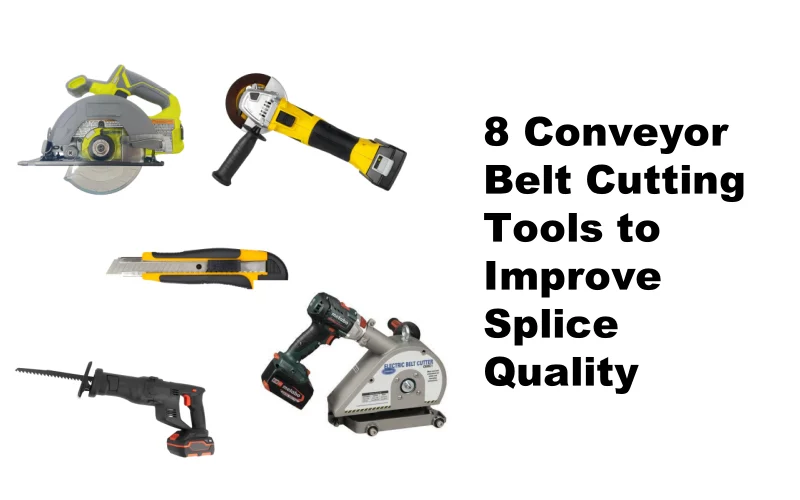

Cutting a conveyor belt looks simple, but the reality is different. The right conveyor belt cutting tools decide whether your splice is strong, safe, and reliable. OSHA reports show that poor preparation and bad cuts often lead to accidents and costly downtime. In this guide, I’ll show you the essential tools for PVC, PU, rubber, and steel cord belts, explain their pros and cons, and match them to real-world use. By the end, you’ll know exactly which tool keeps your belts efficient, safe, and long-lasting.

1.What are Conveyor Belt Cutting Tools

When it comes to conveyor belt splicing or maintenance, the key factor is not the splice material itself, but the conveyor belt cutting tools used before the splice. Each type of belt demands a different tool. That is the real decision point.

PVC and PU belts are thin, flexible, and widely used in food, packaging, and logistics. They need tools such as hot knives or rail-guided cutters to deliver smooth edges without fraying. And there’s more—these tools cut faster, more efficiently, and at lower cost compared to improvised solutions. That’s why they are the smart choice for light-duty belts.

Rubber conveyor belts, on the other hand, can reach more than 50 mm in thickness. Cutting them with ordinary knives is impossible—you need a rubber conveyor belt cutter or a rail-guided cutting machine to keep cuts straight and splices reliable. Steel cord belts are even more demanding. With embedded wires, they require hydraulic or abrasive tools for safe and precise cutting.

This guide is not about teaching you how to cut a belt. Instead, it’s about matching the right cutter to the right belt. The wrong tool means poor splice quality, shorter belt life, and higher safety risks. The right belt cutter machine guarantees clean cuts, saves labor time, and directly reduces downtime costs.

To put it simply:

- PVC/PU belts → hot knife or guided cutter (fast, clean, cost-effective).

- Rubber belts → rail-guided cutter or rotary machine.

- Steel cord belts → hydraulic or water jet cutter.

Conveyor belt cutting tools are not optional extras—they are the backbone of splice quality, efficiency, and cost control.

2.PVC/PU Conveyor Belt Cutting Tools

Light-duty PVC and PU conveyor belts are flexible, thin, and common in industries like food, packaging, and logistics. Most are 1–8 mm thick. Cutting them sounds easy, but the right conveyor belt cutting tools make the difference between a clean splice and a costly failure. Let’s look at the main options.

2.1 Hot Knife

- Pros:Creates a sealed edge, no fraying, hygienic for food belts. Cuts faster than manual blades and reduces labor cost.

- Cons:Needs electricity, warm-up time, and frequent blade replacement.

- Use Case:Best in food-grade or clean environments where edge quality matters. Not practical for outdoor repairs or situations without power.

2.2 Rail-Guided Belt Cutter Machine

- Pros:Ensures perfectly straight cuts, improves splice strength, and saves time in repetitive cutting.

- Cons:Higher investment, heavier to move, not necessary for small fixes.

- Use Case:Ideal in workshops or production lines needing consistent precision. Not suitable if you only do occasional or emergency maintenance.

2.3 Utility Knife / Rotary Cutter

- Pros:Cheap, portable, and always available. Perfect for quick fixes.

- Cons:Hard to cut straight, edges can weaken splices, requires more effort.

- Use Case:Works for emergency or very short repairs where portability matters. Not recommended for long cuts or high-quality splicing.

2.4 Choosing the Right Tool for PVC/PU Belts

If the belt is going into a food or hygiene-sensitive line, the hot knife is the right call. If you run a production floor where accuracy and repeatability matter, the rail-guided cutter machine is worth the investment. If you’re in the field and need fast emergency fixes, the belt cutting knife is your backup.

each tool has its place. Picking the right conveyor belt cutting tools for PVC and PU belts comes down to environment, precision needs, and budget.

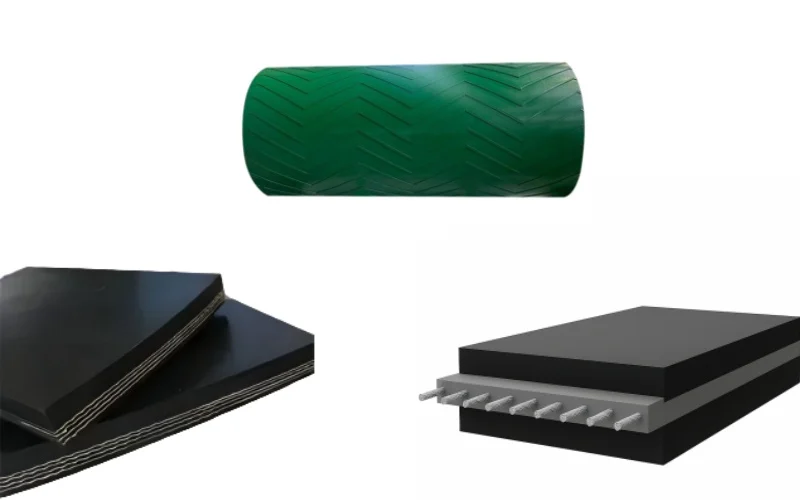

3.Rubber Conveyor Belt Cutting Tools

Rubber conveyor belts (EP/NN) are common in mining, ports, cement plants, and heavy industry. Their overall thickness usually ranges from 6 mm to 40 mm. Thinner belts around 10 mm serve lighter tasks, while thicker belts handle heavy-duty loads. Cutting them is demanding, and only the right conveyor belt cutting tools can guarantee efficiency and safety.

3.1 Rail-Guided Electric Cutter

- Pros: Provides perfectly straight cuts even on thick belts. Improves splice quality, reduces joint failures, and saves time compared to manual cutting.

- Cons: High upfront cost, requires power, and less portable.

- Use Case: Recommended in service workshops or production sites where belts are cut frequently. Not ideal for quick field repairs.

3.2 Portable Rotary Cutter

- Pros: Lightweight, mobile, and able to cut belts up to 30–40 mm thick. A practical rubber conveyor belt cutter for on-site maintenance.

- Cons: Accuracy depends on operator skill. Blades wear quickly on reinforced or highly abrasive covers.

- Use Case: Best for field maintenance and emergency work where speed matters most. Not recommended if maximum splice life is the priority.

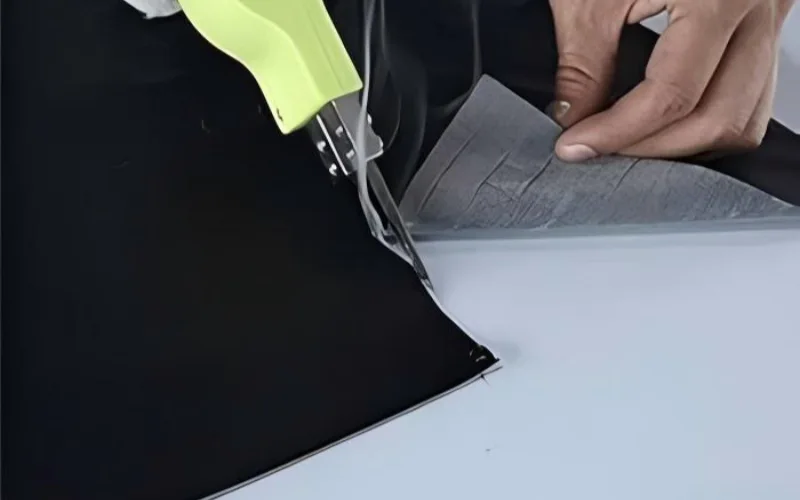

3.3 Utility Knife (for Splice Preparation)

- Pros: Inexpensive, easy to handle, and highly effective for layer-by-layer cutting. Technicians rely on a belt cutting knife to strip off top covers or fabric plies when preparing a joint for hot vulcanizing or cold splicing.

- Cons: Not designed to cut through the full belt thickness. Slow and unsafe if forced as the main cutting tool.

- Use Case: Essential for joint preparation and fine cutting of layers. Not suitable as the primary conveyor belt cutter tool for thick rubber belts.

3.4 Choosing the Right Tool for Rubber Belts

For belts around 6–10 mm, a rail-guided belt cutter machine ensures speed and accuracy.

For belts up to 40 mm, the rail-guided cutter remains the most reliable, while a portable rotary cutter offers the flexibility needed in the field.

For joint preparation, the utility knife is indispensable, but it should never replace machines for full-width cuts.

In short, the best conveyor belt cutting tools for rubber belts are a combination: rail-guided machines for precision, rotary cutters for mobility, and utility knives for layer-by-layer splice preparation.

4.Steel Cord Conveyor Belt Cutting Tools

Steel cord conveyor belts are built for the toughest jobs: long-distance transport in mines, steel plants, and ports. Their carcass contains embedded steel cords, which give extreme tensile strength but also make cutting much more difficult than EP or PU belts. Cutting these belts with the wrong conveyor belt cutting tools not only wastes time but also shortens splice life dramatically.

4.1 Hydraulic Belt Cutter

- Pros:High cutting force with minimal operator effort. Can cut through thick rubber and steel cords safely. Provides a relatively clean cut, reducing splice preparation time. Much safer than abrasive cutting methods since sparks are avoided.

- Cons:Requires a hydraulic pump, which makes the system less portable. Slower than abrasive methods for very wide belts.

- Use Case:Best for service shops and controlled environments where safety and clean cuts are critical. Not always practical for quick field jobs due to setup time and equipment size.

4.2 Water Jet Cutter

- Pros:Delivers the cleanest and most precise cut of all tools. No sparks, no fraying, and no cord distortion. The smooth edge significantly increases splice quality and belt life. Works even on very wide and thick steel cord belts.

- Cons:Very high cost. Requires specialized equipment, skilled operators, and stable water supply. Not portable.

- Use Case:Ideal for high-value applications such as steel plants or large mines where belts are extremely expensive and downtime costs are critical. Not feasible for small or mobile operations.

4.3 Abrasive Wheel Cutter

- Pros:Widely available and relatively cheap. Can cut through steel cords quickly. Portable versions exist for field jobs.

- Cons:Produces sparks and heat, raising fire hazards in certain environments. Cuts are less precise, often leaving rough edges that require additional grinding. Operator skill affects safety and results.

- Use Case:Common in industrial sites for quick and effective cutting. Not recommended in explosive or flammable environments. Also not ideal if splice longevity is the top priority.

4.4 Utility Tools for Layer Stripping

Even with machines, you still need belt cutting knives for preparation. Utility knives are used to strip the top rubber cover and expose the steel cords before vulcanization. They are not for cutting through the entire belt, but they remain essential for splice work.

4.5 Choosing the Right Tool for Steel Cord Belts

- If the focus is splice quality and belt longevity, the water jet cutteris unmatched.

- For a balance of safety and practicality, the hydraulic belt cutteris often the first choice.

- When the job requires speed and portability, the abrasive wheel cutteris the tool most operators turn to, even though it needs extra finishing.

- And for splice preparation, a belt cutting kniferemains indispensable.

Selecting conveyor belt cutting tools for steel cord belts is about trade-offs: precision versus cost, safety versus speed. The tool you choose defines not just the cut, but the future performance of the splice.

5.Conveyor Belt Cutting Tools Comparison

Belt Type | Typical Thickness | Common Tools | Application Scenarios |

PVC/PU Belts | 1–8 mm (up to 10 mm) | Hot knife, rail-guided cutter, utility knife | Food, packaging, logistics, electronics |

Rubber Belts (EP/NN) | 6–40 mm | Rail-guided cutter, portable rotary cutter, utility knife (for splice preparation) | Mining, ports, cement, construction |

Steel Cord Belts (ST) | 6–40 mm+ | Hydraulic cutter, water jet cutter, abrasive wheel cutter, utility knife (layering) | Steel plants, heavy mining, long-distance lines |

5.1 What This Table Tells You

- PVC/PU belts: Tools like hot knivesor rail-guided machines matter most for edge quality and hygiene.

- Rubber belts: Precision and portability are the key trade-offs; rail-guided machinesfor accuracy, rotary cutters for field work.

- Steel cord belts: Cutting tools must handle embedded wires safely; hydraulic and water jet cuttersensure reliable splicing, while abrasive wheels give speed in the field.

This comparison shows one thing clearly: no single tool works for every belt. The right conveyor belt cutting tools depend on belt type, thickness, and working environment.

6.Safety and Operating Guidelines for Conveyor Belt Cutting Tools

Cutting a conveyor belt is not just about speed and precision. It’s also about safety. The tools used—whether a belt cutter machine, rubber conveyor belt cutter, or abrasive wheel cutter—all carry risks if handled carelessly. A clean splice means nothing if the operator gets injured.

6.1 Check Tools Before Use

Always inspect the tool before cutting. Look for dull blades, damaged rails, or hydraulic leaks. A worn blade doesn’t just cut slower—it increases the chance of accidents. For flexco belt cutter systems, make sure guide rails are aligned and the blade locks properly.

6.2 Personal Protective Equipment (PPE)

Never cut without proper protection. Safety glasses protect against sparks and debris. Cut-resistant gloves prevent hand injuries, especially when handling utility knives for splice preparation. In noisy environments, use hearing protection when operating an abrasive wheel cutter.

6.3 Cutting Technique

- Keep cuts straight. A crooked cut shortens splice life and increases the chance of belt failure.

- Apply steady pressure—don’t force the tool. For conveyor belt cutting knives, make shallow passes layer by layer.

- With rotary or abrasive cutters, let the tool’s speed do the work instead of pressing hard.

6.4 Work Environment

Choose the right place for the cut. Avoid cutting near flammable materials when using an abrasive wheel. Ensure adequate lighting and stable surfaces. For hydraulic or water jet cutters, confirm that hoses and pumps are secure before starting.

6.5 Professional Handling for Steel Cord Belts

Steel cord belts demand extra caution. Cutting steel wires creates sharp ends that can injure hands or tear gloves. Use specialized steel cord belt cutters or let trained professionals handle the task. Improper cutting risks both safety and splice integrity.

6.6 Safe Cutting Means Reliable Belts

Safety is not an extra step—it’s part of the job. A splice cut with a dull blade or rushed with no protection will fail faster and put people at risk. By combining the right conveyor belt cutting tools with proper checks, protective gear, and steady technique, you not only extend the life of the splice but also keep every worker safe on site.

7.Matching Tools to Belts

Every belt tells its own story, and the same is true for the tools that cut them. PVC and PU belts may look easy to handle, but only a hot knife or rail-guided cutter keeps the edges smooth and the process efficient. Rubber belts, with their 6–40 mm thickness, demand stronger solutions. A rail-guided belt cutter machine gives precision, while a portable rotary cutter brings flexibility in the field. The utility knife has its place too—not for full cuts, but for carefully stripping layers before splicing.

When it comes to steel cord belts, the challenge rises. Hydraulic cutters provide safety, water jet systems give unmatched precision, and abrasive wheel cutters deliver speed. Each one answers a different need, from controlled shop work to urgent field repairs. And again, the simple utility knife remains essential for layer preparation.

What ties all of this together is one fact: the quality of the splice always starts with the quality of the cut. Choosing the right conveyor belt cutting tools is not just about finishing the job—it’s about extending belt life, reducing downtime, and protecting the people who work with these systems every day.

The tool you bring to the job shapes the belt’s future. Make the choice that keeps it strong, straight, and safe.