This article provides a technical overview of the quarry conveyor belt, explaining how carcass design, rubber grade, and tension rating affect real-world belt performance. Supported by DIN 22102 and ISO 14890 standards, it demonstrates why EP and NN fabric belts deliver better wear resistance, flexibility, and overall efficiency than steel cord conveyor belt . Backed by field data from multiple quarries, it highlights proven methods to extend service life and reduce downtime. Future development will focus on improved rubber compounding and predictive maintenance for higher system reliability.

1.Quarry Conveyor Belt Overview

In every quarry, the quarry conveyor belt does more than carry materials—it defines your production capacity. It links every stage, from the primary crusher to the stockpile, keeping tons of stone moving every hour.

When we work with quarry clients, the first question I ask is simple: What size material are you moving? Because material size determines everything—belt tension, rubber hardness, and even cover grade. In most cases, rock means large, sharp stones, typically 100 to 400 millimeters. These impact the belt directly after the crusher. For that reason, you need a rock conveyor belt with a tensile strength above EP500/4 or NN400/3, and top cover thickness of at least 6 mm. The rubber should meet DIN X abrasion standards, offering wear volume below 120 mm³.

Gravel, by contrast, is smaller—around 5 to 50 millimeters—and travels faster over longer distances. Here, the stress isn’t from impact but from surface abrasion. A gravel conveyor belt typically runs well with EP300/3 or EP250/2 ratings, and 4+2 mm rubber covers. What matters most in this stage is compound quality and consistent adhesion between the rubber and fabric layers.

A quarry, of course, involves both. So the quarry conveyor belt must handle strong impact at the feed point and constant friction at the discharge end. In our factory’s field inspections, we’ve seen belts fail for multiple reasons: roughly 40% from rubber wear, 30% from impact damage, and 20% from fabric fatigue or joint failure. Tensile strength plays a role, but it’s only part of the story.

According to the Conveyor Equipment Manufacturers Association (CEMA), belt reliability can affect over 40% of quarry system uptime (CEMA Report ). That’s why choosing the right EP or NN conveyor belt—with proper tension rating, cover grade, and bonding quality—isn’t optional. It’s the foundation of a stable aggregate conveyor belt system.

2. Quarry Conveyor Belt Working Conditions

The working environment for a quarry conveyor belt is demanding. It’s dusty, abrasive, and full of impact forces that change every second. Most quarry systems operate in sections of 20 to 200 meters, with elevation differences typically below 20 meters. That might not sound extreme, but the stress on the belt is continuous—especially near the loading and transfer points.

At the first stage of material flow, you’re handling hard and angular rock—granite, basalt, or limestone—usually around 100 to 400 millimeters in size. These heavy fragments fall directly from crushers, striking the belt with high velocity. Each drop creates an impact that doesn’t just wear the top rubber; it also affects the belt tension. In real operation, belt tension is never constant. Every impact adds a temporary surge—sometimes reaching 1.5 times the static tension—which increases splice stress and accelerates carcass fatigue. A strong rock conveyor belt needs both tensile strength and shock absorption.

For these primary stages, we typically recommend EP500/4 or NN400/3 rubber conveyor belts with 6+3 mm rubber covers. The top rubber should meet DIN X abrasion standards, ensuring a wear rate below 120 mm³ (ISO 4649). This combination provides enough stiffness to carry large stones while keeping flexibility for system alignment. The choice between EP and NN depends on the layout—EP belts handle higher tension with lower elongation, while NN belts absorb impact better where chutes are short and steep.

Further downstream, the material becomes smaller and smoother. The gravel conveyor belt handles particles between 5 and 50 millimeters—still abrasive, but far less aggressive than raw rock. Here, the main issue isn’t impact; it’s continuous surface friction. Fine dust mixes with humidity to create a thin, grinding layer that slowly removes the cover rubber. In this section, belts with EP300/3 or EP250/2 structures, 4+2 mm covers, and medium-hard compounds (60–65 Shore A) work best. A good wear-resistant rubber mix—based on NR and BR—can extend belt life by up to 40% compared to standard SBR-only compounds.

Environmental exposure adds another layer of stress. Heat from the sun, cold mornings, and rainwater all affect the rubber surface. In many Southeast Asian and Middle Eastern quarries, belt surface temperatures reach 60–70°C in summer. In cooler regions, belts must stay flexible down to –25°C. That’s why polymer choice matters: a balanced natural rubber and synthetic blend maintains both elasticity and adhesion.

From our field audits of over 60 quarry sites, 70% of early belt wear occurred at loading zones, not along the carrying run. Another 20% came from misalignment and poor chute design. These weak spots amplify tension fluctuations and cause edge cracking. Proper installation—impact idlers, smooth transitions, and stable tracking—can reduce wear by nearly 30%, according to our internal test data.

A quarry conveyor belt doesn’t face a single type of stress. It deals with impact, abrasion, and tension shifts at the same time. That’s why belt selection should never rely on tensile rating alone. It’s the interaction between carcass strength, rubber quality, and pulley configuration that defines real performance. When these factors align, your aggregate conveyor belt runs smoother, lasts longer, and keeps your production line moving without interruption.

Category | Rock Conveyor Belt | Gravel Conveyor Belt |

Material Size | 100–400 mm, angular and heavy | 5–50 mm, rounded and uniform |

Material Type | Hard stone – granite, basalt, limestone | Crushed aggregates, sand, and screened gravel |

Main Stress Type | High impact, sharp edges, dynamic tension peaks (up to 1.5× static) | Continuous surface abrasion, fine dust friction |

Recommended Belt Structure | EP500/4 or NN400/3 (Heavy-duty carcass) | EP300/3 or EP250/2 (Medium-duty carcass) |

Top / Bottom Cover (mm) | 6 + 3 or 8 + 3 | 4 + 2 |

Rubber Grade (DIN / ISO) | DIN X (≤120 mm³ abrasion) | DIN Y (≤150 mm³ abrasion) |

Rubber Compound Type | Natural rubber (NR) + butadiene rubber (BR) blend for impact resistance | NR/SBR blend optimized for wear and heat stability |

Operating Speed | 1.6 – 2.5 m/s (slow to absorb impact) | 2.5 – 4.0 m/s (faster for smooth material flow) |

Typical Working Section | After primary crusher / near feed zone | After screening, towards stockpile or loading zone |

Common Failure Modes | Top cover gouging, splice fatigue, edge cracking | Surface wear, rubber aging, belt mis-tracking |

Key Design Focus | Impact absorption, carcass strength, bonding quality | Abrasion resistance, flexibility, consistent tracking |

Expected Service Life | 18 months under normal quarry duty | 24 months with regular maintenance |

3. EP Conveyor Belt Advantages

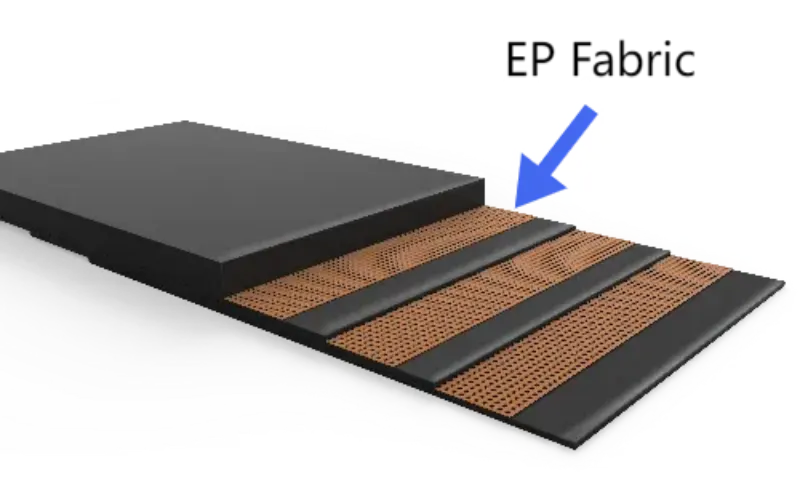

Among all belt types we produce for quarry applications, the EP conveyor belt remains the most balanced and cost-effective choice. Its core combines polyester (warp) and nylon (weft), creating a carcass that’s both strong and flexible. This hybrid structure gives the quarry conveyor belt the dimensional stability it needs under tension and the flexibility to handle small pulley diameters and curves inside the plant.

In simple terms, polyester provides high tensile strength and low elongation, while nylon brings excellent impact absorption. Together, they form a belt that resists stretching under load but still bends easily over rollers. For most quarry systems moving rock and gravel, the result is smoother tracking, longer splice life, and reduced downtime.

When compared with an NN conveyor belt, the EP version stretches far less. The typical elongation rate is 1.2–1.5%, while NN belts often reach 3–4%. That difference matters. Lower elongation keeps the system stable, especially where tension fluctuates at transfer points. It also minimizes belt drift and the need for frequent re-tensioning. In contrast, NN belts absorb shock better but tend to deform under continuous stress, which can shorten splice life if not properly maintained.

Another reason we recommend EP for aggregate conveyor belt setups is its resistance to moisture. The polyester layer absorbs less than 0.5% water, compared to up to 4% in NN fabric. That means no swelling, no dimensional change, and no early delamination in humid or wet conditions—issues that are common in quarry environments where washing and spraying are routine.

In terms of joint efficiency, EP belts also perform well. A hot-vulcanized splice retains around 85–90% of the original belt strength, according to ISO 14890 testing standards (ISO 14890:2022). This high retention rate translates directly into longer operating cycles and fewer unplanned shutdowns.

From a financial perspective, EP belts simply make sense. They cost less than steel-cord belts, install faster, and require simpler maintenance tools. For a quarry conveyor belt carrying mixed rock and gravel, the EP type delivers the right balance—tensile reliability, wear resistance, flexibility, and total cost efficiency.

If you’re running a crushing and screening line with variable loads, an EP conveyor belt is the smarter long-term choice. It doesn’t just carry your material—it keeps your operation stable day after day.

4. NN Conveyor Belt Applications and Advantages

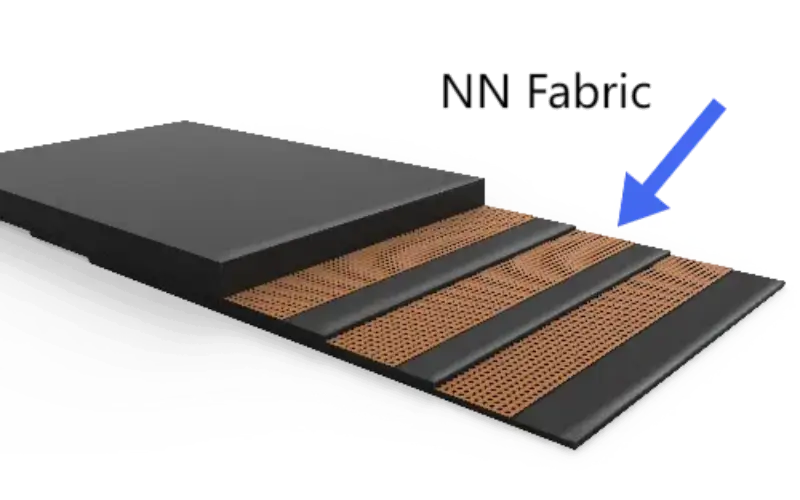

While EP belts dominate most quarry systems, the NN conveyor belt still plays a vital role in certain conditions. Its structure—nylon in both warp and weft directions—creates a fabric with exceptional flexibility and toughness. For quarry conveyor belt setups facing heavy impact and sharp rock edges, that elasticity becomes a major advantage.

When a large rock hits the belt at a transfer point, nylon’s high rebound capacity lets the carcass deform and recover without tearing. This shock absorption helps prevent cover cracks, edge fraying, and internal ply separation. That’s why the NN conveyor belt often performs better than EP belts in high-impact zones—especially near the primary crusher or steep chute areas.

Another key benefit is smooth tracking on short, curved, or inclined runs. The flexibility of nylon fabric reduces stress on pulleys and splices, minimizing vibration and mechanical fatigue. For quarries where belts must handle frequent starts, stops, or tight turns, the NN design ensures steady performance and longer splice life.

Of course, nylon has its trade-offs. It stretches more—typically 3–4% elongation, compared to 1.5% for an EP conveyor belt. It also absorbs more moisture, up to 4% water uptake under high humidity. This can slightly change belt dimensions over time. That’s why we recommend edge sealing and moisture-protected rubber compounds when NN belts are used outdoors or in wet environments.

Some clients use a hybrid system—EP belts for main runs and NN belts for impact sections. This combination leverages EP’s stability with NN’s energy absorption, creating a more durable aggregate conveyor belt setup.

According to the CEMA Belt Conveyors for Bulk Materials (7th Edition), nylon-fabric belts can absorb 25–30% more impact energy than polyester-based belts. That higher resilience directly reduces carcass damage and extends belt service life in heavy-duty rock conveyor belt applications.

In short, if your quarry conveyor belt faces frequent impact, short cycles, or high drop zones, an NN conveyor belt is the right choice. It bends, absorbs, and recovers—exactly what impact-heavy operations need.

5. Why Not Steel Cord Belts for Quarry Operations

Every time I discuss quarry conveyor belt design with new clients, one question comes up:

“Why not just use a steel cord belt? It’s stronger, right?”

It’s a fair question — but strength isn’t the problem in a quarry. In fact, steel cord belts are often too strong for the job, and that strength brings unnecessary cost and complexity.

Let’s start with the basics. Steel cord conveyor belts are designed for long-distance, high-tension applications — like mines, ports, and power plants — where single runs can exceed 2 kilometers and vertical lifts surpass 100 meters. In those systems, tensile demands easily exceed ST630 or higher. Most quarry conveyors, by comparison, operate under far lighter loads: typically under EP500/4 or NN400/3 tension ratings, with runs of 80–250 meters.Even if some special quarry sites need to transport extra-large stones, only EP630/4 is needed. In many smaller quarries, the operating distance is even shorter, depending entirely on the site’s scale and layout.

When we evaluate quarry applications, the failure mode is rarely related to breaking tension. Instead, it’s about surface wear, impact damage, and splice fatigue. Steel cord belts don’t solve those issues. Their carcass resists stretching but provides almost zero flexibility, which means they don’t absorb impact energy well. In a quarry where heavy rock falls directly on the belt, that rigidity transfers shock into the splice or idlers — the very components most prone to failure.

Another drawback is maintenance complexity. Steel cord belts require hot vulcanized splicing only — no mechanical fasteners or cold joints. That means when damage happens, you need trained technicians, special presses, and long downtime. For a busy quarry producing thousands of tons per day, even a few hours offline means serious production loss. In contrast, EP conveyor belts or NN conveyor belts can be repaired quickly using mechanical or cold-vulcanized joints, minimizing downtime.

Then there’s the issue of cost and overengineering. Steel cord belts can cost 30–50% more than equivalent fabric belts. They also require larger pulleys — often 500 mm or more — which increases system cost and limits layout flexibility. Smaller quarries, with tighter curves and shorter runs, simply don’t have the space or need for that level of infrastructure.

Another point many overlook is belt stiffness. Because steel cord belts have minimal elongation, they demand very precise tensioning systems. Any misalignment or uneven loading can cause edge wear or tracking problems quickly. In quarries, where material feed and load vary constantly, this rigidity is more of a liability than an advantage.

Even though steel cord joints are strong, they’re not immune to fatigue. The dynamic tension peaks caused by impact loading — often 1.5 times the static tension — can break adhesive bonds inside the steel cords over time. Once corrosion begins inside the steel strands, the belt’s integrity drops fast. Fabric belts, with synthetic layers, don’t have this corrosion issue and are easier to inspect and repair.

In short, steel cord belts are built for power, not adaptability. They excel in long-haul systems, not in variable-load quarry environments. For the majority of operations, EP and NN fabric belts deliver better performance, easier maintenance, and far lower total cost.

A quarry conveyor belt doesn’t need to be the strongest belt in the world — it needs to be the right one. Choose EP or NN, and you’ll get durability, flexibility, and efficiency without overpaying for unnecessary steel.

6. Engineering Selection Logic for Quarry Conveyor Belts

Selecting the correct quarry conveyor belt isn’t just about choosing a strong belt — it’s about engineering balance. The right selection starts with accurate tension calculation, followed by a fabric choice that matches the impact level and a rubber cover that fits the material’s abrasion grade. Here’s the practical three-step method I use when helping clients build or upgrade their quarry systems.

Step 1: Determine the Required Belt Strength

Belt tension defines the foundation. I calculate the required carcass strength using:

T = (L × G × H) / η

Where:

T = effective tension (N/mm)

L = conveyor length (m)

G = material weight per meter (kg/m)

H = lift height (m)

η = system efficiency (typically 0.85–0.95)

In most quarries, conveyors operate between 80–250 meters, sometimes even shorter depending on site size. Under these parameters, belts rated EP300–EP500 usually meet the required tension safely with enough margin for load variations.

Step 2: Match the Fabric Structure to the Impact Load

The impact level determines the belt’s flexibility and internal strength.

- Heavy-impact zones(under primary crushers) → use EP500/4 or NN400/3. The 4-ply EP structure ensures tensile stability, while NN’s elasticity absorbs shock energy effectively.

- Medium-load sections(secondary crushers or stockpile feed) → EP300/3 works best. Its lower elongation and flexible structure reduce power demand and improve tracking.

- Light or short transfers→ NN400/3 provides good impact absorption and smooth running on small pulleys.

Step 3: Choose the Right DIN Rubber Cover Grade

Rubber defines belt life. According to DIN 22102:

- X Grade (≤120 mm³ abrasion)→ best for rock conveyor belts handling sharp and heavy material.

- W Grade (≤90 mm³ abrasion)→ excellent for gravel conveyor belts and general aggregates.

- Y Grade (≤150 mm³ abrasion)→ suitable for light-duty or clean material transport.

6.1 Recommended Belt Configuration Table

Conveyor Section | Recommended Model | Top/Bottom Rubber (mm) | Key Features |

Primary Crusher Discharge | EP500/4 DIN X or NN400/3 DIN X | 6 / 3 | High impact, tear resistant |

Secondary Crusher Output | EP300/3 DIN W | 5 / 2.5 | Medium load, abrasion resistant |

Finished Aggregate Conveyor | NN400/3 DIN W | 4 / 2 | Light load, flexible tracking |

6.2 Material and Design Optimization

We use a NR + BR compound system with fillers N220/N330, balancing wear resistance and crack growth protection. This compound provides about 40% longer life compared to standard SBR blends.

To extend belt life further, I always recommend adding impact idlers, skirt sealing, and dust covers at transfer points. These prevent edge damage, reduce spillage, and keep the belt surface clean.

One frequent mistake I see is over-specifying belt strength. Using a belt too stiff for the system can overload idlers, cause tracking problems, and even shorten bearing life. Engineering selection should aim for suitability, not excess.

The best-performing quarry conveyor belt systems combine proper tension design, the right fabric structure, and a DIN-rated cover suited to real material conditions — nothing more, nothing less.

To help you find the standard that suits you, we have provided a reference table, which includes some of the world’s mainstream standards.

| Country | Belt Type | Cover Grade | Tensile Strength (MPa) | Elongation (%) | Abrasion Loss (mm³) | Hardness (Shore A) | Standard |

| China | Flame Retardant Solid Woven | Thick Cover | ≥10.0 | ≥250 | ≤200 | 70±5 | MT914-2002 |

| China | Flame Retardant Solid Woven | Flame Retardant | ≥10.0 | ≥350 | ≤200 | 70±5 | MT914-2002 |

| China | General Fabric Belt | Light Duty L | ≥10.0 | ≥300 | ≤250 | 60±5 | GB7984-87 |

| China | General Fabric Belt | Medium M | ≥14.0 | ≥350 | ≤200 | 60±5 | GB7984-87 |

| China | General Fabric Belt | Heavy H | ≥18.0 | ≥400 | ≤150 | 60±5 | GB7984-87 |

| China | General Fabric Belt | Standard L | ≥15.0 | ≥350 | ≤200 | 60±5 | GB7984-2001 |

| China | General Fabric Belt | Strong Abrasion D | ≥18.0 | ≥400 | ≤100 | 60±5 | GB7984-2001 |

| China | General Fabric Belt | Strong Cut H | ≥24.0 | ≥450 | ≤120 | 60±5 | GB7984-2001 |

| China | Flame Retardant Fabric Belt | FR L | ≥14.0 | ≥400 | ≤250 | 60±5 | GB10822-2003 |

| China | Flame Retardant Fabric Belt | FR D | ≥18.0 | ≥450 | ≤200 | 60±5 | GB10822-2003 |

| China | Steel Cord Belt | Heavy H | ≥17.65 | ≥450 | ≤150 | 60±5 | GB9770-88 |

| China | Steel Cord Belt | Medium M | ≥13.73 | ≥400 | ≤200 | 60±5 | GB9770-88 |

| China | Steel Cord Belt | Strong Abrasion D | ≥18.0 | ≥400 | ≤90 | 60±5 | GB9770-2001 |

| China | Steel Cord Belt | Strong Cut H | ≥25.0 | ≥450 | ≤120 | 60±5 | GB9770-2001 |

| China | Steel Cord Belt | Standard L | ≥20.0 | ≥400 | ≤150 | 60±5 | GB9770-2001 |

| China | Steel Cord Belt | Special P | ≥14.0 | ≥350 | ≤200 | 60±5 | GB9770-2001 |

| China | Heat Resistant Belt | T2 | ≥10.0 | ≥350 | ≤200 | 60±5 | HG2297-92 |

| China | Heat Resistant Belt | T3 | ≥12.0 | ≥350 | ≤200 | 70±5 | HG2297-92 |

| Germany | General Type | W | ≥18.0 | ≥400 | ≤90 | 60±5 | DIN22131/22102 |

| Germany | General Type | X | ≥25.0 | ≥450 | ≤120 | 60±5 | DIN22131/22102 |

| Germany | General Type | Y | ≥20.0 | ≥400 | ≤150 | 60±5 | DIN22131/22102 |

| Germany | General Type | Z | ≥15.0 | ≥350 | ≤250 | 60±5 | DIN22131/22102 |

| Germany | Flame Retardant | K | ≥20.0 | ≥400 | ≤200 | 60±5 | DIN22103 |

| Germany | Antistatic FR | V | ≥15.0 | ≥350 | ≤150 | 60±5 | DIN22103 |

| Australia | Wear Resistant | A | ≥17.0 | ≥400 | ≤70 | 60±5 | AS1333-94 |

| Australia | Antistatic | E | ≥14.0 | ≥300 | … | 60±5 | AS1333-94 |

| Australia | Flame Retardant | F | ≥14.0 | ≥300 | … | 65±5 | AS1333-94 |

| Australia | General | M | ≥24.0 | ≥450 | ≤125 | 60±5 | AS1333-94 |

| Australia | General | TDOZ | ≥23.0 | ≥550 | ≤125 | 64±5 | AS1333-94 |

| Australia | General | N | ≥17.0 | ≥400 | ≤200 | 60±5 | AS1333-94 |

| Australia | Antistatic FR | S | ≥14.0 | ≥300 | ≤250 | 65±5 | AS1332:1991 |

| Australia | PVC | S | ≥12.0 | ≥300 | ≤250 | 70±5 | AS1332:1991 |

| ISO | High Cut & Tear | H | ≥24.0 | ≥450 | ≤120 | 60±5 | ISO10247:1990 |

| ISO | High Abrasion | D | ≥18.0 | ≥400 | ≤100 | 60±5 | ISO10247:1990 |

| ISO | Medium Abrasion | L | ≥15.0 | ≥350 | ≤200 | 65±5 | ISO10247:1990 |

| USSR | General | A | ≥24.5 | ≥450 | ≤160 | 40-60 | DOCT20-85 |

| USSR | General | B | ≥19.6 | ≥400 | ≤160 | 50-70 | DOCT20-85 |

| USSR | General | N | ≥15.0 | ≥400 | ≤100 | 55-75 | DOCT20-85 |

| USSR | General | C | ≥10.0 | ≥150 | ≤200 | 50-70 | DOCT20-85 |

| USSR | Heat Resistant | T1 ≤100°C | ≥11.0 | ≥400 | ≤160 | 55-75 | DOCT20-85 |

| USSR | Heat Resistant | T2 ≤150°C | ≥10.0 | ≥300 | ≤200 | 60-75 | DOCT20-85 |

| USSR | Heat Resistant | T3 ≤200°C | ≥11.0 | ≥400 | ≤200 | 55-75 | DOCT20-85 |

| Japan | General | P | ≥8.0 | ≥300 | ≤400 | … | JIS K 6322:1999 |

| Japan | General | G | ≥14.0 | ≥400 | ≤250 | … | JIS K 6322:1999 |

| Japan | General | S | ≥18.0 | ≥450 | ≤200 | … | JIS K 6322:1999 |

| Japan | General | A | ≥14.0 | ≥400 | ≤150 | … | JIS K 6322:1999 |

| Japan | High Cut & Tear | H | ≥24.0 | ≥450 | ≤120 | 60±5 | ISO10247:1990 |

| Japan | High Abrasion | D | ≥18.0 | ≥400 | ≤100 | 60±5 | ISO10247:1990 |

| Japan | Medium Abrasion | L | ≥15.0 | ≥350 | ≤200 | 65±5 | ISO10247:1990 |

| UK | General Fabric Belt | M24 | ≥24.0 | ≥450 | BS490:P1:1990 | ||

| UK | General Fabric Belt | N17 | ≥17.0 | ≥400 | BS490:P1:1990 | ||

| UK | General Fabric Belt | B | ≥15.0 | ≥350 | ≤150 | 60±5 | BS490:P3:1991 |

| USA | General | RMA1 | ≥17.0 | ≥450 | ≤150 | 60±5 | RMA |

| USA | General | RMA2 | ≥14.0 | ≥400 | ≤175 | 65±5 | RMA |

7. Cost and Maintenance Comparison

In most quarries I work with, operators no longer ask if they should use steel cord belts — they already know they don’t need them. What really matters now is how to get the best value from an EP conveyor belt or NN conveyor belt system. The focus has shifted from raw strength to cost efficiency, uptime, and maintenance practicality.

Let’s start with investment. A standard EP500/4 or NN400/3 belt costs about 30–50% less than a steel cord model with similar tensile capacity. The savings go beyond the belt itself. Because fabric belts are lighter and more flexible, they don’t require oversized pulleys or heavy take-up systems. Installation is faster, the supporting structure can be lighter, and layout changes are easier. For a typical quarry conveyor belt, that means thousands of dollars saved right at the setup stage.

Over time, the real cost difference comes from maintenance and downtime. Fabric belts can be repaired on-site using cold vulcanization or mechanical fasteners, often within one hour. Steel cord belts, on the other hand, require hot vulcanized splicing — specialized presses, trained technicians, and long shutdowns. In production terms, that downtime can mean hundreds of tons lost. The ability to fix an EP or NN belt quickly is one of its biggest economic advantages.

Energy use is another hidden factor. Steel cord belts are stiffer, which increases friction and drive power requirements. Tests on aggregate conveyor belt systems show that switching from a steel cord to a properly tensioned EP belt can reduce energy consumption by 4–8%, depending on system length and pulley size. Over the belt’s lifespan, that energy saving easily outweighs the initial purchase difference.

Service life comparisons also favor fabric belts in quarry conditions. While a steel cord belt might last longer in perfect conditions, quarries are unpredictable — with constant impact, dust, and uneven loading. Most failures come from surface wear and splice fatigue, not from breaking tension. High-grade EP and NN belts with DIN X rubber covers consistently deliver 18 months of reliable service, matching the productivity needs of real-world crushing operations.

From a life cycle cost (LCC) standpoint, the numbers are clear. Our field data show that a full quarry conveyor belt system using EP or NN fabric costs 35–45% less to operate over five years compared with any steel cord setup. Lower maintenance cost, easier installation, and faster repair make fabric belts the logical long-term solution.

So the smarter investment isn’t in steel. It’s in stability. A well-designed EP conveyor belt or NN conveyor belt system gives you control, flexibility, and predictable costs — everything a modern quarry operation really needs.

8. Common Wear Patterns and Failure Analysis

In open quarry operations, most conveyor belt failures are easy to trace once you know what to look for. The working conditions are tough — heavy impact, continuous abrasion, variable tension, and constant exposure to sunlight and dust. Based on our field audits, the failure modes of a quarry conveyor belt fall into five main categories: surface wear, tearing, splice fatigue, edge damage, and weather aging.

8.1 Surface abrasion

More than 65–70% of all early belt failures come from cover wear. Sharp-edged rock, usually 100–400 mm from the primary crusher, cuts and grinds the top rubber layer with every drop. Once the top cover thins, the carcass gets exposed and the wear rate increases rapidly. To prevent this, use rubber grades that comply with DIN 22102, particularly X and W types.

- DIN Xoffers tensile strength ≥25 MPa and abrasion loss ≤120 mm³ — ideal for rock conveyor belts under heavy impact.

- DIN Wprovides higher wear resistance (≤90 mm³) and balanced flexibility, suitable for gravel conveyor belts in secondary transport.

Both grades maintain hardness around 60±5 Shore A, ensuring enough grip without becoming brittle.

8.2 Local tearing and impact cuts

About 15–20% of belt failures start with localized cuts. These occur when material falls off-center or when chutes direct material at sharp angles. The falling rocks strike the belt surface, creating deep cuts near the loading zone. A good preventive measure is using belts like EP400/4 or NN300/4 with thicker top covers (6+3 mm) or a breaker layer for impact absorption. Reinforcing transfer points with impact idlers and chute liners helps distribute force evenly.

8.3 Splice fatigue

Dynamic tension peaks — often 1.3–1.5 times the static load — slowly weaken vulcanized joints. Over time, small separations form between fabric layers, especially if the splice was not cured under stable pressure and temperature. In outdoor quarries, dust and moisture accelerate this deterioration. Regular inspection, re-tensioning, and correct curing conditions are essential for longer splice life.

8.4 Edge wear and delamination

Edge cracking usually results from off-tracking or uneven loading. When the belt constantly rubs against chute skirts or frame edges, the heat generated hardens the rubber, leading to cracking or delamination. Installing proper skirt sealing and using belt trackers can reduce edge damage by up to 30%, according to our internal test data.

8.5 Environmental aging

Unlike underground mines, quarries deal with sunlight, ozone, and wide temperature changes. Surface oxidation and UV exposure harden the rubber over time, reducing flexibility. For outdoor use, we recommend UV- and ozone-resistant compounds blended with NR/BR base rubber, instead of flame-retardant grades. This modification improves weather resistance by 20–25% without sacrificing tensile strength or wear life.

From our inspections across more than 100 quarry systems, the failure distribution looks like this:

- Surface wear– 68%

- Tearing or impact damage– 17%

- Splice fatigue– 9%

- Edge wear– 4%

- Aging or oxidation– 2%

The conclusion is clear: most belt failures don’t come from low tensile strength. They result from poor impact control, wrong rubber grade, or neglected alignment. For quarry operations, belts built with DIN 22102 X or W covers deliver the best balance between abrasion resistance, flexibility, and durability — exactly what an aggregate conveyor belt needs for consistent, long-term performance.

9. Choose Adaptability Over Excess

Choosing the right quarry conveyor belt comes down to matching tension, flexibility, and cover quality — not buying the strongest one. Most quarry conveyors run under 300 meters, carrying variable loads and enduring constant impact. In these conditions, EP and NN fabric belts outperform steel cord designs in cost, reliability, and repair time.

For heavy-duty rock handling, an EP500/4 DIN X belt is the best option. It delivers high tensile strength (≥25 MPa), low elongation (≈1.5%), and excellent resistance to cutting and gouging. It’s designed for the toughest parts of the system — right under the primary crusher or at steep discharge points.

For medium-duty or finished aggregate transport, EP300/3 DIN W offers a balanced structure. It provides sufficient strength, better flexibility, and smoother tracking, reducing energy demand and roller wear.

When short-distance or incline conveyors require more shock absorption, a NN400/3 belt works better. Its nylon fabric resists tearing, absorbs dynamic load energy, and adapts well to frequent starts and stops — ideal for flexible transfer points in an aggregate conveyor belt setup.

Cover grade matters most. Around 70% of quarry belt failures come from surface wear, not fabric breakage. Using DIN X or W covers with abrasion loss below 120 mm³, combined with proper skirt sealing and impact rollers, can extend service life by 30–40%.

Over time, the savings are clear. EP and NN belts reduce downtime and repair cost by over 50%, cutting total life cycle cost by 35–45% compared with steel cord conveyor belts.

EP500/4 for strength. EP300/3 for efficiency. NN400/3 for flexibility.

That’s the most reliable combination for a durable, high-performance quarry conveyor belt.

10.FAQ – Advanced Technical Insights on Quarry Conveyor Belts

1.Why are both NN400/3 and EP500/4 belts suitable for heavy-load quarry zones?

Because they solve two different stress conditions. The EP500/4 quarry conveyor beltprovides higher tensile strength and lower elongation—ideal for steady, high-tension runs. The NN400/3 belt, however, absorbs more dynamic energy from impact loads, protecting the splice and idlers when large rocks fall suddenly. In high-impact areas like the primary crusher discharge, both materials perform well, depending on whether tension control or impact absorption is the main priority.

2.Why is tensile strength not the only factor determining belt life?

In quarry operations, 70% of belt failurescome from surface wear, not carcass rupture. Even a strong belt fails early if its rubber compound can’t resist abrasion or if transfer points cause misalignment. That’s why DIN 22102 X or W grades, with abrasion loss below 120 mm³, matter more than over-specifying tension. Longevity depends on balancing carcass strength, cover quality, and mechanical setup—not just tensile rating.

3.When should a quarry use EP belts and when NN belts?

The choice depends mainly on conveyor length, drop height, and impact energy.

If your system runs over 120 metersor handles moderate tension above EP300 level, an EP conveyor belt is the better fit. Its polyester warp offers low stretch (≈1.5%) and excellent tension stability—ideal for long, steady runs between crushers or screens.

When the conveyor is under 100 meters, especially with drop heights over 3 meters or frequent starts and stops, the NN conveyor belt performs better. Its nylon carcass absorbs up to 25–30% more impact energy, protecting the splice and idlers in heavy shock zones.

A balanced approach works best: use EP500/4 for main haul runs and NN400/3 for short transfer or high-impact sections. That combination creates a stable, long-lasting aggregate conveyor belt system without over-designing.

4.How do rubber cover grades affect performance in rock vs. gravel transport?

Rock requires DIN Xcovers (≤120 mm³ abrasion) to resist cutting and gouging, while gravel benefits from DIN W (≤90 mm³) for fine abrasion resistance. Choosing the wrong cover often shortens life by 30–40%. For mixed material systems, we recommend EP500/4 DIN X in the impact zone and EP300/3 DIN W downstream—this ensures consistent wear balance across the quarry conveyor belt system.

5.How can proper engineering design reduce quarry belt downtime?

By integrating the belt with its mechanical environment. Correct chute angles, impact idlers, and skirt sealing can reduce premature wear by up to 30%, based on field tests. Predictive maintenance—regular inspection of splices, pulleys, and tension—adds another 20–25% life extension. A properly engineered quarry conveyor beltdoesn’t rely on expensive materials; it relies on precise setup and proactive service.