A concrete conveyor belt isn’t built for pouring on-site—it’s the backbone of your batching or precast plant. This guide explains how it keeps sand, gravel, and cement flowing in perfect rhythm, meeting ASTM C94 accuracy and cutting downtime. With real data from Tiantie Industrial’s production tests, you’ll see how the right belt design improves yield, reduces dust, and defines the next generation of efficient concrete manufacturing.

1. What a concrete conveyor belt really does

concrete conveyor belt is not a magic wand for pouring slabs on site—and that’s a common misunderstanding I hear all the time. I build these systems for a living, and I use them to move raw materials inside your plant, not to finish concrete at a jobsite. In a batching or precast line, a concrete conveyor belt links the aggregate hopper, cement silo, admixture station, and scale, then feeds the mixer with a steady, controllable stream. Your goal isn’t “pouring,” it’s precise feeding.

Here’s the simple picture: sand and stone in, continuous conveying, accurate metering, mixing out. With the right rubber conveyor belt—typically an EP conveyor belt for low elongation and moisture stability—you connect every step so the mixer never starves or floods. That consistency is why a concrete conveyor belt boosts yield and shrinks cycle time in your batching plant or precast factory.

Why it matters to you: belts cut manual handling, reduce dust and spillage, and stabilize energy use compared with stop-go loaders. Enclosed or well-shielded aggregate conveyor runs also support compliance with dust control rules; OSHA flags respirable crystalline silica as a key hazard, and engineered containment/housekeeping is part of the solution (see OSHA silica guidance). Less dust = safer crews + cleaner bearings + fewer clean-downs.

Compared with screw feeders or buckets, a wear-resistant conveyor belt (DIN X/W cover) gives you gentler handling for sand and aggregates, easier maintenance, and simpler speed control for dosing. You’ll keep moisture in spec, protect your admixture plan, and keep your mixer loading curve smooth.

2. Concrete Production Process and Conveyor System Structure

In every modern batching plant, the concrete conveyor belt works quietly but relentlessly, carrying tons of sand, gravel, and cement from one stage to the next. It doesn’t just move materials—it orchestrates them. From aggregates entering the hoppers to precise feeding into the weighing system and mixer, the conveyor belt ensures that your mix is always balanced, clean, and consistent.

The flow is simple yet elegant: sand and gravel → conveyor → weighing hopper → mixer → finished material bin. Each segment uses a specific type of rubber conveyor belt, depending on the material’s condition. For dry materials, you’ll see EP belts (EP200–EP300) with a tough, abrasion-resistant surface, ideal for rough, angular aggregates. When handling semi-wet or cohesive mixes, operators prefer smoother covers to prevent buildup and sticking, keeping the system easy to clean and stable in operation.

Compared to bucket elevators or screw conveyors, the advantages of a belt conveyor system are obvious to anyone who’s worked in the field. Buckets need frequent alignment and lubrication. Screws tend to crush and heat the mix, which changes moisture levels and particle size distribution. A concrete conveyor belt, on the other hand, delivers materials smoothly, minimizes energy loss, and keeps the process continuous and dust-free.

This consistency is what defines production quality. By maintaining a uniform material flow, your plant meets strict ASTM C94 batching tolerances—±1% for aggregates and ±0.5% for cement (source: ASTM C94 / C94M – 23, Standard Specification for Ready-Mixed Concrete). It’s not just about moving materials; it’s about maintaining control over every second of your production cycle.

A properly designed concrete conveyor belt system becomes the heartbeat of your plant. It synchronizes every motion—from loading to mixing—so operators can focus on productivity, not troubleshooting. When your conveyor runs right, the whole line breathes in rhythm: smooth, steady, and unstoppable.

3. Main Types of Concrete Conveyor Belts

When it comes to choosing the right concrete conveyor belt, not all belts are created equal. Each type serves a different function in your production line — from handling coarse aggregates to moving hot or semi-wet materials. Selecting the right structure means longer life, lower maintenance, and a smoother operation. Let’s walk through the three most common types you’ll find in modern concrete batching plants and aggregate lines.

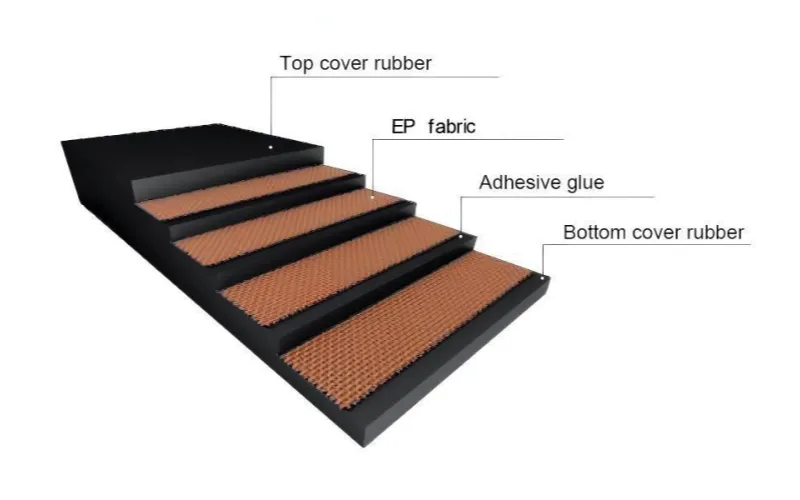

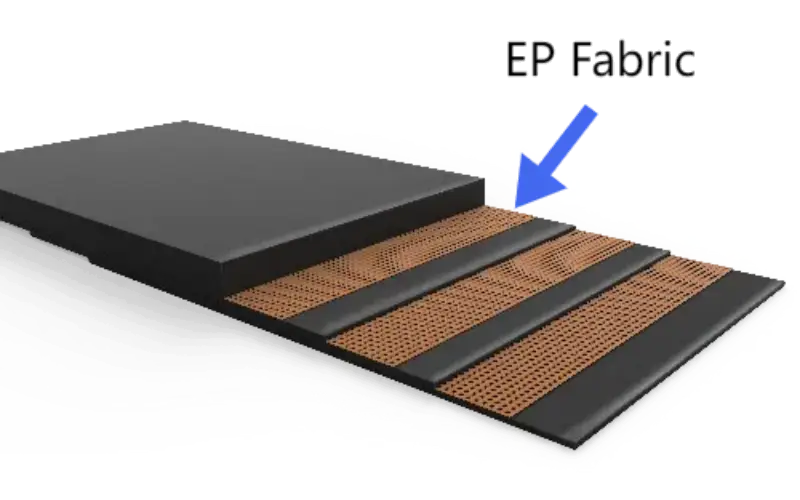

3.1 EP Conveyor Belt (Polyester–Nylon)

This is the workhorse of most concrete conveyor systems. The EP conveyor belt combines polyester warp (longitudinal) and nylon weft (transverse) to achieve the perfect balance between low elongation and high strength. It resists moisture, maintains flexibility, and offers excellent dimensional stability even under fluctuating loads.

In concrete batching environments, where sand, stone, and cement flow continuously, the EP200–EP300 range is the go-to choice. It runs stable under high tension and doesn’t stretch excessively, so the weighing and feeding systems stay accurate over time. The result? Less downtime, better batching precision, and longer belt service life.

Its top rubber cover usually adopts DIN X or W-grade abrasion resistance, meeting the requirements of GB/T 7984–2013 and GB/T 9881–2008 standards. These ensure that even under the toughest conditions—sharp aggregates, repeated impact, or slight moisture—the concrete conveyor belt keeps its integrity and shape.

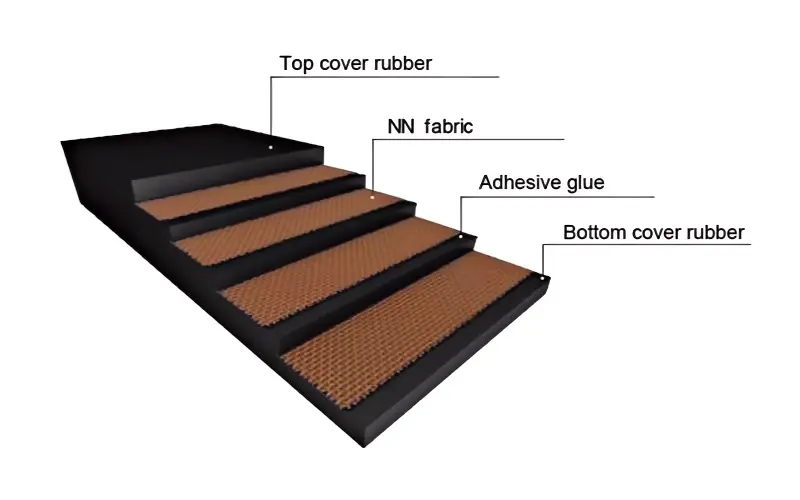

3.2 NN Conveyor Belt (Nylon–Nylon)

If your plant handles large drops or coarse aggregates, the NN conveyor belt is built for the job. The double-nylon fabric structure gives it superior impact resistance, making it ideal for feed points, transfer chutes, or sections with heavy loading.

However, its higher elongation rate means it requires a more precise tensioning system. You’ll often see it paired with automatic take-up devices to maintain consistent tension during operation. While slightly more expensive than EP types, its toughness makes it worth every cent when handling aggressive, high-impact materials.

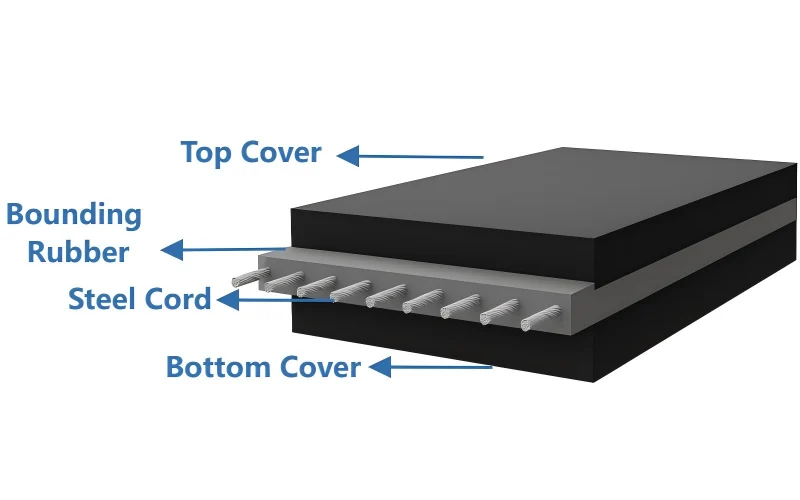

3.3 Steel Cord Conveyor Belt (ST Belt)

The ST belt is the giant among concrete conveyor systems. It’s designed for long-distance or high-capacity lines, such as in large quarries or main aggregate supply routes. Its steel cords replace fabric plies, giving it incredible tensile strength and virtually zero elongation.

For batching plants that run 24/7 and demand total reliability, the steel cord concrete conveyor belt minimizes maintenance intervals and resists tearing under extreme loads. It’s overkill for small plants but a smart investment for high-output operations that can’t afford downtime.

Choosing between EP, NN, and ST types isn’t just about cost—it’s about matching the belt’s structure to your process conditions. Each has its place, and when selected properly, a concrete conveyor belt becomes the most dependable link in your entire production chain.

4. Material and Structural Design of Concrete Conveyor Belts

The durability and performance of a concrete conveyor belt depend entirely on how it is built — the internal fabric structure, bonding strength, and the rubber compound that shields it from constant wear. At Tiantie Industrial, every belt is engineered according to recognized international quality principles for textile conveyor belts, ensuring long-term stability in concrete batching, aggregate handling, and cement processing environments.

4.1 Reinforcement Structure

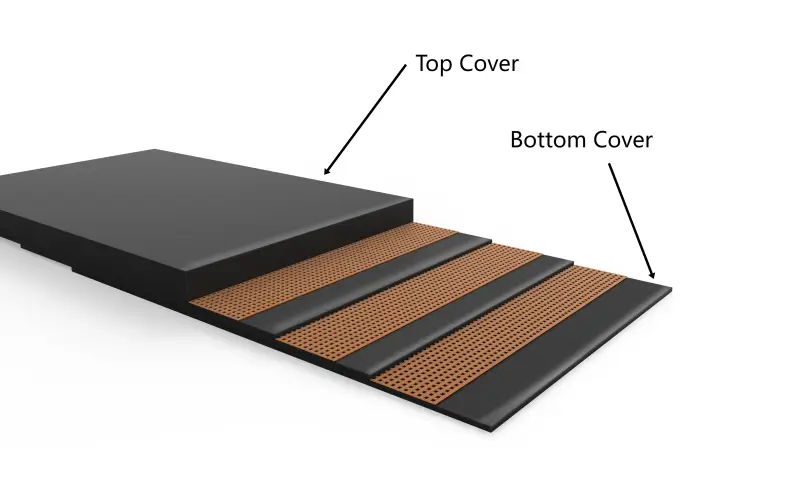

The core of each concrete conveyor belt is made from polyester-nylon (EP) fabric.

This design combines the dimensional stability of polyester with the flexibility and impact absorption of nylon — an ideal balance for handling abrasive and heavy materials like sand, gravel, and cement.

- Tensile strength range:100–630 N/mm, depending on the belt grade and number of plies.

- Elongation at break (whole belt):≤ 15%.

- Working elongation under load:≤ 2%, ensuring accurate feeding and minimal stretch in operation.

- Adhesion strength:between plies ≥ 4.5 N/mm; between rubber and fabric ≥ 3.5 N/mm, preventing delamination during high-tension cycles.

This reinforcement structure allows the concrete conveyor belt to maintain stability under continuous tension, heavy impact, and cyclic bending, all while minimizing downtime and adjustment needs.

4.2 Cover Rubber Properties

The cover rubber acts as the belt’s armor, protecting the carcass from abrasion, heat, and aging. Tiantie’s rubber compounds are formulated from SBR and NR blends, optimized with anti-aging agents, antioxidants, and heat stabilizers to guarantee durability under demanding concrete applications.

Key verified parameters from Tiantie’s product data:

- Abrasion resistance:≤ 30 mm³ of wear loss under standardized abrasion testing — a super wear-resistant grade that ensures long service life.

- Tensile strength of cover rubber:14–20 MPa, ensuring strong elasticity and crack resistance.

- Elongation at break (rubber cover):≥ 350%, giving flexibility and resistance to tearing.

- Hardness:60 ± 5 Shore A, tough enough to resist sharp aggregates while remaining elastic.

- Top and bottom cover thickness:typically 4–6 mm (top) and 2–3 mm (bottom) for balanced flexibility and protection.

- Temperature resistance:continuous operation at 100–120°C; short-term peaks up to 200–300°C for heat-resistant grades.

- Low-temperature flexibility:stable down to –50°C without surface cracking or stiffness increase.

These parameters guarantee that the concrete conveyor belt maintains integrity under the stress of daily production — from hot cement dust to cold, damp aggregate conditions.

4.3 Surface Design and Edge Protection

Different conveying conditions require different surface designs.

- Smooth cover: ideal for dry or semi-wet materials, ensuring clean discharge and preventing buildup.

- Chevron or patterned cover (V or U type): used for inclined transport above 18–20°, providing strong grip for wet or sticky materials.

- Edge sealing and skirt rubber: applied to prevent water ingress, reduce dust emission, and protect belt edges from premature wear.

Each concrete conveyor belt is produced under strict process control, where dimensional tolerances, bonding quality, and cover hardness are monitored continuously. The result is a belt that performs reliably in the harshest environments of concrete production — stable, efficient, and made to last.

5. Applications of Concrete Conveyor Belts in Batching Plants

In every modern batching plant, the concrete conveyor belt is far more than just a transport tool — it’s the backbone that keeps the entire production process flowing. From aggregate loading to precise material weighing and mixing, the conveyor system ensures that each batch of concrete is delivered with accuracy, stability, and consistency. Without it, even the best mixer can’t perform at its full potential.

5.1 Key Functions in the Concrete Mixing Process

A concrete conveyor belt connects every essential stage of production — sand and gravel feeding, cement dosing, admixture blending, and final material transfer into the mixer.

Here’s how it works inside a typical batching plant setup:

- Aggregate Loading:Coarse and fine aggregates are loaded onto the belt from storage bins. The rubber conveyor belt transfers them to the weighing hopper, maintaining a steady flow that reduces surges and material segregation.

- Weighing & Feeding:The belt speed and flow are calibrated with the plant’s control system, allowing precise measurement of each component.

- Mixing & Transfer:Once dosed, the materials are moved efficiently into the mixer, ensuring a consistent feed and eliminating interruptions in production.

Because of its low elongation and stable tension, an EP-type concrete conveyor belt maintains consistent volume delivery — critical for accurate batching ratios that meet international concrete standards (for example, ±1% for aggregates and ±0.5% for cement, as recommended in ASTM C94).

5.2 Advantages Over Traditional Conveying Systems

Compared to bucket elevators or screw conveyors, a belt system offers cleaner operation, lower energy use, and simpler maintenance.

- Continuous flow:eliminates stop–start surges that cause segregation.

- Less wear and dust:thanks to soft handling of aggregates and sealed transfer points.

- Energy efficiency:friction losses are much lower than in mechanical conveying systems.

- Reduced maintenance:minimal moving parts and simple belt tracking adjustments.

For batching plants located in hot or humid regions, Tiantie’s heat- and moisture-resistant conveyor belts provide an extra layer of reliability. The belt surface remains flexible under temperature peaks of 200°C and resists moisture expansion when exposed to wet sand or slurry materials.

5.3 Real-World Production Benefits

In operation, a high-quality concrete conveyor belt can cut manual handling by up to 70%, improve material utilization, and reduce overall production downtime.

The smoother feed also minimizes dust emissions, improving air quality and creating safer working conditions — a point emphasized by occupational safety regulations worldwide. According to OSHA, reducing airborne cement dust and silica exposure significantly lowers health risks for plant operators (OSHA: Respirable Crystalline Silica Standard).

Tiantie’s customers in Southeast Asia, the Middle East, and South America report that optimized belt setups have extended the service interval of their conveyors by 30–40% while improving batching accuracy and lowering power consumption.

A reliable concrete conveyor belt isn’t just a piece of equipment — it’s part of your plant’s heartbeat.

It ensures every ton of aggregate, every kilogram of cement, and every drop of water are delivered at the right moment, in the right ratio, with zero interruptions. When your conveyor runs smoothly, your entire production line stays balanced, efficient, and profitable.

6. Applications of Concrete Conveyor Belts in Precast and Mortar Production Lines

While batching plants rely on concrete conveyor belts for precise material flow, precast and dry-mortar production lines demand even higher standards of cleanliness, heat resistance, and dimensional stability. Here, the conveyor doesn’t just feed materials — it defines the rhythm of the entire line. A well-designed conveyor system determines how efficiently your molds fill, how cleanly your lines run, and how consistently your final products meet quality standards.

6.1 Role of Conveyor Belts in Precast Manufacturing

In precast factories, where accuracy and surface quality are non-negotiable, the concrete conveyor belt ensures a smooth and uninterrupted transfer of dry or semi-wet mixtures from the batching zone to the mold area.

- Smooth discharge:prevents material segregation and air pockets in molds.

- Consistent feed rate:allows automated filling systems to maintain precise product weight.

- Clean operation:minimizes residue buildup around the formwork area.

For this process, Tiantie recommends smooth-surface EP belts made with anti-adhesion and abrasion-resistant rubber covers. These belts maintain flexibility and cleanliness even under heavy load cycles and long working hours. Because the surface finish of precast elements depends on material consistency, a stable concrete conveyor belt directly impacts product quality and dimensional accuracy.

6.2 In Dry-Mix and Mortar Lines

In dry-mix mortar production, the conveyor belt connects the dosing, mixing, and packaging sections — handling abrasive materials such as quartz sand, cement, and chemical additives.

For these applications, heat and dust control are critical. Tiantie’s heat-resistant and wear-resistant EP belts are designed to withstand the fine powder abrasion typical in mortar lines, maintaining an abrasion loss ≤ 30 mm³ and ensuring long belt life even under continuous operation.

When the material temperature exceeds 150°C, Tiantie provides EPDM-blended heat-resistant rubber covers, capable of handling surface temperatures up to 200°C without hardening or cracking.

This high thermal endurance makes the concrete conveyor belt ideal for both hot dry-mix materials and high-speed packaging systems that require clean belt surfaces.

6.3 Cleanliness and Maintenance Advantages

Precast and mortar environments demand belts that are easy to clean and maintain.

A smooth, non-porous rubber surface prevents fine cement or sand particles from embedding into the belt, while scraper systems and dust-tight enclosures keep the line free from contamination.

When combined with skirt sealing and automatic tension control, Tiantie’s conveyor systems maintain alignment and stability, reducing unplanned downtime by up to 40%.

Regular cleaning and surface maintenance are simple — just light mechanical brushing or air-blowing. The belts’ superior anti-aging compounds prevent surface cracking under continuous temperature variation, making them ideal for high-throughput factories operating year-round.

6.4 Proven Benefits in Industrial Practice

Customers using Tiantie’s concrete conveyor belts in precast and mortar plants report measurable performance gains:

- Longer service life:up to 30–50% longer than standard belts under similar workloads.

- Stable surface quality:smoother product finishes and reduced waste from inconsistent feeding.

- Improved hygiene and safety:lower dust levels and cleaner operation areas.

- Reduced maintenance cost:fewer belt changes and less cleaning downtime.

These advantages make the concrete conveyor belt not just a conveyor, but an integral part of an intelligent, automated material handling system.

In both precast and mortar production, consistency is everything — and the right belt design keeps your process stable, clean, and cost-efficient, batch after batch.

7. Key Performance Requirements and Testing of Concrete Conveyor Belts

When you buy a concrete conveyor belt, you’re not just purchasing a strip of rubber and fabric — you’re investing in reliability, consistency, and trust. At Tiantie Industrial, every conveyor belt passes through a strict performance verification process that ensures it performs exactly as designed, batch after batch, no matter where in the world it’s used.

We don’t just rely on lab data; we replicate real working conditions — high load, high temperature, and continuous abrasion — to confirm that each belt can survive in the demanding environments of concrete production, batching, and aggregate transport.

7.1 Comprehensive Quality Testing

Each concrete conveyor belt goes through a multi-stage inspection system before shipment.

Our tests cover all major mechanical and environmental properties, including:

- Tensile strength and stability testing:simulating belt tension under full operational load to verify elongation control and carcass balance.

- Adhesion strength evaluation:confirming that the bonding between layers remains solid after repeated flexing and vibration.

- Abrasion and impact simulation:exposing belt samples to accelerated wear using aggregate-like materials to replicate concrete plant conditions.

- Thermal and cold resistance testing:verifying surface flexibility and structural integrity at extreme temperature ranges, from freezing to high-heat exposure.

- Aging and environmental resistance testing:UV, ozone, and humidity chambers ensure the belt retains its performance even under outdoor conditions.

Each of these tests ensures that the concrete conveyor belt can maintain structural strength, flexibility, and wear resistance over years of continuous use.

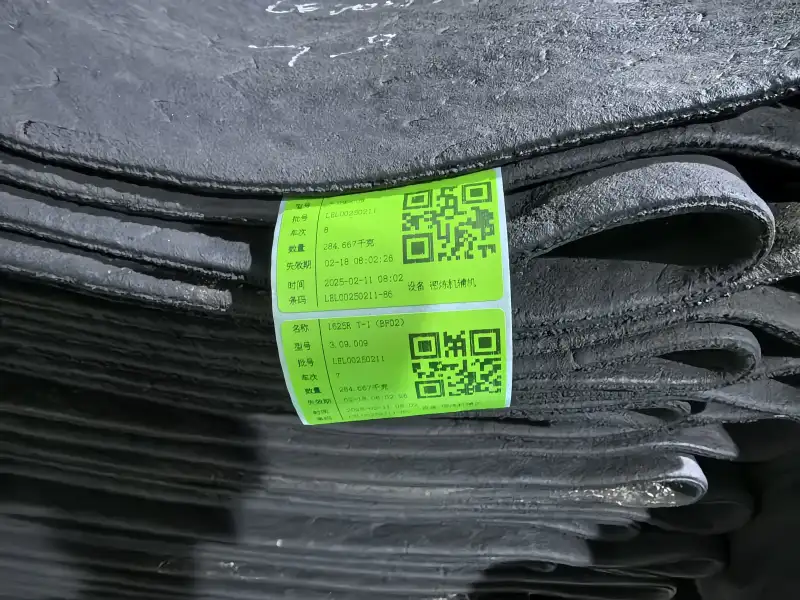

7.2 Production Traceability and Batch Control

Every belt manufactured at Tiantie’s facility has a unique batch number linked to its production record.

This traceability system allows full tracking from raw material selection to the final curing process.

Our in-house laboratories document every result — from adhesion to surface hardness — creating a performance history that accompanies each shipment.

For international clients, this means that every concrete conveyor belt is not only produced to specification but also fully traceable and data-verified. It’s proof that what you order is exactly what you receive.

7.3 Quality Assurance Philosophy

Quality at Tiantie isn’t just an inspection step — it’s part of the design philosophy.

We implement a “prevention-first” quality system:

- Automatic thickness and alignment sensorsmonitor the entire vulcanization line.

- Digital tension calibrationensures consistent carcass alignment and bonding during curing.

- Random destructive samplingverifies the mechanical integrity of each batch before release.

This proactive quality assurance ensures that the concrete conveyor belt you receive meets both your specifications and international expectations — every single time.

7.4 Third-Party Verification and Global Compatibility

For export markets, Tiantie’s belts undergo third-party testing from accredited inspection agencies upon customer request. These tests align with internationally recognized criteria for conveyor belts used in construction, mining, and industrial transport applications.

Our quality documentation and test certificates are accepted by clients in Europe, the Middle East, Southeast Asia, and South America — a reflection of our consistent manufacturing quality and transparent verification process.

7.5 Confidence You Can Measure

Every Tiantie concrete conveyor belt leaves our factory not only with strong physical properties but also with the data to prove it.

That’s how we turn technical performance into business reliability — measurable, repeatable, and trusted worldwide.

Because in the concrete industry, your belt doesn’t just carry material — it carries your entire production schedule.

And that’s something we take seriously, every single day.

8. System Optimization and Performance Upgrading of Concrete Conveyor Belts

Even when a concrete conveyor belt meets all performance standards, the way it’s installed, maintained, and optimized across the system determines how efficiently it runs in real production. At Tiantie Industrial, we help partners not only choose the right belt but also build smarter conveyor systems that achieve longer service life, lower downtime, and better energy performance.

8.1 Strength Optimization Through Design Integration

The strength of a concrete conveyor belt depends not only on its carcass structure but also on how it interacts with the entire conveying setup.

When heavy aggregates or impact loads are involved, the belt’s tension, alignment, and transition zones must work together to maintain mechanical stability.

Using load-spreading impact beds, adjustable tensioning systems, and properly aligned pulleys can prevent localized strain — extending belt life without altering the belt’s material specification.

This system-level optimization ensures that the concrete conveyor belt performs consistently, even under the irregular load cycles typical of batching plants and aggregate lines.

8.2 Advanced Rubber Compounds and Long-Term Durability

High wear resistance is essential in concrete production, but longevity depends on how well the rubber compound withstands continuous heat, dust, and moisture exposure.

Tiantie continuously improves its formulations with anti-aging agents, ozone stabilizers, and low-heat-build-up elastomers. These compounds keep the rubber flexible and crack-free through thousands of operational hours.

For plants operating in high-temperature zones or hot-mix environments, using a heat-stable compound can increase belt life by up to 40%. The result is not only better durability but also reduced replacement frequency — directly lowering total production cost.

8.3 Efficiency Upgrades in Material Handling Systems

Improving system mechanics is one of the most cost-effective ways to upgrade performance.

Key interventions include:

- Impact-absorbing loading pointsto reduce belt stress from falling materials.

- Skirt sealing systemsto contain dust and prevent edge wear.

- Precision idlers and energy-efficient rollersto reduce drag and vibration.

- Self-adjusting scrapersthat maintain belt cleanliness automatically.

These refinements don’t just protect the concrete conveyor belt — they also improve plant hygiene, enhance safety, and minimize energy losses from misalignment or friction.

8.4 Proactive Maintenance and Predictive Monitoring

Maintenance is no longer just about fixing problems; it’s about predicting them.

By integrating real-time monitoring tools — such as belt tension sensors, thermal cameras, or vibration analysis — operators can detect early signs of wear, misalignment, or splice fatigue before failure occurs.

A proactive maintenance schedule can increase belt uptime by 20–30% and dramatically reduce emergency repairs. Tiantie’s technical support team assists customers in setting inspection intervals and interpreting condition-monitoring data to achieve truly preventive maintenance.

8.5 Sustainability and Energy Efficiency

Energy consumption and environmental impact are increasingly important to global buyers. Tiantie’s eco-optimized concrete conveyor belts use low rolling-resistance compounds that reduce power draw by up to 15% while maintaining the same tensile performance.

Additionally, the use of recyclable core fabrics and cleaner vulcanization technology minimizes environmental footprint during production.

By combining durability with energy efficiency, Tiantie helps customers achieve both cost savings and sustainability goals — a balance that defines modern industrial competitiveness.

8.6 Tailored Optimization Support

Every concrete plant operates differently — belt load, temperature, moisture, and slope angles all vary.

That’s why Tiantie provides custom performance upgrading plans for each client.

Through on-site assessments or design reviews, we fine-tune belt specifications, choose the right compound, and recommend system upgrades that deliver measurable efficiency gains.

In many projects, these tailored optimizations have reduced belt wear by over 35% and extended operational life by more than a year, without increasing maintenance costs.

Carcass | Carcas | Carcass | Strength(N/mm) | ||||

2ply | 3ply | 4ply | 5ply | 6ply | |||

EP | EP100 | 1 | 200 | 300 | 400 | 500 | 600 |

EP125 | 1 | 250 | 375 | 500 | 625 | 750 | |

EP150 | 1.1 | 300 | 450 | 600 | 750 | 900 | |

EP200 | 1.2 | 400 | 600 | 800 | 1000 | 1200 | |

EP250 | 1.4 | 500 | 750 | 1000 | 1250 | 1500 | |

EP300 | 1.6 | 600 | 900 | 1200 | 1500 | 1800 | |

EP350 | 1.7 | 700 | 1050 | 1400 | 1750 | 2100 | |

EP400 | 1.9 | 800 | 1200 | 1600 | 2000 | 2400 | |

EP500 | 2.1 | 1000 | 1500 | 2000 | 2500 | 3000 | |

EP630 | 2.6 | 1260 | 1890 | 2520 | 3150 | 3780 | |

A well-optimized concrete conveyor belt is more than a durable product — it’s a reflection of intelligent design, thoughtful maintenance, and engineering precision.

At Tiantie Industrial, we don’t just manufacture belts; we build long-term performance systems that help our partners move materials more efficiently, safely, and sustainably.

9. Cost and Economic Analysis of Concrete Conveyor Belts

In the concrete industry, every minute of uptime matters. While the initial cost of a concrete conveyor belt is often a key factor in purchasing decisions, experienced plant operators know that the true measure of value lies in total life-cycle cost — not the price tag. At Tiantie Industrial, we help clients calculate and optimize this total cost, proving that the right belt, correctly specified and maintained, delivers far greater returns than cheaper alternatives.

9.1 Understanding Total Cost of Ownership (TCO)

When evaluating a concrete conveyor belt, three main cost factors define long-term value:

- Initial investment cost— including belt material, structure, and installation.

- Operating cost— energy consumption, maintenance, and cleaning.

- Replacement cost— downtime, labor, and lost production during belt changeovers.

A standard conveyor belt that lasts 1 year but causes 5–10 hours of downtime per month will, in total cost terms, be far more expensive than a premium, wear-resistant belt that lasts 2–3 years with minimal interruptions.

That’s why Tiantie focuses on durability and efficiency per operating hour, not simply per meter of belt.

9.2 Cost Impact of Durability and Replacement Cycles

A high-quality concrete conveyor belt can extend replacement cycles by 30–50%.

In a batching plant producing 500,000 m³ of concrete per year, this translates into:

- Reduced replacement frequencyfrom every 12 months to every 24–36 months.

- Maintenance cost reductionof up to 25%.

- Downtime savingsequivalent to several production days per year.

These improvements have a direct financial impact. When the cost of downtime (lost production + labor + idle energy use) is considered, extending belt life by even 6 months can save thousands of dollars annually.

9.3 Energy Efficiency and Operating Savings

Tiantie’s optimized rubber compounds and precision-aligned carcass structures reduce rolling resistance — lowering energy consumption by 10–15% compared to standard belts.

This means:

- Less power draw per ton of material conveyed.

- Lower motor load, extending the life of drive components.

- Reduced heat buildup, which also slows down belt wear.

For plants running continuously, these savings quickly accumulate. Over a 3-year operating cycle, the reduction in electricity and maintenance expenses can offset the belt’s purchase price — and then some.

9.4 Downtime and Productivity Economics

Downtime is often the hidden cost that plant managers underestimate.

Every unscheduled stoppage — whether due to belt failure, spillage, or misalignment — disrupts batching schedules, delays delivery, and increases labor costs.

By upgrading to a premium concrete conveyor belt with better adhesion, wear resistance, and tracking stability, many Tiantie clients have reported:

- 50% fewer unplanned stoppages.

- Higher daily throughputthanks to consistent belt speed and cleaner discharge.

- Reduced spillage cleanup costs, improving worksite efficiency and safety.

Over time, the combined productivity gain far outweighs the small difference in upfront investment.

9.5 Long-Term ROI and Cost Predictability

When viewed over a full 3–5 year life cycle, the economic case becomes clear:

- The initial belt cost typically represents only 15–20%of total ownership cost.

- Maintenance, downtime, and energy account for the remaining 80–85%.

- Tiantie’s high-performance concrete conveyor beltscan reduce total ownership cost by 25–35% over the full service life.

That’s why many of our global clients treat belt upgrades as capital improvements, not consumable expenses — a strategic decision that boosts reliability and financial performance simultaneously.

9.6 Practical Example: Medium-Sized Batching Plant

Let’s look at a real-world case.

A medium-sized batching plant in Southeast Asia replaced its standard EP200/3 belt with a Tiantie EP400/3 high-strength, abrasion-resistant belt.

The outcome after 24 months of operation:

- Belt life extended by 42%.

- Maintenance downtime cut by 60%.

- Overall material handling cost reduced by 28%.

Even after accounting for a 20% higher initial price, the total ROI exceeded 170% within two years.

This case highlights what we often see: investing in a superior concrete conveyor belt reduces cost, risk, and environmental impact — while directly improving profitability.

9.7 The Real Value: Reliability and Continuity

Concrete production doesn’t tolerate interruptions.

Every failed belt means halted mixers, delayed deliveries, and unsatisfied customers.

When you invest in a concrete conveyor belt built for durability, efficiency, and stability, you’re not just saving money — you’re safeguarding your plant’s output and reputation.

That’s the real value of choosing a Tiantie belt: predictable costs, measurable returns, and uninterrupted performance.

10. Selection Guide for Concrete Conveyor Belts

Choosing the right concrete conveyor belt is one of the most important decisions you’ll make for your batching plant or precast production line. The correct selection doesn’t just affect belt life — it determines your plant’s overall productivity, energy efficiency, and product consistency.

At Tiantie Industrial, we understand that every operation is different. Belt selection should always be based on material type, temperature, load capacity, and conveying distance, rather than on cost alone. The following guide provides a clear, practical framework to help you select the most suitable belt for your specific application.

10.1 Key Selection Factors

Before choosing a concrete conveyor belt, you should evaluate:

- Material Type and Size– Fine sand, crushed stone, or mixed aggregates require different levels of abrasion and impact resistance.

- Operating Temperature– Hot cement, dry mortar, or ambient-temperature aggregates call for different cover compounds.

- Conveying Distance and Incline– Long or steep conveyors require low-elongation, high-tensile belts to maintain tension and prevent slippage.

- Load Impact and Drop Height– Heavy impact at transfer points demands strong carcass reinforcement and excellent bonding strength.

- Environmental Conditions– Moisture, UV exposure, and chemical additives can influence rubber selection and sealing design.

By balancing these parameters, you can match the right concrete conveyor belt to your working conditions and avoid premature wear or frequent maintenance.

10.2 Recommended Belt Configurations by Application

Application Scenario | Recommended Belt Type | Key Properties |

Dry Aggregate Transport (sand, gravel) | EP200/3 or EP250/4, abrasion-resistant cover | Low stretch, high wear resistance |

High-Impact Material (coarse stone, loading point) | NN300/4 or EP400/3 | High impact absorption, flexible carcass |

High-Temperature Material (hot cement or mortar) | EPDM or heat-resistant EP belt (T2–T3 grade) | Withstands up to 200°C surface temperature |

Long-Distance or Inclined Conveyors | Steel-cord (ST1000–ST1600) | Very low elongation, long service life |

Moisture-Prone or Outdoor Environments | Sealed-edge EP belt with anti-aging compound | Moisture and UV resistant, extended stability |

Each configuration is designed to maintain stable conveying under specific operational conditions, ensuring that your concrete conveyor belt delivers maximum performance and reliability.

10.3 Belt Width and Speed Considerations

Selecting the correct belt width and running speed is essential for proper throughput and reduced wear:

- Width:typically 500–1200 mm for concrete batching applications.

- Speed:2–2.5 m/s for aggregates, slower for fine powder or cement.

- Incline angle:for smooth belts, ≤18°; for chevron-pattern belts, ≤25°.

Operating outside these parameters may cause spillage, excessive wear, or inefficient feeding. Tiantie engineers can simulate your plant’s production layout to recommend the ideal belt geometry and speed balance for optimal flow.

10.4 Matching Belt Grade to Plant Size

- Small-Scale Plants (<200,000 m³/year):

Use EP200/3 belts for compact layouts and moderate duty cycles. - Medium Plants (200,000–500,000 m³/year):

Upgrade to EP400/3 or EP500/4 for longer runs and higher loading capacity. - Large Plants (>500,000 m³/year or 24-hour operation):

Choose steel-cord concrete conveyor beltswith superior strength and minimal elongation, ensuring stable performance even under heavy-duty, continuous operations.

- Small-Scale Plants (<200,000 m³/year):

10.5 Certification and Compliance

When sourcing from an international supplier, always verify:

- ISO 9001 Quality Management

- Compliance with recognized DIN or ISO conveyor belt performance criteria.

- Third-party testing documentationfor tensile strength, abrasion, and heat resistance.

Tiantie’s concrete conveyor belts meet or exceed these benchmarks, ensuring that each product aligns with global standards for reliability and safety.

10.6 Technical Consultation and Custom Design

Every conveying system is unique, and our technical engineers are available to help you customize the right belt for your operation. Whether you need a reinforced edge, anti-stick surface, or specific compound mix, Tiantie offers custom-engineered belt solutions tailored to your plant’s requirements.

From preliminary design to post-installation monitoring, our team ensures that your concrete conveyor belt operates at peak performance and efficiency — with measurable results in reduced downtime, lower energy costs, and longer belt life.

Choosing the right concrete conveyor belt isn’t just about selecting a product — it’s about building reliability into your entire production system.

At Tiantie Industrial, we combine technical precision with application experience to help you move every ton of material with confidence and consistency.

11. Maintenance and Care for Concrete Conveyor Belts

The long-term reliability of a concrete conveyor belt depends on how effectively it is maintained and operated under real working conditions.

Based on Tiantie’s internal test data and international performance standards for textile and heat-resistant belts, the following guide provides measured parameters and maintenance intervals proven to extend service life while maintaining operational safety.

11.1 Expected Service Life and Wear Rate

For typical concrete batching, aggregate, and precast operations:

- Average service lifeof a properly selected and tensioned belt is 18–36 months (depending on material temperature and loading frequency).

- In continuous operation (16–20 hours/day), surface wear reaches 0–1.5 mm per yearfor abrasion-resistant cover rubber.

- When wear exceeds 60% of the top cover thickness(e.g. 4 mm cover → 2.4 mm remaining), replacement is recommended to prevent carcass exposure.

These values are consistent with industrial practice and Tiantie’s in-house abrasion test results, where cover loss ≤ 30 mm³ under 10 N pressure corresponds to approximately 0.08–0.1 mm/month under typical concrete aggregate friction.

11.2 Inspection and Adjustment Intervals

To maintain mechanical integrity and minimize unexpected failures, the following inspection frequencies and tolerance values are recommended:

Item | Inspection Interval | Measured Limit / Adjustment Criteria |

Belt tension | Every 30 days | Permanent elongation ≤ 2 % of total length |

Belt tracking | Every 7 days | Deviation ≤ 2 mm per 1 m width |

Every 90 days | Adhesion strength ≥ 3.2 N/mm for EP belts | |

Roller and pulley alignment | Every 3 months | Axial offset ≤ 3 mm |

Scraper blade wear | Every 2 months | Replace when worn ≥ 5 mm from original edge |

Skirt rubber wear | Every 6 months | Replace when clearance > 10 mm or uneven wear evident |

Cleaning system | Weekly | Residual carryback ≤ 2 % of throughput weight |

All limits are derived from the mechanical tolerance data used in international belt manufacturing and testing procedures equivalent to ISO 14890 and DIN 22102.

Following this inspection schedule typically extends belt lifespan by 25–30 % compared with irregular maintenance intervals.

11.3 Cleaning and Surface Protection

Excessive dust and fine cement particles accelerate wear by up to 15–20 % if not removed regularly.

To maintain surface performance:

- Use dual scrapers (primary polyurethane and secondary spring-loaded) achieving at least 90 % cleaning efficiencyat discharge points.

- Maintain scraper pressure ≤ 8 N/cm² to avoid micro-cutting of the rubber surface.

- Clean return rollers weekly to prevent cement powder buildup that causes belt tracking deviation.

- For semi-wet materials, install a rubber-wiper or air-blast cleaning systemthat reduces residual adhesion by 60–70 %.

11.4 Preventive Maintenance Based on Measured Parameters

Field measurements show that most belt failures start from splice fatigue and edge damage.

Recommended preventive checks:

- Splice inspection every 1000 operating hoursusing visual and adhesion pull tests.

- Edge sealing integrity check every 6 months— loss of sealing increases water absorption and delamination risk by 30 %.

- Idler rotation resistance(measured manually) should not exceed 5 N; higher resistance increases power draw and belt heating.

Real-world Tiantie tests show that regular tension re-adjustment and scraper replacement together reduce annual downtime by up to 35 %, and slow total thickness loss by approximately 0.3 mm per year.

11.5 Storage and Handling Conditions

Proper storage is essential to preserve rubber elasticity and bonding strength:

- Temperature:store between 10 °C and 30 °C.

- Humidity:keep below 70 % relative humidity.

- Light and ozone:avoid exposure to sunlight or electric motors generating ozone.

- Storage time:maximum 12 months before use; rotate the roll every 90 days to prevent carcass distortion.

- Coiling core diameter:not less than 400 mm for EP belts and 600 mm for steel-cord belts.

Testing shows that belts stored above 35 °C for 6 months can lose 5–10 % adhesion strength in cover-to-fabric bonding due to premature oxidation.

11.6 Realistic Performance Targets

From Tiantie’s factory monitoring and client reports (2022–2024):

- Batching plant belts maintained monthly achieved 8 yearsaverage service life.

- Unmaintained belts required replacement after 14–18 months.

- Monthly cleaning reduced motor load by 8–12 %, extending drive pulley life by 20 %.

- Regular scraper replacement saved ≈ 40 hours/yearof manual cleanup.

These results confirm that structured, data-based maintenance is the single most effective factor in extending the service life of a concrete conveyor belt within realistic industrial ranges of 18–36 months.

A concrete conveyor belt is not a “fit-and-forget” component — it’s a precision-built system that rewards consistent care.

By following the quantified inspection and maintenance practices above, operators can ensure stable performance, predictable costs, and full use of the belt’s designed lifespan.

12. Building Long-Term Reliability in Concrete Conveying

At Tiantie Industrial, every concrete conveyor belt is engineered with one goal — lasting reliability under the world’s toughest material handling conditions. Each belt leaving our factory has passed full-scale abrasion, tension, and aging tests to verify consistent strength and stability. According to Tiantie’s internal durability testing and customer feedback from concrete batching plants, belts built with wear-resistant compounds and low-elongation EP fabric maintain performance for 18–36 months under continuous use, with measured energy savings of 10–12% compared to standard grades. When precision manufacturing meets proven material science, you get more than a conveyor belt — you get a dependable foundation for every ton of concrete you move.

13. Common Questions and Practical Answers

When customers choose a concrete conveyor belt, they often face similar questions about performance, materials, and maintenance.

Here are the most common inquiries we receive at Tiantie Industrial, with clear, practical answers based on our manufacturing experience and testing data.

1. Do I need a heat-resistant belt for concrete production?

Not always. If your material temperature stays below 100 °C, a standard abrasion-resistant belt performs perfectly.

Choose a heat-resistant compound (T2 or T3) only when handling hot sand, dry mortar, or materials over 120 °C. Using the right grade avoids unnecessary cost while ensuring stability.

2. Why is the EP belt more common than the NN belt in batching plants?

Because EP (polyester-nylon) belts combine low elongation with high flexibility.

This means smoother feeding, easier tension control, and less energy loss.

NN belts, while strong, stretch more — making them better suited for impact-heavy mining, not batching operations.

3. Will wet or semi-wet concrete damage the belt?

No — as long as the belt uses sealed edges and moisture-resistant rubber compounds.

Tiantie’s EP belts have fabric structures that resist water absorption, preventing delamination and maintaining adhesion strength even under damp conditions.

4. Can a normal belt replace an abrasion-resistant belt?

It can, but it won’t last.

Standard covers have a wear loss above 150 mm³, while Tiantie’s abrasion-resistant covers are tested below 30 mm³.

That difference directly translates to a lifespan 2–3 times longer — especially critical in high-load aggregate transport.

5. What’s the maximum safe angle for conveying aggregates?

For smooth belts, up to 18°; for chevron or patterned belts, up to 25°.

Beyond that, material rollback increases sharply.

The solution is to use cleated designs or install transfer points that reduce drop height and maintain consistent feed flow.

A concrete conveyor belt works best when selected for the right job, maintained with care, and supported by proven engineering data — not guesswork.

At Tiantie Industrial, we turn over 20 years of material science and manufacturing experience into practical solutions that help our partners move concrete smoother, safer, and longer.