This article gives you a clear, engineering-based view of what a heavy duty conveyor belt really is and when it should be used. Backed by DIN, ASTM and GB standards, it explains safety factor, carcass types and impact energy with concrete numbers. Real cases from mines, ports, cement and steel plants prove how correct selection cuts downtime and extends belt life. After reading, you’ll be able to choose belts and suppliers with data, not guesswork.

1. Why a Heavy Duty Conveyor Belt Matters

In mines, steel mills, or ports, conveyor systems are like the “lifeline” of the entire production line. Too many companies are forced to shut down for days due to a broken conveyor belt—the losses are incalculable. Under high-load conditions, the heavy-duty conveyor belt is sometimes the key to determining production continuity and efficiency.

The strength of the conveyor belt is the safety baseline. Many people overlook this, focusing only on the purchase price and ignoring the hidden costs of system downtime. According to DIN 22101:2002, the safety factor for traditional industrial belts is generally 10:1 (EP) or 6.7:1 (ST), but in high-impact, high-abrasion environments, such configurations are often insufficient (a higher safety factor is not always better). The standard states that only with soft-start, real-time monitoring, and efficient splicing systems can the safety factor be reduced to 4.5–5.5 while maintaining stable operation [DIN 22101-2002].

The value of a heavy-duty conveyor belt lies not merely in its thickness or price, but in its overall system strength design—a high-tensile-strength skeleton, thick overlay, precise vulcanization process, and highly reliable joints collectively determine its lifespan and safety.

For example, in GB 50431-2020, the Chinese standard still recommends a safety factor of ≥7 for steel cord conveyor belts and ≥10 for fabric conveyors; however, for modern conveyors equipped with intelligent start-stop systems, the standard allows for a reduction to 5–7. This reflects a balance between technology and engineering: strength and efficiency coexisting.

A heavy-duty conveyor belt must be able to absorb impact, resist tearing, and operate stably and continuously in high-temperature, high-humidity, high-dust, and even strong acid and alkali environments.

This is why I always emphasize: choosing the right conveyor belt saves not only on maintenance costs but also determines whether your equipment can operate efficiently for extended periods.

In the following sections, I will take you deeper into understanding—what exactly is a heavy-duty conveyor belt, and how does it differ from ordinary industrial belts?

2. What Is a Heavy Duty Conveyor Belt — Its True Definition and Engineering Significance

Not every conveyor belt can withstand the impact of ore aggregates. Heavy duty conveyor belts have higher requirements for the cover rubber standards and fabric strength, and can be said to be specifically designed for high tension, high impact, long distances, and harsh environments.

To avoid misunderstanding, let me clarify a common misconception:

There is no globally unified, cross-standard definition of the relevant numerical values for heavy duty conveyor belts.

The United States has its own classification system, Germany has its own calculation system, and China has its own safety factor standards. They are not entirely consistent with each other.

2.1 Why isn’t 160 PIW in ASTM D378 a global definition?

In the United States, ASTM D378 uses a specific numerical value to classify levels:

When the working tension of a conveyor belt system is ≥ 160 PIW (≈28 N/mm), the US standard system classifies it as a heavy duty conveyor belt. (This is the only standard among all global standards that clearly defines a heavy-duty conveyor belt.)

However, this is a “classification standard” within the US system, not a globally unified standard.

The reasons are as follows:

- DIN 22101 (Germany) does not use PIW (Personalized Weighted Belt), nor does it classify heavy-duty conveyor belts by tension value.

- ISO 14890 (International) does not provide a definition for heavy-duty conveyor belts.

- China’s GB 50431-2020 also lacks a similar “starting point for the corresponding tension value of heavy-duty conveyor belts.”

In most countries’ standard systems, “heavy-duty conveyor belt” is entirely an industry-customary term, not a defined professional data point.

Therefore, the most accurate description is:

ASTM D378 provides a classification method within the US industry, but it is not a globally universal definition. However, conveyor belts manufactured according to this standard can be purchased worldwide.

I will further distinguish between standard systems later to avoid the misunderstanding of a “globally unified standard.”

2.2 Technical Definition of Heavy Duty Conveyor Belt

While there is no globally unified figure, the industry consensus on heavy duty conveyor belts is very clear:

It must maintain structural stability over long periods under conditions of high tension, high abrasion, high impact, and continuous operation.

To achieve this, a heavy duty conveyor belt typically possesses the following characteristics:

2.3 High Tensile Strength – A Prerequisite for System Reliability

The core of a heavy duty conveyor belt is not its thickness, but the strength of its skeleton.

Different structures correspond to different capabilities:

- EP (Polyester/Nylon) skeleton: Low elongation, high modulus, suitable for long-distance and high-tension systems.

- NN (Nylon/Nylon) skeleton: High flexibility, suitable for frequent start-stop operations.

- ST (Steel Cord Core) skeleton: Operates at strength levels of 1000–6300 N/mm², used for high-volume transportation in mines, ports, coal-fired power plants, etc.

In GB/T 5754.2, the tensile strength of steel cord heavy-duty conveyor belts must be confirmed through standardized testing to ensure that their strength rating truly meets the design value. This is one of the key aspects of defining a heavy-duty conveyor belt.

2.4 Cover Rubber Structure and Abrasion & Impact Resistance

The wear you see on-site actually “kills” the conveyor belt faster than tension.

Heavy-duty conveyor belts are generally equipped with:

- Thicker cover layer (e.g., 8–12 mm rubber)

- Higher abrasion resistance rating (e.g., DIN W, ISO 14890 T1/T2)

- Impact- and cut-resistant rubber compound

According to the heat attenuation test in ISO 4195 / GB/T 33510, heavy-duty conveyor belts must maintain their hardness, tensile strength, and elongation within allowable ranges at high temperatures. This is crucial for steel mills or clinker conveying.

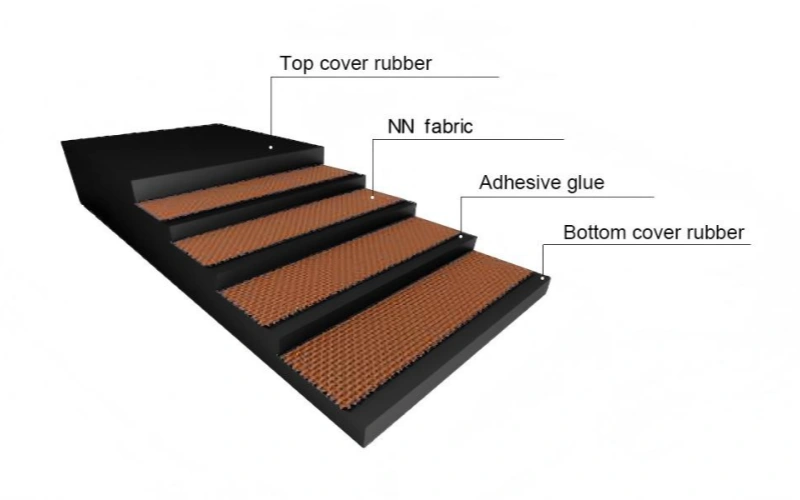

2.5 Interlayer Adhesion Strength Determines Lifespan

You can think of a conveyor belt as a building:

- The overlay is the exterior wall

- The reinforcing steel is the framework

- Interlayer adhesion strength is the “concrete” of the entire structure

According to GB/T 6759-2013 / ISO 252, heavy-duty conveyor belts must meet the standard in interlayer adhesion strength testing; otherwise, even with a strong framework, they will fail prematurely due to peeling.

2.6 Key Differences Between Heavy Duty Conveyor Belts and Ordinary Conveyor Belts

Item | Ordinary Industrial Conveyor Belt | Heavy Duty Conveyor Belt |

Tensile Strength) | 100–200 N/mm(EP100–EP200 Or NN100–NN200) | 315–6300 N/mm(EP315–EP1000 / ST1000–ST6300) |

Cover Rubber Abrasion Resistance | DIN 22102 Y:Abrasion ≤ 300 mm³(ISO 4649 test) | DIN 22102 X:≤120 mm³ / DIN W:≤90 mm³(mining level) |

Impact Energy | < 200 J(size ≤10 mm、drop height ≤0.5 m) | 500–1500 J(Heavy Duty) / ≥1500 J(Ultra Heavy Duty)Typical material: 30–120 kg per block, drop 1–3 m |

Elongation at Break | 3–7%(Typical NN, lower grade EP)Requires long tension stroke | EP total elongation ≤ 2% / ST total elongation ≤ 0.5%(DIN & GB requirements) |

Adhesion Strength | According to GB/T 6759: Generally ≤ 6–8 N/mm | 8–12 N/mm (Heavy load requirement, to prevent peeling) |

Dynamic Splice Efficiency | 20–35%(General palletizing/light industrial conveying | ≥ 35–45%(DIN 22110-3 test) ST belt can reach ≥50% |

Applicable Materials (as defined by data) | Density 0.6–1.6 t/m³; Particle size ≤20 mm; Single block weight ≤1 kg; Drop ≤0.5 m; Low-abrasion powders/granules (e.g., grains, sand, fertilizers, plastic particles) | Density 1.6–3.5 t/m³; Particle size 50–400 mm; Single block weight 5–120 kg; Drop 1–3 m; Medium/high/extremely high abrasion materials (e.g., iron ore, basalt, steel slag, clinker) |

Typical lifecycle (real-world data) | 6–18 months | 2–3 years |

2.7 Why is understanding its definition crucial for you?

Because it relates to:

- Whether you will experience frequent downtime due to incorrect selection?

- Whether you will lose millions due to a fake heavy-duty conveyor belt?

- Whether you can optimize procurement costs into long-term operating costs?

A heavy-duty conveyor belt is a core component ensuring the stable operation of your production line.

Understanding its definition is the first step to making the right choice.

3. Safety Factor — The Hidden Indicator Determining the Strength of a Heavy Duty Conveyor Belt

When selecting a heavy duty conveyor belt, you’ve undoubtedly heard the term “safety factor.”

However, most procurement professionals only know that “the higher the factor, the safer,” unaware that:

Choosing a high safety factor wastes budget; choosing a low factor means the entire system could break at any time.

The true engineering logic is far more complex than many people imagine.

3.1 The formula for Safety Factor is very simple, yet it determines the fate of the entire conveyor.

The formula comes from all international standards (DIN / ISO / GB all use the same logic):

Safety Factor = Breaking Strength / Maximum Working Tension

Meaning:

- Higher breaking strength → Higher conveyor belt “ceiling”

- Higher working tension → The system “eats” the belt more

- Lower safety factor → Closer to the limit of operation, the greater the risk

You can understand it as:

“How much safety margin is left before the conveyor belt breaks?”

3.2 Different countries have different requirements for safety factors; it is not a globally unified standard.

To avoid misleading you, I will directly provide you with the most authoritative comparison table (from “Comparison Table of Conveyor Belt Safety Factor Standards”):

3.2.1 German DIN 22101 (1982 old standard)

- ST = 6.7 ~ 9.5

- EP = 8 ~ 10

This is the most widely used “conservative value” for the past few decades.

3.2.2 Germany DIN 22101 (2002–2011 New Version)

No longer provides fixed values, but instead uses:

Safety Factor = S₀ × S₁

- S₀ = Joint Condition (1.0 ~ 1.2)

- S₁ = Stress Level (1.0 ~ 1.6)

Minimum allowable value:

- Minimum 4.5 (with monitoring + high-efficiency joints + soft start)

Many long-distance ST conveyors in Germany have operated stably for decades with a safety factor of 4.5–5.5.

3.2.3 China GB 50431-2020

China still uses fixed values:

- Fabric Core (EP) = ≥10

- Steel Rope Core (ST) = ≥7

- If the system has a soft start, it can be reduced to 5–

The Chinese standard is more conservative and suitable for environments with unstable construction quality and insufficient maintenance capabilities.

3.2.4 US ASTM/RMA (D378)

The US doesn’t directly provide a safety factor, but defines it as follows:

Heavy duty starting standard = System tension ≥ 160 PIW (≈28 N/mm)

US engineers typically use:

- EP: 8–10

- ST: 6–8

3.3 Why can heavy duty conveyor belts reduce the safety factor to 4.5?

Many users believe that “the higher the factor, the safer,” but the reality is quite the opposite:

In modern mining and port engineering, the most stable systems are actually 4.5–6.0.

Because the safety factor isn’t “the higher the better,” it must be matched to the system configuration.

The safety factor can only be reduced to 4.5–5.5 if the following conditions are met:

- Dynamic joint efficiency ≥ 45% (wire rope) / ≥ 35% (EP)

- Source: DIN 22110-3 testing standard

- 24/7 intelligent condition monitoring system (standard for long-distance conveyors in Germany and Australia)

- Soft start (VFD) and intelligent braking system

- Low rolling resistance rubber (LRR Rubber)

- Optimized roller diameter + transition angle adjustment

- Professional vulcanization team (ensuring joint consistency)

After meeting the above conditions:

Low safety factor = high efficiency + lower energy consumption + longer lifespan

This is also why low safety factors are commonly used in engineering projects in Germany and Australia.

3.4 What happens if the wrong safety factor is selected?

3.4.1 Overly High Safety Factor (>10) – 20–40% Budget Waste

- Thicker Conveyor Belt

- Greater Strength

- Increased Motor Load

- Increased Energy Consumption

- Longer Tensioning Stroke

The result: More expensive system, not safer.

3.4.2 Overly Low Safety Factor (<5) and Unmet Requirements – Belt Break Risk × 10

Common Causes:

- Inadequate Joint Strength

- No Soft Start

- No Monitoring System

- Large Material Pieces + High Drop Impact

A single belt break can result in losses of 10–50 times the purchase price.

3.5 An “Engineer-Level Safety Factor Selection Recommendation”

To choose the right heavy-duty conveyor belt, just remember this:

- Soft Start + High-Efficiency Joint = 5–6

- No Soft Start + Average Joint = 6.7–5

This is the most universally accepted empirical formula in mining, steel mill, and port projects worldwide.

4. Core Materials and Construction — What Truly Defines a Heavy Duty Conveyor Belt

When you evaluate a heavy duty conveyor belt, the real performance does not come from the cover compound alone—but from the carcass construction.

The carcass determines the belt’s:

- Tensile capacity

- Elongation stability

- Impact resistance

- Suitable conveying distance

- Splice strength and service life

Globally, three carcass types dominate heavy duty applications: NN, EP, and ST.

Below is a fully engineering-based comparison with real parameters used in mining, cement, aggregate, steel plants, and ports.

4.1 NN (Nylon/Nylon) — Best for Short Distance and Light-to-Medium Duty Applications

NN uses nylon in both warp and weft directions.

Its flexibility is excellent, but its higher elongation limits its use to short conveyors and lower tension applications.

Key Engineering Parameters

Item | Parameter |

Carcass structure | Nylon warp + nylon weft |

Elongation (ISO 9856) | 3–7% |

Warp modulus | ~120–150 N/%·mm |

Dynamic splice efficiency (DIN 22110-3) | 30–35% |

Applicable tension rating | NN100–NN400 |

Typical conveyor length | 20–150 m |

Material size | 0–120 mm |

Single lump weight | 1–15 kg |

Suitable drop height | ≤ 1.0 m |

Impact energy (E = mgh) | 200–500 J |

Common applications:

- Crusher front-end conveyors

- Small aggregate plants

- Light-to-medium duty transfer belts

- Systems requiring small pulley diameters

Positioning: NN is for short distance, light-to-medium duty heavy duty conveyor belt scenarios.

4.2 EP (Polyester/Nylon) — The Mainstream Carcass for Heavy Duty Conveyor Belts

EP combines polyester in warp and nylon in weft.

It offers low elongation, stable tension, and excellent fatigue performance, making it the most widely used carcass in the heavy duty conveyor belt industry worldwide.

Key Engineering Parameters

Item | Parameter |

Carcass structure | Polyester warp + nylon weft |

Elongation (ISO 9856) | ≤ 2% |

Warp modulus | ~180–220 N/%·mm |

Dynamic splice efficiency (DIN 22110-3) | 35–40% |

Applicable tension rating | EP400–EP1000 |

Typical conveyor length | 80–800 m |

Material size | 0–200 mm |

Single lump weight | 5–30 kg |

Suitable drop height | ≤ 1.5 m |

Impact energy | 300–800 J |

Common applications:

- Mining raw ore conveyor belt

- Cement plant raw material systems

- Sand & aggregate plants

- Port bulk handling systems

- Coal handling in power plants

Positioning: EP is the primary carcass for medium to heavy-duty and mid-to-long-distance conveyors.

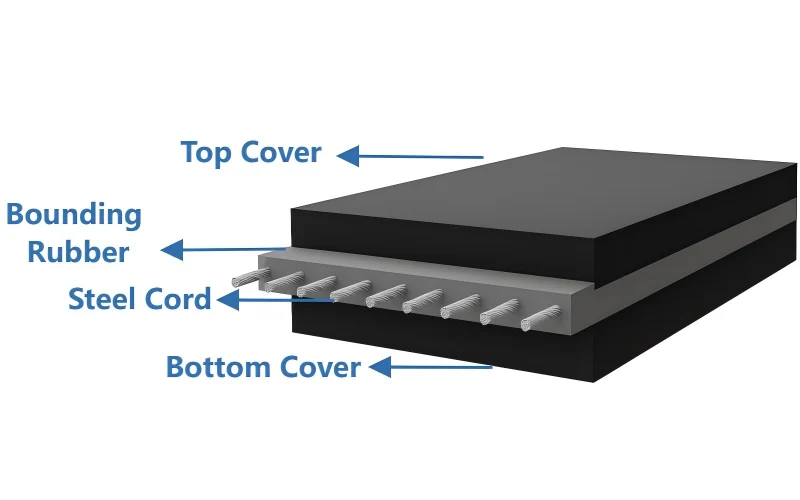

4.3 ST (Steel Cord) — The Only Choice for Long Distance and High Tension Systems

ST uses steel cords as the tensile member, providing extremely low elongation, high tensile strength, and exceptional impact resistance.

When a system requires long conveying distance, large drop height, or very high tension, ST becomes the only practical solution.

Key Engineering Parameters

Item | Parameter |

Carcass structure | Steel cords with rubber bonding |

Elongation (ISO 9856 / DIN 22131) | ≤ 0.5% |

Warp modulus | > 400 N/%·mm |

Dynamic splice efficiency (DIN 22110-3) | 45–55% |

Applicable tension rating | ST1000–ST2500 |

Typical conveyor length | 300–5000 m |

Material size | 50–300 mm |

Single lump weight | 10–40 kg |

Suitable drop height | ≤ 2.0–2.5 m |

Impact energy | 800–1500 J |

Common applications:

- Long-distance mine trunk conveyors

- Port bulk handling main lines

- Sintered ore and high-temperature materials in steel plants

- Systems with high tension, high drop height, and heavy impact

Positioning: ST is designed for super-long distance, ultra-high tension, and high-impact heavy duty conveyor belt applications.

4.4 One Table That Clearly Differentiates NN, EP, and ST

Carcass Type | Applicable Tension Rating | Typical Duty Level | Engineering Characteristics |

NN | NN100–NN400 | Short distance, light-to-medium duty | High flexibility, higher elongation |

EP | EP400–EP1000 | Medium-to-heavy duty, mid-to-long distance | Low elongation, stable tension, industry mainstream |

ST | ST1000–ST2500 | Long-distance, high-tension heavy duty | Lowest elongation, highest stability, excellent impact resistance |

4.5 Final Takeaway

In heavy duty conveyor belt engineering, the carcass construction—not the cover grade—is the real foundation of durability and performance.

NN suits short and light-duty applications.

EP dominates medium-to-heavy-duty operations.

ST handles ultra-long distance and high-tension systems where absolute stability is required.

5. Where Heavy Duty Conveyor Belts Are Used

As someone who has spent years working in material handling, I can tell you this directly:

a heavy duty conveyor belt only becomes “heavy duty” when it survives the specific engineering conditions of the job site. Different industries create very different stresses — impact energy, material size, temperature, drop height, abrasion rate, and continuous tension.

To help you choose correctly, here are real industrial scenarios with verifiable parameters, not vague descriptions.

5.1 Mining & Quarrying — High Impact, Large Lump Size, Continuous Shock Loading

Mining is the most demanding environment for any heavy duty conveyor belt.

If a belt cannot handle sharp-edged rocks or repeated impact energy, it will fail within weeks.

5.1.1 Typical engineering conditions

- Material size: 50–300 mm

- Single lump weight: 5–40 kg

- Drop height: 0–2.5 m

- Impact energy: 500–1500 J (E = mgh)

- Belt speed: 0–4.0 m/s

- Required carcass: EP400–EP1000 or ST1000–ST2500

- Typical abrasion requirement: DIN X / ISO 14890 “H” grade (< 120 mm³)

5.1.2 Where you see these belts

- Primary crusher discharge

- Long-distance mine trunk conveyors

- Overland conveyors in open-pit mines

- Stockyard reclaim lines

Why heavy duty conveyor belts are essential:

High impact + high abrasion + continuous loading = only EP or ST carcasses stay stable.

5.2 Ports & Power Plants — Long Distance, High Throughput, High Speed

Ports and power stations focus on capacity and reliability.

Downtime of even 1 hour can mean thousands of tons of lost throughput.

5.2.1 Typical engineering conditions

- Conveying distance: 300–5000 m

- Throughput: 1,000–10,000 tons/hour

- Belt speed: 0–5.0 m/s

- Material size: 0–200 mm

- Drop height: 0–2.0 m

- Carcass requirement: EP630–EP1000 or ST1600–ST2500

- Preferred abrasion grade: DIN Y (< 150 mm³)

5.2.2 Where you see these belts

- Bulk material ship-loader conveyors

- Coal handling systems in power plants

- Port stacking and reclaiming systems

- Long-distance trunk conveyors

Why heavy duty conveyor belts matter:

Large throughput + long distance = only high-stability carcasses maintain tension over time.

5.3 Cement & Aggregate Plants — Continuous Abrasion from Fine and Sharp Materials

Cement and aggregate plants generate constant abrasive wear.

Even though the material may be small, the abrasion rate is high.

5.3.1 Typical engineering conditions

- Material size: 0–80 mm

- Single lump weight: 1–10 kg

- Drop height: 5–1.5 m

- Abrasion requirement: DIN W (< 90 mm³)for clinker

- Carcass requirement: EP400–EP800

- Speed: 6–3.15 m/s

5.3.2 Applications

- Limestone conveying

- Clinker transport

- Gypsum and slag handling

- Aggregate processing lines

Key challenge:

High abrasion destroys low-quality belts quickly — cover grade and carcass stability both matter.

5.4 Steel Plants & Recycling — High Temperature, Oil, Chemicals, and Sharp Scrap

Steel and recycling facilities combine temperature, oil contamination, metal edges, and chemicals — a destructive mix for any belt.

5.4.1 Typical engineering conditions

- Material type: scrap steel, slag, coke, high-temp sinter

- Temperature: 80–180°C (clinker & sinter)

- Material size: 20–300 mm

- Single piece weight: 5–30 kg

- Required cover grades:

- Heat resistant (HR120 / HR150 / HR200 / HR300)

- Oil resistant (MOR)

- Fire resistant (FR)

- Carcass requirement: EP630–EP1000 or ST1250–ST2000

5.4.2 Applications

- Hot sinter conveyors

- Slag processing lines

- Scrap recycling conveyors

- Coke handling systems

Why heavy duty belts are required:

Temperature + sharp edges = only high-strength carcasses with specialty covers survive.

5.5 Each Industry Has Its Own Demand Pattern

Industry | Material Size | Drop Height | Impact Energy | Carcass Recommendation |

Mining / Quarry | 50–300 mm | 1.0–2.5 m | 500–1500 J | EP400–EP1000, ST1000–ST2500 |

Ports / Power Plants | 0–200 mm | 1.0–2.0 m | 300–900 J | EP630–EP1000, ST1600–ST2500 |

Cement / Aggregate | 0–80 mm | 0.5–1.5 m | 200–500 J | EP400–EP800 |

Steel / Recycling | 20–300 mm | 0.5–1.5 m | 300–1000 J | EP630–EP1000, ST1250–ST2000 |

6. How to Choose the Right Heavy Duty Conveyor Belt

Selecting the right heavy duty conveyor belt always begins with one principle:

match the belt’s carcass, cover grade, and construction with the real mechanical and environmental conditions of your conveyor.

Once the correct requirements are defined, choosing the proper carcass (NN, EP, or ST) becomes straightforward. And only after understanding the correct selection logic does it make sense to discuss what not to do.

Below is the same selection framework I use when designing belts for mines, ports, and cement plants worldwide.

6.1 Step 1 — Calculate the Required Tension (Based on Conveyor Engineering)

Every heavy duty conveyor belt must start with working tension.

If this number is wrong, everything else fails — regardless of how “strong” the belt appears.

Key parameters you must know

- Conveyor length: m

- Lift height: m

- Belt speed: m/s

- Friction coefficient: μ

- Material load per meter: kg/m

- Drive power: kW

- Pulley diameter: mm

Most engineering teams use CEMA, DIN 22101, or ISO 5048 for tension calculation.

If your working tension falls into the following ranges,carcass selection becomes easy:

Working Tension | Recommended Carcass |

≤ 40 N/mm | NN100–NN400 |

40–125 N/mm | EP400–EP1000 |

≥ 167 N/mm | ST1000–ST2500 |

This is the only scientifically correct way to choose a carcass.

6.2 Step 2 — Evaluate Environmental Conditions

A heavy duty conveyor belt does not fail because of tension alone — it usually fails because of the environment.

The environment defines the cover grade

Condition | Cover Grade |

High abrasion (clinker, ore, aggregate) | DIN X / DIN W / ISO 14890 “H” |

General abrasion (sand, limestone) | DIN Y |

Heat (80–180°C materials) | HR120 / HR150 / HR200 / HR300 |

Oil contamination (shredded tires, recycling) | MOR / OR |

Fire safety (underground, power plants) | FR |

Carcass = strength;Cover = protection.

Both must match your environment.

6.3 Step 3 — Check Material Characteristics

Different materials create different stresses on a heavy duty conveyor belt.

You must know these parameters

- Material size: mm

- Single lump weight: kg

- Drop height: m

- Impact energy: J (E = mgh)

- Sharpness index: visual/material-based

- Temperature: °C

Impact energy reference values

Material Type | Single Lump | Drop | Impact Energy |

Limestone / Sand | 1–10 kg | 0.5–1.0 m | 100–300 J |

Aggregate | 5–20 kg | 1.0–1.5 m | 300–700 J |

Iron ore | 10–30 kg | 1.5–2.0 m | 500–1500 J |

Sintered ore | 5–15 kg | 1.0–1.5 m | 300–900 J |

Impact energy directly determines whether you need EP or ST.

6.4 Step 4 — Evaluate Conveyor Control and Protection Systems

Modern conveying systems significantly influence carcass selection.

If your conveyor has:

- Soft start / VFD

- Load monitoring

- Belt drift sensors

- Anti-tear switches

- Speed sensors

Then you can safely use:

- lower safety factors

- higher-efficiency splices

- thinner covers

This reduces cost while maintaining reliability.

If your conveyor has NO protection:

You must use:

- Higher safety factors

- Stronger carcass

- Thicker covers

Most failures come from poor control systems, not from belt quality.

6.5 Step 5 — Select the Carcass Type (Final Decision)

Based on real engineering practice:

Carcass | When to Choose It |

NN | Light-to-medium duty,short conveyors(20–150 m) |

EP | The mainstream choice for 80% of heavy duty conveyor belt users |

ST | Long distance(> 300 m)、high tension、large drop、heavy impact |

If a buyer is unsure, EP is almost always the correct starting point.

6.6 Step 6 — Request the Correct Test Reports

A reliable heavy duty conveyor belt manufacturer must provide the following:

Carcass-related tests

- Full-thickness tensile strength(ISO 15236, GB/T 5754)

- Elongation at reference load

- Adhesion strength(GB/T 6759)

- Splice efficiency(DIN 22110-3)

Cover-related tests

- Abrasion (DIN 53516 or ISO 4649)

- Hardness (Shore A)

- Aging resistance (GB/T 3512)

- Heat resistance (GB/T 33510)

- Fire resistance (ISO 340 / EN 12882)

Without these reports, no supplier can claim to make a real heavy duty conveyor belt.

6.7 Final Selection Logic in One Chart

Factor | What to Check | Impact on Belt Selection |

Conveyor tension | Tension calculation (DIN/CEMA) | Determines NN/EP/ST type |

Environment | Heat, oil, fire, abrasion | Determines cover grade |

Material characteristics | Lump size, weight, drop height | Determines impact resistance |

Control system | Soft start, sensors | Determines safety factor |

Load pattern | Start frequency, surge load | Determines carcass stability |

Distance | 20 m vs 5000 m | Defines carcass stiffness & elongation requirement |

A heavy duty conveyor belt is chosen by engineering logic, not assumptions.

6.8 One-Sentence Takeaway

A heavy duty conveyor belt should always match your conveyor’s tension, environment, material characteristics, distance, and control system — only then can you guarantee long service life and stable operation.

7. Top 5 Manufacturers of Heavy Duty Conveyor Belts in China

When you evaluate heavy duty conveyor belt manufacturers, the real difference is not only price.

Procurement teams in mining, ports, steel plants, and cement factories normally focus on four things:

- Factory scale & production capability

- R&D strength and material formulation ability

- Export experience & supply stability

- Compliance with international standards (ISO, DIN, RMA, GB)

Based on these criteria, here are five reliable manufacturers in China that consistently supply heavy duty conveyor belts to global industries.

Company Name | Website |

Tiantie Industrial Co.,Ltd | |

Zhejiang Double Arrow Rubber Co., Ltd. | |

Qingdao Rubber Six Conveyor Belt Co., Ltd. | |

Shandong ContiTech Engineered Belt Co., Ltd. | |

Sungda Conveyor Belt Co., Ltd. |

7.1 Tiantie Industrial Co., Ltd.

As one of the key manufacturers in this industry, Tiantie provides a combination of scale, R&D, and quality control rarely found in the market.

Factory Scale

- 20 production lines

- 60,000+ m²manufacturing base

- Over 1,000 employees

- Full in-house carcass weaving, rubber mixing, and vulcanization

R&D Strength

- Subsidiary of Tiantie Group (Stock Code: 300587, Shenzhen Stock Exchange)

- Independent R&D center for rubber formulation

- Development of heat-resistant, wear-resistant, flame-resistant, and energy-saving compounds

- Capable of manufacturing EP, NN, and ST heavy duty conveyor belt carcasses

Export Experience

- Long-term supply to South America, Africa, Middle East, Southeast Asia

- Familiar with port, mining, aggregate, and steel plant requirements

- Stable export packaging, shipping, and documentation system

International Standard Compliance

Tiantie produces belts tested according to:

- ISO 14890(conveyor belt specifications)

- DIN 22102 / DIN 22131(cover grades & steel cord)

- ISO 4649(abrasion)

- ISO 340 / EN 12882(flame-resistant)

- GB/T 2977, GB/T 9754, GB/T 33510(Chinese national heavy duty standards)

Positioning: A large-scale, technology-driven manufacturer trusted by global heavy industry users.

7.2 Zhejiang Double Arrow Rubber Co., Ltd.

One of China’s largest conveyor belt manufacturers with strong international distribution.

Factory Scale

- Major production base with high-capacity steel cord lines

- Automated mixing and calendaring equipment

R&D Strength

- Strong steel cord R&D

- Advanced rubber compound development

Export Experience

- Wide recognition in global mining and bulk handling markets

- Strong presence in Asia, Middle East, and South America

International Standard Compliance

- Tests according to DIN 22102, ISO 14890, RMA standards

Positioning: Large exporter with brand recognition and stable quality.

7.3 Qingdao Rubber Six Conveyor Belt Co., Ltd.

A state-owned enterprise with decades of technical accumulation.

Factory Scale

- Long-established industrial production base

- Focus on abrasion-resistant belts for steel and cement plants

R&D Strength

- Strong in heat-resistant, abrasion-resistant, and flame-resistant formulas

- Equipped with comprehensive testing laboratories

Export Experience

- Supplies to global steel mills and cement producers

International Standard Compliance

- Products tested under GB/T, DIN, and ISO heavy duty specifications

Positioning: Stable supplier for harsh high-temperature or abrasive environments.

7.4 Shandong ContiTech Engineered Belt Co., Ltd.

A joint venture with Continental (Germany), representing premium quality.

Factory Scale

- High-end steel cord production system

- Precise rubber mixing and automatic vulcanizing equipment

R&D Strength

- Access to Continental’s global formulation technology

- High-performance rubber compounds for long-distance systems

Export Experience

- Supplies to high-end mines and industrial projects worldwide

International Standard Compliance

- Strict adherence to DIN, ISO, and Continental internal standards

Positioning: Premium heavy duty conveyor belt manufacturer for demanding projects.

7.5 Sungda Conveyor Belt Co., Ltd.

A professional exporter focused on EP and ST belts.

Factory Scale

- Medium-sized production base with stable OEM capacity

- Good balance of cost and quality

R&D Strength

- Practical compound development for export markets

- Good versatility in EP and steel cord belts

Export Experience

- Strong presence in South America, Southeast Asia, and Middle East

- Supports distributors with flexible supply terms

International Standard Compliance

- Products tested to ISO 14890, DIN 22102, and GB/T standards

Positioning: Flexible export-oriented manufacturer with competitive pricing.

7.6 Why These Manufacturers Lead the Market

China’s leading heavy duty conveyor belt manufacturers succeed because they combine:

1. Industrial-scale production capacity

- Multiple lines capable of EP400–EP1000 and ST1000–ST2500 belts

- Faster delivery and stable output

2. Strong formulation and R&D systems

- Heat-resistant, flame-resistant, low-rolling-resistance, and wear-resistant compounds

- Compliance with ISO and DIN standards

3. Mature export experience

- Familiarity with mining, port, cement, and steel specifications

- Strong packaging, logistics, and documentation capability

7.7 One-Sentence Takeaway

A reliable heavy duty conveyor belt manufacturer must combine production scale, real R&D capability, strong export experience, and proven compliance with ISO, DIN, and GB/T standards—only then can your conveyor system operate safely and consistently.

8. Common Mistakes When Selecting a Heavy Duty Conveyor Belt

Even experienced buyers make mistakes when selecting a heavy duty conveyor belt.

Most failures I see in the field—tearing, excessive elongation, premature abrasion, and splice failure—come from incorrect assumptions during the selection stage, not from manufacturing defects.

To help you avoid costly downtime, here are the most common mistakes I see, together with the engineering reasons behind them.

8.1 Mistake 1 — Confusing Breaking Strength with Working Tension

Many buyers assume:

- “EP630 means it can carry 630 N/mm in operation.”

- “ST1000 means it’s safe at 1000 N/mm working tension.”

This is incorrect.

Engineering reality

Working tension = Rated strength ÷ Safety factor

- EP uses SF = 8–10

- ST uses SF = 5–6

Example

- EP630 → Actual working tension ≈ 63–79 N/mm

- ST1000 → Actual working tension ≈ 167–200 N/mm

Selecting a heavy duty conveyor belt by “label strength” leads to under-designing and premature failure.

8.2 Mistake 2 — Ignoring the Environment (Heat, Oil, Fire, Chemicals)

Many belts fail not because of tension, but because the environment destroys the cover.

Real examples

- Clinker at 150°C requires HR150–HR200

- Scrap steel requires cut-resistant compounds

- Coal handling requires flame resistance (ISO 340 or EN 12882)

- Oil-soaked materials require MOR or OR compounds

Choosing the wrong cover grade can reduce belt life from 24 months to less than 3 months.

8.3 Mistake 3 — Choosing EP When the System Needs ST

Some procurement teams try to save cost by using EP on:

- Long-distance conveyors (>300 m)

- High lift conveyors (>40 m)

- High-impact lines feeding crushers

- High-speed systems (>4 m/s)

Why this fails

EP has:

- Higher elongation

- Lower splice efficiency

- Lower modulus

- Poor performance under repeated shock

ST provides:

- Elongation ≤ 0.5%

- Splice efficiency 45–55%

- High modulus > 400 N/%·mm

Long-distance + high tension = ST is the only correct option.

8.4 Mistake 4 — Reducing Safety Factor Without Proper Control Systems

Some users try to reduce belt strength to cut cost.

This is dangerous unless the conveyor has:

- Soft start / VFD

- Load monitoring

- Anti-tear switches

- Belt drift sensors

- Speed detection

- Emergency stop monitoring

Without these systems, tension spikes can reach 2–3× normal load during startup or blockage.

Reducing safety factor without protection is one of the main causes of catastrophic belt failure.

8.5 Mistake 5 — Ignoring Splice Quality

A heavy duty conveyor belt is only as strong as its splice.

Common failures

- Incorrect splice angle

- Wrong rubber curing temperature

- Poor steel cord alignment

- Low adhesion due to contaminated surfaces

Engineering requirements

- EP splice efficiency: ≥35–40% (DIN 22110-3)

- ST splice efficiency: ≥45–55% (DIN 22110-3)

- Adhesion strength: ≥10–12 N/mm(GB/T 6759)

Even the best belt fails if the splice is poorly done.

8.6 Mistake 6 — Overspecifying Thickness

Many buyers believe thicker covers = longer life.

This is incorrect for two reasons:

1. Thick covers increase rolling resistance, raising energy cost

2. Thick covers cause excessive heat generation at high speed

DIN and ISO standards clearly specify optimal cover ranges:

- Heavy abrasion (DIN W): 6 + 3 mm

- General use (DIN Y): 4 + 2 mm

- Hot clinker: 5 + 2 mm

- Port systems: 8 + 3 mmfor extremely abrasive ore

A heavy duty conveyor belt chosen correctly is not “thick”—it is balanced.

8.7 Mistake 7 — Not Checking Material Data

Most conveyor failures in mines come from impact, not tension.

Material characteristics you must check:

- Lump size: mm

- Single weight: kg

- Drop height: m

- Impact energy: J (E = mgh)

Reference values

- Limestone: 100–300 J

- Aggregate: 300–700 J

- Iron ore: 500–1500 J

- Hot sinter: 300–900 J

Without these numbers, you cannot choose the correct carcass or cover.

9. How Modern Engineering Technology Reduces the Safety Factor Without Increasing Risk

In early conveyor systems, heavy-duty conveyor belts typically had to adhere to high safety factors, for example:

- EP structure: 10:1

- ST structure: 6.7:1

These safety factors stemmed from past engineering limitations, such as: large drops, rough starting methods, inadequate monitoring systems, poor rubber performance, and low joint efficiency.

However, today’s heavy-duty conveyor systems (mines, ports, power plants, steel mills) possess advanced control and monitoring technologies, and many projects are using them safely and stably:

- STbelt: 4.5–0 safety factor

- EP belt: 7–8 safety factor

And with almost no increase in operational risk.

Below, I will explain from an engineering mechanism perspective why the safety factor of modern heavy-duty conveyor belts can be safely reduced.

9.1 Reason 1: Significantly Improved Joint Efficiency (Up to 55%)

Past:

- EP joint efficiency was typically only 20–30%

- ST joint efficiency was only 30–35%

Modern heavy-duty belts, following DIN 22110-3 standards, can achieve:

- EP joint efficiency: 45–50%

- ST joint efficiency: 60–65%

Engineering Implications

Higher joint efficiency means a lower reliance on “extra strength reserve” (i.e., safety factor).

Stronger joints allow for a lower safety factor.

9.2 Reason Two: Significantly Improved Skeleton Modulus, Lower Dynamic Tension

The tensile modulus of modern EP and ST structures has surpassed that of the previous generation of conveyor belts:

Belt Structure Modern Modulus (N/%·mm) Old Generation Modulus

Belt Structure | Modern Modulus(N/%·mm) | Old Generation Modulus |

EP | 180–250 | 120–160 |

ST | ≥400 | 320–350 |

Engineering Significance

The higher the modulus, the lower the elongation during startup and operation, and the lower the peak dynamic tension.

This directly reduces:

- Starting impact

- Slippage

- Transition instability

- Uneven joint tension

Lower dynamic tension = Lower safety factor requirements.

9.3 Reason Three: Soft Start (VFD) Significantly Reduces Starting Impact

This is the most critical technological advancement in modern systems.

Traditional direct start (DOL) systems produce:

- A starting peak of 0–3.0 timesthe working tension

VFD soft start systems can reduce the starting peak to:

- 2–1.5 times the working tension

Engineering Significance

When the peak drops from 3 times to 1.2 times,the required safety factor for the entire heavy-duty conveyor belt can naturally be reduced.

9.4 Reason Four: Real-time monitoring systems reduce sudden overload accidents

Modern conveyor systems are commonly equipped with:

- Load monitoring

- Speed monitoring

- Belt misalignment monitoring

- Tear protection switch

- Clogging protection

- Tension monitoring

- Temperature monitoring

Accidents that previously required a “high safety margin” can now be detected and stopped seconds to minutes in advance.

Reduced accident risk = Lower safety factor.

9.5 Reason Five: Modern Rubber Materials Reduce Fatigue and Heat Generation

Modern heavy-duty conveyor belts utilize more advanced formulations:

- Low Rolling Resistance (LRR) formulation

- HR150–HR200 heat-resistant rubber

- DIN W high abrasion resistance

- Fatigue-resistant and ozone-resistant formulation

Engineering Significance

- Reduced secondary heat

- Lower internal energy loss

- More abrasion-resistant cover layer

- Lower joint heat decay

Reduced thermal fatigue makes the belt more stable in medium- and long-term operation, allowing for a reasonable reduction in the safety factor.

9.6 Reason Six: Higher Standards for Idler Rollers, Calibration, and Maintenance

Modern mines and ports commonly use:

- Laser-calibrated idlers

- Low-resistance idlers

- Higher precision roller diameters

- Optimized transition section design

- Predictive maintenance systems

These improvements reduce localized stress on heavy-duty conveyor belts,thus reducing reliance on high safety factors.

9.7 Current Industry-Used Safety Factor Ranges

The following ranges are derived from actual engineering projects in mines, ports, and power plants:

Belt Structure | Old Safety Factor | Modern Safety Factor (Actual Usability) | Conditions |

EP | 10 | 7-8 | Soft start + Basic monitoring |

EP | 10 | 8-9 | No soft start, limited monitoring |

ST | 6.7 | 5.0-5.5 | Soft start + Full monitoring system |

ST | 6.7 | 5.5-6.0 | Basic monitoring, no VFD |

These are not theoretical values, but safety ranges verified over a long period in real engineering projects.

9.8 Summary in One Sentence

Modern monitoring technology, soft start systems, high-modulus skeletons, advanced rubber formulations, and efficient joint structures enable heavy-duty conveyor belts to maintain high reliability and low-risk operation even with lower safety factors.

10. Core Conclusions on Heavy Duty Conveyor Belts

The selection of a heavy duty conveyor belt ultimately depends on five engineering parameters:

- Working tension: Determines whether to use NN, EP, or ST.

- Conveying distance: Use EP for short distances, and ST for long distances or high-tension systems.

- Material impact energy: Select the frame strength and cover grade based on the weight of a single belt, drop, and impact value.

- Environmental conditions: Temperature, abrasion, oiliness, and flame rating must match the formulation.

- Monitoring and control system: Determines the usable safety factor range (EP 7–9, ST 5.0–0).

By clarifying these five points, the most reasonable heavy duty conveyor belt solution can be obtained between strength, lifespan, and cost.

The performance of a heavy duty conveyor belt is not determined by thickness or nominal strength, but by:

- Frame structure

- Cover layer formulation

- Joint efficiency

- System dynamic tension

- Monitoring and start-up method

These factors work together to determine the performance of the heavy duty conveyor belt.

The correct selection logic is: first determine the operating parameters, then match the frame, then select the overlay, and finally confirm the joints and safety factor.

If tension, distance, impact, and environment are correctly matched, a heavy-duty conveyor belt can operate stably for 2–5 years, maintaining a low failure rate and low maintenance costs.

11. FAQs About Heavy Duty Conveyor Belts

Below are the most practical and engineering-driven questions buyers ask when selecting a heavy duty conveyor belt.

Each answer is based on measurable standards, not assumptions.

11.1 What safety factor should I use for a steel cord heavy duty conveyor belt?

Most modern systems use a 5.0–5.5 safety factor, provided that:

- The conveyor uses VFD soft start

- Load, speed, misalignment, and anti-tear sensors are installed

- The transition and troughing geometry are correctly designed

If the system has no soft start or limited monitoring:

- Use 5–6.0

These values align with modern splice efficiency (45–55% under DIN 22110-3) and lower dynamic tension peaks.

11.2 Can I safely reduce the safety factor of EP belts from 10 to 7–8?

Yes—if two conditions are met:

- Soft startreduces the startup peak from 2.5–3.0× to 1.2–1.5×

- The system has controlled loading and moderate impact energy

Modern EP safety factor ranges:

- 7–8for systems with soft start

- 8–9for traditional DOL systems

11.3 Under ASTM and RMA standards, what tension level defines a heavy duty conveyor belt?

According to ASTM D378 / RMA, the threshold is:

- ≥ 160 PIW

Converted to international N/mm:

- 160 PIW ≈ 28 N/mm working tension

If your system exceeds 28 N/mm, it falls into the heavy duty conveyor belt category.

11.4 How do I choose between EP and ST construction?

Use tension and distance as the primary criteria.

Choose EP when:

- Conveyor length ≤ 300 m

- Working tension ≤ 125 N/mm

- Impact energy < 900 J

- Speed ≤ 3.5 m/s

Choose ST when:

- Conveyor length > 300 m

- Working tension ≥ 167 N/mm

- Impact energy ≥ 1200 J(iron ore, hard rock)

- Speed ≥ 4.0 m/s

This rule is widely used in mines, ports, and processing plants.

11.5 How do I verify splice quality for a heavy duty conveyor belt?

Check these three engineering indicators:

1. Splice Efficiency (DIN 22110-3)

- EP: ≥ 35–40%

- ST: ≥ 45–55%

2. Adhesion Strength (GB/T 6759)

- ≥ 10–12 N/mm

3. Visual and structural inspection

- No step waves or blisters

- Uniform rubber thickness

- Correct cord alignment (for ST)

If any of these fail, the entire system is at risk.