If your conveyor belt keeps drifting off-center, you already know the pain—spillage, downtime, and rising costs. But conveyor belt tracking isn’t luck; it’s skill. Studies from the Conveyor Equipment Manufacturers Association show that correct tracking can cut maintenance time by 30 percent. In this guide, I’ll show you how to spot the causes, fix them fast, and keep your line running smooth day after day.

I have compiled a very comprehensive table for your reference, including classification, scenario/problem, action/step, applicable conditions, expected results, etc. (Since there are many types of conveyor belt deviation, and even special cases, this table only applies to general cases)

| Category | Scenario / Problem | Action / Procedure | Location / Conditions | Expected Impact | Notes / Source |

| Fundamentals & Preconditions | Structure out of square; poor base geometry | Verify conveyor frame alignment and structural rigidity against the conveyor centerline using laser/precision straightedge | Entire conveyor | Baseline stability for belt tracking; all later adjustments become effective | Always measure geometry before touching adjustments |

| Pulley not square to centerline | Square head, tail, and bend pulleys to exactly 90° relative to the conveyor centerline | Head/Tail/Bend pulleys | Removes system‑wide run‑off bias | Check against belt centerline; re‑verify after splice work | |

| Contaminated contact surfaces; build‑up | Clean lagging, idlers, chutes; remove carryback and debris | All zones | Eliminates false friction that steers belt | Clean first, then align | |

| Unequal tension across belt width | Equalize take‑up travel and left/right belt tension; verify smooth travel of the tensioning device | Take‑up zone / return path | Belt no longer drifts to low‑tension side | Golden rule: the belt tracks toward the low‑tension side | |

| Diagnosis | Local vs. continuous run‑off unknown | Use chalk line on belt edge; observe multiple revolutions to classify as local (sectional) or continuous (global) misalignment | Any section | Rapidly isolates the problem domain | Diagnose first; adjust later |

| Off‑center loading at feed point | Re‑center chute/feeder so material lands centrally; ensure impact bed and skirt rubber do not bias one side | Load zone | Removes root cause behind majority of tracking issues | Loading symmetry has highest priority | |

| Belt is the cause (new belt, splice, stiffness) | Allow initial run‑in for new belt; verify splice squareness; consider lateral stiffness effects | Entire conveyor | Reduces periodic side pull and wandering | Initial wandering during break‑in is normal | |

| Energy & Economics | Elevated power consumption | Restore correct tracking to reduce idler friction and edge drag | Entire conveyor | Typical 10–15% power reduction when properly tracked | As cited from energy efficiency guidance |

| Concepts | Terminology confusion | Tracking = the centered running condition; Training = the adjustments you perform to achieve tracking | All teams | Common language improves troubleshooting | Use precise terminology in SOPs |

| Core Rules | Rule 1: Belt drifts to low‑tension side | Balance belt tension; check take‑up and return path for equalization | Entire conveyor | Fast correction of persistent drift | Apply in small increments and observe |

| Rule 2: More wrap/contact yields more control | Increase wrap angle with snub/hold‑down pulleys or belt trainers to raise frictional control | Drive and bend zones | Stabilizes tracking by improving guidance | Use only as needed; excess wrap raises heat and wear | |

| Rule 3: First contact point defines path | Start corrections at the head pulley and the first sets of troughing idlers | Head section | Downstream idlers naturally follow corrected lead | Avoid chasing the middle without fixing the front | |

| Rule 4: Adjust small, observe long | Shift components in 5–10 mm increments; observe several belt revolutions before next change | All zones | Prevents over‑correction and oscillation | Finalize under normal load conditions | |

| Rule 5: Balance rather than force | Aim for straight geometry, square pulleys, and freely rotating idlers | Entire conveyor | System tracks naturally with minimal intervention | Design for self‑centering behavior | |

| Structural Measures | Self‑centering by pulley geometry insufficient | Use crowned pulleys (double‑crown for reversible belts) sized to belt width | Head/Tail pulleys | Self‑correcting tension distribution; reduced edge wear (≈40%) | Avoid excessive crown height; precision machining recommended |

| Lateral forces or sidewinds present | Install V‑guide (guiding profile) and matching groove; set groove width to loading severity | Selected runs | Limits lateral drift; improves repeatability | Do not design for continuous hard side contact | |

| Variable loads/long runs need constant correction | Deploy automatic tracking systems: optical, pneumatic, or mechanical edge‑sensing trainers | Long conveyors / harsh or changing conditions | Real‑time correction; reduced downtime | Complements, not replaces, correct base geometry | |

| Return strand unstable; flat idlers give little steering | Use V‑return idlers (10–20° trough); add self‑aligning return rollers; slightly raise/advance last return idler before tail pulley | Return side | Stabilizes return path; pre‑centers belt at tail | Avoid aggressive angles that induce carcass stress | |

| Insufficient control in high‑tension zones | Elevate idlers in tension zones to increase contact angle and steering authority | Concave curves, transitions near head/tail | Improves tracking while minimizing slip | Do not place self‑aligning idlers on convex curves | |

| Training Procedures | Classic field correction required | ‘Knocking idlers’ method: if belt runs to one side, move that side of the idler frame slightly forward in the belt travel direction (5–10 mm) | Carrying strand / return strand | Gentle steering distributed over multiple idler sets | Adjust one frame at a time; reset to neutral if over‑done |

| Mild, unidirectional drift | Forward‑tilt idlers by raising rear foot of the idler stand by 1–2° | Short, single‑direction conveyors | Natural centering effect via pressure bias | Not for reversible conveyors (effect reverses) | |

| Persistent drift; need automatic self‑correction | Install self‑aligning idlers (unidirectional or reversible) placed ~5–10 m before head pulley and on return near tail | Carrying and return strands | Reduces lateral wander; extends belt life | Never install on convex curves; verify free pivoting | |

| Return side amplifies small errors | Combine V‑return idlers with self‑aligning return rollers; micro‑raise/move the last return idler pre‑tail | Return side | Suppresses slow drift and improves start‑up centering | Coordinate with tail pulley alignment | |

| Need finer control via vertical geometry | Adjust idler elevation in tension zones to increase wrap/contact where beneficial | Concave/transition zones | 12–18% better alignment efficiency; reduced power loss (~10%) | Avoid convex segments to prevent ply stress | |

| Adjustments done empty are unreliable | Perform final tracking under normal operating load; let several full cycles run before sign‑off | Entire conveyor | Cuts post‑adjustment drift by ≈50% | Empty‑belt behavior differs from loaded | |

| Auxiliary Devices | Edge damage risk during drift events | Set side guide rollers as protection only with 50–100 mm clearance from belt edge | Load points, head section | Prevents belt climbing the frame; protects edges | Avoid continuous contact to prevent edge burning |

| Low traction at drive; slippage; unstable guidance | Add hold‑down/extra snub pulley to increase wrap by ~20° | Drive zone | Traction gain (~≈18%) and improved tracking authority | Higher wrap increases heat and wear—balance carefully | |

| Dust/moisture reduces roller traction | Use high‑friction lagging (rubber/ceramic/patterned) and self‑cleaning rollers | Dusty/wet sites, return path | Restores grip; stabilizes tracking | Maintain scraper/cleaner efficiency | |

| Special Designs | Short and wide belts tend to wander | Use inclined return idlers for down‑pressure; consider center‑drive; apply narrow groove profiles for lateral constraint | Short/wide conveyors | Suppresses cupping and snake‑like wander | Specify low‑elongation compounds |

| Uneven loading on very wide belt | Split to multiple narrow, parallel belts with independent tensioning | Variable distribution systems | Cumulative tracking deviation reduced (≈35%) | Simplifies maintenance; one belt failure doesn’t stop the system | |

| Hygiene/moisture; need positive tracking | Use modular plastic belts with sprocket engagement (positive drive) | Food‑grade/short/reversing conveyors | Tracking independent of friction/tension | Precision sprocket alignment required | |

| Long run; small structural drift accumulates | Apply small crown on take‑up pulley (≈1–2 mm per 100 mm belt width), verified by laser | Take‑up pulley | Long‑term auto‑centering compensates for frame deflection/thermal growth | Crown height depends on belt width and tension | |

| Inspection & Maintenance | Geometry drifts over time | Quarterly re‑verification of head/tail/bend squareness and splice squareness (laser/straightedge) | Entire conveyor | Prevents chronic slow drift | Re‑check after any pulley/splice change |

| Frame loses rigidity under shock | Inspect cracks, bolts, brackets; reinforce with gussets/heavier cross‑members | Load/discharge zones | Prevents twist‑induced lateral pull | Upgrade to stiffer sections where needed | |

| Idler/bearing roughness drags belt sideways | Spin by hand during shutdown; replace seized/rough/wobbly rollers | All idlers | Cuts parasitic side drag; reduces wear | Listen for bearing noise; stock critical spares | |

| Guides/crowns contacting continuously | Verify side guides have clearance; inspect crowned pulleys for even wear pattern | Guide and crown locations | Ensures guides protect rather than steer | Uneven polish indicates tension imbalance | |

| Carryback and dust cause uneven friction | Maintain primary/secondary scrapers; air knives; clean return path and chutes | Return path / load zone | Stable friction and reduced vibration | Cleanliness precedes alignment | |

| Asymmetric take‑up motion | Confirm synchronized left/right movement; verify hydraulic or gravity response is smooth | Take‑up zone | Prevents single‑side slack and chronic drift | Monitor during live operation | |

| Data & PM | Lack of historical context for drift | Log every alignment, roller change, and tension tweak; add basic vibration/temperature trending | Entire conveyor | Enables predictive maintenance; fewer surprises | Start with disciplined manual logs; scale to sensors later |

| Integrated Best Practices | Over‑reliance on accessories | Fix geometry first; validate squareness before adding trainers | All systems | ≈60% fewer adjustments in operation | Document with as‑built alignment records |

| Large, fast, one‑off adjustments | Adopt ‘small & slow’ policy and load‑based training as standard commissioning practice | All systems | Longer tracking stability; fewer reversals | Record each change and observation for traceability | |

| Cost & Benefit | High maintenance hours & unplanned downtime | Implement full checklist above; prioritize geometry, loading symmetry, and load‑condition training | Entire conveyor | Reduce maintenance time by ~30%; cut downtime | Align with plant KPIs and maintenance windows |

1.Understanding Conveyor Belt Tracking Basics

If you’ve ever worked around a conveyor system, you know this feeling — the moment you see the belt drifting to one side, you can already hear the sound of trouble coming. As someone who’s spent years in the factory, I can tell you this: conveyor belt tracking is the heartbeat of your entire line. Get it right, and everything runs smooth. Get it wrong, and the system starts eating itself alive.

1.1 What Belt Misalignment Really Means

When a belt starts to drift away from its center line, that’s what we call misalignment. You’ll notice signs like edge wear, spillage, or even roller damage. It’s not that your belt is bad — in most cases, it’s the system setup that’s off. Maybe a pulley isn’t square, or the frame’s not rigid enough.

According to Wikipedia, improper tracking ranks among the top three causes of premature conveyor belt failure worldwide. That means you’re not just losing material — you’re losing uptime and money.

So, the first truth is simple: a perfectly aligned conveyor belt is worth more than a new belt that isn’t tracked right.

1.2 Tracking vs. Training – Know the Difference

People often mix these two up. Let’s keep it simple.

- Tracking is the natural state — when your conveyor belt runs smoothly, centered, and stable.

- Training is what you do to make that happen — adjusting rollers, pulleys, or tension zones to guide the belt back.

Think of tracking as the “result” and training as the “effort”. Just like you can’t steer a conveyor belt truck without knowing its load balance, you can’t keep a belt straight without understanding its forces.

1.3 The Golden Rule of Belt Movement

Here’s one rule every technician should memorize:

A conveyor belt always tends to move toward the side of the roller that it touches first.

When one end of the roller meets the belt earlier than the other, that side creates more drag — and the belt naturally follows it.

That means if the belt touches the right side of a roller before the left, it’ll start drifting right. Why? Because that side has more friction and less tension. So, the belt naturally moves that way.

In short, the belt always tracks to the side with lower tension. Once you grasp that, you’ll start reading belt behavior like reading road signs — every shift tells you what’s happening underneath.

1.4 Preconditions for Stable Conveyor Belt Tracking

Before touching a single wrench, check the basics:

- Frame alignment– The structure must be rigid and true.

- Pulley squareness– Each pulley must be exactly 90° to the centerline.

- Clean contact surfaces– No debris, buildup, or worn lagging.

If one of these is wrong, your belt will fight you every step of the way.

That’s why, at Tiantie Industrial Co., Ltd., our steel cord conveyor belts are engineered with uniform steel wire tension and minimal elongation — so even under heavy loads, they naturally hold their alignment. You can see these specs in our official catalog. It’s design intelligence that saves real-world headaches.

1.5 Why It Matters

When your conveyor belt tracking is off, your entire system pays for it. The belt edges wear faster. The idlers and pulleys start misaligning. And your power bill? It climbs.

According to the U.S. Department of Energy , a misaligned conveyor can increase power consumption by 10–15%, depending on load and length. Over a year, that’s not just inefficiency — it’s lost profit.

Good tracking is good economics. It’s that simple.

1.6 Keeping the Belt on Track

Perfect tracking doesn’t come from one big adjustment — it comes from many small, smart corrections. Watch the belt. Learn how it reacts. A clean, aligned setup will always tell you what it needs.

So next time you see your belt drifting, don’t panic. Don’t blame the belt. Look at the system around it. The belt isn’t misbehaving — it’s communicating.

Once you fix the cause, the belt will fall back in line, just like it should.

Now that we’ve covered the foundation of conveyor belt tracking, let’s move on to the next step — learning how to diagnose and correct the real causes behind misalignment before they cost you more than a day’s downtime.

![]()

2.Diagnosing Causes of Conveyor Belt Misalignment

When your conveyor belt tracking starts acting up, it’s not random — it’s trying to tell you something.

Most people rush to adjust the rollers or tighten the belt, but I’ve learned over the years that you should diagnose before you touch anything.

Let’s go step by step, in plain language, just like how I’d walk a new technician through it on-site.

2.1 Local vs. Continuous Belt Run-Off

Not all misalignment is the same. Sometimes it’s just a small drift in one area; other times, it’s the entire system that’s off.

- Local misalignment happens in a specific section — maybe near a loading chute or a transition point. It usually points to a frame or roller issue in that zone.

- Continuous misalignment, on the other hand, means your belt runs off-center from start to finish. That’s a system-wide problem — most likely belt tension, splice angle, or uneven loading.

A quick trick I use? Mark the belt edge with chalk and watch it for a few rotations. If the line shifts only at one spot, it’s local. If it drifts everywhere, you’ve got a global issue.

2.2 Off-Center Loading — The Silent Belt Killer

Here’s a fact few people notice: 80% of tracking problems start at the loading point.

When your material hits the belt unevenly — say, more weight on one side — that imbalance keeps pulling the belt toward the lighter edge.

You can fix that easily:

- Adjust the chute or loading hopper so material lands in the center of the trough.

- Make sure your impact bed or skirt rubber doesn’t push the belt off one side.

Conveyor belt tracking always starts with balanced loading — if your belt eats dust on one side, it’s probably eating profits on the other.

2.3 When the Belt Itself Is the Problem

Sometimes, it’s not the frame, not the pulley, not the load — it’s the belt.

- New belts often wander during the first few hours. That’s normal — the internal tension hasn’t stabilized yet.

- Worn or uneven splices can also cause steady drift. If the joint isn’t perfectly square, it creates a small steering force with every rotation.

- Lateral stiffness matters too. Belts with high rigidity resist correction and take longer to “learn” the center path.

At Tiantie Industrial, our steel cord conveyor belts use a consistent wire pitch and uniform tension distribution. This reduces side pull, keeping the belt straight even in long-distance systems. That’s a design advantage that most generic belts simply don’t have.

2.4 Observation and Pattern Recognition

This part is where real skill comes in.

When I train new engineers, I always tell them — don’t look for what the belt does once; look for what it does every time.

Watch several revolutions of the belt:

- If it drifts steadily in one direction, it’s a structural or installation error.

- If it swings randomly, your problem is more likely uneven loading or inconsistent tension.

- If it jumps or vibrates, check for dirt buildup, stiff splices, or damaged rollers.

Take short videos or photos — it helps spot subtle trends your eyes might miss.

And remember: belts don’t lie; they repeat. If it happens once, it’ll happen again until you fix the cause.

2.5 Environmental and Operational Factors

Sometimes, you’ve done everything right, yet the belt still misbehaves.

That’s when I tell clients to look at the environmental conditions:

- Temperature changescan make the belt expand or contract unevenly.

- Humiditycan affect rubber elasticity, especially in textile or multi-ply belts.

- Dust buildupcreates drag and alters roller friction.

According to research by the European Conveyor Belt Association (ECBA), temperature variation above ±15°C can increase belt wandering by up to 20% in long systems. That’s why seasonal maintenance checks aren’t just “nice to have” — they’re essential.

2.6 Real-World Diagnostic Routine

When I visit a site, here’s how I usually diagnose misalignment step by step:

- Inspect the frame– make sure both sides are level and parallel.

- Check pulley alignment– especially head, tail, and snub pulleys.

- Examine the splice– confirm it’s square and centered.

- Watch the load point– look for off-center or bouncing material.

- Check idlers– any seized or uneven rollers?

- Observe under load– empty and loaded belts track differently.

By following this checklist, you’ll often spot the root cause before even loosening a single bolt.

2.7 Moving Toward Smarter Conveyor Belt Tracking

Good tracking starts with good diagnosis.

Every conveyor system has its own “personality”, and once you learn how to read the signs — belt edges, tension lines, loading angles — you can fix issues faster and with less guesswork.

So next time you notice your conveyor belt truck carrying material unevenly, pause before adjusting anything. Observe, think, and act with precision.

Now that you know how to identify the real causes behind misalignment, the next step is where the fun begins — learning the core rules that drive belt correction and training techniques.

3.Basic Rules of Conveyor Belt Tracking

If you’ve ever fought with a drifting belt, you already know the frustration. One small tilt, and the whole line goes sideways — literally. The good news? Most conveyor belt tracking problems follow three clear rules. Once you know them, you can stop reacting and start controlling. Let’s break it down like we’re in the workshop, not in a textbook.

Rule 1: The Belt Drifts to the Side with Less Tension

This is the number-one rule of conveyor belt tracking.

Your belt always drifts toward the side that has less tension. Think of it like driving a conveyor belt truck with uneven tire pressure — the truck pulls toward the soft side.

In your conveyor, it’s the same. If the take-up isn’t balanced, the belt creeps toward the weaker edge. The cure is simple but critical: equalize the tension.

Check both sides of the take-up pulley. Look at the return path. Adjust gradually until the belt runs straight.

At Tiantie Industrial, our steel cord conveyor belts are built with uniform steel wire pitch and consistent tension, reducing side pull even under high loads. That means smoother, longer-lasting conveyor belt tracking with fewer manual adjustments.

Rule 2: More Contact Means More Control

Friction is your friend. The more surface your belt touches, the better it tracks.

When you increase the wrap angle — the amount of belt that contacts a pulley — you increase friction, which gives you better guidance.

That’s why snub pulleys and training idlers exist: they add wrap and help redirect the belt naturally.

According to The Engineering Toolbox , raising the wrap angle from 180° to 210° can increase frictional efficiency by roughly 15%. That small gain can stabilize most belts before they cause downtime.

But remember, more isn’t always better. Too much contact builds heat and wears the rubber faster. The trick is to use just enough friction to make conveyor belt tracking stable — not sluggish.

Rule 3: The First Roller Controls the Path

Every conveyor has a “leader” — the first roller the belt meets.

If that roller is crooked, the belt will follow that angle all the way down the line.

That’s why it’s smart to start all corrections at the head pulley or the first contact point.

Once the belt meets a properly aligned roller, the rest usually falls in place. Adjusting the middle of the system without fixing the front is like steering a conveyor belt truck from the trailer instead of the cab. It doesn’t work.

A quick check: put a straight edge across your head pulley. If it’s not perfectly square to the center-line, your belt will never track correctly — no matter what you tweak later.

Rule 4 : Adjust in Small Steps and Observe

One of the biggest mistakes I see in conveyor belt tracking is over-adjustment.

Someone sees a drift, swings the roller too far, and makes the problem worse.

Instead, make small moves. Watch several belt revolutions. Then decide.

Belt tracking is like tuning a guitar — gentle turns, not hard twists.

If your system runs both ways, adjust evenly on both sides. Over-correction on one end just creates chaos on the return.

By the way, always test under loaded conditions. Empty belts behave differently.

According to CEMA (Conveyor Equipment Manufacturers Association ), tracking adjustments under load reduce misalignment by up to 60% compared to empty tests. That’s a big improvement for something that takes just a few minutes of patience.

Rule 5: Balance, Don’t Force

A well-designed conveyor doesn’t need constant correction. It should track naturally.

Good conveyor belt tracking happens when your frame is straight, pulleys are square, and idlers rotate freely.

That’s how Tiantie Industrial’s systems are engineered — stable frames, precision pulleys, and high-quality rubber compounds that maintain shape under tension.

Even in heavy-duty environments, like mining or bulk loading for conveyor belt trucks, a balanced system tracks itself.

When you understand these rules, you stop fighting your conveyor. You start guiding it.

Next Step: Turning Rules into Structure

These rules are the foundation.

Next, we’ll take them into the real world — through crowned pulleys, guiding profiles, and automatic systems that make conveyor belt tracking nearly self-correcting.

Once you see how design meets physics, the entire system starts to make sense — and stay in line.

4.Structural Measures for Conveyor Belt Tracking

When it comes to conveyor belt tracking, structure matters more than quick fixes.

A belt that runs true depends on smart design — not luck or daily adjustments.

If your system is built wrong, no training roller or sensor will save it.

Let’s look at the most reliable structural methods that keep your conveyor belt tracking straight, smooth, and stable — even under conveyor belt truck loads.

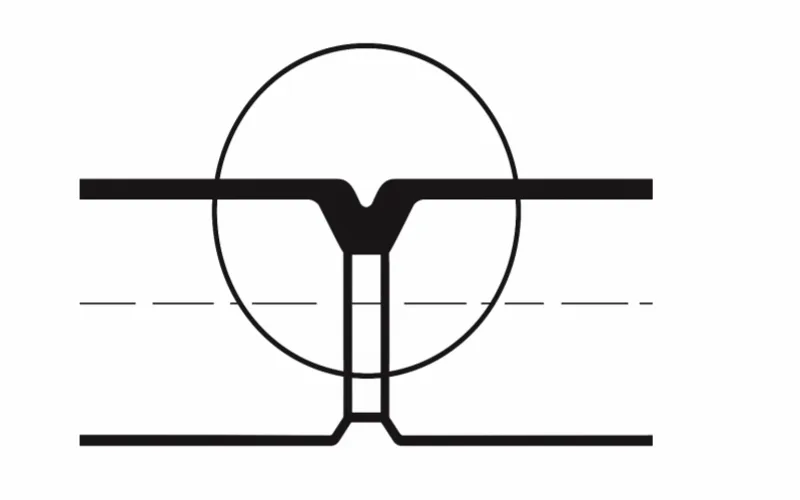

4.1 Crowned Pulleys for Conveyor Belt Tracking — Self-Correcting by Design

A crowned pulley has a slightly raised center.

That shape helps the belt stay in line because tension naturally centers itself.

Used on head or tail pulleys, it keeps conveyor belt tracking stable without sensors or electronics.

But design matters:

- For reversible belts, use a double-crown

- The crown heightshould match the belt width.

- Avoid extreme crowns — too much pressure causes internal stress.

At Tiantie Industrial, our precision-machined crowned pulleys (±0.2 mm) deliver consistent tension balance.

According to Continental Conveyor Handbook, a properly crowned pulley can reduce edge wear by up to 40% — a major win for long-term conveyor belt tracking.

4.2 Guiding Profiles and V-Guides for Conveyor Belt Tracking

Think of V-guides like the lane markers on a road.

They keep your belt from drifting when side forces appear.

Each V-guide fits into a groove, limiting sideways motion and improving conveyor belt tracking consistency.

Design tips:

- No side force? Keep grooves 8–10 mm wider than the guide.

- Heavy side load? Narrow it to 4 mm for tighter control.

- Don’t use full-length guides — they create friction and waste energy.

Tiantie’s laser alignment process ensures each V-guide sits perfectly centered.

That precision means your conveyor belt tracking holds steady — even under dusty, uneven loading.

4.3 Automatic Tracking Systems for Smarter Conveyor Belt Tracking

Modern plants rely on automation.

If your conveyor runs hot, dusty, or under changing loads, an automatic tracking system keeps everything in line.

Sensors monitor the belt edge and adjust guide pulleys in real time.

Three main types exist:

- Optical systems– detect edge position with light beams.

- Pneumatic systems– use air pressure feedback.

- Mechanical systems– rely on rollers or paddles that touch the belt edge.

Tiantie’s intelligent belt controller combines pneumatic and mechanical feedback, perfect for cement, steel, and conveyor belt truck loading systems.

According to the International Society of Automation (ISA), automated tracking reduces downtime by up to 25% versus manual adjustments (isa.org ).

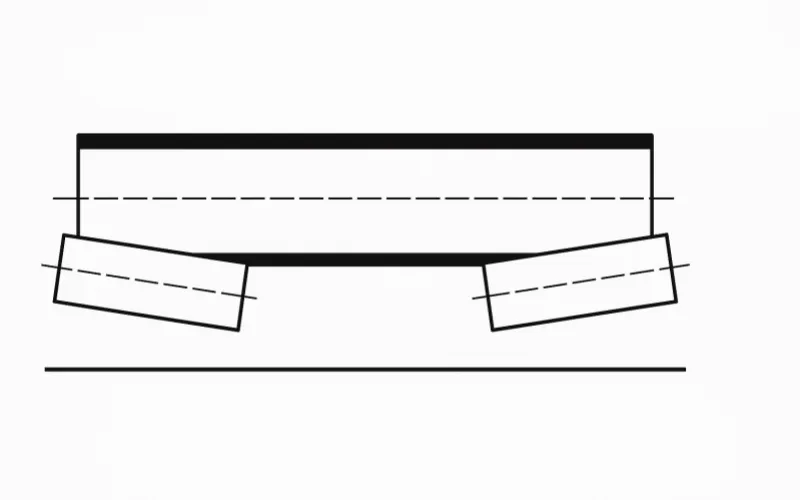

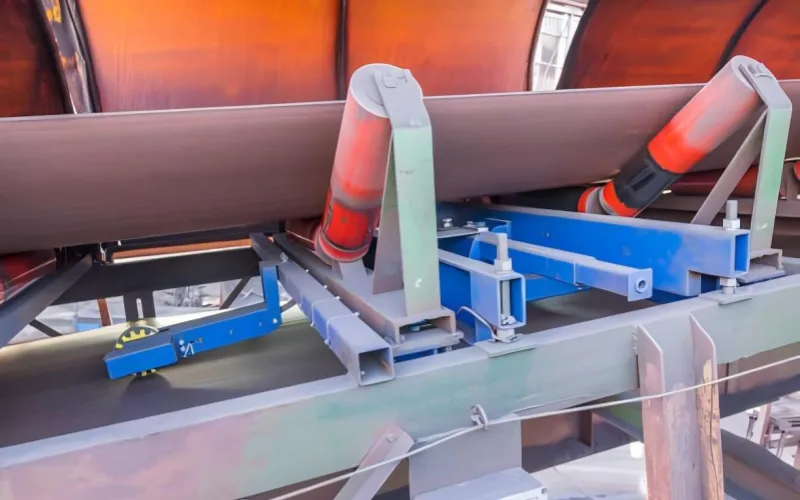

4.4 Return Idler Modifications to Enhance Conveyor Belt Tracking

The return side deserves more attention.

Flat idlers have little steering power.

Instead, use geometry to your advantage:

- Add V-return idlers (10°–20° trough) to stabilize the belt.

- Use self-aligning return rollers to correct minor drift automatically.

- Raise the last roller near the tail pulley slightly to center the belt.

Tiantie’s return idlers use sealed bearings and hot-dipped steel to handle abrasive, dusty environments — keeping conveyor belt tracking solid during conveyor belt truck loading cycles.

4.5 Tension Zone and Elevated Idler Design for Conveyor Belt Tracking

Raising idlers in high-tension areas improves belt grip and reduces side slip.

It’s a small adjustment, but it dramatically improves conveyor belt tracking.

Avoid placing self-aligning idlers on convex curves — they bend the carcass and can cause ply separation.

Use them in flat or concave sections where tension distribution is even.

For long, high-speed belts — especially those feeding conveyor belt trucks — proper elevation helps balance side forces and saves energy.

4.6 The Preventive Philosophy Behind Conveyor Belt Tracking

The best tracking system is one that doesn’t need correction.

Rigid frames, square pulleys, precision crowns, and clean idlers make conveyor belt tracking almost automatic.

That’s why Tiantie Industrial builds structure before sensors.

As we like to say on the shop floor: “The more perfect the geometry, the less you have to adjust”.

4.7 From Design to Action

Get the structure right, and your conveyor belt tracking will take care of itself.

Crowned pulleys, V-guides, smart sensors, and balanced tension — that’s the formula for peace of mind.

Before moving to field adjustments, check your foundation first.

Next, we’ll look at how to train the belt using idlers and on-site methods, bringing these principles to life in real conveyor systems.

5.Idler-Based Training Procedures for Conveyor Belt Tracking

No matter how perfect your design looks on paper, real conveyor belt tracking is won or lost on the site floor.

That’s where rollers, idlers, and small geometry tweaks make all the difference.

Let’s go through the practical methods I use in the factory to train a belt until it runs as straight as a conveyor belt truck on a new road.

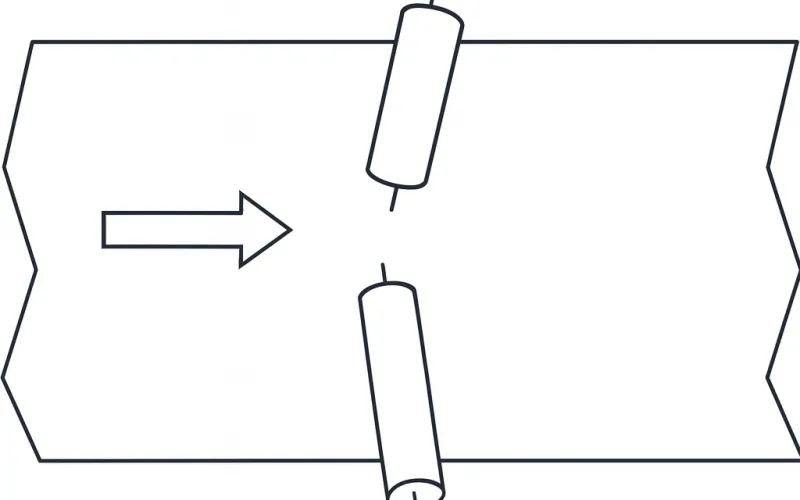

5.1 Knocking Idlers Method for Conveyor Belt Tracking

This is the oldest trick in the book — and still one of the best when done right.

When your belt drifts to one side, move the idler frame on that same side slightly forward in the belt’s running direction.

This creates a gentle steering force that guides the belt back to the center.

Tips for success:

- Adjust only one idler group at a time.

- Move gradually — 5 to 10 mmis usually enough.

- Observe for several revolutions before making more changes.

- Spread adjustments across multiple frames to avoid “over-“

Never hammer idlers backward to fix a previous mistake — reset them to neutral, then fine-tune again.

It’s like adjusting the steering wheel of a conveyor belt truck — one small nudge at a time.

5.2 Forward-Tilted Idlers for Conveyor Belt Tracking

Another subtle but powerful tool is the forward tilt method.

By raising the rear leg of an idler frame, you tilt the rollers forward by 1°–2°.

That tilt increases the belt’s contact pressure on the forward roller, creating a natural centering effect.

This method works great for:

- Light or erratic misalignment.

- Short conveyors with variable loads.

- Systems that run one direction only.

But don’t use it for reversible conveyors — the tilt effect reverses and causes drift.

At Tiantie Industrial, our adjustable idler bases include built-in tilt calibration markers, helping technicians align precisely and maintain stable conveyor belt tracking under both empty and loaded conditions.

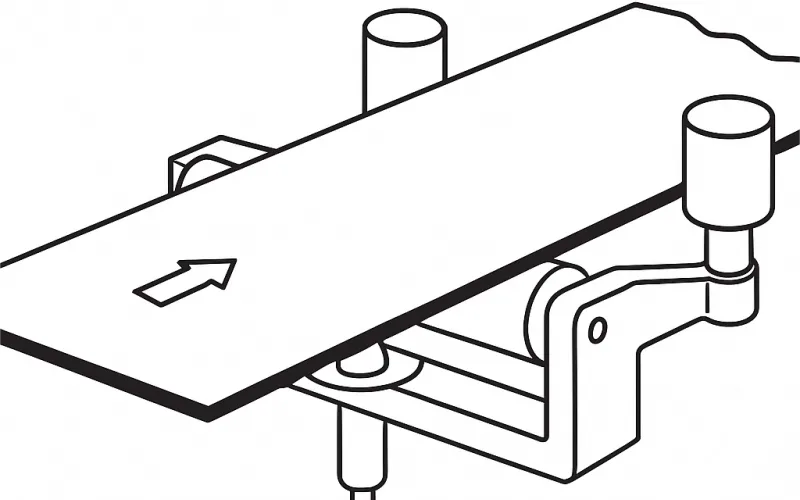

5.3 Self-Aligning Idlers for Automatic Conveyor Belt Tracking

When your system needs constant correction, use self-aligning idlers.

These idlers pivot around a central pin so that when the belt touches one side, the roller frame automatically turns to counter the drift.

Two main types exist:

- Unidirectional – for single-direction conveyors.

- Reversible – for systems running both ways.

Installation tips:

- Never place self-aligning idlers on convex curves; tension variation may damage the carcass.

- The best spots are 5–10 meters before the head pulley or in the return path near the tail pulley.

According to CEMA Technical Report, using self-aligning idlers correctly can reduce lateral belt wander by up to 70%, extending belt life significantly.

Tiantie’s self-aligning idlers use precision-sealed pivot bearings to ensure smooth motion even in dusty or humid environments — ideal for heavy conveyor belt truck loading applications.

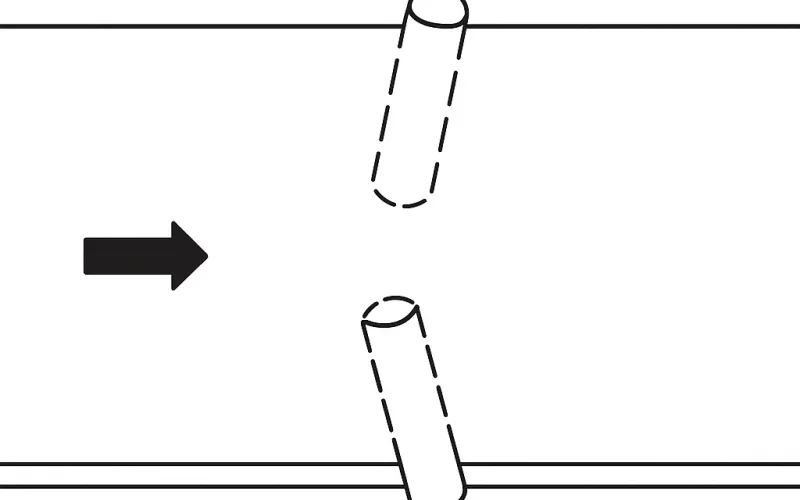

5.4 Return Idlers for Conveyor Belt Tracking Stability

The return side often hides small misalignment problems that slowly grow worse.

Flat return idlers have almost no guiding power, so adding geometry helps.

Pro-level tips:

- Use V-return idlers with 10°–20° trough angles to stabilize the belt.

- Combine them with self-aligning return rollers to counter slow drift.

- Slightly lift or move the last return idler (before the tail pulley) forward and upward to enhance centering.

At Tiantie Industrial, our V-return systems feature hot-galvanized frames and heavy-duty bearings. They’re built for high-impact environments — especially when belts unload directly to conveyor belt trucks.

Good conveyor belt tracking doesn’t end at the top side — it starts again at the bottom.

5.5 Elevated Idlers and Tension Zone Optimization

You can fine-tune tracking by adjusting vertical positions in key areas.

Raising an idler in a high-tension zone increases the belt’s contact angle, adding steering control.

The best zones:

- Concave curves (belt tension stabilizes here).

- Transition zones before the head or tail pulley.

- Areas where load transitions cause uneven stress.

Avoid convex curves — tension differences here can twist the belt carcass.

According to a study by the Bulk Handling Technology Institute, optimizing idler elevation in tension zones improves belt alignment efficiency by 12–18% and reduces power loss by nearly 10%.

5.6 Training Under Load — The Golden Practice

This is one of the most overlooked aspects of conveyor belt tracking.

Belts behave differently when loaded, just like a conveyor belt truck drives differently with cargo.

Always make your final tracking adjustments under normal operating load:

- Adjust idlers when the belt is carrying material.

- Monitor tension changes at the take-up.

- Let the system run several full cycles before calling it “aligned”.

CEMA’s data shows that load-based training reduces post-adjustment drift by 50% compared to no-load setups.

So if your belt tracks perfectly when empty but drifts under load — that’s your sign you adjusted too early.

5.7 Combining Multiple Training Techniques

In real systems, one method rarely solves everything.

The best tracking results come from combining approaches:

- Use crowned pulleys for automatic correction.

- Add a few forward-tilted idlers for fine-tuning.

- Install self-aligning rollers in key zones.

- Always recheck the return path after adjustments.

It’s a layered process. Every small improvement builds toward a belt that tracks naturally, without constant human attention.

5.8 Field Maintenance for Reliable Conveyor Belt Tracking

Even the best alignment won’t last without proper maintenance.

Follow this checklist:

- Clean idlers weekly to remove buildup.

- Verify frame alignment monthly.

- Check roller rotation and bearing noise.

- Inspect the splice angle and tension every quarter.

At Tiantie Industrial, our on-site technicians use digital alignment gauges to verify geometry within ±0.3 mm.

That precision ensures conveyor belt tracking consistency over thousands of operating hours.

5.9 Smarter Corrections, Longer Belt Life

Good training isn’t about constant tweaking — it’s about reading the belt’s behavior.

A smooth, centered belt lowers friction, saves energy, and extends the life of both rollers and rubber.

It’s the same logic we use when loading a conveyor belt truck evenly — balance equals efficiency.

When you understand how tension, idler position, and friction interact, you no longer chase the belt.

The belt starts following you.

5.10 Keeping the Belt Moving Right

Once your belt is trained and running smoothly, your job isn’t finished — it’s just entered the “fine-tuning”stage.

You’ve learned how to control tension, adjust idlers, and read the belt’s behavior like a mechanic reads an engine.

Now it’s time to take that skill one step further.

In the next part, we’ll explore the supporting devices that help your conveyor belt tracking stay reliable day after day — side rollers, friction-enhancing components, and smart control systems that prevent future drift before it starts.

Think of it as giving your belt a safety net, not just a steering wheel.

6.Auxiliary Tracking Devices and Limitations for Conveyor Belt Tracking

Even a well-designed system needs extra control. Harsh environments, uneven loading, or long runs can challenge stable conveyor belt tracking. Auxiliary devices help maintain alignment and prevent edge damage, especially during bulk loading to conveyor belt trucks.

6.1 Side Guide Rollers for Conveyor Belt Tracking

Side guide rollers act as protection, not correction. They prevent the belt from climbing out of the frame when drift occurs but should never apply constant pressure. Continuous contact can burn the edge and cause layer separation. The proper gap is five to ten centimeters from the belt edge. Polyurethane-coated or spring-mounted rollers absorb shocks and protect the carcass. At Tiantie Industrial, these rollers are placed near loading points and head pulleys to stabilize conveyor belt tracking under heavy or fast-changing loads.

6.2 Additional Wrap Pulleys to Improve Conveyor Belt Tracking

Extra wrap pulleys increase the belt’s contact angle and friction. More grip means more control. This setup works well for long conveyors or high-torque drives where slippage is common. According to the Belt Conveyor Safety Institute (BCSI) , adding just twenty degrees of wrap can increase traction by about eighteen percent. However, more contact also means higher tension and wear. Use only as needed. Balanced friction is the key to consistent conveyor belt tracking without stressing the belt.

6.3 High-Friction and Self-Cleaning Rollers

When dust or moisture builds up, rollers lose traction and the belt begins to wander. Using high-friction rollers—rubber, ceramic, or patterned coatings—restores grip and stability. Self-cleaning rollers help remove carryback material that can lift the belt unevenly. Tiantie’s vulcanized coatings maintain strong contact even in wet or dusty operations. These rollers keep conveyor belt tracking stable during continuous unloading to conveyor belt trucks and in humid production sites.

6.4 Automatic Tracking Systems for Continuous Alignment

Modern automation improves precision where manual adjustment falls short. Automatic tracking systems use optical, pneumatic, or mechanical sensors to detect drift and adjust guiding pulleys in real time. Tiantie’s hybrid system combines mechanical feedback with pneumatic correction, keeping the belt within two millimeters of the center line. Automation reduces human intervention and downtime, ensuring reliable conveyor belt tracking in long or remote installations. Still, these systems must complement a solid structure, not replace it.

6.5 Design Boundaries and Practical Limits

Auxiliary devices can’t fix poor alignment or weak frames. They work only when the base geometry is correct. The ISO 14890 standard defines pulley alignment and frame rigidity as essential conditions for effective tracking. Regular cleaning, proper tension, and secure mounts remain non-negotiable. A clean, balanced system will always outperform one overloaded with devices.

6.6 Essential Insight

Auxiliary tracking systems enhance, not replace, good engineering. They keep a healthy conveyor centered under stress, prevent edge wear, and protect against unexpected drift. Combined with precise alignment and steady maintenance, they ensure smooth conveyor belt tracking performance—even when your line feeds a fully loaded conveyor belt truck in demanding field conditions.

7.Special Design Considerations for Conveyor Belt Tracking

Not all conveyors work under ideal conditions. Some run short and wide, others long and flexible. Each design has its own challenge. Proper conveyor belt tracking depends on matching belt geometry, pulley setup, and tension zones to the working environment. What works in a factory may fail on a steep incline or during conveyor belt truck loading. Design must fit the mission.

7.1 Short and Wide Conveyors for Stable Conveyor Belt Tracking

Short belts tend to wander because they lack self-centering distance. Wide belts exaggerate this problem—the larger the width, the easier it folds or waves. For this type, stability depends on control from both the drive and return sides. I recommend using inclined return rollers to apply downward pressure and keep the center line tight. Installing a center drive pulley helps balance tension equally from both sides. When possible, use narrow groove profiles to limit lateral drift.

At Tiantie Industrial, we design short conveyors for packaging and recycling systems using low-tension rubber compounds that resist side rolling. The result is smoother and faster conveyor belt tracking, even when belts start under heavy impact loads.

7.2 Multiple Narrow Belts for Improved Conveyor Belt Tracking

Sometimes, splitting one wide belt into several narrow ones is smarter. Each small belt can be tensioned independently, reducing the effect of uneven load distribution. This design also makes maintenance simpler because one damaged belt doesn’t stop the whole system.

Fenner Dunlop’s technical data shows that using parallel narrow belts can reduce cumulative tracking deviation by up to 35%, especially when load distribution changes frequently (fennerdunlopamericas.com). Tiantie applies this layout in warehouse conveyors that feed conveyor belt trucks for export loading—reliable, efficient, and easier to clean.

7.3 Modular Plastic Belts for Positive Conveyor Belt Tracking

When contamination, moisture, or hygiene are key concerns, modular plastic belts offer an edge. They use sprockets for direct engagement rather than friction. This design ensures positive conveyor belt tracking without relying on tension or idler geometry.

Plastic modules are ideal for short runs, reversing conveyors, and food-grade environments. However, they require precise sprocket alignment and regular inspection. A misaligned sprocket can cause the same drift as a tilted roller. In Tiantie’s assembly lines, we use modular belts with stainless sprockets to handle high-humidity environments safely.

DIN 22102, the German industrial standard, also recommends low-stretch materials and precise tooth alignment for modular belts to maintain reliable tracking (din.de).

7.4 Take-Up Pulley Crown Adjustments for Conveyor Belt Tracking

Even minor alignment errors can cause continuous drift over long runs. Adding a small crown on the take-up pulley is an effective way to fine-tune belt centering. The crown compensates for slight frame deflection and balances side tension automatically.

The ideal crown height depends on belt width and tension level—usually 1 to 2 mm for every 100 mm of belt width. At Tiantie Industrial, we measure this crown by laser during installation. The correction is subtle but makes a significant difference. It keeps conveyor belt tracking consistent even after years of wear or thermal expansion.

7.5 Structural Reinforcements and Environmental Factors

Temperature, humidity, and vibration all affect belt behavior. A belt running smoothly indoors can drift outdoors due to thermal stretch or crosswind. The frame must resist twist and flex. Reinforcing the conveyor’s central beam and ensuring precise roller alignment are the simplest long-term solutions.

I’ve seen cases where a conveyor’s aluminum frame expanded by five millimeters under direct sunlight—enough to pull tracking off-center. Switching to galvanized steel or thermal-stable alloys eliminates that issue. When feeding conveyor belt trucks, where load vibration is constant, anti-vibration mounts also help maintain steady alignment.

7.6 Integrating Smart Design into Everyday Tracking

Design improvements are invisible when done right. A properly crowned pulley, balanced drive, or narrow return path won’t look impressive—but it makes the system work without constant supervision. Combining geometry, materials, and precision engineering ensures predictable conveyor belt tracking under any condition.

Tiantie’s design philosophy is simple: build structure that needs less correction. From modular plastic to heavy rubber belts, we engineer each layout for minimal adjustment and long service life. Smart design saves time, maintenance, and cost for every client—whether running a small plant or loading a conveyor belt truck fleet.

8.Inspection and Maintenance Checklist for Conveyor Belt Tracking

Even the best design can lose alignment without care. Regular inspection keeps conveyor belt tracking precise, prevents premature wear, and saves repair time. A stable system doesn’t happen by chance; it’s the result of small, consistent checks. For conveyors used in production or conveyor belt truck loading, these inspections make the difference between steady flow and costly downtime.

8.1 Alignment and Squaring

Check the geometry first. Every pulley, roller, and frame should stay square to the conveyor centerline. Even a two-millimeter offset can cause gradual drift. Use a laser or a calibrated straightedge to verify alignment across the head, tail, and bend pulleys at least once per quarter. The Conveyor Equipment Manufacturers Association (CEMA) recommends rechecking alignment after any splice or pulley change. Perfect geometry is the foundation of consistent conveyor belt tracking.

8.2 Frame Integrity and Structural Rigidity

A conveyor frame must resist twist and flex. Cracks, loose bolts, and bent brackets shift tension unevenly and slowly pull the belt off center. Inspect welds and supports in loading and discharge zones where vibration is highest. Reinforcing joints with gussets or heavier cross-members helps the structure hold its shape. Tiantie conveyors use rigid steel frames that maintain alignment even under heavy shock loads, ensuring steady conveyor belt tracking over time.

8.3 Roller and Idler Condition

Rollers are small components with major impact. During shutdowns, spin them by hand and listen for grinding or stiffness. A seized bearing drags the belt sideways and accelerates wear. Replace any roller that feels rough or wobbles. According to the SKF Bearing Maintenance Guide, worn rollers can increase belt misalignment by up to 30 percent . Clean each roller thoroughly before restart to keep movement smooth and balanced.

8.4 Guide Rollers, V-Guides, and Crowns

Inspect side guides and crowned pulleys for uneven contact. They should only engage when drift begins, not during every rotation. Continuous contact signals a deeper issue—likely tension imbalance or pulley skew. Check crown wear across the pulley width; if one side looks polished while the other is dull, the tension distribution is uneven. Tiantie technicians often use portable thermal sensors to detect hot spots and predict early misalignment before it escalates.

8.5 Cleanliness and Belt Surface Condition

Cleanliness is simple but powerful. Dust, mud, or carryback create uneven friction that destabilizes the belt. Keep the return path, idlers, and chute areas clear using scrapers or air knives. Inspect belt edges for fraying or cuts that could spread under tension. A clean surface allows the belt to track evenly and reduces vibration throughout the system.

8.6 Tension and Take-Up Adjustment

Belt tension drives direction. Unequal take-up movement quickly turns into lateral drift. Verify that the tensioning device moves smoothly and equally on both sides. Hydraulic or gravity systems should respond without jerks or stalls. In long conveyors that feed conveyor belt trucks, tension variation under load is common, so monitor it continuously during operation. Balanced tension equals balanced tracking.

8.7 Documentation and Predictive Maintenance

Record every alignment check, roller change, and tension adjustment. Trend data reveals small tracking issues before they become failures. Integrating vibration or temperature sensors helps identify bearing fatigue early and keeps conveyor belt tracking predictable. Predictive maintenance turns random downtime into planned service.

Consistent inspection is the simplest form of reliability. When alignment, cleanliness, and tension stay under control, the belt follows naturally. Tiantie follows CEMA-based checklists to keep every conveyor centered and efficient. A well-maintained system runs quieter, lasts longer, and keeps every conveyor belt truck loaded on schedule—without surprises.

9.Integrated Best Practices for Conveyor Belt Tracking

Reliable conveyor belt tracking doesn’t depend on luck. It’s the result of disciplined design, small corrections, and steady observation. The following field-tested practices combine structure, loading, and maintenance to keep any belt running straight—whether it feeds a silo or loads a conveyor belt truck.

9.1 Structure Before Accessories

Always fix geometry first. A true frame, level supports, and square pulleys solve most tracking issues before they start. Accessories can only fine-tune what structure already does right. The Martin Engineering White Paper 2023 reports that conveyors with verified squareness require 60 percent fewer alignment adjustments during operation (martin-eng.com). At Tiantie, we use digital laser alignment tools on every new installation to set that foundation once and for all.

9.2 Adjust Small and Slow

Large corrections create chaos. Move idlers just a few millimeters, then watch several belt revolutions. A patient hand finds balance faster than a hurried one. Treat the belt like a steering wheel under load—steady input keeps control. Experienced technicians know that over-adjustment causes twice the wear compared to minor, timed corrections.

9.3 Train the Belt Under Real Load

An empty belt lies. Only a loaded one shows real tension distribution. Train the system while it’s carrying normal material flow, then record the response. Research published in the Australian Bulk Handling Review (2022) found that load-based calibration improved long-term tracking accuracy by 52 percent compared with idle-belt training. At Tiantie, every commissioning test includes at least one full-load trial to capture genuine tracking behavior.

9.4 Keep Everything Clean and Even

Clean components track true. Material buildup on one side of the return path changes friction and throws alignment off. Plan cleaning as part of daily operation, not an afterthought. The same logic applies to feeding: symmetrical loading keeps the centerline balanced. When conveying to conveyor belt trucks, always position chutes and hoppers so the flow hits the middle, not one edge.

9.5 Inspect, Record, and Predict

Tracking isn’t a one-time fix—it’s a habit. Log every roller change, tension tweak, and splice repair. Patterns tell the truth about wear and drift. Over time you’ll see how temperature, humidity, or vibration affect alignment. Predictive maintenance begins with notes, not software. Tiantie plants use cloud-based logs so engineers can review tracking trends remotely and plan maintenance before trouble starts.

9.6 Match the Belt to the Job

The wrong belt material can defeat perfect geometry. High-temperature, oil-resistant, or extra-stiff carcasses behave differently under tension. Match stiffness and elongation to the working load. Tiantie’s R&D team selects compounds that resist stretch yet stay flexible enough for precise conveyor belt tracking. A properly specified belt tracks naturally and lasts longer.

9.7 Train People as Well as Belts

The system is only as accurate as the people maintaining it. Everyone involved should understand what causes drift and how to correct it gently. One rushed adjustment can undo hours of work. Shared training manuals and regular refresher sessions create consistent technique across shifts and reduce unnecessary intervention.

A conveyor that tracks well is one you rarely think about. Balanced structure, careful adjustment, and clean operation make tracking automatic. Tiantie’s philosophy is simple: design precisely, correct lightly, maintain consistently. Follow those principles and your conveyor belt tracking will stay true—no matter how many conveyor belt trucks you load each day.

10.Advanced Insights and Further Reading on Conveyor Belt Tracking

Even after mastering the basics, conveyor belt tracking offers more to explore. The stability of a conveyor system depends on a mix of physics, materials, and environment. Small design decisions often decide whether a belt runs smoothly for years or needs constant correction. Deeper understanding helps engineers and operators refine performance beyond daily adjustments.

10.1 Root Causes and Engineering Solutions

Most tracking issues begin with uneven tension, poor splicing, or material buildup. But subtle variables like humidity, temperature, and belt stiffness also shift alignment over time. ConveyorBeltGuide.com notes that nearly 40 percent of industrial tracking failures originate from improper belt storage and handling before installation . Prevention starts long before the first pulley turns.

Modern systems now use automatic feedback loops, laser alignment checks, and load sensors that react before visible drift occurs. The key is anticipation, not correction.

10.2 Precision Tools and Alignment Technology

New measuring instruments have changed how alignment is verified. Laser trackers, 3D frame scanners, and digital inclinometers make alignment faster and far more accurate. Reports on Engineering360 show that conveyors aligned using 3D optical mapping maintain consistent tracking 30 percent longer than those calibrated manually. Tiantie has integrated this method into all large-scale installations to ensure consistent accuracy from day one.

10.3 Data-Driven Maintenance and Predictive Control

Tracking reliability improves when data becomes part of maintenance. Temperature, vibration, and load readings help identify where tension shifts begin. Combined with maintenance logs, these metrics create a complete picture of system behavior. Once you can measure how a belt reacts, you can control it with confidence.

10.4 Continuous Improvement and Field Learning

The same principles apply everywhere—from small packaging conveyors to bulk systems feeding conveyor belt trucks. Balanced geometry, proper material flow, and smart monitoring keep tracking predictable. Tiantie’s engineering team uses every project as feedback to improve future belt formulations and tracking mechanisms. The future of conveyor belt tracking is not only mechanical—it’s intelligent, data-informed, and designed for lifetime precision.