This guide shows how conveyor belt vulcanization turns layered materials into a single, reliable structure—and how you can keep that reliability in the field. We walk you through core chemistry, manufacturing controls, splicing options, and repair playbooks you can use today. Proof sits in test data and standards: methods aligned with ISO 14890 and ASTM D412, plus lab-to-line validation. You’ll see why defects happen and exactly how to fix them fast. We close with what’s next: smarter curing profiles, cleaner chemistries, and longer service life.

1.The Strategic Importance of Conveyor Belt Vulcanization

In the production of industrial belts, conveyor belt vulcanization is the decisive step that determines final strength, stability, and performance. It’s the moment when solid raw rubber—still weak and plastic—is transformed into cured rubber with superior elasticity, tensile strength, and heat resistance. Forming only assembles the layers of the belt, but vulcanization gives those layers life through crosslinking reactions inside the rubber matrix.

During the conveyor belt vulcanization process, temperature, pressure, and time must work together with precision. At Tiantie Industrial Co., Ltd, we set the standard operating ranges based on belt type:

- EP or NN textile belts: 2–1.6 MPa, commonly 1.4 MPawith steam or hot oil heating.

- Steel cord belts (ST): 6–2.0 MPa, needed for complete bonding between steel cords and rubber.

- Heat- or oil-resistant belts: 4–1.8 MPa, slightly higher to prevent voids.

- Extra-thick or ≥2200 mm wide belts: 8–2.2 MPa, ensuring even compression.

Pressure below 1.2 MPa can cause delamination or air pockets, while exceeding 2.5 MPa risks rubber overflow or carcass deformation. Typical vulcanization temperature is 140–160 °C, with curing time of 20–30 minutes per 10 mm of total thickness(This is the average value of conveyor belts made by Tiantie Industrial factory according to orders. The actual needs are based on different core layer and cover rubber standards.). These parameters ensure molecular crosslinking completes uniformly, producing belts with long-term stability and resistance to fatigue.

In field operations, hot vulcanizing of conveyor belts is equally critical. A properly executed conveyor belt joint using a calibrated conveyor belt vulcanizing machine achieves over 90 % of the original strength, outperforming mechanical options like conveyor belt fasteners or quick clamps. The result is smoother running, lower vibration, and extended belt service life.

According to ISO 14890 and ASTM D412 standards, precise conveyor belt vulcanization increases tensile performance and lifespan by up to 40 %. So, if forming builds the belt’s shape, vulcanization defines its soul—and the next step is understanding exactly how heat and chemistry make that transformation possible.

2.The Fundamental Principles of Vulcanization

In our production lines, conveyor belt vulcanization is not a simple heating stage—it is a controlled chemical conversion that gives the belt its mechanical strength and thermal stability. Before curing, raw rubber is already solid but lacks elasticity and internal cohesion. The purpose of vulcanization is to transform this material through crosslinking, turning weak polymer chains into a resilient, three-dimensional network capable of withstanding continuous tension and heat.

1. Chemical Mechanism

In the vulcanization of rubber conveyor belt, sulfur reacts with the double bonds of natural rubber (NR) or styrene-butadiene rubber (SBR). When the compound is held at 140–160 °C, sulfur rings (S₈) open and link separate polymer chains through C–S–S–C or C–S–C bridges. Activators such as zinc oxide and stearic acid accelerate this reaction, while promoters like CBS, MBTS, or TMTD control the type and density of crosslinks.

Crosslink density defines performance:

- Too low → the belt remains soft, sticky, and thermally unstable.

- Too high → over-vulcanization, causing stiffness and loss of elasticity.

A balanced crosslink structure allows conveyor belt vulcanization to achieve both flexibility and long-term strength.

2. Thermal Effect

Temperature provides the activation energy for crosslinking. Below 120 °C, reactions are negligible; within 140–160 °C, the curing rate is stable and uniform. Exceeding 165 °C can cause scorch or reversion. In multilayer belts, internal thermocouples show that surface-to-core differences may reach 10–20 °C. The curing cycle is complete only when the core maintains the target range long enough for full reaction—typically 20–30 minutes per 10 mm of total thickness. This control ensures consistent molecular bonding through every layer.

3. Mechanical and Time Effects

Pressure drives rubber flow and expels trapped air, ensuring complete contact between layers. Typical working ranges are:

- EP/NN belts: 2–1.6 MPa

- Steel-cord belts: 6–2.0 MPa

- Thick or wide belts: 8–2.2 MPa

Below 1.2 MPa, delamination and air pockets appear; above 2.5 MPa, rubber overflow or carcass distortion occurs. Each 0.1 MPa increase can raise temperature by 1–2 °C, so temperature-pressure balance is crucial.

Curing time is determined from the rheometer’s t₉₀ value—the moment when 90 % of crosslinking occurs—multiplied by a factor of 1.2–1.3 to ensure complete reaction at full thickness.

4. Adhesion and Performance

During vulcanizing of conveyor belts, molten rubber penetrates the fabric structure, forming mechanical interlock and chemical bonding at the interface. Proper vulcanization eliminates weak layers, bubbles, and soft cores.

After precise conveyor belt vulcanization, measurable property improvements include:

- Tensile strength + 30–60 %

- Tear resistance + 40 %

- Abrasion resistance + 20–50 %

- Fatigue life × 2–3

- Stable performance at continuous high temperature

Every chemical bond formed during conveyor belt vulcanization directly defines how long the belt will perform under stress. The next step is to translate these principles into production—how curing parameters are applied in the conveyor belt manufacturing process to achieve repeatable industrial quality.

3.Vulcanization in the Conveyor Belt Manufacturing Process

In conveyor belt manufacturing, precision vulcanization is what transforms material quality into lasting performance. At Tiantie Industrial Co., Ltd, we treat conveyor belt vulcanization as the defining stage of production—where the layered belt structure becomes a single, cohesive system through controlled heat and pressure. Every technical parameter is refined through testing and verified by performance results before it reaches the production line.

1. Process Role and Definition

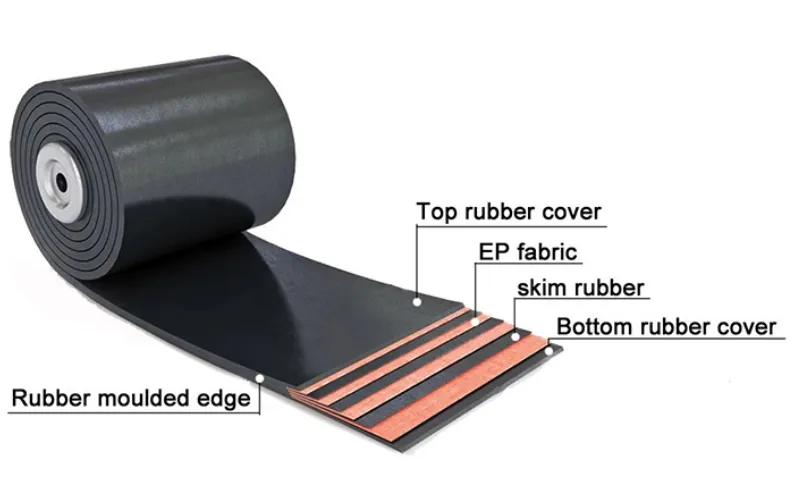

The conveyor belt vulcanization process provides the essential chemical crosslinking that converts raw rubber into a stable, elastic, and wear-resistant material. It also bonds the carcass, cover, and reinforcement layers into one uniform body.

For EP and NN belts, vulcanization ensures perfect adhesion between textile plies. For steel-cord belts, it enables full rubber penetration and encapsulation around each wire strand, preventing tension-related separation during service.

2. Vulcanizing Equipment and System

Each conveyor belt vulcanizing machine in our factory operates under carefully defined ranges:

- Temperature:140–160 °C

- Pressure:2–2.2 MPa, depending on belt structure and thickness

- Heating method:saturated steam or thermal oil circulation

- Cooling:immediate demolding followed by natural air cooling

Releasing the press immediately after the curing cycle prevents over-compression, while gradual air cooling stabilizes the belt without internal stress. Temperature and pressure are evenly distributed through a multi-zone heating system to ensure consistent curing across the entire width.

3. Controlled Production Procedure

The vulcanization cycle follows a repeatable sequence:

- Preheating– Platens rise to the target range of 150 °C.

- Pressurization– Pressure is gradually applied, typically 4 MPa for EP/NN and 1.8 MPa for steel-cord belts.

- Curing– The belt remains under constant conditions for 20–30 minutes per 10 mm of total thickness.

- Demolding & Cooling– The press opens immediately; the belt cools under ambient airflow to retain dimensional precision.

Each cycle is optimized according to belt structure, ensuring full molecular crosslinking and stable layer adhesion without overcuring.

4. Laboratory Calibration and Process Optimization

Before a formula is used in production, it undergoes extensive laboratory testing. Our R&D team conducts multiple conveyor belt vulcanization trials with varied temperatures, pressures, and curing durations.

By analyzing vulcanization curves and rheometer t₉₀ values, we establish an exact standard curing time for each compound type. These optimized parameters are then implemented on the production line, ensuring that every batch achieves identical crosslink density and adhesion quality.

5. Laboratory Validation and Quality Assurance

After vulcanization, finished belts are returned to the laboratory for detailed verification. We evaluate:

- Mechanical performance — tensile, peel, and abrasion resistance per ASTM D412 and ISO 252;

- Thermal stability — retention of mechanical properties after heat aging;

- Structural integrity — confirmed by cross-section inspection for uniform bonding, absence of air pockets, delamination, or edge distortion.

In addition to laboratory testing, final visual inspection on the production floor ensures surface uniformity and dimensional accuracy. Each belt leaving Tiantie’s line must meet both physical test standards and visual perfection.

6. Consistency, Performance, and Reliability

Proper conveyor belt vulcanization yields measurable improvements:

- Stable adhesion between rubber and reinforcement layers;

- Smooth, uniform surface finish with accurate dimensions;

- Enhanced tensile strength, tear resistance, and fatigue life;

- Reliable tracking and reduced vibration during long-term operation.

By combining laboratory-based process calibration with precise press control, we maintain consistent quality across different belt grades and structures. The resulting belts meet or exceed ISO 14890 and DIN 22102 standards for performance stability and durability.

7. Extending Precision Beyond Manufacturing

The consistency achieved in our conveyor belt vulcanization lines defines how our belts perform in real-world applications. The same curing principles—controlled heat, pressure, and timing—are the foundation for our on-site joint splicing and repair systems.

In the next section, we’ll focus on how these factory-grade vulcanization standards are adapted for conveyor belt splicing and vulcanization, ensuring joint integrity that matches the strength of the original belt.

4.Conveyor Belt Splicing and Vulcanization

In industrial conveying systems, connecting separate belt sections is a necessary step, not an emergency measure. Long belts are produced and shipped in rolls for transportation efficiency, and joining them during installation is part of the normal setup process. The quality of the splice—whether made by conveyor belt vulcanization or mechanical fastening—determines the belt’s stability, service life, and maintenance frequency.

From a manufacturer’s point of view, understanding splicing technology is essential for ensuring that the belt performs as designed once installed. While the production process ensures consistent quality across the belt body, the final performance in the field depends largely on how the joints are made.

1. The Role of Splicing

Splicing restores continuity to the belt structure. The joint must transmit tensile load smoothly across the splice area, avoiding stress concentration and misalignment. The two dominant methods in industry are vulcanizing of conveyor belts (hot or cold) and mechanical fastening. Both serve the same purpose: to maintain uniform strength and running stability throughout the conveyor system.

For belts with high working tension or demanding conditions, vulcanized joints are generally preferred due to their seamless structure. For lighter or shorter systems, mechanical fasteners may offer practical and economic advantages.

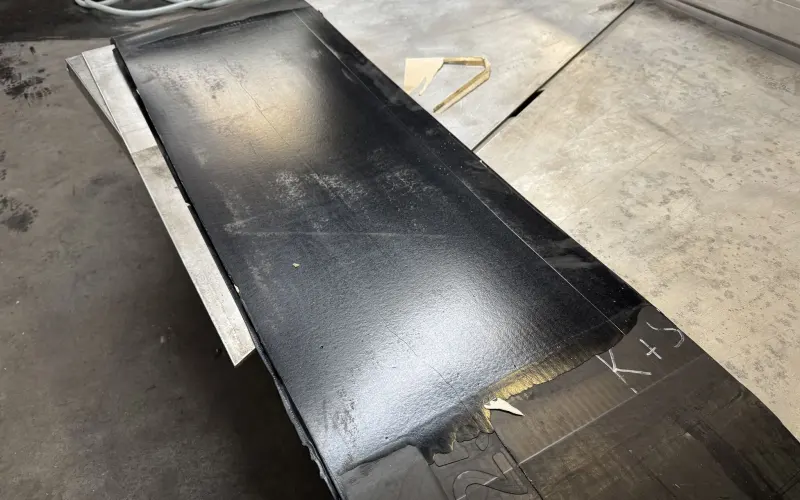

2. Hot Vulcanization

Hot vulcanization replicates the same principle used in belt manufacturing. The joint area is cured through controlled heat and pressure, allowing the rubber to crosslink and bond into a continuous layer. Typical industrial practice involves curing temperatures between 140–160 °C and pressures in the range of 1.4–1.8 MPa, depending on the belt type and thickness.

A correctly vulcanized joint can approach the belt’s original tensile capacity, offering excellent thermal stability and dynamic performance. This method is widely used in heavy-duty applications such as mining, steel production, and long-distance conveying systems.

3. Cold Vulcanization

Cold vulcanization achieves bonding through chemical adhesives at ambient temperature. It requires no heating equipment, making it practical for field conditions or temporary installations. Although the resulting joint strength is lower than that of hot curing, it is suitable for low- to medium-tension conveyors, maintenance replacements, or situations where rapid installation is required.

The adhesive-based method depends heavily on surface preparation, curing time, and environmental conditions such as temperature and humidity. For this reason, many users apply cold vulcanization for auxiliary or emergency use rather than as a long-term primary jointing method.

4. Mechanical Fasteners

Mechanical fastening remains an important alternative to conveyor belt vulcanization.

Modern conveyor belt fasteners and fastener tools are designed for quick installation and reliable clamping strength. They are widely used in portable conveyors, aggregate handling, and material loading systems.

Mechanical joints are not chemically bonded but mechanically locked. Their performance depends on fastener quality, belt tension, and pulley configuration. When used within the fastener’s rated stress limit, they can provide stable and efficient service. However, under excessive load or heat, fasteners may loosen or introduce localized wear, which limits their use in high-tension applications.

5. Industry Standards and Testing

Across the conveyor industry, splicing quality is commonly verified using international standards such as ISO 252, DIN 22102, and ASTM D412.

Typical inspection parameters include:

- Surface condition: free of visible delamination, air pockets, or irregular edges;

- Alignment: consistent belt tracking and uniform thickness at the joint;

- Adhesion strength: peel or shear strength values meeting specified benchmarks.

For steel-cord belts, additional non-destructive testing—such as magnetic or ultrasonic inspection—is often used to confirm cord bonding integrity.

6. Balancing Performance and Efficiency

Each joining method has its own technical and economic advantages.

Conveyor belt vulcanization provides the highest level of mechanical strength and longevity, making it the preferred choice for heavy or continuous-duty operations.

Mechanical fasteners, on the other hand, offer unmatched speed and convenience for systems where flexibility and frequent belt changes are required.

Choosing between these methods depends on the conveyor’s load, operating environment, and maintenance strategy. The goal is always the same: a secure, stable connection that maintains the original belt performance with minimal downtime.

7. A Manufacturer’s Perspective

As a belt manufacturer, Tiantie Industrial Co., Ltd focuses on material consistency and structural precision. We do not provide or supervise field vulcanization services, but we ensure that every belt we produce meets the physical and chemical stability required for reliable joint performance—whether the user applies vulcanization, cold bonding, or mechanical fastening.

Our role is to design belts that respond predictably to any standard splicing method approved in the industry. By combining material uniformity with customer expertise in installation, the full potential of each conveyor belt can be realized safely and efficiently.

5.Vulcanizing Agents and Material Systems

In the production of rubber conveyor belts, vulcanizing agents and material systems determine how the product performs in real industrial environments. While the chemical principle of conveyor belt vulcanization has been explained earlier, the focus here is on how different compounds, curing systems, and material combinations are selected to achieve specific mechanical and thermal properties.

For a manufacturer, the right vulcanization system is not only about curing efficiency—it defines adhesion, aging resistance, and long-term reliability under stress.

1. The Role of Vulcanizing Agents in Belt Manufacturing

A vulcanizing agent is the substance that enables crosslinking between polymer chains. Sulfur remains the most common choice in conveyor belt production because it provides flexibility and excellent fatigue life.

However, not all belts require the same type of crosslink network. The formulation of the rubber—its base polymer, reinforcement, and additives—decides which system works best.

The balance between mechanical strength and thermal stability is achieved by combining sulfur with accelerators, activators, and stabilizers that control how fast and how far the crosslinking progresses.

2. Common Vulcanization Systems in Conveyor Belts

Different conveyor belt types use different curing systems, depending on working temperature, chemical exposure, and mechanical load.

Rubber Type | Vulcanization System | Key Features | Typical Belt Type |

NR / SBR | Sulfur–accelerator system | High flexibility, strong bonding, low cost | General-purpose belts |

NBR | Sulfur or peroxide system | Oil- and fuel-resistant | Oil-resistant belts |

EPDM | Peroxide system | Excellent heat and ozone resistance | Heat-resistant belts |

CR (Neoprene) | Self-crosslinking or metal oxide system | Flame-retardant, anti-aging | Fire-resistant belts |

These systems are the foundation of all vulcanizing of conveyor belts.

For example, an EPDM-based heat-resistant belt requires peroxide curing to maintain structure above 160 °C, while an NBR belt designed for oil exposure uses a modified sulfur system to prevent premature softening.

3. Reinforcement and Adhesion Layers

Beyond the rubber matrix itself, the interaction between rubber and reinforcement (fabric or steel cord) is crucial. The adhesion layer ensures that the carcass and cover move as one unit under tension.

To enhance adhesion, special bonding agents—such as resorcinol–formaldehyde–latex (RFL) for fabrics, or brass-coated steel cords for metal reinforcement—are used. During conveyor belt vulcanization, these materials react chemically with sulfur and accelerators to create a stable interface.

A well-designed adhesion system ensures the belt does not delaminate or blister, even under high dynamic loads or temperature fluctuations.

4. Stabilizers, Fillers, and Additives

The performance of a cured belt depends not only on the vulcanization system but also on secondary ingredients that influence processing and durability.

- Antioxidants and anti-ozonants prevent surface cracking during long-term exposure to oxygen or sunlight.

- Reinforcing fillers such as carbon black or silica improve wear resistance and tear strength.

- Plasticizers and processing oils adjust viscosity and flexibility for easier calendaring and layer bonding.

- Metal oxides and retarders fine-tune curing speed and prevent scorch during the conveyor belt vulcanization process.

Each additive interacts with the vulcanizing system, forming a precise balance between processability and final strength.

5. Performance Matching Through Material Design

At Tiantie Industrial, each belt formulation is engineered to match a specific working condition. For example:

- Heat-resistant belts rely on EPDM or specialized peroxide-cured blends with optimized crosslink density for thermal endurance.

- Oil-resistant belts use NBR compounds with reduced swelling and stable bonding at elevated temperatures.

- Heavy-duty mining belts incorporate NR/SBR with high sulfur network density to deliver maximum dynamic strength and tear resistance.

The objective of this design philosophy is not only to improve curing stability but also to guarantee consistent adhesion, abrasion resistance, and fatigue performance after conveyor belt vulcanization.

6. Toward Environmentally Safer and Efficient Systems

The vulcanization landscape is evolving toward cleaner and more sustainable chemistry.

New generations of accelerators avoid nitrosamine formation, while low-temperature curing systems reduce energy consumption.

Peroxide and hybrid curing technologies are increasingly used to replace high-sulfur formulations, improving thermal stability and reducing emissions during manufacturing.

These innovations align with the industry’s global shift toward eco-friendly conveyor belt vulcanization—combining performance with environmental responsibility.

7. Material System as the Foundation of Quality

Every conveyor belt’s durability begins with its material system.

While process parameters such as temperature and pressure control curing behavior, it is the compound design—the combination of polymer, filler, and vulcanizing agent—that ultimately defines strength, flexibility, and lifetime.

In this sense, the chemistry behind vulcanizing of conveyor belts is not just a reaction; it is the foundation of manufacturing precision.

The next section will discuss how these carefully formulated materials are cured through vulcanizing equipment and control systems, ensuring uniform quality across every meter of conveyor belt produced.

6.Vulcanizing Equipment and Control Systems

At Tiantie Industrial Co., Ltd, precision in conveyor belt vulcanization begins with the equipment that carries it out.

Every meter of cured belt depends on the machine’s ability to maintain stable heat, pressure, and timing.

Even when the rubber compound is perfectly formulated, an unstable press can compromise adhesion, surface flatness, or layer bonding.

For this reason, the control and consistency of the vulcanizing system are considered as critical as the formulation itself.

1. Core Components of the Vulcanizing System

A modern conveyor belt vulcanizing machine operates through several integrated systems working in synchronization:

- Heating plates:use embedded electrical heating elements or thermal oil circulation to maintain uniform temperature across the platen surface.

- Hydraulic system:applies adjustable pressure between 2–2.2 MPa, depending on the belt structure.

- Cooling section:activates immediately after curing to stabilize the belt by controlled air or water-cooling.

- Control cabinet:houses the temperature and pressure regulators, timers, and safety circuits.

Each platen is precision-machined to ensure flatness and even compression. In multi-layer production presses, independent zone control allows consistent heating across the full belt width.

2. Temperature and Pressure Stability

Uniform heating is the foundation of consistent vulcanizing of conveyor belts.

In our factory, platen temperature uniformity is maintained within ±3 °C, verified regularly through infrared mapping.

Pressure is monitored in real time through digital hydraulic sensors, avoiding localized under- or over-compression.

Stable temperature ensures homogeneous crosslinking, while balanced pressure guarantees the belt’s dimensional stability and adhesion integrity.

3. Control and Automation

In conveyor belt vulcanization, automation means more than letting machines run on their own—it’s about keeping every parameter within a narrow, predictable range.

Each production line at Tiantie follows preset curing programs developed through long-term testing of our compounds.

The PLC doesn’t simply heat or press; it regulates how temperature rises, how long it stays stable, and how pressure shifts during the curing cycle.

When those three curves—temperature, pressure, and time—stay synchronized, the vulcanization remains uniform from start to finish.

That’s why we treat automation as a form of quality control, not convenience.

It helps eliminate variation between batches and allows us to trace every meter of belt back to its curing data.

Precision, once achieved manually by experience, is now maintained digitally—every cycle identical, every belt consistent.

4. Safety and Reliability

No vulcanizing press runs at Tiantie without strict safety measures.

The machines are thermally insulated to prevent heat loss and protect the operator area.

Each hydraulic circuit has a pressure-relief valve and emergency stop line.

Electrical units include overload protection and diagnostic functions to detect faults before they affect production.

Regular calibration is part of our maintenance routine—we check platen temperature accuracy, hydraulic response, and timing control after every defined production cycle.

The idea is simple: a safe machine is a stable machine, and stability is what guarantees consistent vulcanizing of conveyor belts across long production runs.

5. Precision as the Core of Consistency

For us, precision isn’t a slogan—it’s the difference between a good belt and a perfect one.

When temperature and pressure stay within limits, the rubber cures evenly, internal stress disappears, and adhesion between layers remains uniform.

That means every belt—EP, NN, or steel cord—comes out with the same structure and the same performance profile.

This control philosophy defines Tiantie’s manufacturing line.

A steady conveyor belt vulcanization process, supported by reliable equipment and disciplined operation, is what allows our belts to perform predictably in mines, ports, and production plants worldwide.

The next section will examine the performance advantages derived from such controlled vulcanization—how precision in curing translates into mechanical strength, durability, and long-term stability in real-world conveyor systems.

7.Advantages of Vulcanization

In industrial conveying, the real advantage of conveyor belt vulcanization lies in how it transforms separate materials into one integrated structure.

The belt is no longer a collection of rubber layers and reinforcements—it becomes a single, elastic composite.

That chemical unity is the foundation of mechanical strength, heat endurance, and long-term reliability that no mechanical joint can reproduce.

1. Structural Continuity and Stress Distribution

When vulcanizing of conveyor belts is properly executed, the belt behaves as one continuous medium under tension.

Stress is transmitted evenly through the rubber matrix and fabric carcass, instead of concentrating at bolt holes or metal plates as in mechanical fasteners.

This even stress field prevents early fatigue, edge cracking, and tracking deviation.

For long-distance conveyors with high tension ratios, this uniformity is the decisive factor that keeps the belt stable over time.

2. Enhanced Thermal and Dynamic Resistance

Vulcanized joints are not just glued—they are chemically crosslinked under controlled heat and pressure.

The resulting bond tolerates continuous flexing, heat buildup, and exposure to oil, water, or abrasive materials.

Because there are no metallic parts, the belt expands and contracts uniformly with temperature, avoiding localized thermal stress.

In systems handling hot clinker, cement, or coal, this stability means fewer shutdowns and a much longer operating cycle.

3. Precision and Energy Efficiency in Operation

A fully vulcanized belt runs smoother, generating less vibration and frictional loss along pulleys and idlers.

This improves energy efficiency, reduces bearing wear, and stabilizes belt tracking.

It also minimizes the micro-slippage that occurs in mechanical joints, helping the drive system maintain consistent torque and speed.

From an operational standpoint, well-executed conveyor belt vulcanization directly translates to measurable energy savings and reduced mechanical maintenance.

4. Life Cycle Advantage

The service life extension achieved through vulcanizing conveyor belts is not accidental—it results from predictable chemistry and stable geometry.

A seamless structure resists delamination and surface wear, keeping its strength profile uniform through years of operation.

While mechanical joints can be convenient for temporary use, vulcanized belts consistently outperform them in environments where downtime is costly or continuous operation is critical.

Vulcanization, in essence, replaces mechanical dependence with chemical integrity.

It’s the point where materials science and production engineering intersect—and it’s what defines the durability of every high-performance conveyor belt we produce.

8.Limitations of Conveyor Belt Vulcanization

Every precise process in manufacturing has boundaries, and conveyor belt vulcanization is no exception. Its strength lies in control and stability, yet those same features make it slower and less adaptable than other joining methods. These limitations are not flaws—they are the natural results of a process built for accuracy.

1. Time and Production Downtime

Vulcanization takes time because rubber crosslinking cannot be rushed. Each curing cycle follows a fixed temperature and pressure curve, then requires slow cooling to lock the structure in place. For thick or steel-cord belts, this can take several hours. In field applications, portable vulcanizing presses make the process even longer. Unlike factory presses, they have no automatic lifting or cooling systems, so the belt and press must cool naturally before separation. This extended period adds hours to the total cycle but ensures even internal stress and stable bonding.

2. Environmental Sensitivity and Temperature Uniformity

Stable environmental conditions are essential for quality. Dust, oil, or moisture can easily interfere with bonding and create weak layers. At Tiantie, temperature control does not rely on thermocouple feedback or platen mapping. Instead, we rely on years of accumulated laboratory data. Through repeated vulcanization experiments, our R&D team defined the ideal temperature–time parameters for each compound. These proven values guide production, keeping the conveyor belt vulcanization process consistent even without automated feedback systems.

3. Skill and Process Discipline

In the workshop, vulcanizing of conveyor belts still depends on people more than machines. The operator decides how fast the temperature should rise and how evenly the pressure spreads across the belt. If the heat climbs too quickly, the surface scorches before the core reacts. If it’s too slow, bonding stays weak. We rely on trained eyes to spot the color and texture change that shows the compound is curing correctly. Experience fills the gaps no sensor can cover—that’s the real skill behind a good joint.

4. Equipment Complexity and Operational Cost

A conveyor belt vulcanizing machine looks simple from the outside, but inside it’s a heavy, power-hungry system. The heating plates must stay flat, the hydraulic circuit must hold pressure, and every control relay needs calibration. When one part drifts, the whole curing curve changes. Maintenance isn’t optional—it’s what keeps the process stable. Running such equipment takes both money and time, and for smaller belts, that cost often outweighs the benefit. That’s why some workshops still keep mechanical splices for light-duty jobs.

5. Structural Rigidity After Curing

Once a belt is vulcanized, it becomes a single solid body. There’s no easy way to cut or shorten it without starting over. For modular or temporary conveyors, that’s a limitation; you lose flexibility. But in high-tension or high-temperature systems, this rigidity is exactly what protects the belt from distortion. In our production lines, we see it as a trade—once the belt is cured, it’s meant to stay there, doing its job for years without a single movement out of line.

Every constraint in vulcanization stems from the same source as its reliability: precision. The process demands patience, control, and consistency, and in return, it delivers the mechanical integrity that defines a truly durable conveyor belt.

9.Quality Inspection and Laboratory Verification of Conveyor Belt Vulcanization

The strength of a vulcanized conveyor belt is not decided by the press—it’s proven by testing.

In any belt factory, inspection is what connects theory with reality. Vulcanization can follow the perfect curve on paper, but only consistent verification ensures that every cured belt meets its mechanical promise.

1. Post-Vulcanization Inspection

Once a belt is released from the vulcanizing press, inspection begins immediately. The first step is visual, but it’s more than a glance. Engineers look for trapped bubbles, edge distortion, or uneven gloss—signs that the internal pressure or heat distribution wasn’t uniform.

Thickness and flatness are then checked across the entire width. Even a small deviation can cause tracking problems or localized stress during operation. This early inspection filters out defects that would otherwise appear only after installation.

2. Mechanical and Adhesion Testing

Mechanical integrity defines the success of conveyor belt vulcanization. Each batch is sampled for tensile strength, elongation at break, and interlayer adhesion. Test strips are taken directly from production belts, not laboratory molds, to reflect real curing conditions.

Peel strength testing reveals how effectively layers bonded under pressure. If adhesion values drop below standard, the issue usually traces back to temperature imbalance or contaminated surfaces. The goal is not to meet a number, but to confirm that chemical bonding reached full crosslink density.

3. Laboratory Verification and Process Refinement

Laboratory work focuses on prevention rather than approval.

Every rubber compound is tested under multiple temperature–time combinations to map its curing characteristics.

By analyzing the reaction plateau—where crosslinking stabilizes without overcuring—engineers determine the optimal vulcanization window used in production.

Accelerated aging and abrasion tests verify how the material behaves after long-term exposure to heat and friction.

When lab data matches factory results, the vulcanization process can be considered stable.

4. Consistency and Traceability

Each roll of belt carries a full record of its vulcanizing parameters—temperature, pressure, time, and test outcomes.

These logs make it possible to trace any issue back to its batch, formulation, or press settings.

Traceability isn’t bureaucracy; it’s process control in its most practical form.

When every belt performs as designed months or years later, it means the curing data collected at the start was right.

In the end, inspection and testing don’t make the belt stronger—they confirm that the strength already built during vulcanizing of conveyor belts is real, repeatable, and reliable.

That’s the difference between producing rubber and producing a working conveyor belt.

10.Quality Inspection & What It Means for You — Plus How to Fix It

You don’t need a tour of our lab; you need clarity. Here’s what each check after conveyor belt vulcanization tells you, why it matters in service, and what to do if results fall short.

1.Visual & Dimensional Checks → Running Stability

We look for bubbles, glaze differences, edge waviness, and measure thickness/flatness across the width. Meaning for you: trapped air or uneven thickness becomes mistracking, vibration, and early edge wear. If issues appear on site: trim and re-square edges; re-profile high spots by controlled grinding; for localized blisters, open the pocket, buff, solvent-clean, and apply a hot-vulcanized patch (≈150 °C, matching belt class) or a cold-bond patch if downtime is tight.

2.Peel Strength (Interlayer Adhesion) → Joint Integrity

Peel tests show whether layers bonded during vulcanizing of conveyor belts. Low values forecast splice lift, ply separation, and shock failures. Field fix: for minor lift, stop, dry the area, re-buff, apply primer/adhesive, and clamp until full cure; for widespread low adhesion, remove the splice and re-make it—hot vulcanization at 140–160 °C, pressure set by belt type (EP/NN ≈1.4 MPa; steel-cord ≈1.8 MPa), with portable presses left to natural cooling before release.

3.Tensile/Elongation → Load Carrying & Stretch Control

Tensile and elongation-at-break confirm the rubber network cured correctly. If the belt creeps or stretches unevenly, downstream you’ll see frequent take-up adjustments and splice stress. Fix path: check drive/tension first; if the belt itself under-performs, re-splice with verified cure time per thickness (typ. 20–30 min/10 mm) or replace the section showing abnormal elongation.

4.Hardness & Abrasion → Wear Life

Uniform hardness and DIN abrasion values predict how long covers will last under fines or clinker. If you’re burning covers fast, confirm you’re on the right compound (heat/oil grade) and review chute design and skirt pressure. Repair: local gouges get a hot patch; broad wear calls for lagging/skirt optimization and, if needed, an upgraded cover compound on the next order.

5.Heat Aging/Set → Temperature Resilience

Aging tests tell you whether the compound keeps strength after exposure. If your belt stiffens or cracks near heaters, use a higher-temp system (e.g., EPDM/peroxide) next replacement. Interim fix: reduce carryback heat, improve ventilation, or install heat shields. Do not over-tension to “force” tracking—this accelerates cover cracking.

6.Typical Failure → Fast, Practical Remedies

- Soft core (undercure):replace the joint; temporary run with reduced load and speed only.

- Brittle surface (overcure):grind to sound rubber and hot-patch; re-make splice at the lower end of the curing window.

- Edge groove/step:re-trim and seal edges; check platen alignment before the next splice.

- Steel-cord disbond:do not cold-repair; cut out and hot-splice to full spec.

- Emergency continuity:use a rated conveyor belt fastener as a temporary bridge, then schedule a hot splice.

7.What You Get

Inspection translates into decisions: keep running, patch now, or re-splice. We use the data to prevent repeat faults and give you a clear path—immediate containment in the field, and parameter corrections for the next conveyor belt vulcanization cycle.

11.Alternative and Fast Splicing Technologies for Conveyor Belts

Not every conveyor needs a full hot-vulcanized splice. When time, environment, or logistics make traditional conveyor belt vulcanization impractical, alternative joining methods keep production moving without major downtime. Each option has its role—speed versus durability, flexibility versus permanence.

1.Mechanical Fasteners

Mechanical fasteners remain the fastest way to reconnect a belt in the field. They install in minutes, require basic tools, and allow the belt to run almost immediately. Modern fasteners are made from stainless or galvanized steel and shaped to minimize noise and impact on pulleys. The trade-off is durability: even premium systems reach about 70–80% of the strength of a vulcanized joint. They’re ideal for short belts, mobile conveyors, or when quick recovery is critical. Always verify that the chosen conveyor belt fastener tool matches belt thickness and tension class.

2.Cold Vulcanization

Cold vulcanization uses chemical bonding rather than heat. A reactive adhesive cures at ambient temperature, forming a flexible, waterproof splice. It’s slower than mechanical fastening but requires no power source or heavy press, making it useful in confined or remote sites. Proper surface cleaning and adhesive mixing are essential. For best results, maintain joint pressure during the first hour of cure and avoid loading for at least 8–12 hours. This technique restores roughly 85–90% of the belt’s original strength when done correctly.

3.Hybrid and Temporary Solutions

Some operations apply hybrid systems—mechanical fasteners combined with adhesive sealing—to extend service life until scheduled maintenance. For emergency repair, vulcanizing conveyor belts with portable kits or chemical patches can bridge short tears or holes without removing the belt from the system. These are stopgaps, not replacements for a proper hot splice, but they keep material flowing while preventing further damage.

Each fast-splicing method exists to buy time, not to replace quality. The key is knowing when to use it: quick fixes restore uptime; proper conveyor belt vulcanization restores reliability.

12.How Conveyor Belt Vulcanization Defines Real Belt Performance

Conveyor belt vulcanization is the process that determines whether a belt performs or fails. It’s the stage where rubber, fabric, and tension layers bond into one solid structure capable of carrying continuous loads. If the curing temperature, pressure, or time deviate from the required range, delamination, cracks, and surface deformation appear long before the belt reaches its expected life.

Vulcanization is precision, not routine. Each curing factor serves a defined role: heat activates crosslinking, pressure ensures adhesion, and time stabilizes structure. Proper testing verifies that these reactions completed as designed. When those parameters stay within control, the belt runs straight, resists stretching, and maintains strength through long operating cycles.

A well-controlled vulcanizing of conveyor belts process guarantees predictable performance and lower maintenance cost. When the curing is right, belts don’t need repair schedules—they simply run. That is the point where production quality turns into real-world reliability.

13.FAQ: Practical Questions About Conveyor Belt Vulcanization

1. Why does the belt show weak adhesion after vulcanization?

Weak adhesion usually comes from poor interlayer bonding formed during the molding stage, not from the conveyor belt vulcanization itself. If fabric layers or rubber sheets weren’t properly pressed or cleaned before curing, no amount of heat or pressure can fix it. The only solution is to cut out the section, clean and buff both ends, and rejoin with fresh uncured rubber under correct vulcanizing pressure—typically 1.4–1.8 MPa depending on belt structure.

2. Why does the splice bubble or blister after curing?

Blisters appear when trapped air or moisture expands during heating. It’s often caused by insufficient venting or uneven compression across the platen. To prevent it, maintain constant pressure and preheat the press evenly. For field repair, open the blister carefully, buff, apply bonding cement, and re-cure using a small portable vulcanizing unit at 145–155 °C until the layer seals completely.

3. What if the belt feels soft or stiff after vulcanization?

A soft belt signals undercure; the chemical crosslinking wasn’t finished. A stiff or cracked belt means overcure. Both affect flexibility and tracking. For undercure, reheat under controlled conditions; for overcure, remove the hardened area and hot-patch with new compound. Future prevention depends on accurate curing time—about 20–30 min per 10 mm thickness—and steady temperature control.

4. Can mechanical fasteners replace vulcanized splices?

Fasteners are quick and convenient but never match the bonding strength of vulcanizing of conveyor belts. They’re effective for temporary restoration or low-tension systems. In heavy-duty or heat-exposed applications, fasteners fatigue quickly and damage pulleys. Use them only as an emergency bridge until a proper hot splice is possible.

5. Why do some belts deform or shrink after cooling?

Deformation occurs when belts are released from the press before internal temperature equalizes. In portable presses without automatic lift, the belt must cool naturally to below 80 °C before tensioning. Forced cooling or water spray causes uneven contraction and layer stress. Controlled air cooling ensures the cured belt remains dimensionally stable and maintains splice geometry for long-term service.