This article gives you a clear preview of how a solid woven conveyor belt is engineered, why its integrated PVC-impregnated core delivers superior flame resistance, and how PVC and PVG types behave under real operating conditions. All conclusions are backed by test standards, structural data, and practical field experience. With this knowledge, you can select belts more accurately, avoid specification errors, and build a safer, longer-lasting conveying system for future operations.

1. Definition and Core Concept of Solid Woven Conveyor Belt

A solid woven conveyor belt is a completely different concept from a traditional multi-layer rubber conveyor belt. Having worked in the conveyor belt industry for many years, I believe the advantage of a solid woven conveyor belt lies in its “integrated structure” of the core layer.

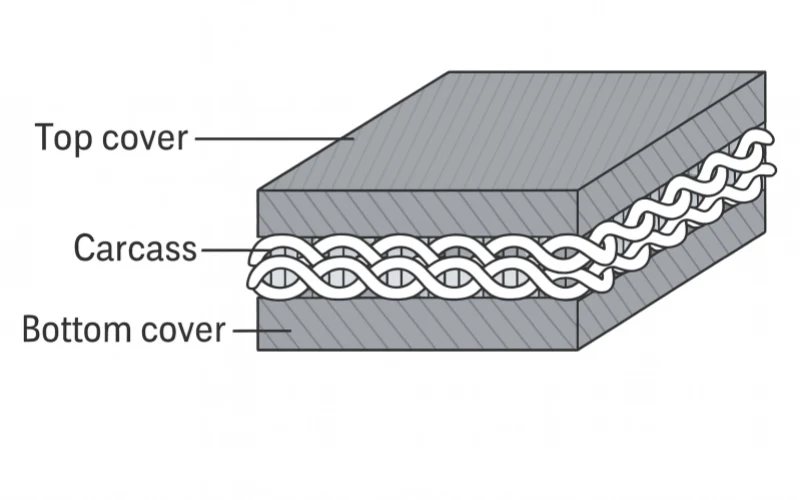

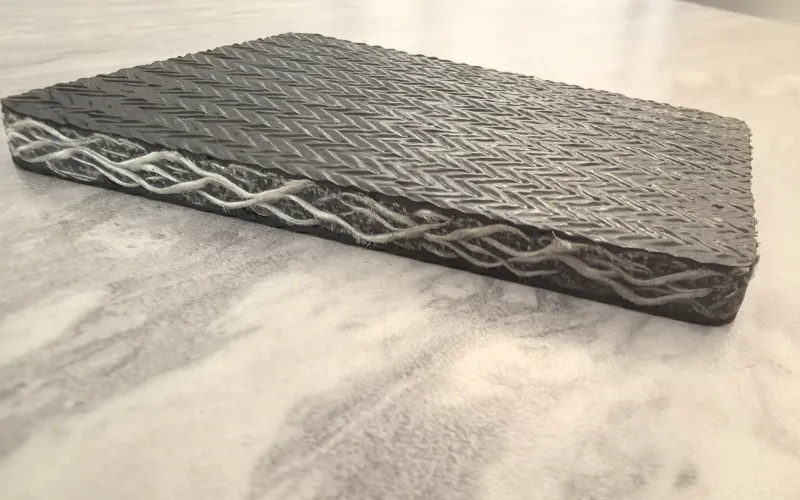

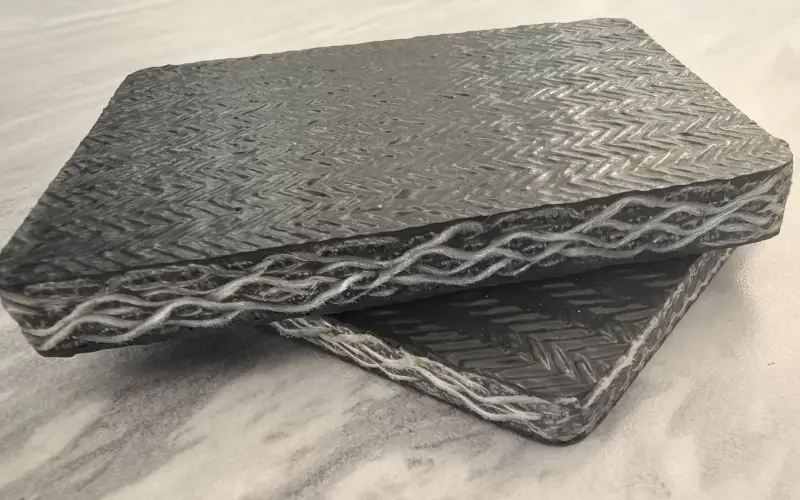

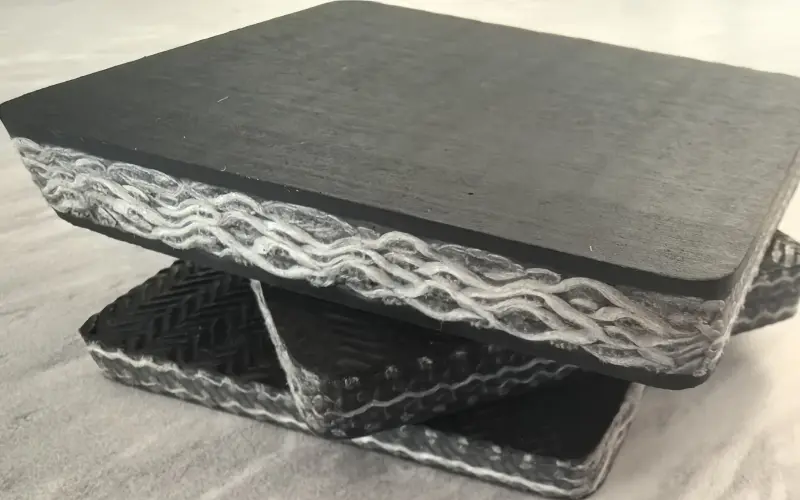

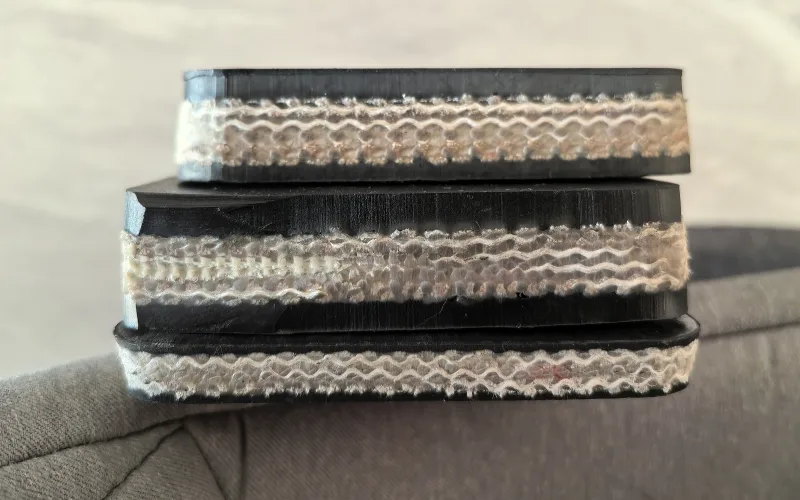

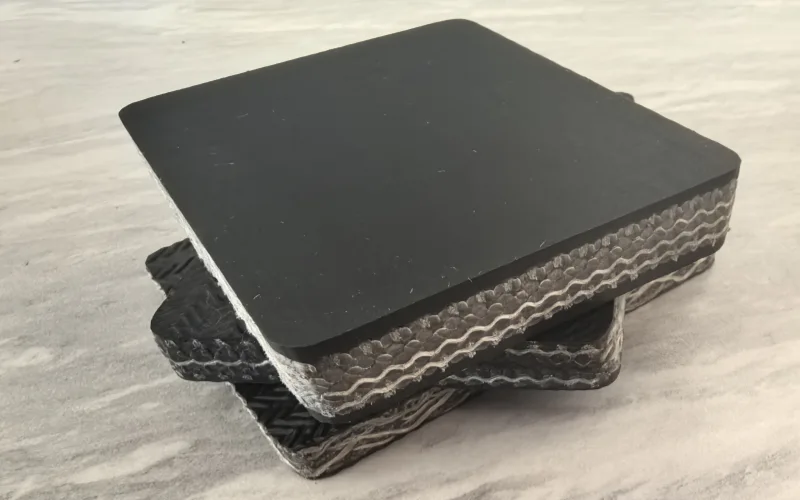

In this structure, the warp yarns use polyester filament, and the weft yarns use nylon filament. The warp and weft yarns are woven in a “cross-interlocking” manner, making the entire core a single, unified structure that does not separate or delaminate, resulting in a very dense fabric. The core is then impregnated with PVC paste resin and plasticized, allowing each yarn to fully fuse with the PVC, forming a truly seamless, integrated structure.

This structure gives solid woven conveyor belts inherent tear resistance, impact resistance, and low elongation, making them a “safe” conveyor belt for industries such as mining, power plants, and metallurgy. Especially in gas and high-dust environments, its flame-retardant and antistatic properties are remarkably stable. For example, ISO 340 flame test explicitly stipulates that conveyor belts passing this standard must possess self-extinguishing properties, making them ideal for underground applications (Source: ISO).

If your operating conditions are more arid, a PVC solid woven conveyor belt would be a more economical choice; if the material contains oil or has high moisture content, a PVC-G conveyor belt offers better moisture resistance, oil resistance, and troughing capability. Structures like solid woven PVC covered conveyor belts also maintain high stability in conventional industrial conveying.

For you, choosing a suitable solid woven conveyor belt essentially means elevating the safety, lifespan, and efficiency of your conveying system to a more reliable level.

2. Internal Construction of the Solid Woven Conveyor Belt Carcass

When you truly understand the internal structure of a solid woven conveyor belt, you’ll find that its robustness is not accidental, but rather a result of every step, from the yarn to the impregnation process, preparing for high-intensity operation. As someone who has long been responsible for conveyor belt process development, I particularly value its overall weave structure because there are no interfaces between layers that could potentially peel off—all forces are transmitted along the integrated core, resulting in exceptional stability.

2.1 Woven Structure Details

In terms of the core structure, the logic of solid woven is very simple yet extremely effective:

- The warp yarns use high-strength, low-elongation polyester filaments to ensure stable tension even during long-distance transport;

- The weft yarns use impact-resistant nylon filaments to help the core resist impacts from stones and abrasions from sharp materials;

- The high-density, integrated weave structure eliminates the delamination interface within the belt core, naturally eliminating the risk of delamination.

You might also be concerned about actual performance. According to technical data, this integral woven structure offers five key performance characteristics:

- High tear resistance

- Strong impact resistance

- Extremely low running elongation

- High fastener holding force

- Significantly longer lifespan

These are all difficult to achieve with ordinary laminated conveyor belts.

2.2 PVC Paste Resin Impregnation Process

What I appreciate most about solid woven belts is the deep PVC impregnation process. It’s not a simple coating, but rather allows the PVC paste resin to completely penetrate between every single yarn. After plasticizing and vulcanizing, the core and PVC form a truly integrated whole. This process directly brings three significant benefits:

- Stronger grip on connectors, especially suitable for high-intensity applications.

- More stable flame retardant performance, meeting EN/ISO 340 self-extinguishing requirements.

- Controllable antistatic properties, with surface resistance maintained within the 10⁶–10⁹ Ω

Thanks to this impregnation technology, even the most basic PVC solid woven conveyor belt exhibits excellent safety in high-risk areas such as mines and power plants. If you choose a PVC conveyor belt, the NBR coating provides even better moisture and oil resistance.

In continuous high-load operation scenarios, this structure offers advantages that become increasingly apparent with use.

3. Types of Solid Woven Conveyor Belts

As a technician with extensive experience in production environments, I’ve increasingly realized that choosing the right solid woven conveyor belt isn’t about selecting a “model,” but rather choosing a “system capability.” The moisture content, oil content, slope, and temperature of the materials you encounter directly influence which type is best suited for you. While the overall weave structure is uniform, the difference between PVC and PVG overlays will result in completely different performances of the conveyor belt under various operating conditions.

3.1 PVC Solid Woven Conveyor Belt

If your site primarily operates in dry conditions, such as underground coal mine roadways, main conveyor belts, coal transportation in power plants, or chemical raw material handling, then a PVC solid woven conveyor belt is the most direct and stable choice:

- The core is a monolithic woven polyester/nylon belt.

- It is fully impregnated with PVC Paste Resin.

- The cover layer thickness is typically 1.0–0 mm.

This structure gives it natural flame retardancy and antistatic properties, and meets the laboratory flammability requirements of GB/T 3685-2017, equivalent to ISO 340 (self-extinguishing, with clearly defined parameter ranges in the document). More importantly, the document indicates that the PVC type is suitable for temperatures of 10–40°C and a maximum conveyor slope of ≤16°, making it ideal for oil-free, dry, and powdery materials.

If you are budget-conscious, PVC-type solid woven conveyor belts are the most economical and widely used structure. Solid woven PVC covered conveyor belts are also commonly seen in general industry, maintaining stable performance under medium to light loads during continuous operation.

3.2 PVG Solid Woven Conveyor Belt

In contrast, if you are handling materials with high humidity, moisture content, oil content, or high hygroscopicity, you will clearly appreciate the advantages of PVG conveyor belts. The PVG coating is a PVC + nitrile rubber composite structure (NBR), resulting in the following significant improvements:

- Significantly enhanced moisture resistance

- Significantly superior oil resistance compared to pure PVC

- Abrasion life increased by approximately 30–50% (the performance improvement percentage is clearly listed in the data)

- Stronger trough retention force, suitable for conveying at steep angles

Its coating thickness can be 1.5–8 mm, applicable temperature -10–50°C, and maximum conveying slope ≤20°.

I would typically recommend:

- Dry → PVC

- Damp/Oil-containing → PVG

- Long life, high impact → PVG thickened cover

When you want a solid woven conveyor belt to maintain stable high productivity in complex environments, PVG often offers greater peace of mind.

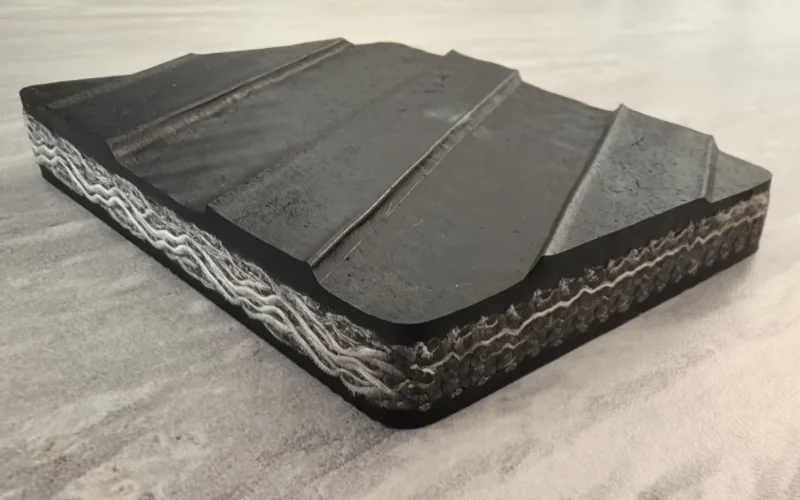

4. Covering Materials and Performance Differences

When choosing a solid woven conveyor belt, the type of cover layer often determines the operating conditions the entire system can withstand. While the solid woven core is fundamental, the cover layer material truly determines abrasion resistance, moisture resistance, oil resistance, and flame retardancy. I often say in projects: never underestimate the power of a cover layer; it’s crucial to the conveyor belt’s lifespan.

4.1 PVC Cover (Standard and Pressed Types)

In dry conveying environments, PVC solid woven conveyor belts are the most common type. The PVC cover thickness of this type of conveyor belt is typically between 0.8 and 4 mm. Through deep impregnation of the integral woven core, the conveyor belt possesses:

- Stable flame-retardant properties (meeting the requirements of equivalent ISO 340 in GB/T 3685-2017)

- Good antistatic properties

- Maintaining a stable coefficient of friction over long periods in mining, power plants, and chemical powder conveying applications

If your conveying system operates under medium to light loads, or in a dry environment, using solid woven PVC covered conveyor belts usually results in more controllable operating costs and simpler maintenance.

4.2 PVG Cover (PVC + NBR)

When ambient humidity is high, or the material has a slight oil content, I would recommend PVG conveyor belts. PVG coatings, employing a composite structure of PVC and NBR (nitrile butadiene rubber), can be achieved in thicknesses ranging from 1–8 mm, offering the following significant advantages:

- Significantly improved moisture resistance

- Superior oil resistance compared to pure PVC coatings

- Abrasion life increased by approximately 30–50% (data from technical documentation)

- Higher trough shape retention, suitable for inclined conveying

This type of coating is particularly suitable for wet coal mine roadways, coal washing plants, grain distribution, bulk fertilizer transport, and general oily material conveying.

4.3 Nitrile Rubber (NBR) Cover

In applications requiring even higher oil resistance, nitrile rubber covers further enhance the conveyor belt’s resistance to oil and chemical corrosion. NBR’s molecular structure inherently possesses excellent hydrocarbon resistance, therefore:

- Light oils, mineral oils, and grease-containing materials

- Some light chemical and feed industries

- Mildly corrosive materials

All significantly extend the lifespan of solid woven conveyor belts.

5. Mechanical Ratings & Dimensional Specifications

In engineering selection, I typically categorize the core specifications of a solid woven conveyor belt into four main types: belt strength, bandwidth, overlay thickness, and surface texture (including whether a pattern is required).

These four parameters collectively determine the impact, tension, conveying angle, and material stability the conveyor belt can withstand. If these four parameters are not matched to the operating conditions, even the best materials and structure will struggle to perform optimally.

Especially regarding surface texture—including whether a patterned surface is required—not all conveyor belts are equipped with this feature. The need for increased friction is determined based on your specific inclination angle, degree of wetness, and material type.

5.1 Strength Rating

The integral woven structure provides stable low elongation performance and covers the full strength range of 315–2500 N/mm, including:

- 315 / 400 / 500 / 630 / 800 / 1000 / 1250 / 1400 / 1600 / 1800 / 2000 / 2240 / 2500 N/mm

My experience in mining and power plant projects commonly uses:

- Dry, light to medium loads → PVC solid woven conveyor belt

- High moisture, high tension, high impact → PVG conveyor belt

A higher strength rating reduces the risk of belt breakage and improves joint retention.

5.2 Width

Current solid woven production capacity supports:

- 300–2400 mm

This range covers all large and medium-sized conveyor systems in coal mines, thermal power plants, chemical plants, ports, grain processing, and logistics.

The wider the belt, the higher the load-bearing capacity; in scenarios with steep inclines or large-particle materials, a wider belt surface also significantly enhances lateral stability.

5.3 Surface & Cover Thickness

Cover thickness determines abrasion resistance, flame retardancy, moisture resistance, and conveyor belt life, making it an extremely important parameter.

Currently available thickness ranges:

- PVC Cover: 0.8–6 mm

Suitable for dry conditions, underground coal mines, power plants, chemical powder environments, etc.

Commonly found in solid woven PVC covered conveyor belts.

- PVG Cover: 1–10 mm

- Provides better moisture resistance, oil resistance, and abrasion resistance.

Suitable for wet coal, oily materials, fertilizers, grains, and slippery environments.

PVG conveyor belt lifespan can be increased by approximately 30–50% in these scenarios .

In actual projects, more than one-third of early failures are due to “cover thickness mismatch,” rather than insufficient belt strength.

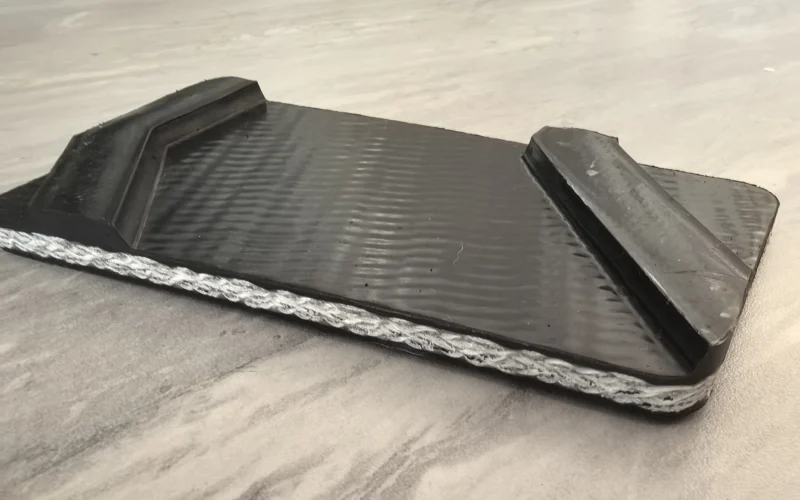

5.4 Patterned Surface Options (Optional, Non-standard configuration)

Surface patterns are not standard on all solid woven conveyor belts, but in certain conditions, they can significantly improve conveying stability.

The core functions of a pattern are only two:

- Increasing the coefficient of friction

- Improving material gripping in inclined conveying and wet/slippery environments

I usually recommend considering patterned structures in the following situations:

- Significant conveying angles requiring higher gripping force

- Materials prone to slippage: wet coal, fertilizer, grains, bagged materials, packaging boxes

- Logistics systems requiring more stable material adhesion and conveying rhythm

- Scenery scenarios with short feeding sections, frequent starts, and small roller diameters

If your conveying system is long-distance, straight-line, and heavy-load, a patterned structure is generally unnecessary; however, if inclination angles, humidity, or material slippage risks are involved, choosing a patterned surface is often more effective than simply thickening the cover layer.

6. Core Performance Characteristics of Solid Woven Conveyor Belts

The performance of a solid woven conveyor belt does not stem from a single material, but rather from the combined effect of four factors: yarn, weave structure, overlay, and impregnation process.

This determines why it is more stable, safer, and more impact-resistant than ordinary fabric laminates.

6.1 Mechanical Performance

The mechanical performance of a solid woven conveyor belt comes from three core factors: the synergistic effect of the warp material, the weft material, the overall weave structure, and the overlay.

① High Tensile Strength (Determined by High-Strength Polyester Warp)

The longitudinal strength of a solid woven conveyor belt depends entirely on the high-modulus, high-breaking-strength polyester warp.

Polyester possesses:

- High tensile modulus

- Excellent fatigue resistance

- Breaking strength far exceeding that of ordinary fabrics

This is why solid woven conveyor belts can cover strength grades of 315–2500 N/mm.

Warp yarns = The core material determining longitudinal load-bearing capacity.

② Low operating elongation (dual control of integral weave structure + polyester warp yarns)

Low elongation is not caused by a single reason, but rather by:

a.The integral weave structure locks the yarns in place, preventing interlayer slippage.

The integral fabric structure ensures all yarns work synchronously under stress, preventing “independent layer slippage.”

b.The polyester warp yarns themselves have extremely low elongation.

The stress-strain curve of polyester determines that it will hardly continue to elongate within the operating range.

The structure prevents “slippage,” and the yarns prevent “stretching”—this is the fundamental reason for the stable operation of solid woven conveyor belts.

③ Strong Tear Resistance (Contributed by the Cover Layer + Nylon Weft)

Tear resistance must be understood from two perspectives:

a.The cover layer is the first line of defense against impact and cuts.

- PVC cover layers have high hardness.

- PVG cover layers, containing NBR, have better elasticity and cut resistance.

The cover layer is always the first layer to contact the material, bearing the initial impact, abrasion, and cuts.

b.Nylon weft provides core toughness and internal tear resistance.

Nylon has extremely high elongation at break and impact toughness, preventing external tears from continuing to propagate.

The cover layer blocks external forces, and the nylon weft prevents internal tears; this is a dual-protection structure.

④ Strong Impact Resistance (Nylon Weft Toughness + High-Density Structure Energy Absorption)

The extensibility and energy absorption capacity of the nylon weft allow solid woven materials to maintain structural stability at conveyor points with high material impact, preventing damage from instantaneous impact.

⑤ No risk of delamination (only the PVC is cross-linked and impregnated; the core layer is cured as a whole)

This is the most crucial and also the most easily misunderstood point regarding solid woven conveyor belts.

Two things must be clarified:

a.The core layer itself is not a “multi-layered laminate,” but rather a “one-piece, integral woven structure.”

There are no independent bonding interfaces between layers, therefore, there is no possibility of delamination.

b.The impregnation is performed using PVC Paste Resin, not the rubber component in PVG.

Regardless of whether it’s PVC or PVG:

- Deep impregnation of the core layer is always achieved by PVC Paste Resin.

- PVC penetrates all yarn gaps during the high-temperature plasticization stage.

- After curing, it forms a “monolithically cured, integrated core layer.”

As for PVG:

The NBR (rubber) in PVG is not used for core layer impregnation.

It is blended with PVC during plasticization to form the elastic phase of the capping layer.

Therefore, the PVG rubber does not penetrate the core layer.

Summary:

- Impregnation = PVC

- Capping layer performance (moisture resistance/oil resistance/abrasion resistance) = PVC + NBR blend forming PVG

- The core layer ultimately becomes a monolithic entity → without delamination.

This is the key to its extremely high reliability under high-speed, high-tension conditions in underground coal mines.

6.2 Safety Performance

The superior safety performance of solid woven conveyor belts has been a major reason for their widespread adoption in mines and power plants.

① Flame Retardant Performance (Self-Extinguishing)

Through a deep PVC impregnation structure, the conveyor belt possesses self-extinguishing capabilities, meeting the requirements of equivalent standards such as ISO 340/GBT 3685.

② Reliable Antistatic Performance

Stable surface resistance effectively reduces the risk of dust explosions.

③ No Delamination, Reducing Accident Risk

The integrated structure means that accidents caused by interlayer peeling are less likely to occur during high-speed, heavy-load operation.

6.3 Environmental Performance

Different cover layer structures allow solid woven conveyor belts to adapt to a wider range of environments:

6.3.1 PVC type (PVC solid woven conveyor belt)

- Suitable for dry, clean, and normal temperature conditions

- For example, power plants, chemical powders, and logistics systems

6.3.2 PVG type (PVG conveyor belt)

- NBR provides stronger resistance to moisture, oil, and abrasion

- Lifespan can be increased by 30–50% in environments with wet coal, fertilizers, grains, and oily bulk materials

6.3.3 The overall structure has more stable chemical resistance

In particular, the NBR in PVG can resist a wider range of chemical attacks.

7. International Standards & Safety Certifications

When selecting conveyor belts for mining, power plant, or chemical clients, my primary concern is whether the solid woven conveyor belt meets flame retardant and antistatic requirements.

In most industrial production scenarios, flame-retardant conveyor belts are unnecessary. Only industries involving combustible dust, coal, chemicals, or those with stringent regulatory requirements must use flame-retardant structures.

Below, I will explain the most crucial international standards in four categories based on your application scenario.

7.1 EN 12882 (Flame Retardancy Rating for Surface Industrial Use – Use Only When Required)

EN 12882 is not a mandatory standard for all industrial scenarios, but applies to the following surface conditions:

- Coal-fired power plant systems

- Chemical powder systems

- Industries involving combustible dust such as grain and biomass

- Port coal terminals

This standard includes several grades, among which the following are commonly used:

- Class 2A (K category)

- Class 2B (S category)

EN 12882 is not required for general industrial or logistics industries.

For coal powder, grain dust, chemical powders, etc. → it is mandatory.

7.2 EN 14973 (Flame Retardancy Standard for Underground Mines – Most Strict)

This is the highest safety requirement for the use of solid woven conveyor belts in underground coal mines.

Why are the requirements more stringent underground?

- Coal mine methane (CH₄) is flammable and explosive.

- High dust concentration.

- Poor ventilation.

- Uncontrollable ignition source.

- Smoldering can spread for thousands of meters.

Solid woven conveyor belts have become the global standard in underground mining because:

- No risk of delamination.

- Self-extinguishing.

- Antistatic and stable.

- PVC complete integral impregnation structure.

For underground systems, PVC solid woven conveyor belts and PVG conveyor belts must meet this standard.

7.3 EN / ISO 340 (Flame Test – Must Self-Extinguish After Flame Source Removal)

The standard procedure for flame retardant testing is:

- Expose the sample to a flame source.

- Remove the flame source within a specified time (flame removal).

- Check for self-extinguishing.

- Check if the charring marks exceed safe limits.

Key point:

- Self-extinguishing after removal from the flame source = Flame retardant tape is qualified.

- Both PVC and PVG will form a char layer, which is a normal flame retardant reaction (PVC will char; NBR in PVG will also char).

The char layer is an important protective mechanism for flame retardant tape to prevent further flame propagation.

It’s not only carbon black rubber that chars.

7.4 EN ISO 284 (Antistatic Performance Test)

Antistatic properties are crucial for industries such as coal mining, power plants, and fertilizer production.

Standard Requirements:

Surface resistivity ≤ 3 × 10⁸ Ω (Required)

For safety margin, actual production typically controls it to:

10⁶–10⁸ Ω

This ensures that dust or gas ignition is not caused by charge accumulation.

Because the core layer of solid woven tape forms a continuous conductive path through deep PVC impregnation, its antistatic stability is more reliable than ordinary fabric laminates.

7.5 ISO 4195 (Applicable to special heat-resistant coatings)

Solid woven tape is not the mainstream heat-resistant tape, but in some scenarios requiring a combination of “flame retardant + medium-temperature heat resistance,” special coatings meeting ISO 4195 are used.

Main Applicable Industries:

- Short-distance hot material transportation in seaports

- Hot coal loading points

- Medium-temperature chemical materials (120–150°C)

Not a mainstream mining requirement; only optional for special needs.

8. Application Scenarios of Solid Woven Conveyor Belt

In engineering design, belt selection is not based on “industry name,” but rather on site conditions, material characteristics, risk level, and regulatory requirements to determine whether a solid woven conveyor belt is necessary.

This structure is not a general-purpose conveyor belt; it is specifically designed for high-risk, high-humidity, high-impact systems that require flame retardancy and antistatic properties.

Its core advantages come from the integral woven core layer, deep PVC impregnation, cover layer composition, and stable self-extinguishing capability.

8.1 Underground Coal Mines (The Only Structure Meeting Regulatory and Safety Requirements)

Underground coal mine environments are highly hazardous, including factors such as methane, coal dust, concentration variations, continuous high humidity, and strong impacts.

In this environment, the conveyor belt must simultaneously meet the self-extinguishing requirements of flame-retardant systems, stable antistatic performance, and stringent structural safety conditions.

The solid woven conveyor belt has become the standard configuration in underground mines because:

- The core layer, with its integral woven structure and deep PVC impregnation forming a unified, cured structure, completely prevents interlayer delamination.

- The flame-retardant system runs throughout the entire core layer, independent of surface flame retardants, and maintains self-extinguishing capability even after cutting or abrasion.

- The antistatic resistance remains consistently below 3 × 10⁸ Ω, preventing gas or dust accidents caused by electrostatic sparks.

- The PVC conveyor belt enhances moisture and oil resistance through the NBR elastic phase, exhibiting greater stability in wet roadways, oily coal seams, and coal washing plant conditions.

- The PVC solid woven conveyor belt is suitable for dry roadways and conventional coal seam conveying.

These characteristics make the solid woven conveyor belt an irreplaceable conveying structure in underground coal mines.

8.2 Thermal Power Plants and Coal Conveying Systems

Although thermal power plants are surface systems, their hazards are very close to those underground, such as smoldering coal, enclosed belt conveyor corridors, long-distance conveying, and multi-stage transfer impacts.

These systems require conveyor belts with continuous flame-retardant properties, reliable self-extinguishing capability, and resistance to interlayer shear.

The advantages of solid woven conveyor belts include:

- The PVC-infiltrated core layer forms an integral flame-retardant system that does not fail due to surface wear.

- Self-extinguishing capability effectively prevents the spread of smoldering coal dust in the belt conveyor.

- The integral core layer structure avoids the delamination problem common in EP belts and can withstand higher continuous tension.

- In wet coal and rainy/snowy seasons, PVC conveyor belts maintain low moisture absorption and strong friction, improving operational stability.

For high-power, long-distance thermal power plant conveying systems, solid woven conveyor belts offer higher safety redundancy than EP belts.

8.3 Fertilizer and Chemical Powder Conveying

Fertilizers and chemical materials often possess properties such as hygroscopicity, oil content, corrosiveness, and combustible dust, which can easily cause wetting, interlayer shearing, or chemical degradation of ordinary woven core conveyor belts.

Solid woven conveyor belts perform consistently well in this field primarily due to the following reasons:

- The NBR in the PVG cover provides oil and corrosion resistance, adapting to the chemical properties of NPK, urea, ammonium chloride, and various composite materials.

- The integrally impregnated core layer is non-absorbent, preventing structural relaxation or strength loss under high humidity conditions.

- The structural strength is stable, withstanding continuous tensile and stacking pressures from sticky materials.

- Self-extinguishing and antistatic properties reduce the risk of dust explosions.

PVG conveyor belts are widely used in most fertilizer plants, chemical plants, and bulk material packaging plants.

8.4 Ore and Metallurgical Material Conveying

The core challenges in conveying ore and metallurgical raw materials are impact, tearing, humidity, and changes in material morphology.

Solid woven conveyor belts offer the following engineering advantages in this scenario:

- The PVC or PVG cover absorbs the initial impact, effectively absorbing energy before it enters the core layer.

- Nylon weft yarns provide tear resistance and maintain elongation toughness when subjected to edge pulling or ore scratches.

- The integral woven core structure prevents interlayer slippage due to repeated impacts, maintaining long-term operational stability.

- The PVG cover layer offers better trough shape retention, making it suitable for high-capacity metallurgical production lines.

- It is more adaptable to various material types, including wet ore, mixed materials, and fine ore.

These conveyor lines rely more on the structural stability of the solid woven conveyor belt compared to EP belts.

8.5 High Humidity, Inclined Conveying, and Patterned Surface Requirements

In scenarios with high humidity, easy material slippage, or high inclination angle requirements, solid woven conveyor belts also offer unique advantages.

Typical applications include wet sand, wet coal, wet fertilizer, lifting conveyors at inclination angles of 12–20°, or production lines requiring enhanced gripping force.

This is because:

- The NBR phase in the PVG cover layer has superior dynamic friction properties, making it suitable for slippery materials.

- The cover layer’s pattern can be selected according to requirements; not all solid woven conveyor belts come with a pattern by default. Patterns are optional, used to increase the coefficient of friction or improve tilt performance.

- The PVC-impregnated core layer is non-absorbent, maintaining structural stability under continuous humidity and preventing tension fluctuations due to moisture absorption.

- Suitable for humid storage, mine elevator sections, wet material screening lines, and tilt sorting systems.

Solid woven PVC covered conveyor belts maintain higher operational stability in the above operating conditions.

9.Jointing Methods and Strength Retention Rate of Solid Woven Conveyor Belts

In any system using solid woven conveyor belts, the jointing method directly affects the operational safety factor, the consistency of flame retardant performance, and the maximum permissible tension of the entire conveyor line. Because the core layer of this type of conveyor belt is a monolithic woven structure, deeply impregnated with PVC paste resin during the manufacturing stage, it becomes a complete, interlayer-free load-bearing body. Therefore, its jointing system must be compatible with the PVC or PVG cover layer while not compromising the integrated characteristics of the core layer.

The three most common jointing methods in engineering are: mechanical joints, cold-bonded joints, and heat-fusion joints.

9.1 Mechanical Joints (Mechanical Fastener)

Mechanical joints are typically used in systems requiring rapid resumption of operation, where heating construction is not possible, or where downtime is strictly limited, even for short-cycle conveyor belt systems. It clamps and secures the belt at both ends using metal fasteners and is the most common method for mine repairs and temporary production resumption.

The engineering characteristics of mechanical joints are as follows:

(1) Strength retention rate: Approximately 60%–65%

The fastener structure itself makes it impossible to establish a continuous load path, thus preventing the achievement of a high retention rate.

(2) Applicable belt types: Both PVC solid woven conveyor belts and PVG conveyor belts can be used.

Metal fasteners rely on the mechanical gripping force of the cover layer, rather than chemical bonding.

(3) Fast installation speed, no need for specialized vulcanization equipment

This method is commonly used in downhole environments or emergency repairs.

(4) Not recommended for high-tension main conveyor systems

When the belt strength exceeds 1000 N/mm, mechanical joints may generate concentrated stress at the drive end, shortening service life.

Mechanical joints are suitable for low to medium tension, short distances, or temporary recovery tasks, but are not suitable as a long-term joint solution for high-strength solid woven conveyor belts.

9.2 Cold Bonding Joint

Cold bonding joints achieve bonding through room temperature chemical curing and are a medium-to-high strength solution for solid woven conveyor belts, second only to hot-melt joints. Due to the different materials of the PVC and PVG overlays, the chemical systems used must also be different.

The core value of cold bonding joints lies in: achieving higher strength and better operational smoothness than mechanical joints, while eliminating the need for high-temperature vulcanization equipment.

(1) Strength retention rate: approximately 75%–80%

Cold bonding can establish interfacial chemical bonds, but it cannot rebuild the integrated core structure of the solid woven conveyor belt; therefore, the retention rate cannot be higher.

(2) Cold Adhesive for PVC Coating: Chlorinated PVC Two-Component System

The cold adhesive used for PVC solid woven conveyor belts consists of two parts:

Component A

Chlorinated PVC Resin Adhesive

Contains:

- Chlorinated polyvinyl chloride

- Methyl ethyl ketone (MEK)

- Cyclohexanone or ketone-like solvents

Function: Swells the surface of the PVC coating, exposing polymer segments and forming a re-bonding interface.

Component B

Isocyanate Hardener

Function: Chemically bonds with the chlorinated polymer, improving bond strength, moisture resistance, and long-term stability.

(3) Cold-bonded PVG cover layer: PVC–NBR composite two-component system

The cover layer of the PVG conveyor belt contains both PVC and NBR rubber phases, therefore it needs to:

- Swell PVC

- And form segmental bonds with NBR

- Form a mixed interface after curing

This type of adhesive typically contains chlorinated PVC, NBR microparticles, and isocyanate curing agents, giving the joint higher oil and moisture resistance.

(4) Chemical mechanism of cold-bonded joints

Cold bonding is not simply “glue sticking together.” Its essential process includes:

- The cover layer surface swells with solvent

- Polymer segments are exposed

- Isocyanate curing agent reacts with the polymer

- Segment bonds cross the interface

- Re-curing forms a continuum

Therefore, cold-bonded joints can provide medium to high strength, but cannot restore the overall properties of the solid woven conveyor belt core layer.

9.3 Thermo-Fusion Splicing

For solid woven conveyor belts, “thermo-fusion splicing” is the correct engineering term, not the more common “thermal vulcanization splicing.”

This is because the core material of solid woven conveyor belts is a thermoplastic PVC system, not a rubber vulcanization system; its splicing process relies on PVC replasticization-fusion-curing, rather than vulcanization crosslinking.

Thermo-fusion splicing is the highest-performing splicing solution among the three methods.

(1) Strength retention rate: 90%–95%

Thermo-fusion splicing allows the PVC paste in the splicing area to fuse again with the core layer of the main belt, thereby reconstructing a continuous load path and achieving strength close to that of the main belt.

(2) Process Mechanism (Key to Performance)

The process of hot melt jointing includes:

- Applying heat and pressure to the joint area

- Replasticizing and flowing the PVC paste

- Filling the gaps between the braided yarns

- Fully fusing with the PVC in the core layers on both sides

- Coldening and solidifying to form an integral structure without delamination interfaces

This is completely different from the vulcanization mechanism of rubber conveyor belts, but it is suitable for thermoplastic material systems of solid woven conveyor belts.

(3) Scope of Application

- Suitable for high-strength solid woven conveyor belts of 1000~2500 N/mm

- Main underground transportation systems

- Main conveyor belts in thermal power plants

- High humidity, heavy load, long distance, high power drive systems

- PVG conveyor belts have a wider hot melt window and more stable fusion

Hot melt joints can maximize the preservation of the conveyor belt’s flame retardancy, self-extinguishing, antistatic properties, and overall strength, and are the standard method for underground coal mines and high-power conveyor systems nationwide.

10. Solid Woven Conveyor Belt Engineering Selection Guide

In engineering design, the core of selecting a suitable solid woven conveyor belt for clients is not based on industry names, but on accurately assessing environmental humidity, downhole risks, temperature range, material particle size, oil content, system tension, and tilt angle requirements.

The advantages of solid woven belts come from their overall woven structure and deep PVC impregnation system; therefore, the selection logic must revolve around material behavior and operational risks.

10.1 Selection by Operating Environment

(1) Dry Environment: PVC Type Preferred

Applicable operating conditions include:

- Dry roadway transportation

- Dry coal lines in thermal power plants

- Indoor conveying and sorting systems

- Dry materials such as powders, fine ore, and fertilizers

The flame retardant and antistatic properties of PVC solid woven conveyor belts meet downhole standards and exhibit stable performance in dry environments. For underground mining applications, PVC is permitted, but only under the following conditions:

- Dry roadways

- Low moisture content

- Minor impact

- Not a main conveyor belt

PVG is used in wet areas, PVC in dry areas; this is standard practice in mines, not that “PVC cannot be used underground.”

(2) Damp, high humidity areas: PVG is preferred

The PVG cover layer is a composite system of PVC matrix + NBR rubber phase.

The addition of NBR gives PVG the following advantages:

- Higher dynamic friction coefficient

- Stronger moisture resistance

- Better flexibility

- Better fatigue resistance

Applicable operating conditions:

- Wet coal, wet sand

- Washing plants

- Open-air conveying during rainy season

- Underground high humidity areas

- High humidity power plant coal lines

PVG conveyor belts are more stable than PVC in humid environments because NBR reduces wet friction attenuation.

(3) Oily materials: PVG or PVG with higher NBR content must be used.

Applicable materials:

- Oil-bearing coal seams

- Oil-based fertilizers (such as some NPK)

- Petrochemical powders

- Oil-bearing minerals

Solid woven PVC covered conveyor belts are not suitable for continuous contact with oil.

Oil will enter the PVC system and cause softening; therefore, PVG is the standard selection.

10.2 Selection based on material form and particle size

(1) Powdered materials (pulverized coal, pulverized ore, fertilizer powder)

Powdered ore refers to:

- Iron ore powder

- Copper ore powder

- Molybdenum ore powder

- Sintered powder

- Fine pellet powder

- Mineral tailings powder

Characteristics: Particle size <10 mm, strong flowability, and obvious frictional characteristics.

Both PVC and PVG can be used; the selection of the covering layer depends on the humidity.

(2) Medium particle size (10–50 mm) and ordinary bulk materials

Commonly found in:

- Granular fertilizers

- Granular metallurgical raw materials

- Building materials

Both PVC and PVG are acceptable; ambient humidity remains the primary criterion.

(3) Coarse particle size or high impact discharge

When materials have:

- Large particle size

- Large drop

- Frequent impacts

- High edge hardness

The following should be selected:

- PVG with a thicker overlay (up to 10 mm)

- A solid woven conveyor belt with a higher weave density

The NBR phase of PVG can absorb impact energy and reduce core layer damage.

10.3 Selection by Temperature Range

Based on the material properties of PVC and NBR:

Cover Layer | Allowable Temperature Range | Engineering Suitability |

PVC | 10–40°C | Normal temperature, dry, stable material temperature |

PVG | -10–50°C | Low temperature, high humidity, slightly elevated material temperature |

Note: Solid woven conveyor belts are not recommended for materials or environments exceeding 60°C; heat-resistant rubber conveyor belts should be selected instead.

10.4 Selection by Conveying Angle

(1) Angle ≤ 16°: PVC optional

Suitable for:

- Dry coal

- Powdered ore

- Dry fertilizer

- Various stable granular materials

(2) Angle ≤ 20°: PVG preferred

Because PVG has a higher coefficient of friction, it is suitable for:

- Wet coal

- Wet sand

- Wet fertilizer

- Oil-containing bulk materials

(3) For wet materials or further increased angle: Patterned cover layer optional

Patterns are not a standard feature of solid woven belts, but are selected according to working conditions to increase friction and prevent slippage.

10.5 Selection by Tension Level (Regenerated, entirely according to engineering logic)

The strength of a solid woven conveyor belt comes from:

- Warp yarn (polyester yarn) linear density

- Weft yarn (nylon yarn) linear density

- Weaving density

- PVC paste penetration

- Cover layer thickness

The following is the correct tension selection method.

(1) 680–1000 N/mm: Medium to low tension system

Applications:

- Sorting lines

- Surface fertilizer lines

- Short to medium distance conveying

- Underground auxiliary transport

- Low power drive

PVC/PVG are both suitable, depending on humidity.

(2) 1000–1400 N/mm: Medium Tension System

Applicable to:

- Underground branch conveyors

- Auxiliary systems in thermal power plants

- Intermediate conveyors in metallurgical plants

Recommendation:

- PVG is preferred in wet areas

- PVC can be used in dry areas

(3) 1400–1800 N/mm: Medium-High Tension System

Applicable to:

- Long-distance conveying

- Medium-impact material handling

- Multi-drive systems

PVG is usually chosen because it has:

- Better flexibility

- Better fatigue resistance

- Better moisture resistance

- Stronger surface friction stability

(4) 1800–2500 N/mm: High Tension System

Applicable to:

- Underground main conveyor belts

- Main coal lines in thermal power plants

- High-impact, high-capacity, steep-slope transport

Must use:

- High-density braided structure

- Core layer with higher adhesive penetration

- Thick PVG coating (up to 10 mm)

- Thermo-Fusion Splicing

PVC This range is not suitable because PVC has insufficient long-term fatigue performance under high tension.

11. Quality Inspection Items for Solid Woven Conveyor Belts

Quality inspection is crucial during the manufacturing and shipping of solid woven conveyor belts. This is because the structure of these belts relies on an integral woven core layer and a deep PVC impregnation process. Failure to meet any inspection standard will directly affect the belt’s load-bearing capacity, flame retardant stability, self-extinguishing ability, and service life.

Whether it’s a PVC solid woven conveyor belt, a PVC-G conveyor belt, or a solid woven PVC covered conveyor belt, their inspection procedures must be carried out in accordance with national standards, industry standards, and mining flame retardant requirements.

Specific inspection items are as follows.

11.1 Appearance Quality Inspection

Appearance inspection ensures the solid woven conveyor belt has consistent structural integrity, including:

- The cover layer surface should be smooth, without obvious wrinkles, delamination, or bubbles.

- The belt edges should be neat, without chipping or glue peeling.

- The core layer should not be exposed or damaged.

Appearance defects typically indicate:

- Insufficient PVC paste penetration

- Insufficient calendering pressure of the cover layer

- Uneven fabric tension

These issues will affect subsequent strength and joint quality.

11.2 Dimensional Inspection (Width, Thickness, Deviation)

Standards:

- Width deviation is generally controlled within ±5 mm.

- Total thickness deviation is generally controlled within ±10%.

For solid woven conveyor belts, thickness deviation directly affects:

- Channel shape performance

- Tension distribution

- Stability of the feed channel area

PVG cover layers are thicker (up to 10 mm), therefore thickness consistency is an even more important indicator.

11.3 Cover Thickness Inspection (Top & Bottom Covers)

Your technical specifications state:

- PVC cover thickness is 0.8–6 mm

- PVG cover thickness is 1.5–10 mm

The purpose of inspecting cover thickness includes:

- Ensuring top/bottom cover thickness conforms to the order technical agreement

- Insufficient cover thickness reduces impact and abrasion resistance

- Excessive cover thickness affects channel shape and energy consumption

Cover thickness must meet design values; otherwise, the overall performance of the solid woven conveyor belt will be difficult to guarantee.

11.4 Overall Belt Tensile Strength Inspection

Overall belt strength determines whether the solid woven conveyor belt can withstand the rated tension.

Key testing points include:

- Whether the nominal force rating (e.g., 680/800/1000/1250/1600/2000/2240/2500 N/mm) meets the standard

- Multi-point sampling to verify strength consistency

Substandard strength usually means:

- Insufficient warp yarn density

- Low weft yarn strength

- Insufficient adhesive penetration leading to insufficient core layer bonding strength

This is one of the most crucial tests for solid woven conveyor belts.

11.5 Interlayer Adhesion and Bonding Strength Testing

Although solid woven conveyor belts do not have a traditional “interlayer interface,” the following bonding strengths must still be tested:

- Adhesion between the cover layer and the core layer

- Bonding strength between cover layers

- The bonding quality between the PVG cover layer’s adhesive and the PVC adhesive layer

The minimum requirement is typically ≥3.0 N/mm.

Insufficient adhesion can lead to the following during operation:

- Cover layer peeling

- Wide deviation

- Impact zone failure

- Unstable adhesion at joints

This is especially critical for PVG conveyor belts, as the thick PVG cover layer bears significant impact loads.

11.6 Flame Retardant Performance Testing

Flame retardant performance is a key safety indicator for solid woven conveyor belts, including:

- Flame propagation

- Self-extinguishing time

- Coal dust ignition suppression capability

- Smoke density

- Flame hang time

The deep impregnation of PVC means that the flame retardant penetrates the entire core layer; therefore, the flame retardant capability must remain stable regardless of the wear of the cover layer.

Flame retardant testing is required for each batch of solid woven conveyor belts.

11.7 Antistatic Performance Testing

Solid woven conveyor belts must meet antistatic requirements; otherwise, they pose an ignition risk in coal mines, chemical powder environments, or oily environments.

Antistatic testing includes:

- Surface resistance measurement

- Overall resistance stability

- Comparison between wet and dry states

Generally, a resistance value ≤ 3 × 10⁸ Ω is required.

PVC and PVG systems must maintain long-term stability and not fail due to humidity changes.

11.8 Trough Shape Performance and Stiffness Testing

Trough shape performance is determined by the following factors:

- Fabric density

- Warp and weft stiffness

- Cover layer thickness

- PVC adhesive penetration

PVG cover layers have better trough shape retention due to the NBR elastic phase; therefore, they should be the focus of testing in ore, metallurgical, and wet area conveying.

11.9 Abrasion Resistance Testing

Abrasion resistance directly affects the lifespan of solid woven conveyor belts, especially:

- PVG thickened cover

- High-impact areas

- Transfer points

- Receiving areas

PVG generally has better abrasion resistance than PVC because NBR provides additional cushioning.

11.10 Joint Quality Inspection

Joint inspection includes:

- Thermo-Fusion fusion quality

- Cold-bonded joint adhesion strength

- Mechanical joint fastener stability

- Joint thickness consistency

- Joint flame retardancy consistency

High-tension systems of solid woven conveyor belts rely heavily on thermo-fusion joints; therefore, joint inspection accounts for a very high proportion of the overall inspection.

11.11 Operational Fatigue Testing (Dynamic Performance Inspection)

Used to verify:

- The lifespan of the woven structure under repeated bending

- Fatigue behavior of the PVC adhesive layer

- Crack propagation in the overlay

- Edge wear rate

- Dynamic tear resistance

This is one of the biggest structural differences between solid woven conveyor belts and ordinary EP belts.

12. Maintenance and Troubleshooting of Solid Woven Conveyor Belts

The core layer of a solid woven conveyor belt is a monolithic woven structure, with PVC paste infiltrating the fibers to form an integrated load-bearing body. Therefore, its operating characteristics differ from traditional EP conveyor belts.

Maintenance must focus on: flame retardant stability, cover layer wear, aging characteristics of the PVC paste layer, joint fusion quality, and changes in physical properties under humid conditions.

The following maintenance and troubleshooting methods are based on the structural characteristics of solid woven conveyor belts and the material behavior of PVC/PVG.

12.1 Daily Inspection Items

(1) Surface Wear and Cover Layer Damage

The wear pattern of PVC and PVG cover layers directly reflects:

- Impact strength of the material

- Sliding friction state

- Sealing state of the guide chute

Key inspection points:

- Whether the top cover layer has local wear through

- Whether the thick PVG cover layer has fatigue cracks

- Whether the cover layer shows signs of separation from the core layer

PVC solid woven conveyor belt wears more stably in dry areas, while PVG conveyor belt wears more slowly in wet areas, but once cracks appear, they should be dealt with promptly.

(2) Belt Misalignment

The overall woven structure of solid woven conveyor belt is more prone to concentrated wear of the edge rubber when misaligned, therefore, the following should be inspected:

- Idler roller angle

- Roller centerline

- Guide chute alignment

- Tensioning device stroke

If misalignment continues, it will weaken the cover layer → accelerate the exposure of the core layer → affect flame retardant performance.

(3) Joint Condition

Inspect different joint types separately:

- Thermo-Fusion:Check if the fusion zone is flat, if there are condensation white spots, and if stress concentration cracks are present.

- Cold-bonded: Check if the bonding interface is delaminated and if it has softened again due to humidity or temperature changes.

- Mechanical Joint:Check for loose fasteners, fastener pull-out, and damage to the belt edge.

Wear or delamination in the joint area is the most common starting point for belt breakage accidents.

(4) Roller Coating Wear and Sweeper Condition

Roller coating wear can lead to:

- Slippage

- Insufficient tension

- Uneven stress in the joint area

- Local scorching of the cover layer

Sweeper failure can lead to wet material accumulation, accelerating localized wear of solid woven PVC covered conveyor belts.

(5) Tensioning System Status

The low elongation of a solid woven conveyor belt means:

- It is more sensitive to any tension changes

- Insufficient tension stroke can easily lead to slippage

- An unbalanced tensioning system can cause edge overload

The tension stroke position needs to be recorded daily to prevent the system from entering the low tension zone.

12.2 Common Faults and Troubleshooting Methods

(1) Deviation

Possible causes:

- Material accumulation on idlers, idlers and bearing jamming

- Misalignment of the guide chute

- Misalignment of the joint

- Uneven tension distribution during startup

Troubleshooting steps:

- Clean the idlers

- Adjust the angle of the upper and lower idlers

- Correct the center line of the joint

- Check if the tensioning system is biased to one side

(2) Slippage

Solid woven conveyor belts are more prone to slippage in high humidity, especially PVG conveyor belts in coal slime or wet sand environments where the coefficient of friction decreases.

Possible causes include:

- Insufficient tension

- Wear of the drive roller coating

- Material accumulation causing localized pressure abnormalities

- Smooth surface of the PVG cover

Troubleshooting measures:

- Increase tension

- Replace the coating

- Clean up spilled material

- Readjust the cleaner pressure

(3) Tearing or localized damage

The tear resistance of solid braided belts comes from the nylon weft yarns, but damage can still occur due to foreign hard objects.

Typical causes:

- A cutting point is formed after the idler roller jams

- The metal plate of the guide chute sinks

- Sharp foreign objects are mixed in with the material

- Inadequate protection at the transfer point

Treatment methods:

- Remove foreign objects

- Replace the damaged idler roller

- Add idler roller protection

- Cold-bonded repair of the damaged area

A PVC-NBR-specific repair system must be used during repair to ensure that flame retardancy is not affected.

(4) Coating Delamination or Peeling

PVC coating peeling typically occurs due to:

- Excessive impact from the material

- Thin coating

- Aging of the cold-bonded joint adhesive system

- Decrease in PVC cross-linking density in high humidity environments

PVG coating peeling is mainly related to:

- NBR phase fatigue

- Stress concentration in thick coating areas

- Excessive cleaner pressure

Handling methods:

- Repair the structure of the receiving area

- Re-repair the cover layer

- Check the alignment of the sweeper and the idler roller

(5) Flame retardant performance degradation or high surface static electricity

The flame retardant of the solid woven conveyor belt is present throughout the core layer, but the following conditions may lead to a decrease in performance:

- The cover layer is severely worn through

- The core layer is exposed and dust accumulates

- Improper repair of the joint area

- Long-term wet conditions lead to an increase in surface resistance

Troubleshooting methods:

- Re-measure whether the surface resistance exceeds 3×10⁸ Ω

- Check whether the flame retardant layer is exposed

- Whether the wrong repair material was used in the joint area

- Remove accumulated coal dust

(6) Joint failure

The root causes of failure are different for different joint types:

- Hot melt joint:Insufficient temperature, insufficient pressure, uneven cooling leading to insufficient fusion

- Cold bonding joint:Improper chemical ratio, excessive humidity, incomplete surface treatment

- Mechanical joint:Loose fasteners, damaged belt edges

Check each item according to the joint type and redo the construction.

13.Conclusion

Whether you’re dealing with mines, power plants, fertilizer production lines, or metallurgical bulk material systems, as long as the operating conditions involve flame retardancy requirements, high humidity, strong impact, or long-term continuous operation, a structurally stable solid woven conveyor belt can significantly improve system safety and durability. The integral woven core layer and deep PVC impregnation process make it superior to traditional EP belts in terms of non-delamination, low elongation, and flame retardancy; the choice between PVC solid woven conveyor belts and PVG conveyor belts depends on the environmental humidity and material characteristics.

As a Chinese listed company with over 20 production lines, Tiantie Industrial has large-scale production capacity and a professional R&D team, enabling us to provide customized solid woven conveyor belts based on different humidity, temperature, slope, and impact levels. If you are looking for a safe, reliable, longer-lasting solid woven conveyor belt that meets international requirements, tell me your operating conditions, and I will provide you with precise technical selection advice.