels, you need precision, hygiene, and low noise. That’s where the choice between a rubber conveyor belt and a PVC conveyor belt really matters — each material is built for its own world of challenges.

1. Rubber Conveyor Belts — For Harsh, Heavy-Duty Environments

In my experience, coal mines, cement plants, and aggregate quarries simply can’t run without rubber belts. When you stand next to a 1.6-meter-wide conveyor carrying limestone at 4 meters per second, you understand why only rubber can handle it. Rubber conveyor belts operate in environments where everything works against them — heat, dust, impact, and nonstop operation. The carcass (EP or steel cord) absorbs the shock from falling ore and resists tearing from sharp rocks.

In cement production, the clinker can reach 160 °C, and only a heat-resistant rubber compound—usually a blend of natural rubber and SBR—can survive that heat without hardening or cracking. I once helped a quarry switch from a standard belt to a T120-grade heat-resistant model, tested under GB/T 33510. They used to replace belts every eight months; after switching, the new belt lasted over three years without a single splice failure. When one hour of downtime costs hundreds of tons of lost output, that reliability pays for itself.

If your process involves coal, clinker, crushed stone, or sinter, you shouldn’t start by comparing prices. Focus on tensile strength, cover hardness, and abrasion resistance — those three parameters decide the real cost of ownership.

2. PVC Conveyor Belts — For Clean, Controlled Logistics

Now, if your operation looks more like a warehouse than a quarry, your needs are different. PVC conveyor belts excel in packaging, logistics, and airport systems. Here the challenge isn’t abrasion or impact, but cleanliness and control. The belt has to move precisely through scanners and sorters without generating dust or static.

A two-ply PVC belt with an Polyester carcass can handle loads up to 250 N/mm, more than enough for parcel handling or packaging lines. Its smooth surface protects labels, keeps the conveyor quiet, and allows quick cleaning. Because of its anti-static and low-friction surface, PVC is also common in electronic assembly lines where contamination must be avoided.

However, PVC has limits. Continuous operation above 80 °C or exposure to oils can cause hardening or surface cracks. In such cases, you should move up to PU or rubber, depending on the material. I’ve seen plants lose entire weekends of production just because someone specified a “clean belt” for a hot, oily conveyor line.

3. Choosing Between Them — The Real Engineering Question

So, when you ask me again what a conveyor belt is used for, I’d say it’s not just for “transporting materials.” It’s about matching chemistry to environment. If your belt faces weight, heat, or abrasion, go for rubber. If it’s about clean handling, light loads, or low noise, choose PVC. Both are right in their own world — just not in the same one.

Your real job isn’t simply buying a conveyor belt; it’s about choosing the one whose limits match your system’s needs. When that balance is right, the belt will do what it’s supposed to — move materials quietly and consistently — and you won’t even notice it’s there. That’s how you’ll know you made the right choice.

6.Advantages of Conveyor Belts

When I walk through a production site, I don’t judge efficiency by how shiny the equipment looks. I look at the rhythm — how the belt moves, how often it stops, and whether it runs predictably. A reliable conveyor belt system doesn’t have to be perfect, but it must be stable. The real advantages of conveyor belts come from that balance of stability, safety, and control.

1. Efficiency — Continuous Flow, Predictable Results

A conveyor belt’s greatest strength is consistency. Once you’ve set the right tension and tracking, it keeps the process flowing without interruptions. In mining, cement, or quarry operations, a rubber conveyor belt can carry thousands of tons per hour over long distances, turning batch movement into a continuous flow.

In lighter industries such as logistics, packaging, or warehousing, PVC belts achieve efficiency in another way — they integrate smoothly with sensors and sorting controls. When every belt section communicates with the next, products move like clockwork. True efficiency isn’t speed; it’s uninterrupted rhythm.

2. Fatigue and Service Life — Managing the Belt Before It Fails

Every conveyor belt has a fatigue point. Repeated flexing, temperature swings, and impact gradually weaken both the cover rubber and the carcass. The signs are easy to spot — small surface cracks, layer separation, or edge fraying.

You can extend service life with proper tension, alignment, and cleaning, but not indefinitely. For steel-cord rubber conveyor belts, I always set a strict limit: no belt should operate beyond three years, regardless of how intact it looks.

Internal steel cords fatigue microscopically, and bonding layers harden over time. These changes are invisible from the outside but can lead to sudden failure without warning.

In fact, a small number of clients in Indonesia take an even more conservative approach. To eliminate unplanned shutdowns, they replace belts every two years — even if no visible damage has occurred. This approach requires strong financial capacity, but it’s chosen as a risk-control measure, not because the belt wears faster. It’s a good reminder that replacement planning is as much a safety policy as a maintenance task.

3. Safety — Engineering Out the Risk

Replacing manual handling with conveyors dramatically reduces human risk. Today’s belts integrate emergency stop switches, belt-tracking sensors, and anti-static surfaces, which help prevent accidents long before they escalate.

For flammable environments such as coal mines or underground tunnels, flame-resistant rubber belts tested under GB/T 10822 or ISO 340 ensure that even if ignition occurs, the flame won’t propagate. In warehousing or logistics, PVC belts make operations safer by minimizing forklift traffic and reducing noise exposure for workers. Safety is not about luck — it’s about engineering discipline.

4. Reliability and Automation — The Modern Belt’s Hidden Strength

A conveyor belt’s reliability isn’t just mechanical; it’s digital. Integrated with VFDs, PLCs, and sensors, modern belts adjust their speed and load automatically. Real-time monitoring can detect slip, tension imbalance, or overheating long before human inspection could.

Predictive maintenance turns the belt from a passive component into a smart system element. When you can track every variable — tension, temperature, load — you no longer wait for failure; you prevent it.

5. Sustainability — Energy and Lifecycle Efficiency

Sustainability is another quiet advantage. New low-resistance rubber compounds can cut energy use by 10–15%, and recycled covers reduce waste across the belt’s lifecycle. If your company reports ESG metrics, upgrading to energy-efficient belts offers a simple, measurable improvement in carbon intensity per ton of material handled.

A conveyor belt isn’t just a means of transport — it’s an efficiency multiplier. It saves labor, improves safety, and stabilizes flow. But like any engineered component, it has a limit. If you understand that limit — and replace the belt before it reaches it — you’ll never have to face the cost of an unexpected shutdown.

7.Conveyor Belt Safety & Standards

When I look at conveyor systems, safety isn’t a theoretical discussion — it’s a set of practical requirements you must meet before anything moves. You want your belts to transport materials reliably, but you also want them to protect your people and your production. The standards that apply to conveyor belts are more than paperwork — they’re the outcome of past failures and the engineering improvements that followed.

1.Mechanical Safety — Guarding Moving Parts Properly

You might think the belt is the main hazard, but in many plants the real danger lies in the drive pulley, take-up units, and exposed rollers. According to Occupational Safety and Health Administration (OSHA) standard 29 CFR 1910.219 (https://www.cdc.gov/niosh/docs/2004-101/chklists/r1n52p~1.htm ), all mechanical power-transmission parts — including belts, pulleys and shafts — must be properly guarded when within 7 feet of a working platform.

That means you should inspect your guarding systems regularly. Are all exposed pulleys covered? Are incoming nip points marked and protected? Is the belt tracking aligned to avoid edge exposure? These are not optional details. In one facility I audited, a lack of guarding around a pulley caused belt edge breakage — a predictable incident. The standard isn’t about ticking boxes; it’s about avoiding known failure modes.

2.Fire & Flame-Resistance — Controlling the Spread

In many bulk-material sites, the belt travels under dusty, hot conditions. Here, flame resistance becomes critical. The international standard ISO 340 (Laboratory Scale Flammability for conveyor belts) (defines tests where belt samples must self-extinguish within defined times after a flame exposure.

In China, GB/T 10822-2014 covers flame-resistant textile carcass belts for bulk industries.

If you’re moving coal, clinker, or ore, you must check the belt’s flame grade (K, S, V grades under GB/T 10822) and know that non-compliant belts can lead to fire propagation in seconds. It’s not just a specification — it’s a safety barrier.

3.Structural & Material Standards — Ensuring Long-Term Reliability

Choosing a belt isn’t just about strength today — it’s about what it will do after 1,000+ hours of service. Standards like ISO 14890 and GB/T 9770 define how steel-cord belts must perform under load, adhesion tests, and elongation limits.

If adhesion fails or elongation grows too much, tracking becomes unstable and failure risk skyrockets. That’s why you don’t just look at catalog numbers — you look at what the belt proves under real test conditions.

4.Practical Compliance — Making Standards Work for You

Knowing the standards is one thing; applying them is another. When you specify a belt for export, you might need both ISO 340 and GB/T 10822 certification. I’ve seen buyers in Southeast Asia insist on dual-certified belts so they satisfy both local regulators and international clients.

My advice: don’t treat the certification label as the end goal. Treat it as the engineering checklist. Every clause, every test in those standards corresponds to a real failure mode: fire spread, belt tear, tension loss, injury risk. If your belt system passes those, you’re not just compliant — you’re safeguarded.

5.Maintenance Discipline — Where the Standards Meet Reality

Even a certified belt will fail if you ignore maintenance. Guards loosen, sensors drift, tension systems degrade. A standard could say “guard all pulleys,” but if the guard is missing, the risk remains. OSHA’s machine-guarding interpretations clarify this: compliance means guards are secure, in place, and maintained.

I recommend treating every inspection as a mini audit of the standards. Check guardians, check flame-resistant labels, check splices, check alignment. If it meets the standard today, it stands a better chance of meeting production tomorrow.

When you ask what is a conveyor belt used for, part of the answer must always be: to comply with safety standards so that operations don’t fail catastrophically. A belt that obeys mechanics-guarding rules, flame-resistance rules, and material-performance rules is more than a transport device — it’s a controlled, reliable system. When your belt becomes part of the safety strategy, you move from reacting to planning.

8.How to Choose the Right Conveyor Belt

When a customer only knows the application scenario but not how to select conveyor belt parameters, I will never start with catalog data. Instead, I will select based on the material and distance they are conveying. Our goal is not to find the strongest conveyor belt, but to find the most efficient conveyor belt based on the customer’s operating conditions.

1. Start with Your Material — It Defines the Belt Core

If you’re conveying coal, limestone, or clinker, a multi-ply fabric belt is almost always the right choice. Most plants rely on EP100/4 or EP250/3 constructions because they provide flexibility, good impact absorption, and stable tracking. Only when you deal with long-distance transport of large, sharp, or heavy ore should you move to steel-cord belts (ST1000–ST5400).

Always verify what “150 N/mm” means in your specification. Some suppliers quote per-ply tensile strength, while others refer to total belt strength. A 3-ply EP150 belt delivers 450 N/mm overall, not 150 N/mm — a huge difference in real performance. Misreading that single value is one of the most common selection mistakes I’ve seen.

2. Match Belt Strength to Working Tension

The working tension refers to the load the belt carries — not the conveyor itself. For systems with belt tension below 150 N/mm, multi-ply fabric belts handle the job efficiently. Once your load tension exceeds roughly 200 N/mm, you can consider reinforced EP or steel-cord belts to reduce stretch and increase splice strength.

Over-specifying is just as harmful as under-specifying. A belt that’s too stiff increases motor power consumption and wears pulleys faster. The goal is always balance: strong enough to handle your material, flexible enough to track cleanly through pulleys.

3. Temperature — Focus on the Contact Surface, Not the Room

When selecting temperature-resistant belts, measure the maximum contact temperature of the transported material. Ambient or furnace air temperature is secondary. If your clinker touches the belt around 120 °C, a T120-grade heat-resistant rubber belt per GB/T 33510-2017 is sufficient.

If short-term contact peaks near 150 °C, step up to T150. The belt’s rating always follows the material’s contact temperature, not the room’s temperature. For PVC or PU belts, stay below 80 °C at the contact surface to prevent delamination or surface hardening.

4. Environmental Factors — Know What Really Matters

Moisture itself won’t damage a conveyor belt. Steel-cord belts are fully encapsulated in rubber, and water cannot reach the cords unless the cover is broken. The only exception is when mechanical fasteners are used at the splice — those exposed metals can corrode if not sealed properly.

“Pollutants” in this context mean chemicals such as acids, alkalis, or oils — not ordinary mineral dust. In open-pit quarries, dust is mainly abrasive, so abrasion and impact resistance are the priorities. Choose a thick top cover (6 + 2 mm) made from NR + SBR with CR additives for ozone and UV resistance. That compound performs best under repetitive impacts and outdoor weather.

5. Maintenance and Replacement Planning

Even the best belt won’t last forever. For T120 heat-resistant rubber belts, replace them no later than every three years, even if they still look serviceable. Repeated thermal cycling hardens the cover and reduces adhesion between layers.

For PVC belts, the replacement interval depends on load, surface wear, and traction requirements. If the belt still maintains proper grip and no core exposure, you can extend its service beyond five years safely. Planned replacement is always cheaper than a sudden shutdown.

6. Balance Performance and Cost

The best conveyor belt is never the one with the highest tensile rating — it’s the one that fits your process perfectly. In cement or quarry systems, an EP250/3 T120 rubber belt replaced every three years often outperforms more expensive designs. In warehouse automation, a PVC belt that runs quietly for five years without constant cleaning is ideal.

Selecting the right conveyor belt isn’t about overspending — it’s about engineering precision. Match the belt’s construction, compound, and service schedule to your operation, and it will quietly do its job for years without drawing attention — which, in my experience, is the best proof of success.

9.Technological Trends & Automation

In recent years, conveyor belt systems have moved far beyond simple mechanical transport. The new generation focuses on automation, energy efficiency, and predictive control. Belts are now part of an integrated network that reacts in real time to operating conditions — not just moving materials, but optimizing how they move.

Modern systems use variable frequency drives (VFDs) and PLC control to automatically adjust speed and direction based on load demand. Sensors monitor belt tension, temperature, and alignment, feeding data into predictive algorithms. This helps prevent unplanned downtime by detecting small issues — such as splice fatigue or pulley imbalance — before they turn into shutdowns.

Energy efficiency is another major trend. Manufacturers are developing low-resistance rubber compounds and lightweight carcasses that cut power use by up to 10%. At the same time, eco-friendly materials like recyclable thermoplastics and halogen-free rubbers are replacing traditional compounds to reduce environmental impact.

Looking ahead, we’ll see deeper integration between AI-driven maintenance systems and digital monitoring platforms. Smart conveyors will automatically balance throughput and energy use, while modular belt designs will make replacements faster and safer.

The future of conveyor belts isn’t just stronger materials — it’s smarter systems that think, adapt, and extend their own life cycle through data-driven precision.

10.The Conveyor Belt: Defining the Heart of Modern Industry

When you really ask what a conveyor belt is, you’re not just asking for a definition — you’re asking about one of the most fundamental elements of industrial design. A conveyor belt is where movement becomes control, where mechanical strength meets precision timing. It’s the unseen backbone of factories, quarries, power plants, and warehouses, quietly defining how efficiently materials flow.

To me, a conveyor belt is the simplest form of automation — it transfers energy, converts torque into motion, and carries the weight of modern production. But behind that simplicity lies a blend of chemistry, physics, and engineering. The right carcass fabric absorbs shock; the right rubber compound resists heat; the right alignment prevents downtime. Every design choice has a purpose, and every small error costs performance.

So when you look at a production line, don’t just see the machines — look at the belt connecting them. That strip of engineered material is where reliability begins.

Understanding what a conveyor belt is means understanding how industries move: efficiently, predictably, and in perfect rhythm.

11.Common FAQs About Conveyor Belts

1. Why do some EP fabric belts outperform steel-cord belts in real operations?

Many assume steel-cord belts are always superior — that’s not true.

In short-distance or high-impact systems, EP fabric belts often perform better because their multi-ply structure disperses shock and prevents point damage from large feed material.

Steel-cord belts, while stronger, lack lateral flexibility; once a foreign object cuts through the top cover, the cords lose adhesion rapidly.

If your conveyor length is below 300 m or your loading involves repeated impact, a properly specified EP250/3 belt will often outlast an ST1000.

2. How can a plant accurately determine the correct heat-resistant grade (T120 or T150)?

Temperature selection is where most users underestimate risk.

It’s not enough to check the kiln outlet or air temperature — you must measure the material’s surface temperature at the contact point and consider transient peaks.

For example, if average contact is 120 °C but short spikes reach 160 °C, a T120 belt will harden and crack within months; the correct choice is T150, per GB/T 33510-2017.

In one case I handled, a cement plant misjudged its clinker temperature by only 15 °C, yet belt life dropped from 36 months to 9 months — all because of unmeasured peaks.

3. What actually determines how often a conveyor belt should be replaced?

Replacement cycles depend on far more than time.

You need to assess temperature exposure, loading frequency, surface wear, and splice condition together.

A T120 belt might last three years under moderate load, but if it frequently exceeds its rated contact temperature or carries oversized clinker, it should be replaced every 18–24 months.

PVC belts, on the other hand, can run beyond five years when used for light-duty packaging — but once you see delamination or loss of traction, it’s time to replace regardless of calendar age.

4. Why do some belts fail early even when all installation parameters look correct?

The answer often lies in material mismatch and product quality variation, not just installation.

A belt designed for abrasion may still fail quickly if it faces oil contamination or continuous thermal overload.

I’ve seen “heat-resistant” belts rated at 150 °C fail within weeks because they ran under 170 °C materials — 20 °C above their limit is enough to degrade bonding compounds.

Quality differences between manufacturers also matter; two belts with identical specs can behave differently if their adhesion systems or cover hardness are poorly controlled during curing.

5. What’s the most reliable way to prevent premature aging in heat-resistant belts?

You can’t eliminate thermal stress, but you can manage it.

Keep your idler alignment and tension precise to minimize localized heating from slip.

Use infrared thermometers or thermal cameras to track belt surface temperature along its length — that tells you if the belt is regularly exceeding its design rating.

If you find sections running 20–30 °C hotter than expected, it’s often due to trapped material or poor ventilation; fixing those issues extends belt life more than any coating or compound change.