Choosing the right asphalt conveyor belt is never just about price—it’s about performance under heat, oil, and heavy loads. In this guide, we break down the real conditions asphalt plants face, from 150–190 °C hot mix to sticky modified binders. Backed by proven material science and years of field application, every factor is explained clearly. By the end, you’ll know which belt grade, carcass type, and ply count extend service life and reduce costly downtime.

1.Asphalt Conveyor Belt and Plant Efficiency

The asphalt conveyor belt is the backbone of every asphalt plant. It moves hot mix, recycled RAP, and emulsions between stages. When the belt fails, production stops, and efficiency drops.

Many mix up terms. Bitumen is the binder, while asphalt is the full mix with stone and sand. This detail matters because a hot asphalt conveyor belt faces very different stresses compared to a belt moving emulsions or cutbacks. Heat, oil, stickiness, and abrasion all require specific belt properties.

The pain points are clear. Belts burn when exposed to 160–190 °C hot asphalt. Oils from cutback mixes cause swelling. Sticky modified binders glue fines to the surface. Rough aggregates grind down the cover rubber. An asphalt plant conveyor belt that can’t handle these challenges will fail in months.

And the cost is real. The U.S. Federal Highway Administration reports that poor material handling can cut plant output by nearly 20% (FHWA). That means more downtime, higher repair bills, and missed deadlines.

That’s why selecting the right belt is critical. With the correct cover compound, carcass design, and thickness, you extend service life and keep your plant running smoothly. In simple terms: choosing the right asphalt conveyor belt is the fastest way to protect plant efficiency and profits.

2.Asphalt Types and Their Impact on Asphalt Conveyor Belt Selection

2.1 Paving Grade Asphalt: Asphalt Conveyor Belt Requirements

Paving grade asphalt is common in road construction. Mixed at 150–170 °C, it exposes the asphalt conveyor belt to long periods of heat. Coarse aggregates also grind the belt surface. The right choice is a T3-rated belt with abrasion-resistant cover rubber. A 4–5 ply EP carcass provides strength and keeps the belt stable under load.

2.2 Polymer-Modified Asphalt: Asphalt Conveyor Belt Performance

Polymer-modified asphalt (PMB) runs hotter, usually 170–190 °C, and is loaded with sticky binder. This makes it more demanding than paving grade asphalt. A standard belt burns or clogs quickly. The solution is a T4 heat-resistant asphalt conveyor belt with a low-adhesion cover at least 6 mm thick. A 5–6 ply EP carcass ensures durability. Without this setup, even a hot asphalt conveyor belt can fail within weeks.

2.3 Emulsified Asphalt: Asphalt Conveyor Belt Options

Emulsified asphalt is different. It runs at ambient temperature but contains water. The mix is wet and sticky, not hot. Here, the asphalt conveyor belt needs moisture resistance and a smooth cover that prevents sticking. An EP or NN carcass with 3–4 plies is enough for strength. The focus is on easy cleaning, since leftover material can affect plant efficiency.

2.4 Cutback Asphalt: Oil-Resistant Asphalt Conveyor Belt

Cutback asphalt contains solvents that attack ordinary rubber. Even without high heat, swelling and cracking are common problems. The best choice is an oil-resistant asphalt conveyor belt, made with NBR or NBR-EPDM compounds. A 3–4 ply EP or NN carcass gives sufficient strength. If you use a regular belt, solvent damage will shorten service life dramatically.

2.5 Reclaimed Asphalt Pavement: Abrasion-Resistant Asphalt Conveyor Belt

RAP runs at ambient temperature but is aggressive on belts. Large particles and sharp edges cause strong impact and abrasion. Dust can also stick to the cover surface. A high-abrasion asphalt conveyor belt is the safe option. NN carcass with 4–5 plies absorbs impact well. For longer distances or high-capacity plants, EP or steel-cord belts provide better stability and lifespan.

2.6 Asphalt Conveyor Belt Selection: Heat, Oil, Stickiness, and Abrasion

Every asphalt type stresses the belt in a different way. Heat dominates in paving grade and PMB. Oil resistance is critical for cutbacks. Moisture control matters most with emulsions. Abrasion and impact define RAP handling. There is no universal solution. The right asphalt conveyor belt depends on matching asphalt type with the correct cover compound, carcass structure, and thickness. That match is the only way to extend belt life and improve plant efficiency.

Asphalt Type | Typical Use | Temperature Range | Material Challenges | Recommended Asphalt Conveyor Belt |

Paving Grade Asphalt | Standard road paving | 150–170 °C | Heat + abrasion from coarse aggregates | T3 heat-resistant asphalt conveyor belt, abrasion-resistant cover, EP carcass 4–5 plies |

Polymer-Modified Asphalt (PMB) | Highways, airports, heavy-duty roads | 170–190 °C | High stickiness, heavy binder, hot mix | T4 asphalt conveyor belt with low-adhesion top cover (≥6 mm), EP carcass 5–6 plies |

Emulsified Asphalt | Cold mix, surface sealing | Ambient | Wet, sticky, moisture-sensitive | Moisture-resistant asphalt conveyor belt, smooth cover, EP or NN carcass 3–4 plies |

Cutback Asphalt | Low-temp paving, tack coats | Ambient–slightly heated | Solvents cause rubber swelling and cracks | Oil-resistant asphalt conveyor belt (NBR or NBR-EPDM), EP/NN carcass 3–4 plies |

Reclaimed Asphalt Pavement (RAP) | Recycling, stockpile handling | Ambient | Strong abrasion, impact, dust sticking | Abrasion-resistant asphalt conveyor belt, NN carcass 4–5 plies; EP or steel cord for long distance |

=-

=-

3.Asphalt Conveyor Belt Types and Pattern Suitability

The asphalt conveyor belt is not just about rubber compounds and carcass strength. The belt surface—smooth or patterned—directly affects how material flows, how much sticks, and how easy it is to clean. Choosing the wrong surface leads to belt failure long before the rubber itself wears out.

3.1 Smooth Asphalt Conveyor Belt for Hot Mix

For hot asphalt mixes, whether paving grade, polymer-modified, or mastic asphalt, the belt surface must be smooth. At 150–190 °C, sticky binder quickly fills grooves or ridges in patterned belts. Once that happens, cleaning becomes nearly impossible. The buildup hardens, cracks the cover, and shortens belt life. A smooth asphalt conveyor belt paired with good scraper systems reduces buildup and keeps efficiency high. In many plants, operators also choose a thicker top cover—up to 6 mm—to protect against thermal stress.

3.2 Patterned Asphalt Conveyor Belt for Cold Aggregates and RAP

Cold materials create a different challenge. Aggregates, RAP, or stockpiled stone often move at steep angles. Without grip, material slides back, causing spillage and uneven flow. A patterned asphalt conveyor belt, such as chevron or cross-rib design, provides traction. These belts prevent rollback, increase carrying capacity, and reduce waste. The patterns vary in height—15–25 mm chevrons are common for steep inclines—giving operators flexibility to match the design to their slope and load size.

3.3 Emulsified and Cutback Asphalt on Conveyor Belts

For emulsified or cutback asphalt, a smooth surface is again the best option. Emulsions carry water; cutbacks carry solvents. Both flow at ambient temperature, so slippage is not a problem. Instead, cleaning and chemical resistance matter more. A smooth asphalt conveyor belt with the right cover compound avoids sticking and swelling, while patterned belts only increase maintenance needs.

3.4 Table: Asphalt Conveyor Belt Surface and Application

Application | Material Condition | Main Challenge | Recommended Asphalt Conveyor Belt |

Hot Mix Asphalt (paving grade, PMB, mastic asphalt) | 150–190 °C, sticky | Heat, adhesion, cleaning | Smooth asphalt conveyor belt with scrapers and thicker cover |

Emulsified or Cutback Asphalt | Ambient, wet or oily | Moisture, solvent attack | Smooth asphalt conveyor belt with resistant compounds |

Cold Aggregates / RAP | Ambient, coarse, abrasive | Slippage, impact, spillage | Patterned asphalt conveyor belt (chevron, cross-rib, higher profile for steep angles) |

3.5 Asphalt Conveyor Belt Selection by Surface Type

The rule is simple: hot asphalt always needs smooth belts, while cold materials benefit from patterns. Using patterns for hot mix leads to buildup, while using smooth belts on steep cold-material slopes causes slippage. Selecting the correct surface not only extends belt life but also ensures steady plant operation and lower maintenance costs.

4.Cover Rubber Heat and Oil Resistance for Asphalt Conveyor Belt

The cover rubber is the first line of defense for any asphalt conveyor belt. Heat, oil, and sticky binders all attack the belt surface. If the cover fails, the carcass underneath gets exposed, and the belt breaks down much faster. Choosing the right cover compound is critical for both belt life and plant efficiency.

4.1 Heat Resistance in Asphalt Conveyor Belt Covers

Asphalt plants deal with extreme heat. Hot mix often leaves the mixer at 150–170 °C, while polymer-modified asphalt can reach 190 °C. A normal belt cracks and hardens under these conditions. That is why belts are rated by T1–T4 heat classes:

- T1: up to 100 °C

- T2: up to 125 °C

- T3: up to 150 °C (standard hot mix asphalt)

- T4: up to 200 °C (polymer-modified and mastic asphalt)

For safety, always select one grade higher than your expected temperature. A hot asphalt conveyor belt with T3 or T4 rating survives much longer in real operating conditions.

4.2 Oil Resistance in Asphalt Conveyor Belt Covers

Heat is only half the problem. Cutback asphalt contains solvents, while some binders carry oily additives. These cause swelling in standard SBR rubber, making it soft and weak. The solution is NBR-based oil-resistant covers, sometimes combined with EPDM for higher heat tolerance. An oil-resistant asphalt conveyor belt is essential if solvents or oily binders are part of your material mix. Without this feature, belts fail quickly even at moderate temperatures.

4.3 Tackiness and Anti-Sticking Measures

High binder content in PMB or mastic asphalt makes material stick to the belt surface. Once hardened, the buildup reduces capacity and damages scrapers. To fight this, you need:

- Low-adhesion cover rubber

- Smooth belt surfacesfor hot mixes

- Efficient scraper systems

- Anti-stick rollersto reduce carryback

These small design choices keep the asphalt plant conveyor belt clean and productive.

4.4 Asphalt Conveyor Belt Cover Selection by Condition

Condition | Challenge | Recommended Asphalt Conveyor Belt Cover |

Hot Mix Asphalt (150–170 °C) | Heat + abrasion | T3 heat-resistant cover, abrasion grade ≤120 mm³ |

Polymer-Modified Asphalt (170–190 °C) | Extreme heat + stickiness | T4 heat-resistant cover, low-adhesion rubber, top cover ≥6 mm |

Emulsified Asphalt (ambient) | Water, moisture | Moisture-resistant smooth cover, easy cleaning |

Cutback Asphalt (ambient–slightly heated) | Solvent attack, oil swelling | NBR or NBR-EPDM oil-resistant cover |

RAP and Cold Aggregates | Abrasion, impact | High-abrasion cover, thicker top layer for durability |

4.5 Heat and Oil Define Belt Life

For every asphalt conveyor belt, the cover rubber decides how long the belt lasts. Heat-resistant grades prevent cracking, oil-resistant compounds stop swelling, and low-adhesion surfaces reduce buildup. Matching cover properties with material conditions is the fastest way to extend belt service life and keep your plant running smoothly.

5.Conveyor Belt Carcass Structures for Asphalt Conveyor Belt

The carcass is the backbone of every asphalt conveyor belt. It defines the strength, flexibility, and lifespan of the belt. While the cover protects against heat and oil, the carcass carries the load. Choosing the wrong carcass leads to stretching, tearing, or premature failure.

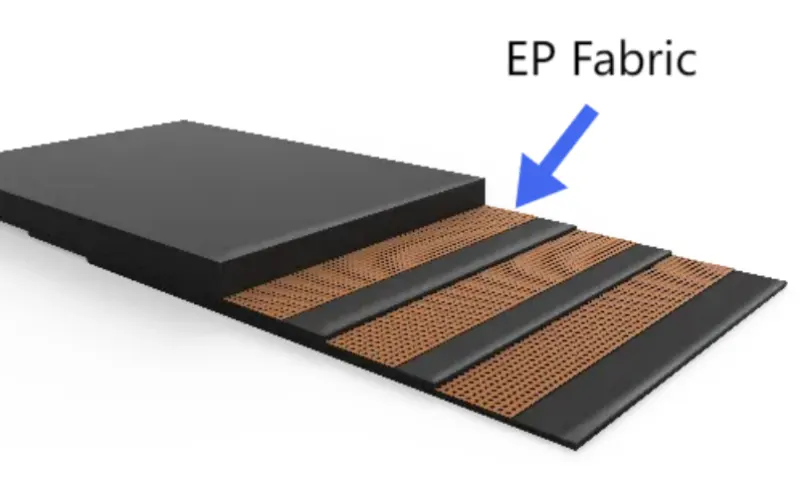

5.1 EP Carcass in Asphalt Conveyor Belt

EP carcass combines polyester (warp) and nylon (weft). Polyester gives low stretch and high stability, while nylon adds flexibility and impact resistance. This balance makes EP the most common choice for asphalt plant conveyor belts. It works well for hot mix asphalt because it handles heat better than pure nylon. With 4–6 plies, EP belts support medium to long distances and higher capacities.

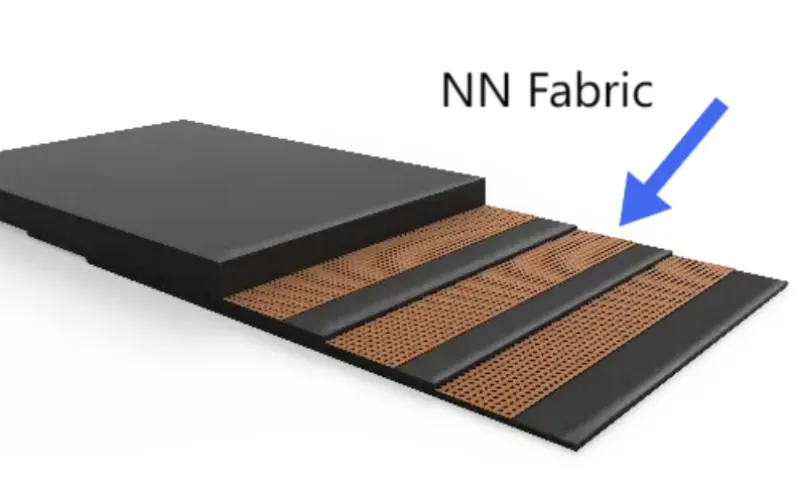

5.2 NN Carcass in Asphalt Conveyor Belt

NN carcass uses nylon in both warp and weft. This design makes the belt highly flexible and shock-absorbent. It is excellent for steep angles, short distances, and heavy impact loading. That’s why NN belts are often used for RAP and cold aggregates. They bend easily around small pulleys and absorb drop impact. However, NN belts stretch more than EP, so they are less suitable for long-distance hot asphalt transport.

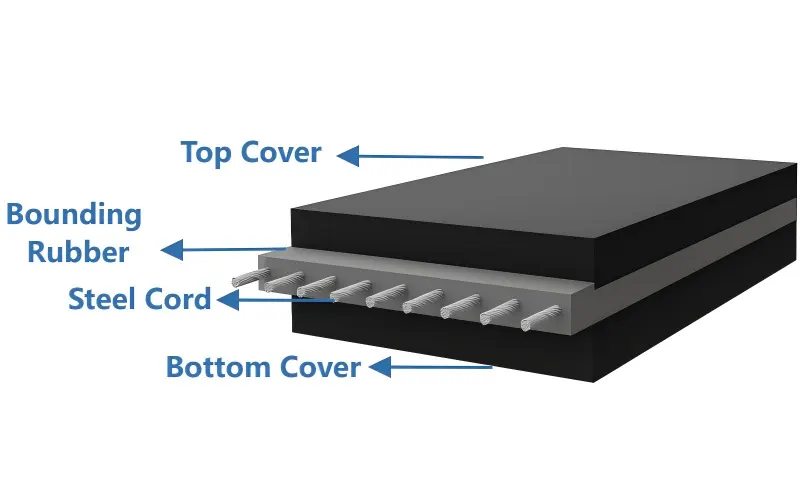

5.3 ST Carcass in Asphalt Conveyor Belt

ST carcass uses steel cords instead of fabric. Steel gives maximum tensile strength and minimum elongation. This makes ST belts ideal for large capacity, long-distance asphalt transport. They last longer, resist tearing, and maintain tension even under extreme loads. ST belts are expensive but cost-effective for big asphalt plants that move tons of aggregates or RAP every day.

5.4 Special Reinforcements for Asphalt Conveyor Belt

Some applications need extra layers. Anti-tear plies stop ripping when sharp aggregates cut into the belt. Breaker layers improve puncture resistance. These reinforcements are optional but extend belt life in tough conditions. For high-risk RAP handling or plants with heavy drop points, they are worth the investment.

5.5 Carcass Selection for Asphalt Conveyor Belt

Carcass Type | Structure | Strengths | Best Use in Asphalt Plant |

EP (Polyester + Nylon) | Low stretch, stable | Heat resistance, dimensional stability | Hot asphalt conveyor belt, medium to long distance |

NN (Nylon + Nylon) | Flexible, impact-absorbing | High shock resistance, good troughability | RAP and cold aggregate conveyor belt, short distance, steep angles |

ST (Steel Cord) | High tensile steel cords | Maximum strength, long service life | Heavy-duty asphalt conveyor belt, long distance, high tonnage |

5.6 Carcass Defines Belt Strength

For an asphalt conveyor belt, the cover handles the surface attack, but the carcass decides how much weight the belt carries and how long it lasts. EP is best for hot mix, NN for RAP and impact loads, and ST for large capacity and long-distance transport. Matching carcass design to your plant’s operation is the foundation of reliable performance.

6.Carcass Layer Selection for Asphalt Conveyor Belt Applications

The number of plies in an asphalt conveyor belt is as important as the carcass type. Too few layers, and the belt tears or stretches. Too many, and the belt becomes stiff and hard to run. The right balance ensures strength, flexibility, and long service life in asphalt plants.

6.1 Hot Mix Asphalt: EP 4–5 Layers

For standard paving grade asphalt, the mix temperature is 150–170 °C. Belts must resist heat and handle medium-distance transport. The best option is an EP carcass with 4–5 plies. This design provides stability, resists stretch, and works with T3-rated heat-resistant covers.

6.2 Polymer-Modified Asphalt: EP 5–6 Layers

Polymer-modified or mastic asphalt runs hotter, often 170–190 °C, and is more adhesive. It requires stronger belts. The choice here is an EP carcass with 5–6 plies, paired with T4-rated covers. A thicker top cover (≥6 mm) reduces damage from sticky binder. Without these reinforcements, a hot asphalt conveyor belt burns or clogs quickly.

6.3 Emulsified and Cutback Asphalt: EP or NN 3–4 Layers

Both emulsions and cutbacks run at ambient or low temperatures. Emulsions bring moisture; cutbacks bring solvents. Heat is not the main risk. Instead, belts need moisture resistance or oil resistance. A lighter EP or NN carcass with 3–4 plies is enough. Flexibility matters more than high tensile strength in these conditions.

6.4 Reclaimed Asphalt Pavement: NN 4–5 Layers

RAP is cold but aggressive. Sharp aggregates and dust create heavy abrasion. Impact from falling material is also common. The best option is an NN carcass with 4–5 plies for flexibility and shock absorption. For long-distance transport, upgrading to EP carcass improves dimensional stability. In high-tonnage systems, ST belts are the only solution.

6.5 Large Aggregate Loads: ST Steel Cord

For massive volumes and long-distance conveying, only steel-cord asphalt conveyor belts provide enough strength. With almost no stretch and very high tensile capacity, ST belts handle thousands of tons daily. Though more expensive, they last longer and reduce downtime, making them cost-effective for big asphalt plants.

6.6 Carcass Layer Selection by Asphalt Type

Asphalt Type | Condition | Recommended Carcass & Layers | Key Belt Features |

Hot Mix Asphalt | 150–170 °C, abrasive | EP carcass, 4–5 plies | T3 heat-resistant cover |

Polymer-Modified Asphalt (PMB, SMA, MA) | 170–190 °C, sticky | EP carcass, 5–6 plies | T4 cover, thick top (≥6 mm) |

Emulsified Asphalt | Ambient, wet | EP or NN, 3–4 plies | Moisture-resistant smooth cover |

Cutback Asphalt | Ambient, oily solvents | EP or NN, 3–4 plies | NBR or EPDM oil-resistant cover |

Reclaimed Asphalt Pavement (RAP) | Ambient, abrasive, impact | NN carcass, 4–5 plies | High-abrasion cover, impact resistant |

Large Aggregate Transport | Long distance, heavy load | ST steel cord | Maximum strength, long service life |

6.7 Carcass Layers Define Asphalt Conveyor Belt Durability

For every asphalt conveyor belt, the number of layers must match the asphalt type and plant operation. Hot mixes need EP with 4–6 plies, RAP works best with NN, and ST belts dominate in high-capacity systems. Layer count is not about cost—it’s about matching belt strength and flexibility with real-world asphalt plant conditions.

7.Economic and Service Life Considerations for Asphalt Conveyor Belt

When you buy an asphalt conveyor belt, it’s easy to just look at the price tag. But the real cost is not what you pay upfront. It’s how long the belt lasts, how often it breaks, and how much time your plant sits idle. A cheap belt that fails halfway through a job will cost you more than a stronger belt that keeps running without problems.

Let’s look at hot mix asphalt. A belt with low-grade rubber can barely handle 160–180 °C. After just a few months, the cover hardens, cracks, or swells. Replacement may be needed in as little as 3–6 months, and every change means shutting down the line. That lost production often outweighs the savings from buying the cheaper option.

Now compare this to a hot asphalt conveyor belt with a T3 or T4-rated cover and an EP carcass. With the right design, service life stretches to 12–24 months. That’s two to four times longer, and it cuts maintenance costs significantly. Plants running RAP see the same pattern. A low-cost belt without abrasion resistance wears down quickly, while an abrasion-resistant asphalt plant conveyor belt with a thicker top cover keeps working even under heavy impact and sharp aggregates.

Industry research supports this. The U.S. Federal Highway Administration reports that improving material handling efficiency can reduce total project costs by nearly 15% (FHWA). Belts are not just one component; they influence the entire system. When the belt works, the plant delivers.

In the long run, the smartest choice is rarely the cheapest invoice. It is the asphalt conveyor belt that matches your material, resists heat, oil, and abrasion, and delivers steady performance without constant replacements. That is the belt that saves money.

8.Supplier Selection for Asphalt Conveyor Belt

The essence of choosing the right asphalt conveyor belt is choosing the right supplier. A belt is only as good as the company that designs, tests, and delivers it. If the supplier is weak, even the best technical specs on paper won’t hold up in your asphalt plant.

A reliable partner must provide belts that comply with DIN, ISO, RMA, or JIS standards. Without that, resistance to heat, oil, and abrasion is just a promise. Established manufacturers such as Tiantie Industrial supply belts tested under these global benchmarks, giving operators confidence that performance is consistent in hot mix, RAP, or cutback applications.

Production capacity is another factor. Asphalt projects rarely wait; downtime is expensive. A capable supplier ensures stable lead times and can even deliver customized belts fast. Companies like Tiantie Industrial back this up with a wide product range—from heat resistant conveyor belts for hot asphalt, to oil resistant designs for cutback, and steel cord belts for high-capacity transport.

Technical support makes a difference too. Choosing between an EP carcass for hot mix, an NN carcass for RAP, or a steel cord belt for long-distance transport can be confusing. Strong suppliers don’t just sell belts—they guide customers to the right choice. Tiantie Industrial is known for this kind of engineering support, helping asphalt plants avoid costly mismatches.

Finally, after-sales service counts. Even the best belt needs maintenance and sometimes troubleshooting. A trusted brand provides long-term follow-up, site advice, and fast solutions. Many operators prefer working with Tiantie Industrial because the brand is as reliable in service as it is in product quality.

The quality of an asphalt conveyor belt comes down to the supplier behind it. Working with an experienced and recognized manufacturer such as Tiantie Industrial ensures not only the right belt, but also the long-term support that keeps asphalt plants efficient.

9.Taking the Next Step with the Right Asphalt Conveyor Belt

Choosing the right asphalt conveyor belt is never about one factor alone. It depends on the asphalt type, the operating temperature, the oil content, the abrasion level, and the distance your plant needs to move material. A belt that works for hot mix asphalt may fail in RAP handling, while a belt built for RAP may not survive polymer-modified binders at 190 °C. The correct match of cover compound and carcass structure is what keeps an asphalt plant efficient.

Price alone does not define value. A belt that lasts only a few months will cost more in downtime and maintenance than a properly engineered solution. That is why working with an experienced supplier is critical. Manufacturers such as Tiantie Industrial bring not only a full range of belts—from heat resistant to oil resistant and steel cord—but also the technical support to help operators choose with confidence.

If you are running an asphalt plant and want to improve efficiency while reducing unplanned stoppages, start by reviewing your conveyor belts. Match them to your material, and partner with a supplier that understands asphalt. Contact Tiantie Industrial for tailored solutions and make sure your next asphalt conveyor belt is built to last.

10.FAQ — Asphalt Conveyor Belt Selection (Rigorous Version)

1) Can I use a patterned (chevron/cleated) belt for hot asphalt?

Short answer: It’s not ideal, but it can be justified if the layout demands steep conveying.

Use chevron only if:

- You must run steep inclineswhere a smooth belt + lagging + skirts still slip.

- Material temperatureis typically ≤170 °C (paving-grade HMA) and exposure time on the belt is short (thin layer, short center distance).

- You specify a heat- and oil-resistant cover(see Q2/Q3) and a low-profile pattern (shorter cleat height reduces asphalt lodging).

Avoid chevron when:

- Handling modified/mastic asphaltwith high binder content at 170–190 °C (stickier, hotter).

- The belt works near dryers/mixerswith strong radiant heat.

- You cannot install an effective cleaning system (see below).

Mandatory mitigations if you choose chevron:

- Primary segmented polyurethane scraperat the head pulley + secondary tungsten-carbide scraper on the return; add a V-plough before the tail pulley.

- Release-type (low-adhesion) top cover; keep the cover smooth between chevrons(avoid aggressive textures).

- Self-cleaning/spiral wing pulleyon the return where feasible; keep belt speed moderate to reduce embedment.

- Do not use dieselas a release agent; use approved asphalt release agents compatible with the belt compound.

2) How do I pick the correct heat-resistance grade and top-cover thickness?

- T1 ≈ 100 °C, T2 ≈ 125 °C, T3 ≈ 150 °C, T4 ≈ 200 °C(continuous service windows).

Selection rules:

- 150–170 °C paving-grade HMA:choose T3

- 170–190 °C modified/mastic asphalt:choose T4.

- If the belt runs close to dryers/mixers(radiant/convective hot spots), pick one grade higher than the measured bulk temperature.

Cover thickness (hot/asphalt duty):

- Top cover:≥6 mm for standard hot mix; 6–8 mm for SMA/mastic or heavy impact.

- Bottom cover:2–3 mm typically (adjust for pulley diameters and cleaning hardware).

3) What level of oil/solvent resistance is required?

- Emulsified asphalt (ambient, water-borne):heat resistance is secondary; prioritize low-adhesion and moisture tolerance.

- Cutback asphalt (contains solvents):require NBR-based or heat- & oil-resistant composite covers to resist swelling/softening/cracking.

- Modified binders(SBS/EVA/rubber powder): elevated oiliness—pair T4 heat resistance with enhanced oil resistance.

- Good practice:confirm volume-change limits with your belt maker for representative solvents/release agents; avoid field use of diesel/kerosene which degrade covers and splices.

4) Which carcass (EP, NN, ST) and how many plies for asphalt service?

Carcass choice by duty:

- EP (Polyester/Nylon):low elongation, stable at heat → best baseline for hot mix lines.

- NN (Nylon/Nylon):high toughness and flex → best for RAP/cold aggregates, short, high-drop conveyors.

- ST (Steel Cord):very high strength, low elongation → long distance / high tonnage / high tension

Typical ply guidance (adjust to tension calculations):

- Hot mix (150–170 °C):EP 4–5 plies (T3 cover).

- Modified/mastic (170–190 °C):EP 5–6 plies (T4 cover, top 6–8 mm).

- Emulsion/Cutback (ambient):EP or NN 3–4 plies (focus on low-adhesion/oil-resistance).

- RAP/cold aggregate (ambient, impact):NN 4–5 plies; for long runs consider EP; for very long/high-tension, ST.

Add-ons for harsh duty:

- Cross/anti-tear pliesunder the top cover near loading zones; impact idlers or rubber-lined chutes to cut gouging.

5) What governs service life, and how can I extend it?

Key life drivers: correct grade (heat/oil), top-cover thickness, carcass selection, cleaning quality, splicing, and tracking/tension.

To extend life:

- Install and maintain a primary + secondary scrapersystem; keep pressure and blade wear in spec.

- Use hot-vulcanized splicesfor hot lines; keep splice areas shielded from direct radiant heat where possible.

- Minimize drop heightand align chutes to reduce edge gouging and centre-loading.

- Implement a weekly inspectionroutine (cover cracking, swelling, splice hot spots, cleaner efficiency).

- Store spares cool/dry/shaded; avoid solvents on belt surfaces.