Conveyor belt clips might seem like a minor detail, but in reality, they often decide whether a line keeps moving or comes to a standstill. I’ve seen more than one operation lose precious hours simply because the wrong clip was chosen. The evidence is clear: when thickness, pulley size, and clip type are matched correctly, belts last longer and downtime drops. From PVC packaging lines to rubber belts in heavy industries, the right connection always makes a difference. In the end, it’s these small choices that secure big results.

1.How Conveyor Belt Clips Affect Performance

Let’s be honest—nobody ever praises conveyor belt clips when everything is running fine. They’re small, often ignored, and usually noticed only when things go wrong. But here’s the twist: these little clips can decide whether your system runs like clockwork or grinds to an expensive halt.

Think about it. Choose the wrong clips, and suddenly your “smooth production line” becomes a waiting line. Downtime starts ticking, maintenance crews rush in, and profits take a hit. All because a tiny piece of metal or plastic wasn’t the right fit. It’s a bit like losing a soccer match because the shoelaces came undone—frustrating and completely avoidable.

That’s why this guide matters. It’s built for people who deal with real belts in real factories. We’ll look at light-duty belts like PVC, PU, TPU, felt, and light rubber, as well as heavy-duty belts such as EP and NN. For steel cord belts (ST), we’ll keep it short, since vulcanized splicing is still the main rule.

Here’s the deal: mechanical conveyor belt joining clips and hot splicing aren’t rivals—they’re tools for different jobs. Clips are fast, flexible, and easy to maintain. Hot splicing gives you seamless strength but demands downtime and skilled hands. Knowing when to use which is what saves you money.

The secret to picking right? Three things:

1.Belt thickness and minimum pulley diameter

2.Compatibility with scrapers and cleaners

3.How often you plan to open and close the joint

Stick with these, and you’ll avoid the usual headaches. In the next sections, I’ll break down the types of conveyor belt fasteners, explain where they shine, and point out common traps. The goal is simple: fewer shutdowns, longer belt life, and smarter use of your conveyor belt clips.

2.Types of Light Duty Conveyor Belt Clips-PVC,PU

When it comes to light-duty conveyor belts—PVC, PU, TPU, thin felt, and light rubber—the choice of conveyor belt clips can make or break your system. These belts may look flexible and easy to handle, but the wrong fastener can turn them into a maintenance nightmare. To save you from costly mistakes, let’s break down the most common clip types, how they perform, and where they fit best.

2.1 Plastic Spiral Clips

The plastic or monofilament spiral is often underestimated. Many people assume it’s only suitable for “plastic film” type belts, but in reality, it works with most PVC, PU, TPU belts, and even some felt and light rubber belts. Its sweet spot is 1–8 mm belt thickness with a minimum pulley diameter of 12–30 mm.

The big win here is flexibility and silence. Spirals bend smoothly around small pulleys, produce low noise, and can even be made completely non-metallic—ideal for food-grade applications where metal detectors are in place. Need to open and close your belt frequently? This is your friend. Just be careful in high-heat or aggressive chemical environments; standard PET or PA spirals might not hold up. If that’s your case, PEEK spirals step in with higher resistance.

2.2 Wire Hook Clips

If you’re dealing with knife-edge transfers or tiny pulleys, wire hook clips shine. With a range of 1–5 mm belt thickness and minimum pulley diameters of 10–50 mm, they are among the thinnest fasteners available. Installation is lightning fast, which is why many plants love them for urgent repairs.

However, there’s a catch. Wire hooks have a profile, and when you add heavy scrapers or cleaners, those hooks can take a beating. That’s why “low-profile hooks” or alternatives like spirals are often recommended when cleaner pressure is high. Still, for delicate products and fast-paced operations, wire hooks are hard to beat.

2.3 Small Alligator Clips

Also known as toothed-plate clips, these are stronger than wire hooks and offer quick on-site installation. They typically cover 2–6 mm thickness with 25–100 mm pulleys. Their strength lies in higher pull-out resistance, making them suitable for belts that need more security.

The downside? Those teeth create a height. If you run a strong scraper, it may clash with the plates unless you skive the belt to bury the fastener flush with the surface. For medium-duty work and quick replacements, small alligator clips are a practical choice.

2.4 Butterfly Hinge Clips

Simple, clean, and surprisingly effective—the butterfly hinge fastener works in the 1.5–5 mm range with pulleys from 20–60 mm. Its design makes it easy to clean, which is why it’s common in food-processing lines. Available in both stainless steel and plastic, it adapts well to hygiene-sensitive industries.

One thing to check before you install: the “wings” of the hinge when unfolded. They can interfere with side guides or cleats if the design is too tight. Beyond that, it’s a straightforward solution that does exactly what you need—keep things moving with minimal fuss.

2.5 Staple Fasteners

Finally, the staple fastener (sometimes called ready-set fastener) is the versatile all-rounder for light to medium loads. It handles 1.5–6 mm belts with pulleys of 25–75 mm. It offers a low profile, better impact resistance, and compatibility with cleaners—a neat balance between strength and smoothness.

The installation, however, requires a proper conveyor belt fastener tool to drive the staples securely. Once in place, they deliver reliable performance. For plants that need a durable solution without sacrificing scraper compatibility, staples are often the go-to.

2.6 Comparison Table

Here’s a quick reference table to help you visualize the differences:

| Fastener Type | Belt Thickness (mm) | Min. Pulley Diameter (mm) | Advantages | Watch-outs | Typical Use Cases |

| Plastic Spiral | 1–8 | 12–30 | Super flexible, quiet, non-metallic option | Limited in high-heat or harsh chemicals | Food-grade, packaging, frequent opening |

| Wire Hook | 1–5 | 10–50 | Ultra-thin, ideal for knife-edge transfer, quick install | Scraper pressure may damage hooks | Light products, fast transfers |

| Small Alligator | 2–6 | 25–100 | Stronger than wire hooks, quick replacement | Teeth height can interfere with scrapers | Medium-duty, field repairs |

| Butterfly Hinge | 1.5–5 | 20–60 | Easy to clean, simple design | Wing spread may clash with guides | Food lines, hygiene-sensitive |

| Staple Fastener | 1.5–6 | 25–75 | Low profile, impact-resistant, cleaner-friendly | Requires proper tool for install | General light to medium duty |

2.7 Standards and Technical References

You can’t talk about types of conveyor belt fasteners without mentioning standards. Two are particularly important for light-duty clips:

- ISO 1120:2012 defines how to measure the static strength of mechanical joints in textile conveyor belts. In practice, this ensures your clip isn’t weaker than the belt itself.

- ISO 703:2017 covers the measurement of troughability—the ability of a belt to flex. For light-duty belts with small pulleys, this is crucial. Low-profile clips like wire hooks and spirals perform better in such flexibility tests.

These standards remind us of a simple truth: a fastener must not become the weak link in the system. Always confirm with suppliers whether their clips meet or exceed these benchmarks.

Light-duty conveyor belt clips might be small, but they decide whether your system keeps humming or keeps breaking. Plastic spirals give you quiet flexibility. Wire hooks handle knife-edge transfers. Small alligators add strength. Butterfly hinges simplify cleaning. And staples provide balance and scraper compatibility.

By understanding their ranges, strengths, and limits, you avoid guesswork and downtime. In the next section, we’ll move into heavy duty conveyor belt clips, where impact, tension, and durability play a much bigger role. But for now, if you’re running light-duty belts, the right clip is your first insurance policy against trouble.

3.Heavy Duty Conveyor Belt Clips-Rubber

When you step into the world of heavy-duty belts—EP, NN, and even steel cord when emergency repair is needed—the stakes change. Here, belts are thicker, loads are harsher, and failures are far more expensive. Choosing the right heavy duty conveyor belt clips isn’t just a matter of convenience; it’s a matter of keeping entire plants running.

3.1 Rivet-Hinged Fasteners

The rivet-hinged clip is a workhorse. It covers belts from 6–14 mm thickness with pulley diameters of 125–400 mm. Thanks to multiple rivets, it distributes load evenly and resists pull-out better than smaller clip types. It’s the go-to in aggregates, coal, and mining where belts face constant impact.

Its key strength? Impact resistance. Unlike smaller clips, rivet fasteners can take a pounding without loosening. Installation is straightforward, and with the right tool, it can be done in the field. The downside: if not installed with precision, rivets may weaken the belt carcass.

3.2 Bolt-Hinged Fasteners

When tension gets serious, bolt-hinged clips step in. They handle 6–16 mm belts with pulley diameters of 150–600 mm. Bolts offer higher tensile strength and re-tightening capability, which makes them durable under high loads.

Think of these as the “long-distance runners” of conveyor belt joining clips. They don’t just hold the belt; they allow you to adjust and maintain tension over time. The trade-off is that installation requires more time, and the joint is stiffer compared to lighter options.

3.3 Solid Plate Fasteners

When things get extreme, solid plate fasteners (bolt solid-plate) take over. They fit belts from 8–20 mm thickness, with pulley diameters of 300–800 mm or more. These are not hinged, which means less flexibility but maximum strength.

You’ll see these in temporary repairs for extremely heavy loads or in applications where impact resistance is more critical than smooth running. They’re tough but not elegant—the belt loses bending ability, so use them only where absolutely necessary.

3.4 Rubber Screw Splices

Here’s where things get interesting. Rubber screw splices handle 6–15 mm belts and pulleys around 150–400 mm. Instead of creating a rigid metal joint, they integrate screws into rubber, leaving a continuous rubber surface. That makes them scraper-friendly, water-resistant, and quick to install.

They shine in wet, muddy, or corrosive environments—think quarries, construction, or fertilizer plants. Because the splice blends with the belt’s surface, it reduces wear from scrapers and offers a near-seamless transition.

3.5 Heavy Alligator Clips

Large toothed-plate fasteners, often called heavy alligator clips, typically work with 5–12 (up to 14) mm belts and pulleys above 150–400 mm. They’re popular in quick assembly jobs, especially in markets where local brands produce cost-effective versions.

Their advantage lies in speed: quick installation, easy maintenance, and good performance for medium tension applications. But when facing high impact or heavy drop heights, rivet-hinged or bolt-hinged options are safer bets. Heavy alligator clips are the compromise between speed and strength.

3.6 Comparison Table

Fastener Type | Belt Thickness (mm) | Min. Pulley Diameter (mm) | Advantages | Watch-outs | Typical Applications |

Rivet-Hinged | 6–14 | 125–400 | Excellent impact resistance, distributes load evenly | Needs precise installation | Mining, coal, aggregates |

Bolt-Hinged | 6–16 | 150–600 | High tensile strength, can be re-tightened | Stiff joint, slower install | High-tension conveyors |

Solid Plate | 8–20 | 300–800+ | Maximum strength, handles extreme loads | Poor flexibility, temporary use | Emergency heavy-load repairs |

Rubber Screw Splice | 6–15 | 150–400 | Scraper-friendly, water-resistant, quick to install | Limited to mid-range loads | Wet/muddy environments |

Heavy Alligator | 5–12(14) | 150–400 | Quick assembly, easy maintenance | Not ideal for high impact | Medium-tension conveyors |

3.7 Standards and Technical References

Heavy-duty belts don’t forgive poor fastener choices, and international standards back this up:

- DIN 22131specifies requirements for steel cord conveyor belts, including splice strength and pulley diameters. Even if you use mechanical fasteners temporarily, the belt itself is designed with these standards in mind. (DIN 22131 Reference )

- ISO 15236-1:2016covers steel cord conveyor belts, including test methods for measuring strength and elongation. It reinforces the point that mechanical joints should be temporary on ST belts, since vulcanized splicing achieves full rated strength. (ISO 15236-1)

- For fire and safety, the MSHA flame resistance standard(30 CFR Part 14) applies to belts used in underground mines. Any fastener choice must consider whether the belt itself meets these requirements. (MSHA Flame Resistance )

These references underline a simple rule: never push mechanical clips beyond their limits. They are excellent tools, but standards show us that beyond certain belt thickness or strength levels, vulcanized splicing remains the only reliable option.

Heavy-duty conveyor belt clips are not “one-size-fits-all.” Each type has its battlefield: rivet-hinged for impact, bolt-hinged for tension, solid plates for brute strength, rubber screw splices for wet conditions, and heavy alligator clips for speed.

Get the match right, and your belt runs longer with fewer breakdowns. Get it wrong, and downtime eats into your budget faster than you think. The good news? With standards like DIN 22131 and ISO 15236 guiding the way, you don’t have to guess. You just have to choose wisely.

4.How to Select Conveyor Belt Clips

Selecting the right conveyor belt clips is one of those decisions that looks simple on paper but carries big consequences in practice. Get it right, and your belts run smoothly, your scrapers last longer, and your maintenance crew spends more time drinking coffee than fixing joints. Get it wrong, and downtime becomes a regular guest on your shop floor.

From years of field experience, I can tell you that three factors matter more than anything else: belt thickness and pulley diameter, cleaner compatibility, and maintenance frequency. These are the pillars of smart fastener selection.

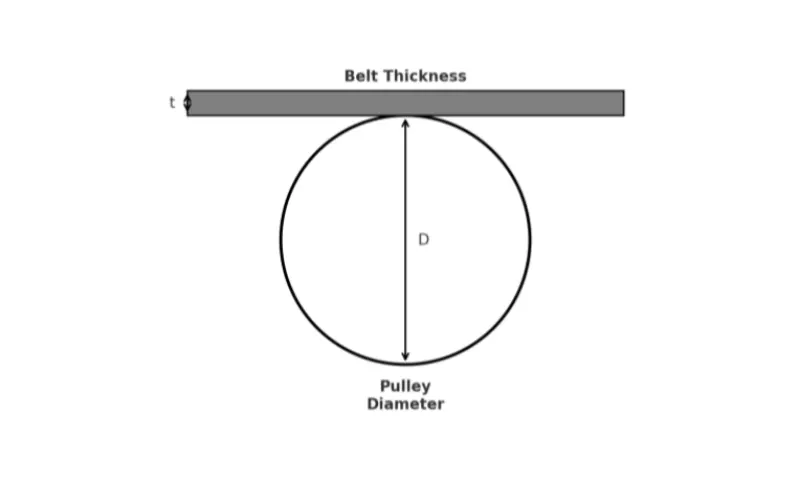

4.1 Belt Thickness and Pulley Diameter

Every conveyor system is designed with a certain belt thickness and pulley size. Ignore these, and you’ll see failures faster than you expect.

- Light-duty belts (PVC, PU, TPU, felt, light rubber) usually fall between 1–8 mm thickness with pulley diameters as small as 10–50 mm. For these, flexible clips like plastic spirals or wire hooks are ideal.

- Heavy-duty textile belts (EP, NN) range from 6–20 mm and demand pulleys between 125–800 mm. Here, only rivet-hinged or bolt-hinged clips can handle the tension.

- Steel cord belts (ST) are a different story. According to ISO 15236-1:2016, mechanical fasteners are only suitable for emergency repairs; vulcanized splicing is the only way to achieve full rated strength (ISO Reference).

One common mistake? Installing conveyor belt alligator clips on belts thicker than they’re designed for. Yes, they’ll fit—for a week. But as soon as the belt bends over a pulley, fatigue starts, and you’ll soon be calling for emergency repair.

Pro tip: Follow CEMA’s guideline that pulley diameter should be at least 20 times the belt thickness for textile belts. It’s a small detail that drastically extends belt and fastener life (CEMA Belt Book).

4.2 Cleaner and Scraper Compatibility

Now let’s talk about scrapers. They’re essential for keeping your belt clean, but they’re not friends with every type of clip. Some conveyor belt clips sit above the belt surface, and when a scraper applies pressure, two things happen:

- The fastener wears faster, sometimes loosening long before its rated life.

- The scraper itself takes serious damage, especially if it’s a tungsten carbide or ceramic blade. High-profile clips and aggressive scrapers don’t mix—they end up destroying each other.

So what’s the solution?

- Low-profile fasteners such as staple fasteners or rivet-hinged clips are scraper-friendly, especially when installed with a skive so the fastener sits flush with the belt surface.

- Rubber screw splices are even better, because they leave a continuous rubber surface, eliminating the clash between scraper and metal.

- High-profile fasteners like heavy alligator plates are risky in scraper-heavy environments; you’ll burn through both clips and cleaners.

According to DIN 22131, poor compatibility between fasteners and cleaning systems can reduce overall belt service life by up to 30% (DIN Standard Reference ). That’s not a margin you can afford to ignore.

Pro tip: Always tell your supplier what type of scraper system you use—primary, secondary, or both. It changes the fastener recommendation completely.

4.3 Maintenance Frequency and Accessibility

Finally, think about how often you’ll need to access the belt joint. Some operations open belts weekly for cleaning or inspection. Others run for months without interruption.

- Frequent access → Choose clips like plastic spirals, wire hooks, or butterfly hinges. These allow quick opening and closing without damaging the belt each time.

- Occasional access → Staple fasteners or conveyor belt alligator clips strike a balance. They’re strong enough for daily use but still manageable if you need to break the belt occasionally.

- Rare access → If your belt runs continuously and doesn’t need frequent opening, hot splicing or heavy-duty permanent clips are more reliable.

It’s like choosing a door hinge. If you open it 30 times a day, you need something flexible and forgiving. If you open it once a year, strength matters more than convenience. Belts are no different.

4.4 Final Checklist for Conveyor Belt Clip Selection

By now, you’ve seen that choosing the right conveyor belt clips is not about brand loyalty or guesswork—it’s about fitting the fastener to your system’s needs. Here’s the condensed checklist:

- Check belt thickness and pulley diameter → Never mismatch; follow ISO and CEMA guidelines.

- Evaluate scraper compatibility → Go low-profile or rubber-friendly if cleaners are in place.

- Consider maintenance frequency → Pick clips that match how often you’ll need to open the belt.

- Don’t skip standards → ISO 15236, DIN 22131, and CEMA rules exist to save you money and downtime.

- Communicate with suppliers → Always provide full details—belt type, environment, cleaners, and expected use—before ordering clips.

The bottom line is simple: the right conveyor belt joining clips save you downtime, extend belt life, and protect both your fasteners and your cleaners. The wrong choice? It costs more than just parts—it costs trust, time, and productivity.

5.Conveyor Belt Clips Parameters

When it comes to selecting conveyor belt clips, nothing saves more time than a clear parameter table. You don’t want to dig through catalogs every time you need to match a clip to a belt. Below are quick-reference charts for both light-duty and heavy-duty applications. These tables summarize thickness ranges, minimum pulley diameters, and typical strengths of the most common fasteners.

5.1 Light Duty Conveyor Belt Clips

Light-duty fasteners are designed for PVC, PU, TPU, thin felt, and light rubber belts. They prioritize flexibility, frequent access, and low-noise operation.

Fastener Type | Belt Thickness (mm) | Min. Pulley Diameter (mm) | Key Features | Typical Applications |

Plastic Spiral | 1 – 8 | 12 – 30 | Very flexible, quiet, non-metallic option | Food lines, packaging, frequent openings |

Wire Hook | 1 – 5 | 10 – 50 | Ultra-thin, ideal for knife-edge transfers | Light products, fast transitions |

Small Alligator | 2 – 6 | 25 – 100 | Higher pull-out strength than wire hooks | Medium-duty repairs, quick assembly |

Butterfly Hinge | 1.5 – 5 | 20 – 60 | Simple, easy to clean, stainless/plastic versions | Food processing, hygiene-focused |

Staple Fastener | 1.5 – 6 | 25 – 75 | Low profile, scraper-friendly, impact-resistant | General light to medium duty |

5.2 Heavy Duty Conveyor Belt Clips

Heavy-duty clips are built for EP, NN, and special cases of ST belts. Their focus is impact resistance, high tension, and durability under demanding loads.

Fastener Type | Belt Thickness (mm) | Min. Pulley Diameter (mm) | Key Features | Typical Applications |

Rivet-Hinged | 6 – 14 | 125 – 400 | Excellent impact resistance, load distribution | Mining, coal, aggregates |

Bolt-Hinged | 6 – 16 | 150 – 600 | High tensile strength, re-tightenable | High-tension conveyors |

Solid Plate | 8 – 20 | ≥ 300 – 800 | Maximum strength, poor flexibility | Temporary heavy-load repairs |

Rubber Screw Splice | 6 – 15 | ~150 – 400 | Continuous rubber surface, scraper-friendly | Wet/muddy environments |

Heavy Alligator | 5 – 12(14) | ≥ 150 – 400 | Quick assembly, easy to maintain | Medium-tension conveyors |

5.3 Why These Parameters Matter

Tables like these may look simple, but they reflect critical standards. For example:

- ISO 703:2017specifies how to measure belt troughability, directly linked to minimum pulley diameters (ISO 703 PDF ).

- ISO 1120:2012ensures that mechanical fasteners deliver enough static strength relative to the belt (ISO 1120 PDF ).

By keeping belt thickness, pulley diameter, and application in mind, you can quickly choose the right fastener without guesswork.

6.Materials and Pins for Conveyor Belt Clips

When choosing conveyor belt clips, most people focus only on type and size. But here’s the secret: the material of the clip body and the pin holding it together can make or break your joint. Pick the wrong combination, and you’ll either replace clips too often or damage your belt prematurely. Pick the right one, and your system runs longer, cleaner, and safer.

6.1 Clip Body Materials

The clip body is the backbone of any fastener. Its job is to hold tension, resist impact, and survive in your operating environment. The three most common materials are:

- Galvanized Steel– Affordable and widely available. It handles most general-purpose applications, but it may corrode in wet or chemical environments.

- Stainless Steel (304/316)– Ideal for food-grade operations or corrosive conditions. Type 304 resists rust, while Type 316 offers superior resistance to chemicals and saltwater.

- Specialty Wear-Resistant Steel– Designed for high-abrasion or mining applications. Stronger than galvanized, but also heavier and more expensive.

Pro tip: If your system requires metal detection, stainless steel is usually the safer choice, since it’s both durable and compliant with industry requirements.

6.2 Pin Options

The pin is the small part that often gets overlooked, yet it plays a critical role in fastening performance. It’s the hinge that allows clips to open and close. Options include:

- Nylon Pins – Lightweight, flexible, and non-metallic. Perfect for food lines or operations requiring metal detection compliance.

- Stainless Steel Pins – Strong and corrosion-resistant. Suitable for most environments where durability and hygiene matter.

- PEEK Pins – High-performance plastic with excellent heat and chemical resistance. Great for specialty applications.

- Coated Steel Pins – Provide extra wear protection, especially in abrasive conditions.

Think of the pin as the “silent worker.” It doesn’t get much attention, but if it fails, your entire belt joint fails.

6.3 Installation Considerations

Material choice also affects installation. A harder steel clip may require a dedicated conveyor belt fastener tool to ensure proper fit. Softer materials like plastic spirals are easier to install but need careful handling to avoid deformation. Always match the tool to the material—forcing the wrong tool can reduce fastener life by 20–30%.

At the end of the day, choosing the right materials and pins for conveyor belt clips is about matching the environment, the product being conveyed, and your maintenance needs. Galvanized steel may be cheap, but it won’t last in salty air. Nylon pins may be light, but they can’t take high heat. Balance cost, performance, and environment—and your clips will stay where they belong: holding the belt together, not lying broken on the shop floor.

7.Ordering Conveyor Belt Clips

Ordering conveyor belt clips is more than telling a supplier your belt width. Without complete details, you risk getting a fastener that doesn’t fit, wears out too quickly, or even damages your belt and cleaners. To save time and prevent mistakes, always provide a full ordering checklist.

7.1 The Ordering Checklist

When you contact your supplier, make sure you include:

7.1.1 Belt Type and Structure

- PVC, PU, TPU, EP, NN, or ST

- Food-grade, oil-resistant, or heat-resistant options

7.1.2 Belt Dimensions

- Width × total thickness

- For rubber belts: top and bottom cover thickness

7.1.3 Pulley Information

- Minimum and drive pulley diameters

- Whether pulleys are lagged

- Belt speed

7.1.4 Tension and Load

- Rated tension (N/mm or PIW)

- Drop height, impact, and material abrasiveness

7.1.5 Cleaning System

- Type of scraper (primary, secondary, or both)

- Blade material (polyurethane, steel, ceramic)

7.1.6 Operating Environment

- Water, mud, dust, chemicals, or extreme temperatures

- Magnetic or metal detection requirements

7.1.7 Fastener and Pin Preferences

- Clip body: galvanized steel, stainless steel, or wear-resistant steel

- Pin type: nylon, stainless steel, PEEK, or coated steel

- Whether a conveyor belt fastener toolis needed

7.1.8 Maintenance Habits

- High-frequency access → hinge or spiral clips

- Low-frequency access → staple or rigid clips

7.2 Example Ordering Form

Parameter | Example |

Belt Type | EP 200/2, oil-resistant |

Width × Thickness | 800 mm × 10 mm |

Pulley Diameter | Drive 250 mm, Min. 200 mm |

Belt Speed | 2.5 m/s |

Tension | 8 N/mm |

Cleaning System | Primary scraper, polyurethane blade |

Environment | Wet, ambient 25–40 °C |

Fastener Material | Galvanized steel |

Pin Type | Stainless steel |

Tool Required | Yes – stapling tool |

Maintenance | Low-frequency access |

7.3 Case Studies: Three Common Fasteners

While the checklist covers the basics, the exact parameters you must provide can change depending on the fastener type. Let’s look at three of the most common options for rubber belts—solid plate, alligator, and butterfly hinge fasteners—and see what details are critical.

7.3.1 Solid Plate Fasteners

1)Typical Material Options:

- Galvanized steel (standard applications)

- Stainless steel (corrosive or food-related environments)

- Specialty wear-resistant steel (heavy impact or mining operations)

2)Critical Ordering Parameters:

- Belt thickness range (usually 8–20 mm)

- Belt width (mm)

- Minimum pulley diameter (≥ 300–800 mm)

- Cover thickness (top and bottom rubber layers)

Because solid plates are rigid, suppliers need exact thickness and pulley details to ensure the fastener won’t overstress the belt during flexing. Cover thickness is especially important—too thin, and the fastener may tear through the carcass. If the belt is thicker than 20 mm, most suppliers will recommend either customized solid plates or vulcanized splicing to ensure long-term reliability.

7.3.2 Alligator Fasteners

1)Typical Material Options:

- Carbon steel with zinc coating (general use)

- Stainless steel (resistant to moisture and corrosion)

2)Critical Ordering Parameters:

- Belt thickness (2–14 mm, depending on model)

- Belt width

- Minimum pulley diameter (≥ 25–400 mm)

- Belt tension rating (N/mm or PIW)

Alligator clips use teeth that bite into the belt carcass. If you don’t provide accurate belt thickness, the teeth may over-penetrate or fail to grip securely. Pulley diameter also defines which model fits best—choose the wrong one, and fatigue will set in too quickly. For higher-tension belts, giving the supplier your exact tension rating helps them recommend a stronger series.

7.3.3 Butterfly Hinge Fasteners

1)Typical Material Options:

- Stainless steel (food-grade or corrosion-resistant)

- Engineering plastics (low-noise, light-duty applications)

2)Critical Ordering Parameters:

- Belt thickness (1.5–5 mm)

- Belt width

- Minimum pulley diameter (≥ 20–60 mm)

- Presence of belt accessories (guides, cleats, sidewalls)

Butterfly clips unfold like wings when installed. If you don’t specify whether your belt has cleats, guides, or sidewalls, suppliers cannot guarantee that the fastener will fit without interference. This is a common oversight in food and packaging conveyors. The right material choice also matters—plastic hinges reduce noise and eliminate rust, while stainless steel offers durability and hygiene.

Ordering conveyor belt clips is about more than width and thickness. The checklist ensures you provide the essentials, but examples like solid plates, alligator clips, and butterfly hinges show why extra parameters matter. Solid plates need cover thickness, alligator clips depend on tension and pulley size, and butterfly hinges require accessory clearance. Share these details upfront, and your supplier will deliver clips that fit, last, and perform exactly as expected.

8.Choosing the Right Conveyor Belt Clips

At the end of the day, conveyor belt clips decide whether your system runs smoothly or breaks down when you least expect it. Every choice—clip type, material, size, and installation—matters.

We’ve seen how light-duty and heavy-duty clips differ, why belt thickness and pulley size are non-negotiable, and how cleaners, maintenance, and environment all shape the right selection. The checklist, the parameters, and the case studies all point to one truth: the right clip is the difference between reliability and downtime.

So when you order your next set of clips, don’t guess. Provide full details, think about long-term performance, and match the fastener to your belt and system. Choose wisely, and your conveyor keeps moving the way it should.

9.FAQ – Conveyor Belt Clips

1) Why do you show clip usage only up to 20 mm belt thickness?

Great question. The 20 mm figure is a recommended range based on our field experience, not a hard ceiling. You can adjust it to your situation. For belts thicker than ~20 mm (rubber or PVC), I recommend hot splicing for a longer-lasting joint, especially under high tension or large pulleys. Oversized solid-plate clips do exist, but they typically require larger pulley diameters, lower speeds, and de-rated tensions. Bottom line: choose clips for speed and access; choose hot splicing for maximum joint life.

2) Mechanical clips or hot splicing—which should I pick?

Use mechanical conveyor belt clips when you need fast installation, easy removal, or frequent access (washdowns, inspections, changeovers). Use hot splicing for permanent, seamless, high-strength joints—it’s the default for steel-cord (ST) belts and many heavy EP/NN belts. If uptime between interventions is long and tension is high, hot splicing wins. If you need speed and flexibility, clips win.

3) Will belt cleaners damage clips—or will clips damage cleaners?

Both can happen. High-profile clips under heavy scraper pressure can wear fast and chip metal or ceramic blades. Mitigate it by using low-profile fasteners, skiving the joint flush, or choosing rubber-surface solutions (e.g., rubber screw splices) where possible. Also match blade material and pressure to the clip type, and keep alignment tight. Good compatibility protects both the joint and the cleaner and extends belt life.

4) What clip materials and pins should I choose?

Match them to the environment and detection needs.

- Clip body:Galvanized steel (general), 304/316 stainless (food/corrosion), wear-resistant steel (abrasion/impact).

- Pins:Nylon/PEEK (non-metal, low noise, good for metal detection), stainless (durable, hygienic), coated steel (abrasion).

If you run metal detection, avoid carbon-steel pins. For caustic washdowns or salt air, go 316 stainless or PEEK Right material = longer, safer service.

5) Can conveyor belt clips be used on steel cord or special rubber belts?

Generally, steel cord (ST) belts are designed for hot vulcanized splicing, because clips cannot fully lock into the rigid steel reinforcement. Mechanical fasteners may be used only as emergency or temporary joints, often with solid plate or oversized alligator fasteners, but this requires larger pulley diameters and reduced tension.

For special rubber belts—like flame-retardant, heat-resistant, or oil-resistant belts (DIN, ISO, RMA, CSA standards, as listed in the Tiantie catalog)—mechanical clips are technically compatible if the thickness and cover allow, but suppliers still recommend hot splicing for maximum strength and safety.

use clips on textile belts (EP/NN, PVC/PU) as a primary method; use them on steel cord or extreme belts only as a temporary fix or quick repair.