Understanding a rubber conveyor belt specification is not just about reading numbers—it’s about knowing the real language of performance, safety, and lifetime. From carcass strength to cover grade, every detail carries proof from decades of engineering and international testing standards. Real-world cases show how incomplete specifications lead to failures, while precise data extends service life by more than 40%. This guide explains each parameter clearly, compares global standards, and connects theory with practice. By the end, you’ll be ready to read, apply, and trust specifications with confidence.

1.Why Rubber Conveyor Belt Specification Matters

I spend my days in a factory that produces thousands of meters of conveyor belts. Over the years, I’ve learned one thing very clearly: a rubber conveyor belt specification is never just a set of numbers. It’s the common language that connects you as the buyer and me as the manufacturer. Without it, I cannot design the right belt for your needs, and you cannot be sure that the product you receive will actually work for your operation.

Many buyers send me short requests like, “I need a 1200mm EP belt.” At first glance, that sounds like enough information, but in reality it’s not. Imagine walking into a car dealership and only saying, “I need four wheels.” You might get a car, but chances are it won’t be the right one for your road, your cargo, or your budget. The same applies to conveyor belts. A proper ep conveyor belt specification must include conveyor belt strength, number of plies, cover thickness, rubber grade, and roll length. Without these details, any price I give you will be little more than a guess.

I remember working with a cement plant in South America. Their initial request was only “EP belt, 1200mm wide.” When we asked more questions, we discovered their actual needs were EP400/3, 1200mm width, 6+3mm cover, DIN-Y grade, 250m roll. Had they bought based on the vague request, the belt would have worn out within months. By providing the complete rubber conveyor belt technical specifications, they not only got the right belt, but also reduced their maintenance costs by about 25% and avoided weeks of downtime.

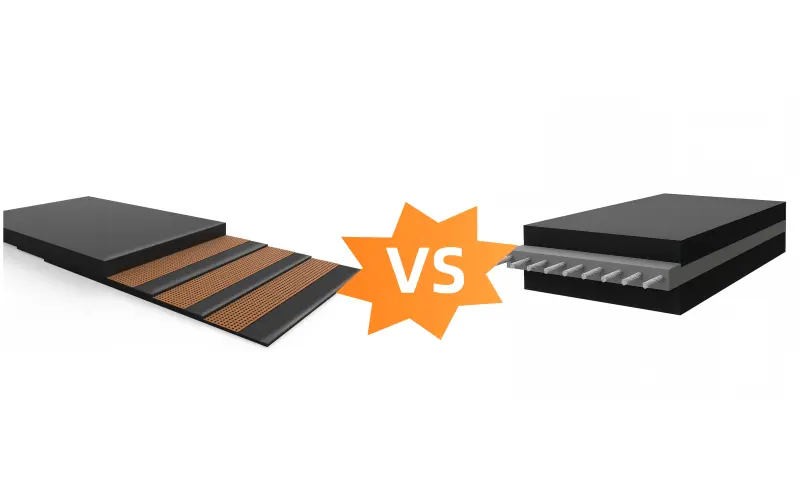

Each element in a specification is tied to real performance. Conveyor belt strength determines how much load the belt can carry safely. Cover thickness affects wear resistance and energy use. The choice of rubber conveyor belt material decides whether it can survive heat, oil, or chemicals. For heavy-duty operations like mining, a steel cord conveyor belt specification may be the only way to ensure safety and long service life. Leaving out any of these details can lead to accidents, wasted money, and unnecessary replacement.

Industry data backs this up. According to the Conveyor Equipment Manufacturers Association (CEMA), choosing a belt based on the full specification can extend its service life by more than 40%. That’s not theory—it’s based on years of testing and field results.

Whenever you prepare for your next purchase, think of the rubber conveyor belt specification as your passport. With complete details, you get accurate pricing, a safer product, and a belt designed to match your exact working conditions.

2.How to Read a Rubber Conveyor Belt Specification

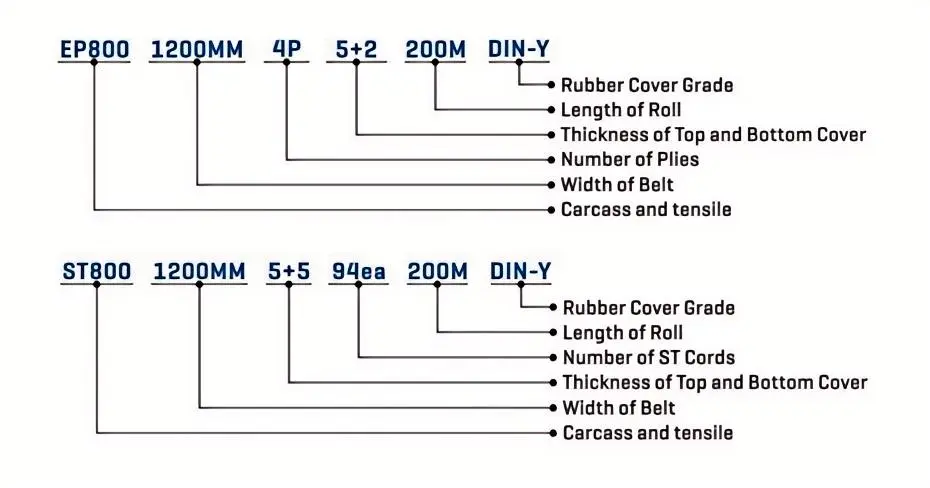

When you first see a rubber conveyor belt specification, it can look like a string of codes. But once you know how to read it, every number tells you something important about performance, safety, and cost. Let me walk you through each parameter step by step.

2.1 Carcass & Tensile Strength

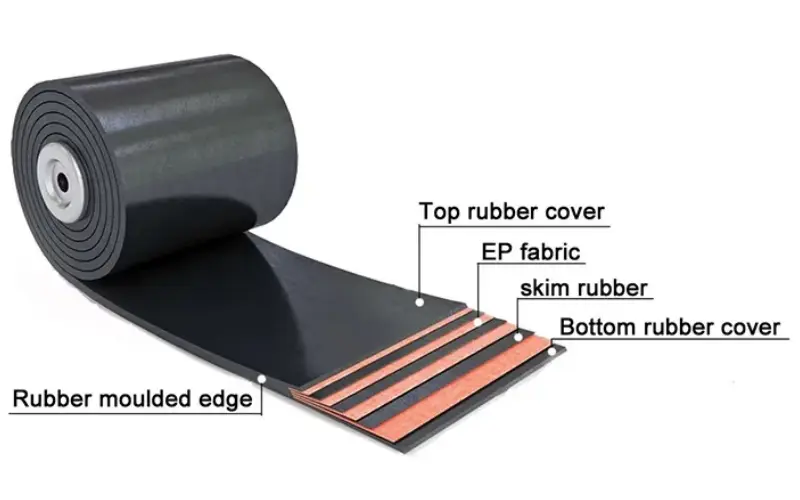

The carcass is the backbone of the belt. It decides the conveyor belt strength and flexibility. There are several types:

- EP (Polyester + Nylon): Strong warp direction, flexible weft. For example, EP400means 400 N/mm tensile strength. With 4 plies, that’s 1600 N/mm total strength. In our factory, EP ratings go from EP100 (200 N/mm for 2 plies) all the way up to EP630 (3780 N/mm for 6 plies).

- NN (Nylon + Nylon): More stretch, higher impact resistance. Example: NN200, with 200 N/mm per ply. Good for medium-length conveyors with impact loading.

- CC (Cotton): Now less common, but still used in light-duty applications. Example: CC56, with 112 N/mm at 2 plies.

- TC (Polyester + Cotton): Rare, but combines strength and cost-efficiency. Example: TC70, around 140 N/mm with 2 plies.

- ST (Steel Cord): This is the steel cord conveyor belt specification. For example, ST2000has 2000 N/mm tensile strength with cord diameters around 6 mm. These belts are used in mining and long-distance systems. Our range goes from ST630 to ST5400, with minimum pulley diameters from 500 mm to 1800 mm.

So if you’re moving coal for 10 km, an ST2500 or higher might be your only safe choice. But for a cement plant line of 100 m, EP400/3 is often enough.

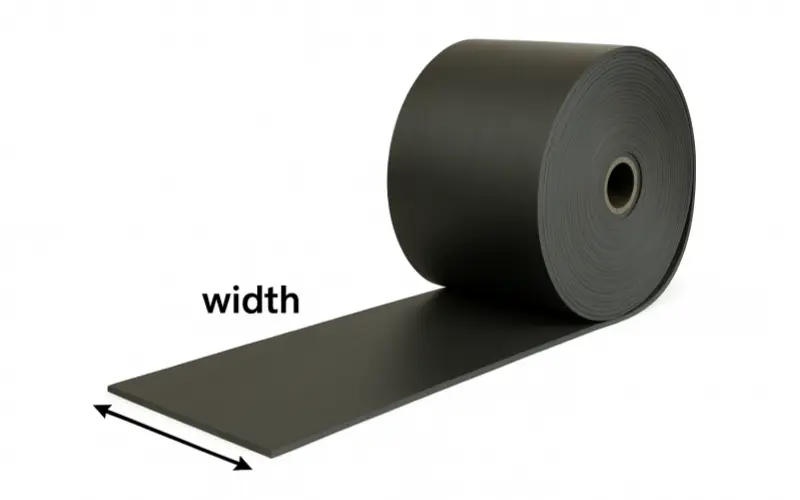

2.2 Belt Width

This is the simplest part of a specification. Width usually ranges from 300 mm to 3500 mm. A 1200 mm belt is common in ports and cement plants, while coal mines often use 1400 mm or more.

But width isn’t just about how much material you can carry. It also decides the pulley size, trough angle, and roller arrangement. If you oversize the belt without adjusting the system, you’ll get mistracking and faster wear. That’s why width must always match system design, not just capacity.

2.3 Number of Plies or Steel Cords

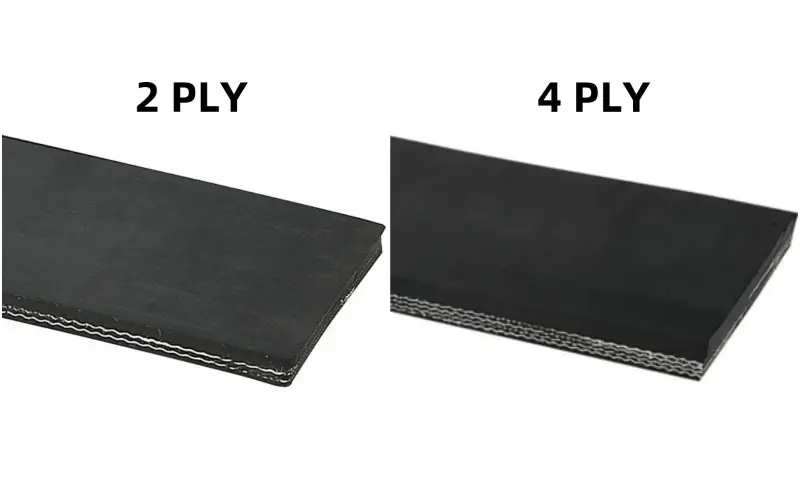

In an ep conveyor belt specification, you’ll see something like EP400/3. The “3” means 3 plies. Each ply adds strength, but too many plies can reduce flexibility. For example:

- EP200/2: Light duty, good for agriculture.

- EP400/3: Standard for cement and power plants.

- EP800/4: Heavy-duty, for high tonnage or steep conveyors.

In steel cord belts, instead of plies, we look at cord count. For example, ST2000 with 7.2 mm cord diameter and 15 mm pitch gives you very high strength with controlled elongation.

So more plies ≠ better. It’s always about balancing strength and pulley diameter.

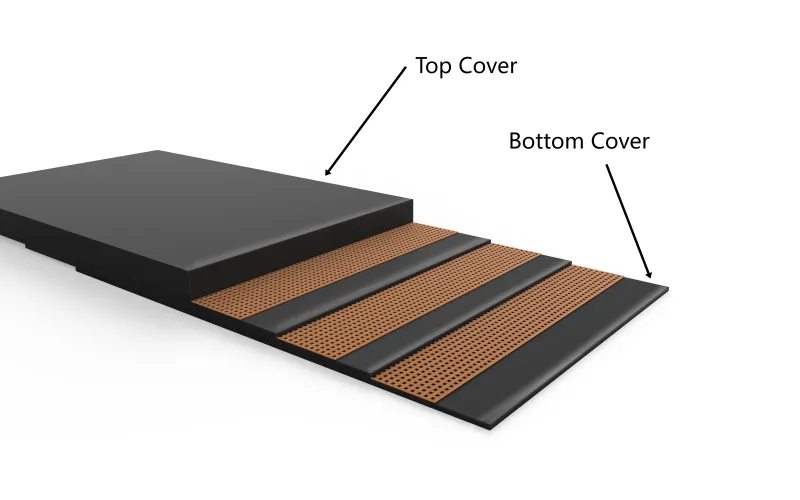

2.4 Cover Thickness

Cover is the protective rubber layer. You’ll usually see it written as 5+2 (5 mm top, 2 mm bottom) or 8+5 for heavy loads. In our production, we offer top cover thickness from 1.5 to 30 mm, and bottom cover from 1.5 to 20 mm.

- Thin covers (e.g., 3+1.5 mm): Good for light loads, reduce weight and energy use.

- Medium covers (e.g., 5+2 mm): Balance of wear life and cost.

- Thick covers (e.g., 8+8 mm): Used in mining and stone industries.

Thicker cover extends life but also increases power consumption. So it’s always about finding the balance between durability and efficiency.

2.5 Length of Roll

Most belts are shipped in rolls. A 200 m roll length is standard because it fits a 20’ or 40’ container. Shorter rolls may be easier to handle on site, but require more splicing. Longer rolls reduce joints but can be difficult to transport.

When you tell me your roll length in the rubber conveyor belt specification, I can optimize container loading and reduce waste.

2.6 Rubber Cover Grade

This is where things get technical—and very important. The rubber conveyor belt material defines how the belt resists abrasion, heat, flame, or oil. Let’s look at the main standards:

- China (GB/MT/HG standards):

- Grade M (General Purpose, GB7984): ≥14 MPa tensile, ≤200 mm³ abrasion.

- Grade D (High Abrasion Resistant, GB7984): ≥18 MPa tensile, ≤100 mm³ abrasion.

- Grade H (High Cut & Tear Resistant, GB7984): ≥24 MPa tensile, ≤120 mm³ abrasion.

- Grade T2 / T3 (Heat Resistant, HG2297): For materials at 150℃–200℃.

- Germany (DIN 22102 / 22103):

- Grade W: High abrasion resistance, ≤90 mm³.

- Grade X: High tensile + abrasion, ≥25 MPa.

- Grade Y: Standard quality, ≤150 mm³.

- Grade Z: Economy, ≤250 mm³.

- Grade K / V: Fire-resistant and anti-static.

- Australia (AS1332/1333):

- Grade A: Abrasion-resistant.

- Grade M: General purpose, ≥24 MPa tensile.

- Grade S: Fire-resistant and anti-static.

- Grade TDOZ: Special wear-resistant grade.

- ISO 10247:

- Grade H: High cut & tear resistance.

- Grade D: Severe abrasion resistance.

- Grade L: Moderate abrasion.

- RMA (USA):

- RMA1: High grade, ≤150 mm³ abrasion.

- RMA2: Standard grade, ≤175 mm³.

- China (GB/MT/HG standards):

Each grade fits a different industry: mining needs DIN-X or Grade D, cement prefers DIN-Y or RMA2, ports often choose Grade W for abrasion resistance, and grain handling usually requires oil-resistant rubber.

2.7 Full Specification Example

When you combine all the details, you get a complete rubber conveyor belt technical specification. Here are two real examples:

- EP400 / 1200 mm / 3 plies / 6+3 mm / 200 m / DIN-Y

- Polyester-nylon carcass, 400 N/mm per ply, 3 plies

- 1200 mm width

- 6 mm top, 3 mm bottom cover

- 200 m roll

- DIN-Y grade (abrasion-resistant)

- ST2000 / 1600 mm / steel cord / 8+8 mm / 250 m / DIN-X

- Steel cord carcass, 2000 N/mm strength

- 1600 mm width

- 8 mm top, 8 mm bottom cover

- 250 m roll length

- DIN-X grade (high tensile + abrasion)

- EP400 / 1200 mm / 3 plies / 6+3 mm / 200 m / DIN-Y

These are the kind of specs that allow me to design and produce exactly what you need, with accurate pricing and guaranteed performance.

Reading a rubber conveyor belt specification is not about memorizing codes. It’s about understanding how each number relates to your working conditions. Once you master it, you’ll avoid vague quotes, prevent downtime, and always get a belt that truly fits your job.

3.The Engineering Logic Behind Rubber Conveyor Belt Specification

Every detail in a rubber conveyor belt specification is linked. If one parameter is wrong, the whole system is at risk. Here are the key engineering relationships you need to understand.

3.1 Cover thickness vs. lifespan and energy use.

A 10+5 mm cover lasts longer against abrasion than a 5+2 mm cover, but it adds weight. Heavier belts demand more drive power and increase operational cost. For moderate conditions, a medium cover often delivers the best balance between durability and efficiency.

3.2 Carcass strength vs. pulley diameter.

A belt’s tensile strength must fit the pulley size. For example, an EP400/3 with 6+3 mm cover works safely on a 400 mm pulley. Upgrade to EP800/4 with 8+8 mm cover, and the same pulley becomes too small. The bending stress causes cracks and early failure. In design, checking pulley compatibility is not optional—it’s essential.

3.3 Steel cord belts under tension.

A steel cord conveyor belt specification like ST2000 with 8+8 mm cover requires a 1000 mm pulley. Smaller pulleys will fatigue the cords, leading to breakage. In mining, one broken belt can stop production for weeks. The cost of downtime is often far greater than the price of the correct belt.

3.4 Rubber grade vs. working environment.

Material properties must match operating conditions. A cement plant once used a standard abrasion-resistant belt for hot clinker at 180℃. The surface cracked in weeks. Switching to a T3 heat-resistant grade extended service life to over two years. Abrasion resistance is meaningless if the belt cannot handle temperature, oil, or fire.

3.5 System balance matters.

Thicker covers protect but consume more energy. Stronger carcasses require larger pulleys. Heat-resistant rubber may sacrifice some abrasion resistance but ensures survival at high temperatures. Each decision affects the others.

When you read a rubber conveyor belt technical specification, don’t treat the values as isolated. They are part of one engineering system. Correct balance of thickness, conveyor belt strength, pulley size, and rubber grade is what keeps the belt running safely and efficiently.

4.Testing and Verification Standards in Rubber Conveyor Belt Specification

When I prepare a rubber conveyor belt specification, it’s not just about listing dimensions and grades. Every belt must pass strict tests before it leaves the factory. These tests prove whether the belt will survive in real working conditions. Let me explain the key standards we use.

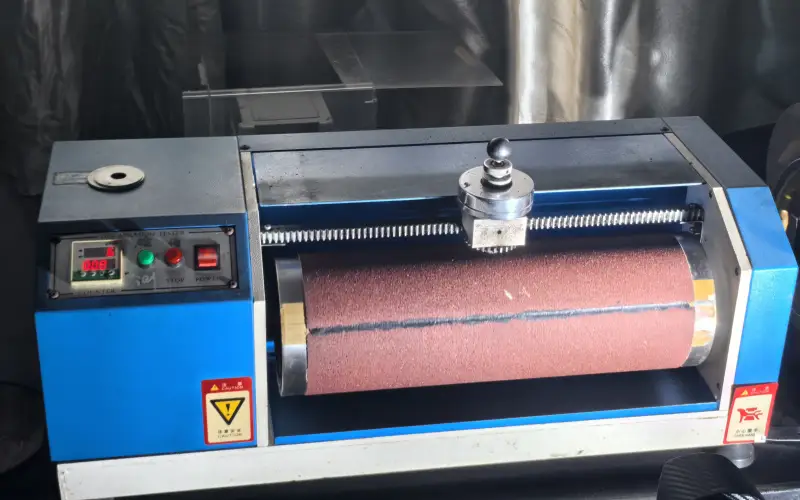

4.1 DIN Abrasion Test

Abrasion is one of the most common failure points. To measure it, we use the DIN abrasion test (DIN 53516). A rubber sample is pressed against a rotating drum with standardized abrasive paper. After a fixed distance, the volume loss in cubic millimeters is measured.

- DIN-W grade: ≤90 mm³ volume loss (very high abrasion resistance).

- DIN-X grade: ≤120 mm³ with added tensile strength.

- DIN-Y grade: ≤150 mm³, standard quality.

- DIN-Z grade: ≤250 mm³, economy level.

In practice, the difference between DIN-W and DIN-Y is significant. A belt in a mining site with sharp ore might last three years with DIN-W but wear out in less than one year with DIN-Y. That’s why abrasion grade is one of the first questions I ask buyers.

4.2 Heat Resistance Classification (T1–T4)

Heat can destroy a belt even faster than abrasion. That’s why we test belts under the ISO 4195 or equivalent standards. Belts are exposed to hot surfaces for a fixed time, and the strength loss is measured.

- T1: For material up to 100℃.

- T2: For material up to 150℃.

- T3: For material up to 200℃.

- T4: For extreme cases, above 200℃.

One cement client initially used a T2 belt for hot clinker. Within months, the covers cracked. After switching to T3, the same line ran reliably for over two years. Choosing the correct grade is not just technical—it saves huge replacement and downtime costs.

4.3 Flame Resistance and Anti-Static Tests

For coal mining and power plants, fire safety is critical. A flame-resistant belt must self-extinguish when exposed to fire. We follow ISO 340 and DIN 22103 standards.

In the test, a flame is applied to the belt sample for 45 seconds. The belt must stop burning within a specific time and must not drip molten material. For anti-static testing, we measure electrical resistance. A qualified belt must stay below the safe resistance limit to prevent sparks in explosive environments.

I’ve seen cases where buyers skipped this detail to save cost. The result? A conveyor fire that caused weeks of shutdown. That’s why I always emphasize: for underground or power applications, a proper fire-resistant and anti-static belt is not optional—it’s mandatory.

4.4 Laboratory vs. Field Performance

Lab tests give standardized numbers, but real life adds more variables. Dust, humidity, sharp edges, and material impact all affect results. A belt that passes abrasion tests may still fail early if material drops from a high chute. That’s why I always ask for detailed working conditions, not just the specification. A rubber conveyor belt technical specification backed by test results is powerful, but only when matched with the reality of your site.

A complete rubber conveyor belt specification is not finished until it’s tested. Abrasion, heat, flame, and anti-static tests turn numbers into real-world reliability. The data is what protects your investment and ensures safe, continuous operation.

Key Testing Standards at a Glance

Standard | Grade | Abrasion / Heat / Property | Typical Application |

DIN 53516 (Abrasion) | W | ≤90 mm³ volume loss | Mining, heavy ore, stone crushing |

X | ≤120 mm³ + higher tensile | Mining, ports, steel plants | |

Y | ≤150 mm³, standard | Cement, power plants | |

Z | ≤250 mm³, economy | Light-duty, short-distance conveying | |

ISO 4195 (Heat Resistance) | T1 | Up to 100℃ | Fertilizer, grain drying |

T2 | Up to 150℃ | Cement clinker (moderate heat) | |

T3 | Up to 200℃ | Steel, cement, high-heat environments | |

T4 | Above 200℃ | Foundries, extreme heat handling | |

RMA (USA) | RMA1 | ≤150 mm³ abrasion | Mining, long-distance conveyors |

RMA2 | ≤175 mm³ abrasion | Cement, power plants, ports |

5.International Standards in Rubber Conveyor Belt Specification

A rubber conveyor belt specification is only meaningful when it matches the right standard. Different countries have their own testing systems, and the same belt may look very different depending on whether you measure it under ISO, DIN, RMA, AS, GOST, or JIS standards. Understanding these differences is critical for global trade and for making sure your belt will be accepted at the port of entry.

5.1 ISO vs. DIN

ISO 10247 is the international reference. It classifies belts by abrasion resistance into H (high cut & tear), D (severe abrasion), and L (moderate abrasion). It is widely recognized, but many industries still prefer DIN (Germany) because of its stricter abrasion values. For example, DIN-W (≤90 mm³ loss) is tougher than ISO’s general abrasion class. In practice, if a buyer in Europe asks for DIN-W, an ISO-L belt may not be acceptable.

5.2 RMA (USA)

The Rubber Manufacturers Association (RMA) sets two main grades: RMA1 and RMA2. RMA1 allows ≤150 mm³ abrasion loss, while RMA2 allows ≤175 mm³. Compared to DIN, these numbers are less strict, but they are the U.S. benchmark. Many American buyers will specifically ask for RMA compliance, so even if you have a DIN-certified belt, you must provide RMA test data when exporting to the U.S.

5.3 AS (Australia)

The Australian standards AS1332 and AS1333 place a strong focus on fire resistance and safety factors. Grades include A (abrasion), M (general purpose), S (fire-resistant and anti-static), and TDOZ (special high wear resistance). Compared with DIN or ISO, AS adds higher requirements for safety in underground mining, making it one of the strictest standards for fire safety worldwide.

5.4 GOST (Russia / CIS)

The Russian GOST 20-85 standard uses a different system, with grades like A, B, C, M, N for abrasion and T1, T2, T3 for heat resistance (ranging from 80℃ to 200℃). It even includes food-grade belts (JI). GOST belts are often heavier and designed with a larger safety margin. If you plan to export to CIS countries, compliance with GOST is mandatory, even if your belt already meets ISO or DIN.

5.5 JIS (Japan) and BS (UK)

Japan’s JIS K 6322 and Britain’s BS490 both align closely with ISO, but they use their own grade names. For example, BS M24 corresponds to a high-strength, abrasion-resistant belt, while BS N17 is closer to DIN-Y. Japanese standards often include extra emphasis on tensile strength, while BS highlights abrasion categories in simple commercial terms.

5.6 Why This Matters

As a manufacturer, I often see confusion when a buyer requests “DIN-Y” but later checks if it also meets “RMA2.” The truth is: a belt can meet multiple standards, but only if it’s tested under each one. This is why a complete rubber conveyor belt technical specification should always mention the standard used. Without it, the numbers can mean very different things depending on the country.

Standard | Grade | Abrasion Loss (mm³) | Tensile / Heat / Property | Typical Industry |

ISO 10247 | H | ≤120 | High cut & tear | Mining, steel |

D | ≤100 | Severe abrasion | Quarry, stone | |

L | ≤200 | Moderate abrasion | Cement, power | |

DIN 22102 | W | ≤90 | High abrasion resistance | Mining, heavy ore |

X | ≤120 | Abrasion + tensile | Steel, ports | |

Y | ≤150 | Standard | Cement, power | |

Z | ≤250 | Economy | Light duty | |

RMA (USA) | RMA1 | ≤150 | High grade | Mining, long runs |

RMA2 | ≤175 | Standard | Cement, ports | |

AS 1332/1333 (Australia) | A | ≤70 | Abrasion resistant | Quarry, mining |

S | ≤250 | Fire resistant + anti-static | Underground coal | |

TDOZ | ≤125 | High wear resistance | Iron ore | |

GOST 20-85 (Russia) | A–N | ≤100–200 | Varies | Mining, industry |

T1–T3 | ≤200 | Heat 80–200℃ | Cement, steel | |

JI | Food grade | Non-toxic | Food handling | |

BS 490 (UK) | M24 | High strength, ≤150 | Strong abrasion | Heavy industry |

N17 | Standard, ≤200 | Medium abrasion | Power plants |

6.Applications and Typical Rubber Conveyor Belt Specification Combinations

A rubber conveyor belt specification only makes sense when matched with the real working environment. Different industries have very different requirements. Here are the most common applications and the belt types that fit them best.

6.1 Mining and Coal

Mining is one of the toughest environments for conveyor belts. Heavy loads, sharp rocks, and long distances demand both strength and durability.

- Typical Specification: ST2000 / 1600 mm / 8+8 mm cover / 250 m roll / DIN-X

- Why: Steel cord construction provides high conveyor belt strength, low elongation, and resistance to impact. A thick 8+8 mm cover protects against sharp ore and abrasion. DIN-X grade ensures both tensile and abrasion resistance.

For underground coal, safety is just as important. Flame-resistant and anti-static belts are mandatory.

- Typical Specification: EP800/4 / 1200 mm / 6+3 mm cover / 200 m / DIN-K (FRAS)

- Why: Fabric carcass for flexibility in shorter runs, with fire-resistant and anti-static properties to comply with mining safety standards.

6.2 Steel Plants and Cement

Both steel and cement industries involve extreme heat. Standard abrasion-resistant belts cannot survive when clinker or slag exceeds 150℃.

- Typical Specification: EP400/3 / 1200 mm / 6+3 mm cover / 200 m / T3 Heat Resistant (200℃)

- Why: Fabric carcass gives flexibility for shorter conveyors. Heat-resistant T3 rubber grade prevents cracking and extends belt life beyond two years.

For heavy loads in steel plants:

- Typical Specification: ST2500 / 1800 mm / 8+8 mm cover / 250 m / DIN-T

- Why: Steel cord carcass to handle massive tonnage with heat-resistant covers.

6.3 Ports and Bulk Terminals

Ports handle massive volumes of coal, ore, and grain, often requiring wide belts and long distances. The priority is width, strength, and abrasion resistance.

- Typical Specification: EP800/4 / 2000 mm / 6+3 mm cover / 250 m / DIN-W

- Why: Wide belt for capacity, strong EP carcass for reliability, abrasion-resistant grade for bulk handling.

In some cases, steel cord belts are used for long-distance port conveyors.

- Typical Specification: ST1600 / 2200 mm / 8+6 mm cover / 300 m / DIN-X

6.4 Grain and Chemical Industries

Here the focus is on oil resistance, moisture resistance, and sometimes food safety.

- Typical Specification: EP200/2 / 1000 mm / 4+2 mm cover / 200 m / Oil-Resistant Grade

- Why: Lightweight EP carcass with oil-resistant rubber prevents swelling and degradation from grain oils .

For fertilizer handling:

- Typical Specification: EP400/3 / 1200 mm / 5+2 mm cover / 200 m / DIN-L (Moderate Abrasion + Oil Resistant)

Each industry comes with unique risks. Mining requires strength and flame safety. Steel and cement demand heat-resistant belts. Ports rely on wide, abrasion-resistant belts for bulk handling. Grain and chemicals need oil resistance or food-grade materials even Acid and alkali resistant materials.

A complete rubber conveyor belt specification is the bridge between your operation and the right product. By matching carcass type, width, cover thickness, roll length, and cover grade to your actual working conditions, you get more than a belt—you get reliability, safety, and efficiency built into your system.

7.Common Mistakes and Purchasing Traps in Rubber Conveyor Belt Specification

I often see buyers making the same mistakes when ordering conveyor belts. These errors look small on paper but can cause serious problems in the field. Let me walk you through the most common traps.

7.1 “Thicker is Always Better”

Many buyers believe that a thicker cover guarantees longer life. The truth is more complex. A 10+5 mm cover may protect against wear, but it also makes the belt heavier, increases power consumption, and stresses the system. For moderate applications, a 5+2 mm or 6+3 mm cover often performs better. The right cover is about balance, not just thickness.

7.2 Giving Only Width and Carcass

Another common mistake is sending me a request like “EP belt, 1200 mm wide.” That is not a rubber conveyor belt specification—it’s incomplete. Without tensile strength, number of plies, cover thickness, rubber grade, and roll length, I can only give you a rough price. And a rough price often means the wrong belt. One cement plant learned this the hard way: their “EP 1200 mm” belt failed within months because they never specified heat resistance.

7.3 Ignoring Pulley Diameter Compatibility

Every carcass has a minimum pulley requirement. An EP400/3 may run smoothly on a 400 mm pulley, but an EP800/4 with thick cover will crack on the same pulley. Steel cord belts are even more sensitive: an ST2000 needs at least a 1000 mm pulley. I’ve seen belts destroyed within weeks because this simple rule was ignored. Checking pulley diameter is not optional—it’s critical engineering.

7.4 Blind Price-Pressure

Price always matters, but chasing the lowest quote without checking specifications is a trap. A cheaper belt with weaker carcass or lower-grade rubber may save you 10% upfront, but cost you 50% more in downtime and replacements. The real cost of a belt is not just the invoice—it’s the lifetime performance and system uptime.

7.5 Overlooking Standards

Standards like DIN, ISO, RMA, AS, or GOST are not just paperwork. They define abrasion resistance, heat limits, and flame safety. Ignoring them may mean your shipment is rejected at customs or fails on site. A complete rubber conveyor belt technical specification should always mention the relevant standard to avoid confusion.

8.Total Cost of Ownership in a Rubber Conveyor Belt Specification

Cheap per-meter pricing can be expensive in the field. For a typical quarry conveyor of ~120 m center distance (≈ 250 m belt length with pulleys and take-up), compare two realistic options under the same duty:

8.1 Initial Price vs. Service Life (quarry short line)

- Option A — EP200/2

Unit price (illustrative): $50/m→ $12,500 per belt (250 m).

Typical service life on crushed stone: < 1 year. - Option B — EP400/3

Unit price (illustrative): $65/m→ $16,250 per belt (250 m).

Typical service life: ≈ 3 years on the same line.

- Option A — EP200/2

Over five years:

- EP200/2 is replaced roughly once per year→ 5 belts × $12,500 = $62,500 in belt spend.

- EP400/3 needs ~2 belts(year 0 and around year 3) → 2 × $16,250 = $32,500 in belt spend.

8.2 Downtime dominates the ledger

Each changeout halts production and ties up the crew. Even a single day of stoppage often outweighs the “saved” $3–5k at purchase. Fewer, longer-lived changeouts with the stronger carcass cut lost tons, overtime, and safety exposure during maintenance. That is why a rubber conveyor belt specification that properly sets carcass strength and cover is financial risk control, not paperwork.

8.3 Keep the long-distance story where it belongs

Quarries are short-line systems. For multi-kilometer conveyors—rare in quarries but common in world-scale open-pit coal/iron ore—you move to steel cord. A steel cord conveyor belt specification (e.g., ST1600–ST2000 with 8+8 mm covers) handles high tensions with low elongation. Different application, different economics; it doesn’t change the short-line quarry math above.

8.4 Five-Year Cost Snapshot (revised with 250 m belt length)

Belt Type | Spec Example | Unit Price ($/m) | Belt Length (m) | Cost per Belt | Typical Life | Belts in 5 Years | 5-Year Belt Spend |

Fabric (light) | EP200/2 | 50 | 250 | $12,500 | < 1 yr | 5 | $62,500 |

Fabric (stronger) | EP400/3 | 65 | 250 | $16,250 | ~3 yrs | 2 | $32,500 |

Numbers above exclude labor and downtime. In practice, the spend gap widens further in favor of the stronger belt once you account for fewer stoppages and safer maintenance intervals.

A precise rubber conveyor belt specification—carcass strength, number of plies, correct cover thickness, and the right grade—cuts total cost over the life of the system. Matching those parameters to the real belt length (≈ 250 m for a 120 m center distance) keeps the math honest and the savings real.

9.Factory Practice and Unique Experience in Rubber Conveyor Belt Specification

At Tiantie, every rubber conveyor belt specification is tied to real production data. We don’t rely on paperwork or surface labels. Instead, all belts are tracked through a cloud-based data system. Each roll carries a digital code that our staff scans with a PDA. Only then can the full production record—carcass type, tensile strength, cover thickness, curing batch—be accessed. This eliminates mislabeling and ensures that any belt can be traced back to its exact production line and shift.

9.1 Forming as a Critical Control Point

Forming is not just stacking plies. It is the stage where two of the most common failure risks appear:

- Adhesion strength: Poor bonding between plies leads to early delamination in the field.

- Air bubbles: If air is trapped between layers and not pressed out during forming, it creates blisters. After vulcanization, those bubbles harden into weak points. Large blisters are clear evidence that gas was never discharged properly in forming, and these often become the fastest failure points once the belt is in service.

By training operators to detect and eliminate both adhesion problems and trapped air at this stage, we cut off the biggest sources of premature belt failure.

9.2 Dual Vulcanization Presses

We operate double vulcanization presses, curing two belts simultaneously. This not only increases throughput but also stabilizes curing quality across large orders. Uniform curing conditions reduce variations that smaller single-press factories often struggle to control.

9.3 Semi-Finished Storage Management

Before vulcanization, semi-finished belts are stored under strict isolation. Layers are separated with protective cloth to prevent surface contamination and sticking. This keeps the rubber surface clean for final curing, ensuring proper bonding integrity.

9.4 Scale with Traceability

With more than 20 production lines and 600+ workers, every belt is produced under a documented, traceable workflow. From mixing to calendaring, forming, vulcanizing, and inspection, every parameter is stored digitally. If a belt ever shows issues in the field, we can track back to the precise batch and production data in our cloud system.

These practices mean that when you specify an EP400/3 with 6+3 mm DIN-Y cover or an ST2000 with heat-resistant T3, you can be confident it is manufactured exactly to spec—not just in theory, but with verifiable data behind it.

10.Rubber Conveyor Belt Specification Is the Core of Smart Selection

A rubber conveyor belt specification is not a side detail. It is the backbone of price accuracy, belt performance, and workplace safety. Every parameter—carcass type, tensile strength, cover thickness, roll length, and rubber grade—decides whether a belt lasts for months or for years.

The lesson is simple: an incomplete request like “EP belt, 1200 mm wide” will never get you the right belt. It only produces rough quotes and rough products. A complete specification such as EP400/3, 1200 mm, 6+3 mm, 200 m roll, DIN-Y gives both buyer and manufacturer the clarity to design, price, and deliver a belt that performs under real conditions.

When you select a belt, think beyond price. Match the specification to your material, temperature, distance, and safety requirements. For short quarry lines, the right fabric carcass prevents early failure. For steel or cement plants, heat-resistant grades like T3 protect against cracking. For mines and ports with long distances, steel cord belts such as ST1600 or ST2000 are the only reliable choice.

If you are not sure which combination fits, the best move is to share your operating data with the factory. As a manufacturer, I can only design the right solution when I know the working environment. That is why a detailed rubber conveyor belt technical specification is your strongest tool: it protects your budget, ensures safety, and keeps your system running without costly interruptions.

11.FAQ: Rubber Conveyor Belt Specification

1) EP300/3 vs EP500/4 — What’s the Difference?

Both are fabric belts with polyester warp and nylon weft. The numbers indicate total rated tensile strength and the number of plies.

- EP300/3→ Total rated strength 300 N/mm, with 3 plies. Each ply carries about 100 N/mm, which is the industry’s minimum threshold for stability.

- EP500/4→ Total rated strength 500 N/mm, with 4 plies. Each ply carries about 125 N/mm.

Application logic: EP300/3 is suitable for light to medium-duty conveyors—short lines, smaller pulley diameters, and moderate loads. EP500/4 is chosen when higher tension or longer conveyors demand extra strength and lower elongation. However, more plies mean higher stiffness, which can increase flex fatigue on small pulleys. Always match belt strength and ply count to both the load and the pulley system.

2) What is the difference between DIN-Y and DIN-W cover grades?

These grades are defined under DIN 22102 abrasion standard (DIN 53516 test):

- DIN-Y→ Standard abrasion resistance, ≤150 mm³ volume loss. Common in cement plants, ports, and power stations.

- DIN-W→ Superior abrasion resistance, ≤90 mm³ loss. Required in quarries, mining, and handling sharp stone or ore.

In real operations, a W-grade cover often lasts twice as long as Y-grade under heavy abrasion. The trade-off is higher hardness and slightly increased energy demand.

3) When should I choose a steel cord belt instead of a fabric belt?

Switch to steel cord conveyor belt specification (ST belts) when:

- Conveyor length exceeds 1 km;

- Tension requirements surpass EP ratings (e.g., ST1600, ST2000);

- Very low elongation is critical (fabric belts stretch more).

Fabric belts (EP/NN) are enough for short quarry conveyors and general plant use. Steel cord belts are essential in mines, ports, or cross-country conveyors where downtime risks are huge.

4) How do I decide the right cover thickness?

Cover thickness is about balance, not “the thicker the better.”

- Thin (e.g., 4+2 mm)→ Lower weight, lower power demand, but shorter life.

- Medium (e.g., 6+3 mm)→ Balanced choice for cement, ports, and power plants.

- Thick (e.g., 8+8 mm, 10+5 mm)→ For extreme abrasion or impact, common in mining.

Important: cover thickness protects against wear, but carcass strength (EP, NN, ST) decides tension capacity. For example, a 5+2 EP500 belt will still outperform a 10+5 EP200 belt in strength and pulley compatibility.

5) How do I make sure my belt meets import country requirements?

Each region uses different standards. Always specify the standard in your rubber conveyor belt specification and request certified lab reports.

- Europe→ DIN, ISO.

- USA→ RMA (RMA1, RMA2).

- Australia→ AS1332/1333.

- Russia/CIS→ GOST.

- Japan/UK→ JIS, BS.

One belt can meet multiple standards, but each requires testing. For example, a belt tested under DIN-Y may also meet RMA2 abrasion limits, but you cannot claim compliance without dual certificates. To avoid customs rejection, always confirm which standard applies before production.