This article gives you a practical, engineering-level framework to select and evaluate a polyester conveyor belt for real heavy-duty applications. It explains how EP structure, carcass design, adhesion and cover rubber jointly determine performance, with references to GB/T standards and quantifiable test methods as proof. Typical use cases such as mining, aggregates, cement and long-distance conveying are broken down by load conditions. Finally, it offers clear selection rules and configuration strategies to reduce failures, extend service life and lower lifecycle cost.

1. Definition and Application Scope of Polyester Conveyor Belt

The skeleton material of a polyester conveyor belt is polyester (PET) fiber, which bears the main tensile force in the warp direction. According to the material properties provided by Wikipedia—Polyester , PET has high tensile strength, low moisture absorption, and excellent dimensional stability. These parameters can be directly used in the engineering design of heavy-duty fabric-core conveyor belts.

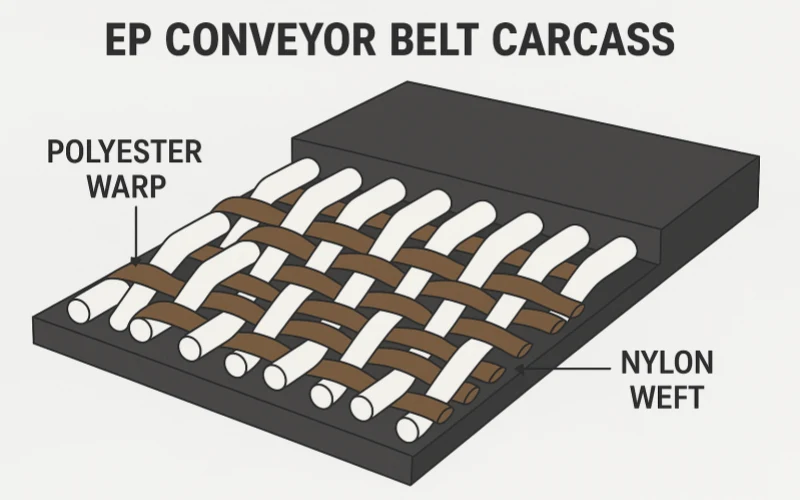

In heavy-duty applications, a single polyester fabric is not used; instead, an EP structure (warp-direction Polyester + weft-direction Nylon) is employed, thus forming the technical classifications of polyester fabric conveyor belt and polyester nylon conveyor belt. The technical advantages of the EP structure can be quantitatively verified through standardized testing: In GB/T 3690–2017 “Test Method for Tensile Strength and Elongation at Full Thickness of Fabric-Core Conveyor Belts”, the elongation value of EP fabric at the reference force is significantly lower than that of NN fabric, indicating that its elongation control is stronger in long-distance, high-tension conveying.

These polyester conveyor belts are primarily used in high-tension, long-distance, large-scale conveying systems, including but not limited to:

- Sand and gravel crushing and aggregate main lines

- Cement raw material and clinker conveying lines

- Continuous conveying systems for mine overburden and ore

- Long-distance main channels for stackers and reclaimers

These operating conditions share common characteristics: high continuous tension, large impact loads, severe environmental fluctuations, and high downtime costs.

Therefore, in the engineering field, the definition of polyester conveyor belt is not merely a material name, but a structural-level product based on quantifiable mechanical performance indicators (strength, elongation, interlaminar adhesion) and standardized testing systems.

2. Technical Relationship Between Polyester Conveyor Belt and EP Conveyor Belt

In textile-reinforced rubber conveyor belts, the terms polyester conveyor belt and ep conveyor belt are often used together but represent different levels of definition. One refers to the material used in the warp, and the other refers to a complete, internationally standardized reinforcement structure. Understanding this distinction is essential for correct belt selection, design verification, and performance prediction.

2.1 EP Is a Standardized Structural Code

In global conveyor belt standards (ISO / DIN / GB), EP is an exact structural designation:

- E = Polyester warp (longitudinal direction)

- P = Polyamide/Nylon weft (transverse direction)

Example:

EP200 means Polyester warp + Nylon weft with a minimum longitudinal tensile strength of 200 N/mm, measured through full-thickness testing procedures such as those defined in GB/T 3690.

EP is therefore a validated engineering structure, not a commercial name.

2.2 Why EP Conveyor Belts Belong to the Polyester Conveyor Belt Family

The warp direction carries the majority of the working tension on a conveyor.

Therefore:

- If the warp = Polyester, the belt belongs to the polyester conveyor belt family.

- EP belts use Polyester in the warp → so all EP belts are polyester beltsat the material level.

What makes EP special is not the Polyester warp alone, but the combination of Polyester warp + Nylon weft, which gives the belt its characteristic performance:

- low longitudinal elongation under load

- high transverse flexibility

- high impact absorption

- improved resistance to weft-direction tearing

These are the reasons EP is the dominant reinforcement structure in medium- to heavy-duty conveyor systems.

2.3 “Polyester Nylon Conveyor Belt” Is Simply EP Expressed in Descriptive Form

The term polyester nylon conveyor belt explicitly states:

- warp = Polyester

- weft = Nylon

This is functionally identical to the formal EP designation.

The only difference is that EP uses a coded structural notation, while “polyester nylon conveyor belt” uses a descriptive notation.

Engineering meaning:

Both terms refer to the same reinforcement system.

2.4 Why Some Buyers Say “Polyester Conveyor Belt” When They Actually Mean EP

Even though “polyester conveyor belt” is a broad category, it is frequently used to indicate EP belts in real-world engineering communication. This comes from field practice:

- Heavy-duty textile belts (quarrying, mining, cement, ports, aggregate) almost always use the Polyester warp + Nylon weft

- Polyester warp is the critical parameter engineers focus on for elongation control.

- Therefore, many buyers use “polyester conveyor belt” as an informal shorthand, even though the accurate technical term is EP.

To avoid selection errors, the belt structure should always be confirmed using its formal EP rating (e.g., EP150, EP250, EP315).

2.5 Engineering Summary

Term | Technical Meaning | Structural Identifier | Equivalent to EP? |

polyester conveyor belt | Any belt using Polyester in the warp | No | No |

ep conveyor belt | Polyester warp + Nylon weft, strength-rated | Yes | Yes |

polyester fabric conveyor belt | Belt using Polyester-based fabric; weft material unspecified | No | Not necessarily |

polyester nylon conveyor belt | Polyester warp + Nylon weft | Yes | Yes (descriptive form) |

2.6 Core Engineering Conclusion

- EP is the internationally standardized reinforcement structure defined as Polyester warp + Nylon weft.

- EP belts are a subset of polyester conveyor belts because the warp is Polyester.

- Any name that explicitly states Polyester warp and Nylon weft is technically equivalent to EP.

- Using “polyester conveyor belt” to refer to EP is common in field communication, but the structural rating (EP200, EP300, EP400…) must be used for engineering decisions.

3. Mechanical Performance of Polyester Conveyor Belt Structures in Heavy-Duty Applications

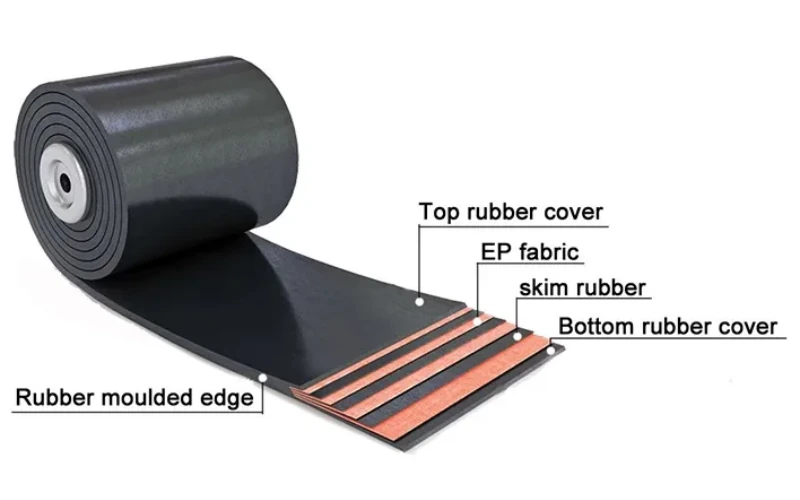

The mechanical behavior of a polyester conveyor belt—specifically in EP construction—directly determines its suitability for long-distance, high-load, and impact-intensive conveying environments. The following subsections describe the performance characteristics validated through standardized procedures such as GB/T 3690, GB/T 6759, and GB/T 10822.

3.1 Tensile Strength Performance of Polyester Conveyor Belt (Warp-Direction Behavior)

In EP construction, the warp direction uses Polyester, which carries the majority of tensile load.

According to GB/T 3690, full-thickness tensile testing evaluates:

- minimum breaking strength (N/mm)

- elongation at break

- elongation at reference load

EP ratings (EP200, EP300, EP400, etc.) define allowable working tension, which determines:

- maximum conveyor center distance

- required drive power

- start-up tension stability

Engineering meaning:

Higher EP ratings improve resistance to creep, reduce re-tensioning frequency, and maintain tracking stability.

3.2 Dimensional Stability and Low Elongation of Polyester Conveyor Belt

Polyester warp provides low creep and a stable modulus, which ensures predictable elongation under load.

This directly benefits:

- long-distance conveyors (80–300 m or more)

- systems with frequent start/stop cycles

- installations requiring precise alignment

Nylon weft, with its higher elasticity, does not affect longitudinal stretch. Instead, it contributes to lateral flexibility, preventing cracking and premature fatigue during troughing and bending.

Outcome:

EP-type polyester conveyor belts maintain longitudinal stability while preserving transverse flexibility—an optimal mechanical balance.

3.3 Impact Resistance of Polyester Conveyor Belt in Heavy-Duty Loading

Heavy-duty applications often involve:

- large lump sizes (80–300 mm)

- high drop heights

- concentrated impact zones (feed hoppers, crushers)

The Polyester warp provides tensile stiffness, while the Nylon weft absorbs impact energy due to its higher elongation capability. This reduces:

- transverse tearing

- ply deformation

- localized overstress damage

EP belts significantly outperform Polyester–Polyester systems in environments where impact energy is high and uneven.

3.4 Fatigue Resistance of Polyester Conveyor Belt Under Continuous Flexing

Conveyor belts experience millions of tension–relaxation cycles during their operational life. Fatigue resistance depends on:

- warp modulus retention

- weft elasticity

- ply adhesion strength

- cover rubber–carcass bonding quality

According to GB/T 6759, adequate ply adhesion prevents delamination under repeated flexing and is essential in systems with:

- small pulley diameters

- reversing operation

- high-cycle working conditions

Conclusion:

EP-type polyester conveyor belts maintain structural integrity under continuous cyclic loading and are suitable for environments requiring long service life with minimal deformation.

4. Typical Heavy-Duty Applications of Polyester Conveyor Belt with EP Structure

The EP-structured polyester conveyor belt is engineered for continuous heavy-duty conveying where high tension, impact energy, and long-distance stability are required. Its balanced reinforcement system—Polyester warp and Nylon weft—enables reliable operation across a wide range of industrial processes.

4.1 Application of Polyester Conveyor Belt in Aggregate and Stone Crushing Systems

Aggregate systems operate under severe mechanical conditions, including:

- variable feed rate

- large lump sizes (80–300 mm)

- repeated drop impacts

- abrasive surfaces

An ep conveyor belt used in these systems offers:

- stable longitudinal modulus due to the Polyester warp

- high impact absorption from the Nylon weft

- reliable ply integrity as verified through GB/T 6759ply adhesion testing

Common installation points include:

- primary crusher discharge conveyors

- secondary crushing lines

- inclined conveyors transporting mixed-density aggregates

The mechanical behavior of the ep conveyor belt reduces structural deformation and prevents breakdowns in high-impact areas.

4.2 Application of Polyester Conveyor Belt in Cement Raw Material and Clinker Conveying

Cement plants require conveying systems capable of:

- handling abrasive limestone, shale, iron ore, and clay

- maintaining tension stability across long center distances

- operating under thermal fluctuations near kiln lines

The polyester conveyor belt with EP reinforcement demonstrates:

- low longitudinal elongation under sustained load

- consistent tracking during long-distance transport

- compatibility with heat-resistant cover compounds validated under GB/T 33510

For clinker transport, the ep conveyor belt combined with specially formulated covers maintains structural integrity by limiting:

- hardening

- shrinkage

- crack formation

4.3 Application of Polyester Conveyor Belt in Mining and Overburden Handling

Mining environments impose extreme material and impact demands, including:

- lump ore sizes exceeding 100–400 mm

- continuous exposure to sharp-edged minerals

- high drop heights and aggressive impact beds

The ep conveyor belt delivers the required mechanical resilience through:

- Polyester warp strength for primary tensile load

- Nylon weft flexibility for impact and shock absorption

- high transverse tear resistance

- controlled fabric deformation across loading cycles

These properties make the ep conveyor belt the primary textile carcass solution for surface mines, overburden conveyors, and underground transfer points where flame-retardant requirements do not apply.

4.4 Application of Polyester Conveyor Belt in Stackers, Reclaimers, and Long-Distance Trunk Conveyors

Long-distance conveying systems (300–800 m and beyond) demand:

- extremely low creep

- consistent tension distribution

- stable tracking over long operating cycles

The polyester conveyor belt with EP reinforcement fulfills these requirements by providing:

- longitudinal stability from Polyester warp

- lateral compliance for troughing from Nylon weft

- high fatigue resistance supported by ply adhesion values defined in GB/T 6759

Such characteristics ensure operational stability in automated stockyard equipment, where belt deformation directly affects stacking geometry and reclaiming precision.

5. Key Factors Affecting the Service Life of Heavy-Duty Polyester Conveyor Belt

The long-term performance of a heavy-duty polyester conveyor belt—specifically those reinforced as an ep conveyor belt—depends on the interaction between carcass structure, cover rubber properties, adhesion quality, and operational loading profile. The following factors directly influence belt lifespan in real industrial environments.

5.1 Wear Resistance of the Cover Rubber in Polyester Conveyor Belt

For a polyester conveyor belt operating in abrasive environments such as aggregate, underground mining, cement plant , the durability of the cover rubber plays a decisive role. Key parameters include:

- DIN abrasion value (mm³ loss)

- tensile strength and elongation of cover rubber

- resistance to micro-cutting and surface fatigue

Heat-resistant or abrasion-resistant compounds must comply with performance thresholds defined in GB/T 33510 for high-temperature exposure and GB/T 10822 for general safety and physical properties.

A failure in cover rubber typically appears before carcass damage and is directly linked to:

- large lump impact

- sharp materials

- improper chute design

- insufficient material flow control

5.2 Matching Carcass Strength to Conveyor Length and Tension Requirements

The structural strength of the ep conveyor belt must align with system parameters such as:

- center distance

- head pulley drive power

- inclination angle

- start-up torque

- counterweight force

Carcass tensile properties—breaking strength, reference load elongation, modulus—are determined by GB/T 3690 full-thickness tensile testing.

Incorrect strength selection leads to:

- excessive permanent elongation

- increased take-up travel

- tracking instability

- premature joint failure

Engineering rule:

Long-distance conveyors require higher EP ratings to maintain low creep and stable running tension.

5.3 Ply-to-Ply Adhesion Strength in Polyester Conveyor Belt

Ply adhesion quality determines the structural integrity of the polyester conveyor belt under repeated impact, flexing, and reversed motion.

Adhesion is verified through GB/T 6759:

- adhesion between cover rubber and fabric

- adhesion between plies

- force required to separate layers under defined speed and angle

Insufficient adhesion will lead to:

- internal delamination

- edge separation

- blister formation

- premature carcass exposure

These failures reduce useful life dramatically and often result in complete belt replacement.

5.4 Structural Balance and Tracking Stability

The mechanical symmetry of the ep conveyor belt influences tracking behavior.

Critical factors:

- warp and weft tension balance

- uniformity of fabric shrinkage

- precision of calendering and ply alignment

- equality of rubber penetration into the carcass

- consistency of edge rubber thickness

Tracking instability is often caused by:

- carcass asymmetry

- uneven ply tension

- non-uniform rubber distribution

- misaligned joining of the belt ends

A well-manufactured polyester conveyor belt maintains stable tracking, even in systems with variable loading or high trough angles.

5.5 Environmental and Operational Factors

Service life is also influenced by external conditions:

- excessive heat and thermal cycling

- chemical contamination

- oil or hydrocarbon exposure

- humidity-induced carcass shrinkage

- material drop height and loading style

These influences determine the appropriate cover compound and reinforcement class required for reliable long-term performance.

6. Common Failure Modes Caused by Incorrect Selection of Polyester Conveyor Belt

Improper selection of polyester conveyor belts—especially when the tensile strength of the polyester conveyor belt does not match the application requirements—can lead to predictable structural failures.

6.1 Edge Cracking in Polyester Conveyor Belt

Edge cracking typically appears when:

- the tensile strength rating of the ep conveyor belt is insufficient for system load

- the trough angle exceeds the belt’s transverse stiffness capacity

- edge rubber hardness is mismatched to impact or lateral stress

- the system has chronic tracking deviations

Mechanical root causes include:

- excessive stress concentration at edges

- inadequate rubber penetration into carcass edges

- asymmetric tension distribution across belt width

Once edge cracking initiates, it propagates quickly under bending and loading cycles. Early-stage edge cracking indicates a mismatch in carcass stiffness or insufficient structural uniformity.

6.2 Ply Separation and Delamination in Polyester Conveyor Belt

Delamination is one of the most severe structural failures and is directly linked to adhesion quality. According to GB/T 6759, ply-to-ply adhesion strength must meet defined thresholds to prevent internal separation during flexing and impact.

Delamination occurs when:

- the polyester conveyor belt is selected with insufficient adhesion grade for impact zones

- rubber penetration during calendering was uneven

- longitudinal load exceeds design strength

- chemical or thermal exposure deteriorates rubber-fabric bonding

Industrial symptoms include:

- soft spots along belt length

- bubbling or blister formation

- visible fabric exposure

- sudden loss of structural rigidity

Delamination rapidly compromises carcass integrity and often requires immediate belt replacement.

6.3 Joint Failure in Polyester Conveyor Belt

Incorrect joint design is a major failure source in an ep conveyor belt. Joint integrity depends on:

- correct splice length for the belt’s tensile rating

- matching splice pattern to the EP structure (Polyester warp + Nylon weft)

- adhesion values meeting standards under GB/T 6759

- uniform rubber distribution and proper curing temperature

Common failure modes include:

- joint pull-out

- shear tear across splice line

- premature separation at step transitions

These failures mostly occur when the tensile class (e.g., EP200, EP300) is mismatched to conveyor tension or when splice workmanship falls below structural requirements.

6.4 Excessive Elongation in Long-Distance Applications

Although Polyester warp provides a low-elongation profile, incorrect model selection or insufficient EP rating still results in:

- excessive take-up travel consumption

- unstable tracking

- delayed start-up due to elastic stretch

- overload on drive pulleys

Reference-load elongation measured under GB/T 3690 defines acceptable deformation rates for a polyester conveyor belt under working tension.

Excessive elongation is common when:

- the conveyor length exceeds 150–300 meters

- the system has high start-up torque

- the selected ep conveyor belt has insufficient modulus

- there is continuous operation under fluctuating loads

This failure mode leads to chronic readjustments, material spillage, and accelerated wear.

6.5 Additional Failure Modes from Misapplication

Other avoidable issues arising from incorrect belt selection include:

- cover wear-throughdue to insufficient abrasion resistance

- carcass shrinkagewhen exposed to unaccounted thermal cycles

- impact fracturingwhen Nylon weft density is mismatched to drop height

- bending fatiguewhen pulley diameters are too small for the belt rating

To ensure reliable operation, this principle must be followed:

The tensile strength of the polyester conveyor belt must match the mechanical and environmental conditions of the conveying system.

7. Limitations of Selecting Polyester Conveyor Belt Based Only on EP Rating

Polyester conveyor belts cannot be selected solely based on their EP rating, which only indicates tensile strength. To avoid structural mismatch and premature failure, a multi-parameter evaluation is required.

7.1 Understanding the Meaning of EP100, EP150, and EP200

An ep conveyor belt rating includes two embedded parameters:

1.Reinforcement structure

- Polyester warp

- Nylon weft

2.Minimum tensile strength per unit width

- EP100 = 100 N/mm

- EP150 = 150 N/mm

- EP200 = 200 N/mm

These values originate from standardized full-thickness tensile testing as defined in GB/T 3690, which measures:

- breaking strength

- elongation at break

- elongation at reference load

However, this tensile rating alone cannot describe how the belt behaves under real operating conditions.

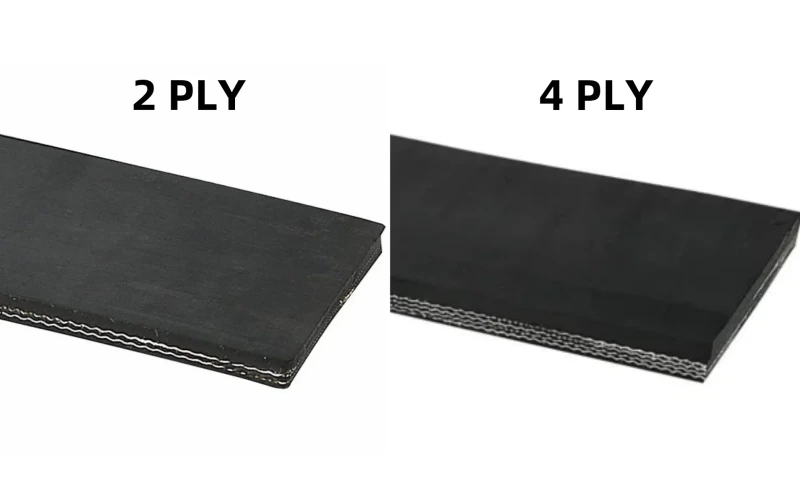

Carcass | Carcass Structure | Carcas | Strength(N/mm) | |||||

Warp | Weft | 2ply | 3ply | 4ply | 5ply | 6ply | ||

EP | Polyester | Nylon | EP100 | 200 | 300 | 400 | 500 | 600 |

EP125 | 250 | 375 | 500 | 625 | 750 | |||

EP150 | 300 | 450 | 600 | 750 | 900 | |||

EP200 | 400 | 600 | 800 | 1000 | 1200 | |||

EP250 | 500 | 750 | 1000 | 1250 | 1500 | |||

EP300 | 600 | 900 | 1200 | 1500 | 1800 | |||

EP350 | 700 | 1050 | 1400 | 1750 | 2100 | |||

EP400 | 800 | 1200 | 1600 | 2000 | 2400 | |||

EP500 | 1000 | 1500 | 2000 | 2500 | 3000 | |||

EP630 | 1260 | 1890 | 2520 | 3150 | 3780 | |||

7.2 Risks of Selecting Only by Tensile Strength Rating

Relying solely on EP strength values ignores several critical structural and application-specific factors:

(1) Ignored Transverse Properties

The EP rating does not reflect:

- transverse modulus

- impact absorption capability

- weft density or fabric structure

- lateral stiffness required for troughing

Incorrect transverse stiffness leads to edge cracking, off-tracking, and premature carcass distortion.

(2) No Information About Adhesion Strength

EP ratings do not include ply adhesion strength, which is tested separately under GB/T 6759.

Weak adhesion results in:

- ply separation

- carcass delamination

- premature structural failure under impact or flexing

These failures can occur even when tensile strength is sufficient.

(3) No Indication of Cover Rubber Performance

EP ratings do not specify:

- abrasion resistance

- heat resistance

- oil or chemical resistance

- aging properties

Standards such as GB/T 33510 and GB/T 10822 govern these characteristics, not the EP strength class.

Applications with high abrasion or thermal cycles require specially formulated rubber, regardless of EP rating.

(4) Elastic Behavior Under Load Is Not Defined

Even two belts with identical EP ratings may behave differently under operational tension due to:

- warp modulus

- fabric weave construction

- Nylon weft elasticity

- internal damping characteristics

These factors influence:

- take-up travel requirements

- start-up tension behavior

- long-distance elongation

- dynamic load response

Thus, EP strength alone is insufficient for engineering calculations.

7.3 Importance of Matching Structural Design to Operating Conditions

Correct selection of a polyester conveyor belt requires evaluating:

- loading pattern

- drop height

- lump size distribution

- center distance

- pulley diameter

- belt speed

- start-up torque

- environmental conditions (temperature, moisture, chemistry)

The ep conveyor belt must be selected as a complete structural system, not as a single numerical rating. The wrong carcass configuration can lead to:

- increased elongation

- loss of tracking

- premature edge wear

- delamination

- splice failure

These failure modes frequently occur in systems where the EP rating was chosen correctly but structural parameters were ignored.

7.4 Engineering Summary

Choosing a polyester conveyor belt based solely on its EP strength rating disregards essential mechanical, structural, and environmental factors.

A correct selection must consider:

1.tensile class (EP rating)

2.carcass structure

3.ply adhesion strength

4.cover rubber formulation

5.conveyor geometry and loading conditions

Only when these elements are aligned can the ep conveyor belt perform reliably in heavy-duty operation.

8. Cost Drivers Within the Polyester Conveyor Belt Family, Including EP Heavy-Duty Structures

Within the broader polyester conveyor belt family, cost differences arise from variations in reinforcement structure, material grade, bonding systems, and manufacturing precision. The ep conveyor belt represents the heavy-duty structural configuration within this family, and its engineering requirements naturally lead to higher production complexity and cost. The following factors explain how cost is distributed across different performance levels inside the same polyester conveyor belt system.

8.1 Reinforcement Structure and Fabric Engineering Requirements

The reinforcement fabric is the core determinant of cost inside the polyester conveyor belt family.

All belts in this family rely on Polyester warp, but the structural configuration differs depending on mechanical demands.

Higher-performance structures—such as the ep conveyor belt—utilize:

- Polyester warp engineered for controlled modulus, low creep, and stable elongation under load

- Nylon weft designed for transverse flexibility, impact absorption, and tear resistance

These reinforcements require:

- higher yarn quality

- greater density control

- specialized finishing treatments

- precise warp–weft balance to maintain carcass stability

Such enhancements significantly increase fabric cost because they directly support heavy-duty performance requirements.

8.2 Rubber Cover Formulation Requirements Across Different Performance Levels

The rubber cover represents a major portion of total production cost.

Inside the polyester conveyor belt family, cover properties vary by application:

- abrasion resistance

- heat resistance

- oil or chemical resistance

- aging and ozone resistance

In heavy-duty requirements—typical for an ep conveyor belt—rubber compounds must meet stringent performance thresholds specified in GB/T 33510 for thermal resistance.

High-grade compounds require:

- more complex polymer systems

- specialized fillers

- controlled curing behavior

This increases both raw material and processing costs.

8.3 Adhesion System and Interlayer Bonding Strength

Adhesion quality is a defining cost factor in higher-performance polyester conveyor belts.

Bonding performance is evaluated using GB/T 6759, which specifies:

- cover-to-fabric adhesion

- ply-to-ply adhesion

- delamination resistance

To meet the demands of a heavy-duty ep conveyor belt, the adhesion system must deliver:

- deeper rubber penetration

- higher interlayer strength

- optimized calendering conditions

- precise curing control

These requirements impose tighter process tolerances and increased production time, leading to higher manufacturing costs.

8.4 Structural Enhancements for Heavy-Duty Operating Conditions

Inside the polyester conveyor belt family, heavy-duty configurations incorporate additional structural elements. These include:

- increased Nylon weft density for impact zones

- thicker skim rubber to improve flex fatigue performance

- reinforced edges for tracking stability

- moisture-resistant warp treatments

- optional anti-tear reinforcements depending on material drop height and lump size

Such enhancements increase the material volume, processing steps, and manufacturing precision required, directly raising the cost of belts designed to function as an ep conveyor belt.

8.5 Manufacturing Precision and Quality Control Intensity

Higher-tier polyester conveyor belts require stricter manufacturing tolerances.

These include:

- ply alignment accuracy

- rubber gauge uniformity

- precise warp tension balancing

- controlled rubber penetration profiles

Quality control must also follow standardized procedures such as GB/T 3690 for tensile properties and GB/T 6759 for adhesion performance.

A heavy-duty ep conveyor belt undergoes more rigorous inspection and more frequent sampling, which increases both production time and quality assurance cost.

8.6 Engineering Summary

Cost variation within the polyester conveyor belt family is driven by structural and material requirements—not by product categorization.

Higher-performance configurations (such as the ep conveyor belt structure) require:

- superior reinforcement fabric

- advanced rubber formulations

- enhanced adhesion systems

- additional carcass reinforcement

- tighter manufacturing tolerances

- expanded quality-control procedures

These engineering requirements naturally increase cost because they directly support reliable operation in high-impact, high-tension, and long-distance conveying environments.

9. Application-Oriented Selection Guidelines for Polyester Conveyor Belt

This final section translates the structural and mechanical principles discussed earlier into practical selection guidance. The goal is to help engineers, procurement teams, and plant operators determine when a heavy-duty polyester conveyor belt, especially in the form of an ep conveyor belt, is the correct choice and how to configure it based on the application environment.

9.1 Industrial Scenarios That Require Heavy-Duty Polyester Conveyor Belt

The ep conveyor belt configuration becomes essential in environments where the mechanical load exceeds what standard fabric structures can safely tolerate. Typical applications include:

- primary and secondary aggregate crushing lines

- cement clinker transport and high-temperature raw material conveyors

- open-pit and underground mining systems

- stockyard stacking and reclaiming equipment

- long-distance trunk conveyors (200–2,000+ m center distance)

These applications present combined challenges such as high impact, abrasive flow, thermal cycling, and continuous duty—all conditions in which the polyester conveyor belt must deliver stable modulus, strong adhesion, and resistance to long-term fatigue.

9.2 Default Structural Configuration Requirements

A heavy-duty polyester conveyor belt should meet several baseline structural requirements:

- Polyester warp with controlled modulus and minimal creep

- Nylon weft with elasticity engineered for transverse impact absorption

- ply count matched to system tension and troughing geometry

- skim rubber thickness sufficient for flex-fatigue life

- reinforced edges for stable tracking

- cover rubber formulation matched to material abrasiveness and temperature

Unlike catalog-style rules, these requirements are always determined by actual conveyor loading, not label strength or marketing categories.

9.3 Selection Strategy Based on Application Conditions

(1) High Impact + Large Lump Size

Choose an ep conveyor belt with:

- high-density Nylon weft

- increased skim thickness

- abrasion-resistant cover

- reinforced carcass to distribute shock load

Typical industries: mining, primary crushers, quarry belts.

(2) Continuous High-Temperature Material

For clinker, hot return material, and kiln-feed conveyors:

- select heat-resistant rubber compound per GB/T 33510

- ensure stable modulus under thermal cycling

- avoid structures sensitive to thermal shrinkage

(3) Long-Distance Conveyors

Critical selection points:

- low reference-load elongation

- high EP rating matched to steady-state tension

- precise carcass symmetry for tracking stability

- splice design capable of handling cumulative tensile load

Long-distance conveying amplifies every structural weakness, so reinforcement stability becomes the dominant criterion.

(4) Abrasive or Sharp-Edged Material

Material such as quartz, copper ore, iron ore, or clinker requires:

- high abrasion-resistant cover

- correct cover thickness to avoid premature penetration

- controlled carcass tension to minimize surface wear patterns

A polyester conveyor belt with under-specified cover hardness will fail regardless of carcass strength.

(5) Variable Load + Frequent Start-Stop Operation

For conveyors with unstable feeding conditions:

- modulus stability

- high adhesion between plies (verified by GB/T 6759)

- strong weft elasticity

- durable splice configuration

These factors prevent delamination and excessive deformation.

9.4 Principle-Based Selection Rules

To avoid misalignment, cracking, rapid wear, or splice failure, selection must follow these final industry-proven rules:

- Rule 1:The reinforcement structure must always match the worst-case loading condition.

- Rule 2:The EP rating is a minimum threshold, not the final indicator of performance.

- Rule 3:Cover rubber selection is as important as carcass selection.

- Rule 4:Conveyor geometry dictates the minimum carcass stiffness.

- Rule 5:Heavy-duty systems must prioritize long-term stability over initial price differences.

- Rule 6:A polyester conveyor belt achieves its true performance only when carcass, cover, adhesion, and installation are correctly matched.

9.5 Final Selection Framework

A practical engineering method for selecting the correct polyester conveyor belt:

- Define system tensile requirements→ choose EP rating

- Confirm impact and material flow characteristics→ choose weft density + ply structure

- Identify abrasion and temperature conditions→ choose cover compound

- Review system geometry (pulley diameter, troughing, transition)→ verify flex-fatigue capability

- Assess operational duty cycle→ confirm adhesion and stability requirements

- Evaluate cost vs. structural suitability→ eliminate structures that cannot meet duty

10.Conclusion

A polyester conveyor belt—including its heavy-duty structure as an ep conveyor belt—should never be selected by strength labels alone.

Its real performance comes from how well the carcass structure, rubber formulation, adhesion system, and conveyor loading conditions match each other.

The essential rule is simple:

Choose structure based on actual mechanical demand, not catalog categories.

When the reinforcement design matches tension, impact load, geometry, and temperature, the belt becomes stable, predictable, and long-lived.

When it does not, failure is certain—regardless of nominal strength.

Correct selection is not about picking a belt.

It is about engineering compatibility.

This framework ensures the chosen ep conveyor belt is not simply “strong enough,” but truly engineered for the target environment.

11.FAQs

1. Why does an ep conveyor belt with correct EP rating still show longitudinal deformation during the first 200–500 hours of operation?

Because Polyester warp goes through modulus stabilization, a known mechanical behavior where:

- internal fiber tension equalizes

- residual stresses from calendering relax

- rubber–fiber interface adjusts under load

This period is defined in GB/T 3690 as “elongation under reference load,” and belts with lower-quality Polyester warp show larger creep.

A stable belt should stabilize after this period with predictable residual elongation < 1.0%.

2. Why do some polyester conveyor belts exhibit asymmetric tracking even when the conveyor alignment is within tolerance?

Because tracking instability is often caused by carcass asymmetry, not conveyor structure.

Common internal causes:

- unbalanced warp–weft tension

- uneven rubber penetration on the edges

- differential shrinkage of Polyester warp during vulcanization

- off-center ply alignment during assembly

Measured via carcass camber and edge straightness deviation per factory QC.

Even a 1–2 mm asymmetry can cause persistent drift.

3. How does Nylon weft density influence impact energy absorption and damage tolerance?

Higher Nylon weft density:

- increases transverse elasticity

- distributes shock load over a larger structural area

- prevents localized weft rupture

- reduces carcass tearing when large lumps hit the belt

In high-impact conveyors, weft density is more important than EP strength rating.

An ep conveyor belt with insufficient weft density will fail even at moderate tensions.

4. Why does delamination often start near the idler junction rather than material loading point?

Because idler junctions create cyclic interlayer shear stress, which over time exceeds adhesion strength if:

- skim rubber is too thin

- rubber penetration into fabric is insufficient

- bonding agents were poorly distributed

- curing temperature was uneven

This failure is detected through GB/T 6759 adhesion tests; belts with marginal adhesion will fail first at cyclic flex points—not at loading points.

5. Why can two polyester conveyor belts with identical cover hardness show dramatically different abrasion rates?

Because abrasion is controlled by:

- polymer network crosslink density

- filler–rubber dispersion uniformity

- heat buildup during operation

- carcass stiffness (affects surface pressure distribution)

Hardness alone does not describe wear behavior.

Two covers at 65 Shore A can differ in abrasion resistance by 30–50%, depending on mix precision and vulcanization curve.

6. Why do splices in ep conveyor belts fail predominantly under reversible conveyor operation?

Reversible conveyors impose:

- alternating shear direction

- non-uniform load reversal

- fluctuating tension zones near the splice

- increased flex–shear cycles

If the splice fabric alignment deviates even 1–2 mm, or if the skim rubber bond is not symmetric, splice fatigue accelerates.

Reversible conveyors require:

- longer splice length

- higher adhesion grade

- symmetric rubber penetration

- matched warp tension during preparation

This is one of the highest loads an ep conveyor belt splice can experience.

7. Why do belts with excellent tensile strength still fail in systems with small pulley diameters?

Small pulleys increase bending strain, creating:

- longitudinal cracking

- rapid splice fatigue

- micro-fractures in the skim layer

- delamination at ply interfaces

The limiting factor is flexural modulus, not EP strength.

If pulley diameters violate the minimum recommended bending radius, the belt will fail regardless of tensile rating.

8. Why does a polyester conveyor belt used in high-humidity environments develop carcass stiffening over time?

Polyester warp absorbs minimal moisture, but Nylon weft absorbs significantly more (up to 3–4%), causing:

- dimensional change

- transient swelling–shrink cycles

- altered warp–weft balance

- local tension concentrations

These cyclic changes stiffen the carcass and increase bending resistance.

Moisture-resistant warp/weft finishing treatments are required to prevent this effect.

9. Why can an ep conveyor belt show increasing elongation even after initial stabilization?

This late-stage elongation usually indicates:

- progressive Nylon weft relaxation

- skim rubber fatigue

- micro-delamination under cyclic loading

- inadequate carcass modulus for the conveyor’s start-up tension

When elongation increases after stabilization, this is a structural mismatch problem—not a wear issue.

10. Why does cover rubber cracking often start near the belt edges instead of the center?

Because belt edges endure:

- higher flexing frequency

- higher bending strain

- asymmetrical tension

- increased exposure to environmental elements

- lower effective thickness due to trimming tolerances

Edge cracking is a structural signal that the belt’s transverse stiffness and carcass symmetry are insufficient for the application.