Choosing the right food conveyor belt is not guesswork—it is a systematic decision shaped by food characteristics, temperature limits, cleaning chemistry, and equipment constraints. This guide clarifies the true selection logic, exposes common pitfalls, and provides engineering-level criteria backed by industry standards and practical manufacturing experience. By understanding how each material behaves under real operating conditions, buyers and engineers can avoid premature failures and hidden compliance risks. Ultimately, the goal is simple: build a production line where stability, hygiene, lifetime, and cost are all predictable and controllable.

1. Selection Logic for Your Food Conveyor Belt

I previously wrote an article about how to choose PVC conveyor belts in the food industry. However, other materials suitable for the food industry are also suitable. Different production environments and different food characteristics will have varying degrees of impact on the selection of food conveyor belts, and even determine the material selection for food-grade conveyor belts.

If the logic is wrong from the start, problems such as misalignment, cracking, bubbling, and difficulty in cleaning are basically only a matter of time.

1.1 What You Really Want From a Food Conveyor Belt

Clearly stating your goals first will save you 80% of the pitfalls.

In a food factory, a qualified food conveyor belt must meet at least four goals simultaneously:

- Food safety standards are always insurmountable: The belt body must use food-grade conveyor belt material, pass FDA or equivalent food contact tests, and must not shed fibers, release off-odors, or contain plasticizer flavorings.

- Stable operation, no hassle: Consistent speed, tension, and tracking eliminate the need for daily engineer adjustments.

- Easy cleaning, conforming to your cleaning SOP: Withstands existing disinfectant treatments, varying cleaning temperatures and frequencies, rather than aging after six months of cleaning.

- A triple match between lifespan, budget, and production environment: Not simply buying the cheapest option, but choosing the food processing conveyor belt with the lowest overall cost within your envisioned lifespan and without exceeding the limits of your set production environment.

1.2 Let the Application Choose the Material

For food conveyor belts, material selection isn’t about arbitrarily choosing PU, PVC, or PTFE, but rather about working backward from the application scenario:

- Frying areas, high-oil areas, meat cutting lines → typically prioritize PU, or specific high-end food-grade conveyor belt materials.

- High-temperature baking, microwave drying, freezing tunnels → more likely to use PTFE, silicone, or composite structures.

- For grain packaging and dry goods conveying→ PVC is often sufficient and the most economical conveyor belt solution for food processing. However, for applications like grain silos, rubber conveyor belts may be necessary.

What you really need to do is label each production line: oil/high sugar/high temperature/freezing/cleaning intensity/operating speed, and then let the material “self-eliminate.” What remains are usually only 1-2 reasonable options.

1.3 Common Traps You Should Avoid

Many buyers fall into the same pitfalls when choosing food conveyor belts for the first time:

- Looking only at the “food grade” label, ignoring operating conditions: Food grade doesn’t mean oil resistance, high temperature resistance, or strong cleaning resistance; it might only be fine for dry goods at room temperature.

- Confusing “usable” with “good”: A belt that can rotate doesn’t mean stable tracking or that it won’t crack after a year.

- Ignoring cleaning chemicals and pH range: Are you using neutral foam or strong alkaline CIP? This directly determines whether a food conveyor belt can reach its designed lifespan.

Once you have the goals, scenarios, and common misconceptions clear in your mind, your choices between different food conveyor belt materials will shift from “gut feeling” to “rational deduction.”

2. Key Selection Dimensions for a Food Conveyor Belt

When you actually begin selecting a food conveyor belt, you’ll find that: Correct selection isn’t as simple as “choosing between PU and PVC,” but rather a complete systems engineering process encompassing material characteristics, temperature range, mechanical parameters, cleaning chemicals, and delivery boundaries.

Food-grade conveyor belts are inherently highly customized industrial products; no factory will stock them in large quantities. Therefore, every technical parameter affects the final production scheduling, processing, and delivery cycle.

The following five selection dimensions are key variables that any food factory, equipment manufacturer, or food-grade conveyor belt manufacturer must consider simultaneously during design, procurement, and operation.

2.1 Material Characteristics of the Transported Food

Each type of food “chooses” its own food conveyor belt. Ignoring material characteristics will result in failure for any material, just sooner or later.

● High Oil Content (Meat, Fried Foods, Fatty Foods)

Oil can penetrate and damage PVC. Therefore, in frying areas, cooked food sections, and meat processing sections, PU or specific rubber formulations should be prioritized.

PU has significantly higher oil resistance than PVC (data can be found in FDA CFR 21.177.1680 ).

● Dry & Free-Flow Materials (Powders, Coffee Beans)

The focus here is not on oil resistance, but rather on the coefficient of friction, anti-slip patterns, and baffle structure.

PVC is a more cost-effective food processing conveyor belt.

● High Sugar / Sticky Products (Candy, Chocolate, High-Sugar Baking)

Sugars become stickier at higher temperatures, and only silicone or PTFE food conveyor belts can maintain long-term non-stick properties. However, many factories lower the workshop temperature to prevent “sugar sticking,” in which case PVC is also an option.

● Wet, Acidic, or Aqueous Products (Seafood, Fruit Washing)

Hydrolysis resistance and abrasion resistance are important considerations; typical options are PU or food-grade white rubber conveyor belts.

● Dough / Semi-liquid Foods

Smooth PU or silicone is necessary to avoid adhesion, stringing, or dents.

2.2 Temperature Requirements

Temperature is the number one killer of conveyor belt life in the food industry. Each food conveyor belt material has a defined physical limit.

● Low-Temperature Processing (-20°C to -70°C)

PTFE > PE > PU

PVC will rapidly become brittle when exposed to low temperatures for extended periods, so PVC conveyor belts are not recommended in this temperature range.

● Standard Food Processing Temperature (-10°C to 80°C)

PU, PVC, and rubber are all suitable and represent the normal temperature range for most production lines. However, if your temperature limit is close to 80°C, we generally do not recommend using PVC. We generally begin to discourage the use of PVC above approximately 65°C.

● High-Temperature Baking (100°C ~ 200°C)

Silicone > PTFE

Ordinary PU will hydrolyze after prolonged exposure to temperatures above 100°C, such as in applications involving high-temperature steam.

● Extreme Baking & Microwave (200°C ~ 260°C)

Only PTFE can withstand this for extended periods.

PTFE can operate continuously at temperatures up to 260°C (Source: DuPont™ PTFE TDS, ).

2.3 Operating Parameters

Operating parameters are the root cause of premature failure in many Chinese food conveyor belts, and are far more easily overlooked than the material itself.

● Speed (Recommended ≤ 2.5 m/s)

Based on industry recommendations in DIN 22102. Higher speeds result in faster wear and increased slippage after cleaning.

● Minimum Pulley Diameter

The roller diameter varies significantly depending on the material:

- PU: Suitable for small diameters (20–50mm)

- PVC: Requires a larger diameter

- PTFE conveyor belt: Must be set according to the mesh structure, otherwise the mesh surface will deform.

● Tracking Stability

Material sensitivity to deviation, ranked as follows:

PU < PVC < Rubber < Silicone < PTFE (most sensitive)

2.4 Cleaning & Chemical Compatibility

The cleaning intensity of food-grade conveyor belts is one of the variables that determines their longest lifespan.

● pH Compatibility

Most materials can withstand pH 5–9; strong alkaline CIP (pH > 10) will accelerate PVC aging.

● Water Hydrolysis

High-temperature water cleaning will significantly shorten the lifespan of PU (especially >60°C).

● Oxidation & Sanitizers

Chlorine-containing and oxidizing cleaning agents will accelerate silicone surface whitening or rubber hardening.

● Cleaning Frequency

Cleansing twice daily versus twice weekly can result in a 3–5 times difference in lifespan (Reference: EHEDG Cleaning Validation Guidance).

2.5 Budget & Delivery Boundaries (No-Stock Industry Reality)

Food-grade conveyor belts differ from general industrial belts; for factories, they are almost never inventory items.

Whether you’re sourcing PU, PVC, rubber, silicone, or PTFE, the delivery time depends on:

- Material production schedule

- Coating/Laminating/Patterning (except Rough Top)

- Processing structure (baffles, skirts, guides)

- Food contact migration testing

- Quality inspection and dimensional verification

- Export packaging and logistics window

✔ PU/PVC food-grade conveyor belts (custom production)

12–20 days

✔ Rubber food-grade conveyor belts (EP/NN skeleton + food-grade adhesive)

18–30 days

✔ Silicone food-grade conveyor belts

20–28 days

✔ PTFE/Teflon food-grade conveyor belts

15–30 days

Why No Factory Has Real “Stock”?

Because every food conveyor belt differs in:

- width

- length

- ply

- hardness

- pattern

- reinforcement

- cleats / sidewalls / guides

- food safety requirements

- cleaning SOP

Therefore, the food-grade conveyor belt industry is a “make-to-order (MTO) industry” rather than a “stock-based (MTS) industry”.

3. Food-Grade Conveyor Belt Material Characteristics

As a manufacturer with over a decade of experience in the conveyor belt industry, I’ve come to believe more and more: The success of food-grade conveyor belts isn’t based on the “quality of the material,” but rather on whether the material is well-suited to the operating conditions.

In this chapter, I won’t just describe the materials; I’ll tell you: under what operating conditions each food-grade material performs exceptionally well, in which applications it’s absolutely unusable, how failures typically occur, why they occur, and how to prevent them.

3.1 PU Food Grade Conveyor Belt

If I could only recommend one material to the food industry, I would unhesitatingly tell you: PU, the food conveyor belt you can never go wrong with.

Why PU Is the Benchmark Material

PU has passed FDA CFR 21.177.1680 food contact regulations, making it a true food-grade conveyor belt material. Its four core advantages directly cover most food processing conditions:

- Strong oil resistance (edible oil/animal oil)—suitable for meat, fried, and prepared food production lines

- Excellent abrasion resistance—2–4 times higher than PVC

- Strong hydrolysis resistance—suitable for daily washing or even multiple washings per shift

- Dense surface, non-absorbent of odors, oil, and lint

In the high-frequency washing, high humidity, and high-grease environment of the food industry, PU’s stability is very close to that of “golden material.”

Structural Features

PU conveyor belts can achieve almost all the structures required in the food industry:

- Glossy/Matte finish

- Diamond pattern, cross pattern, golf ball pattern

- Skirt baffles (30–120mm)

- Guide strips (key tracking structure)

- Anti-stick surface/Sponge layer/Red rubber bottom layer

Unique advantage: The bottom fabric can be completely encased in PU, with no exposed fabric texture on the belt surface, resulting in an extremely high level of hygiene.

Performance Data

- Thickness: 8 mm – 20 mm

- Width:≤ 2000 mm

- Hardness: 80–90 Shore A

- Tensile Strength: ≥100 N/mm (1.8mm fabric-resin)

- Temperature Range:-20°C ~ +80°C

- pH compatibility: 5–9

These data are from our factory’s standard models and are consistent with mainstream international standards.

Failure Modes & Solutions

You may see PU failure in the following situations:

① Long-term strong alkaline cleaning (pH>10) → Whitening, hydrolysis, foaming

Solution: Customer provides cleaning SOP → We adjust the formula’s tolerance window.

② Turkey processing/fried foods → Insufficient oil resistance in the old formula

Solution: Add oil-resistant additives + optimize resin formula.

③ Small roller diameter + high-frequency start/stop → early cracking

Solution: Choose a higher tensile strength skeleton (such as 2-ply PU).

PU is the safest and most versatile food-grade conveyor solution.

If you’re unsure what to choose, choose PU; you can’t go wrong.

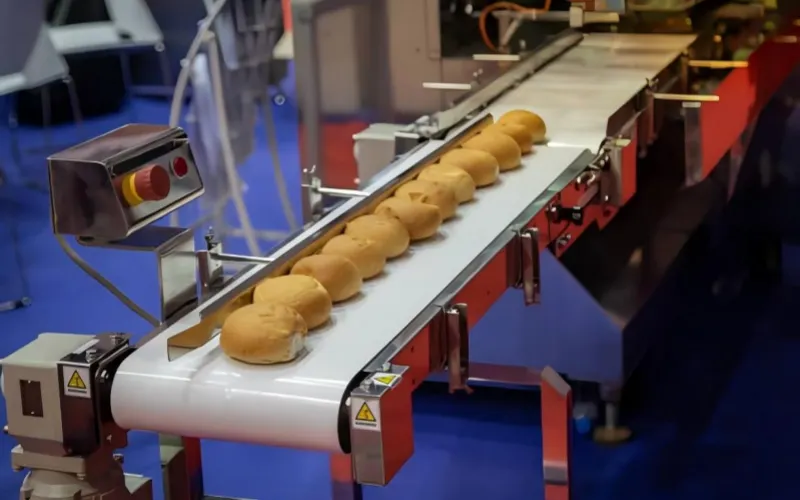

3.2 PVC Food Grade Conveyor Belt

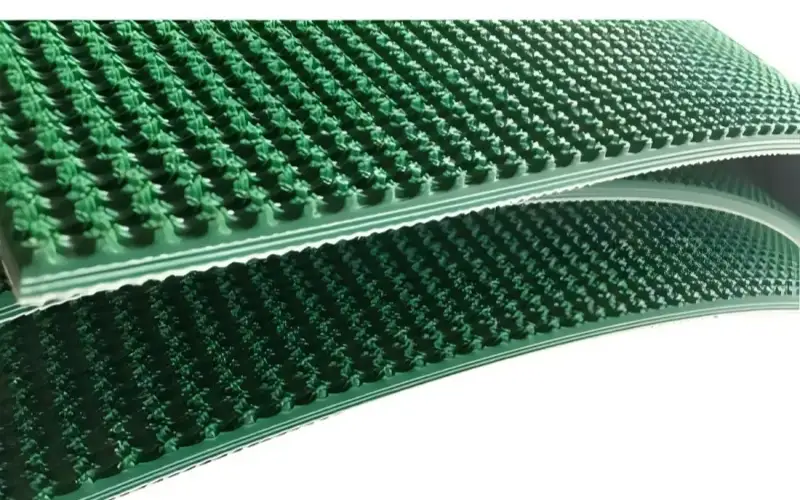

PVC is the “most cost-effective” food conveyor belt in the food industry, but not the strongest. It’s suitable for dry goods, packaging, and light loads.

Where PVC Performs Best

PVC is suitable for:

- Bread packaging lines

- Biscuit packaging sections

- Dry bulk materials (grains, coffee, cereals)

- Light-duty conveying in dry environments

Its biggest advantages are: affordable price, diverse structures, and flexible processing.

Material & Structure

PVC food belts consist of:

- Polyester fiber cloth (belt core)

- PVC overlay

comprising a paste-like PVC coating and curing in a foam oven.

Available patterns include:

- Lawn pattern

- Diamond pattern

- Herringbone pattern

- Grid pattern

- Golf pattern

- Fabric pattern and over twenty other structures

Performance Data

- Thickness: 0.8–5 mm

- Width: 2000–3000 mm

- Hardness: 65A–75A

- Tensile Strength: 100–400 N/mm (PL12–PL50)

- Temperature: -10°C ~ +80°C

PVC is very stable in room temperature food packaging applications.

Failure Modes & Warnings

① Oil penetration → Cracking, blistering (high probability)

PVC inherently has poor oil resistance; this is a material property, not a brand issue.

Cannot be used for frying/meat processing.

② Low-temperature brittleness (< -10°C)

Avoid cold storage conditions.

③ Strong alkaline cleaning → Cover adhesive hardening

PVC is not suitable for CIP with pH > 10.

In summary:

PVC is the “king of dry goods packaging,” but not an all-around material for food processing.

3.3 PE Food Grade Conveyor Belt

PE conveyor belts are uncommon in the food industry, but they are very valuable in certain special conditions, especially in low-temperature processing and scenarios with high chemical compatibility requirements.

Where PE Works Best

- Frozen food conveying

- Low-temperature packaging lines

- Factories with extremely high chemical resistance requirements

- Transferring certain lightweight materials

PE itself is naturally food-grade and widely used in food contact materials (including packaging films).

Structural Characteristics

PE does not use a “multi-layered fabric and rubber” structure; it is:

- Extruded molding

- Uniform overall structure

- High rigidity

- Non-absorbent and odor-free

Performance Data

- Thickness:Customized to order

- Width / Length:Fully customized

- Temperature: -30°C~+80°C

- Chemical resistance: Extremely strong

- Surface energy: Low (not easily absorbed)

Failure Mechanisms

① Small roller diameter → Difficulty bending, early cracking

PE is not suitable for complex roller systems.

② Medium and high temperature deformation

It softens significantly above 80°C.

PE is a “powerful performer for specific scenarios,” not a general-purpose conveyor material.

3.4 Silicone Food Grade Conveyor Belt

If your products include chocolate, candy, gummies, and high-sugar baked goods, silicone is the absolute winner.

Why Silicone Rocks in Sticky Food Processing

Silicone has the following characteristics:

- Extremely strong non-stick/release properties

- High temperature resistance (-40°C to 260°C)

- Odorless, non-toxic, and food-grade certified

The confectionery industry describes it in one sentence:

“Silicone strips don’t stick to sugar, and they don’t stick to chocolate.”

Structural Characteristics

- Single or double-layer silicone

- Can be reinforced with fiber cloth

- Typical thickness 2–5 mm

- Extremely easy to clean, suitable for areas containing sugary foods

Typical Failure Cases

① High-temperature aging (exceeding continuous 220°C)

Silicone material gradually hardens → temperature reduction or formula upgrade required.

② Poor roller bending performance → unstable tracking

Due to the material’s softness, stronger guides or tracking systems are required.

③ Lower tensile strength than PU/rubber

Not suitable for heavy loads.

Silicone is the “ultimate material for confectionery baking lines,” but it is not suitable for heavy loads.

![]()

3.5 PTFE (Teflon) Food Conveyor Belt

PTFE is the absolute primary material for extreme temperature conditions in the food industry.

Extreme Temperature Superiority

PTFE’s continuous operating temperature:

- -70°C ~ +260°C (Source: DuPont PTFE data)

This is the widest temperature range of all food-grade materials.

Where PTFE Dominates

- Baking oven inlet and outlet

- Microwave drying line

- High-temperature dehydration equipment

- Quick-freezing tunnel

- Release of high-sugar, non-stick foods

- Low-temperature frozen food transportation

PTFE is the “arsenal-grade material of the baking line.”

Structural Options

- PTFE Flat Tape

- PTFE Mesh Tape (1×1, 2×5, 4×4, 10×10 mm)

- Fiberglass Base Fabric / Kevlar Base Fabric (determines tensile strength)

Performance Data

- Thickness:5–1.35 mm

- Tensile Strength: 310/290 N/cm ~ 900/600 N/cm

- Temperature: -70°C–260°C

- Chemical resistance: Resistant to strong acids, strong alkalis, and most solvents

Failure Modes

① Mesh structure tension decay

Requires regular tracking and adjustment.

② Insufficient base fabric strength → tearing

High-strength fiberglass or Kevlar must be used.

③ High-speed operation → edge opening, curling

Edge sealing or PTFE reinforcement strips are required.

PTFE = The ultimate solution for high temperatures+non-stick properties+extreme working conditions.

3.6 Rubber Food Grade Conveyor Belt

Food grade rubber belts are not commonly used for light-duty conveying in direct contact with food, but they perform strongly in high-load, high-impact applications, particularly in grain and packaging applications.

Where Rubber Works Well

- Signal-angle conveyor

- Grain warehouse

- Packaging conveyor

- Medium-to-heavy load food handling

- Cold storage loading area

Features of rubber belts:

- High impact resistance

- High abrasion resistance

- Extremely high stability

Structure

Unlike PU/PVC, rubber belts do not use a “layers of fabric, layers of rubber” structure, but rather:

- EP canvas (EP100, EP150, EP200…)

- NN canvas

- Cover rubber ≥0mm (top layer)

- Bottom rubber ≥5mm

Performance Data

- Tensile Strength of Cover: ≥15 MPa

- Adhesion Strength:

- Between layers ≥2 N/mm

- Cover rubber and fabric layer ≥1 N/mm (ordinary)

- EP/NN high-end structure ≥5 / ≥3.2 N/mm

- Temperature: -20°C~+80°C

Failure Modes

① Unclean → Microbial growth

Food factories must add antibacterial formulas or increase cleaning frequency.

② Poor bending performance

Rubber is suitable for straight conveying, but not for complex multi-roller systems.

③ Excessive weight → Increased equipment energy consumption

Requires collaborative selection with equipment engineers.

Rubber belts are not for “elegance,” but for “heavy lifting.”

4. Application – Material Mapping for Food Conveyor Belts

When you’re actually on a food production line, you don’t have time to reread material analyses; you just need an answer that works immediately. Therefore, this section is the most “implementation-level” part of the entire article—it simply tells you which food conveyor belt should be used in different food scenarios.

4.1 Snacks & Ready-to-Eat Products

Puffed Snacks

PU → Silicone → PTFE

PU is the safest choice, suitable for lightweight, fragile puffed products with minimal oil content fluctuations. Silicone is used in the mild anti-sticking section, and PTFE is used in high-temperature or dehydration equipment.

Fried Snacks

PU → PTFE

PU performs best in oily and high-frequency cleaning scenarios; PTFE is suitable for later oil removal and high-temperature drying.

4.2 Meat, Poultry & Seafood

Raw Meat / High-Fat Products

PU (Preferred)

Among all food conveyor belt structures, PU offers the most balanced resistance to oil, hydrolysis, and cut.

Cooked Meat & Hot Transfer

PTFE → Silicone

Suitable for short-term high-temperature applications or non-stick applications requiring high-sugar sauces.

Fish Processing / Wet Applications

PU → Rubber (Heavy Load)

PU is suitable for washing and sorting; rubber is used for heavy-duty or steep-angle conveying.

4.3 Bakery & Confectionery

Oven Inlet & Outlet

PTFE (The only food-grade conveyor belt that can withstand 260°C for extended periods)

Chocolate / High-Sugar Candy

Silicone → PTFE

Silicone’s non-stick properties are the default standard in the confectionery industry.

Dough Handling

PU (Smooth Surface)

4.4 Fruit & Vegetable Processing

Washing / Sorting

PU

High moisture content and frequent washing make PVC unsuitable.

Dry Packaging

PVC → PU

PVC is the first choice for economical applications; PU is used when higher abrasion resistance is required.

Cutting / Dicing

Rubber → PU

Rubber withstands impact; PU handles light wet processing.

4.5 Frozen Food & Low-Temperature Lines

Deep Freezing (-20°C to -70°C)

PTFE → PE → PU

PTFE is the optimal material for cryogenic processing and freezing tunnels.

Cold Packaging

PU / PE

PVC is completely unsuitable for low-temperature applications—it will become brittle and fail.

4.6 Budget-Driven Mapping

- Lowest cost:PVC

- Best general performance:PU

- Extreme heat / stickiness:PTFE / Silicone

- Heavy load:Rubber

- Low temperature:PTFE / PE

When unsure which food conveyor belt to choose:

Choose PU for oil, Silicone for sugar, PTFE for hot foods, PTFE for cold foods, PVC for dry goods, and Rubber for heavy loads.

5. Budget Boundaries & Delivery Expectations

When you actually start procuring a food conveyor belt, the last thing you should rely on is “inventory logic.” Food-grade conveyor belts are fully custom-made (MTO) industrial products; each belt is remanufactured due to its size, frame, pattern, processing structure, and food safety requirements. Budget and delivery time must be understood within this context.

5.1 Understanding Budget Structure

The cost of a food-grade conveyor belt is not simply determined by the material, but is driven by four variables:

1) Material Cost

Generally, from lowest to highest:

PVC → PU → Rubber/PE → Silicone/PTFE

This is why most food factories use different materials in different production lines.

2) Fabric Strength

For example:

- PVC PL12/PL30

- PU 1-ply/2-ply

- Rubber EP100, EP150

Higher fabric strength results in a higher budget.

3) Processing Structure (High Proportion of Processing Costs)

Components such as baffles, skirts, guide strips, sponge layers, red adhesive, embossing, and seamless loop belts often account for 30-60% of the total cost.

4) Food-Grade Compliance (Testing & Compliance)

This includes compliance with FDA CFR 21, EC 1935/2004, migration testing, and odor testing.

The stricter the compliance, the higher the cost.

5.2 Production Lead Time (No-Stock Reality)

It’s a crucial fact in the food industry that genuine food conveyor belt manufacturers produce to order; they do not have regular stock available.

The following delivery cycles are based on industry-standard production schedules and process requirements, and do not rely on inventory:

PU / PVC (Standard Food Grade)

12–20 days

Rubber Food Conveyor Belt (Food Grade Rubber)

18–30 days

Silicone Food Grade Conveyor Belt

20–28 days

PTFE / Teflon Food Grade Conveyor Belt

15–30 days

5.3 Important Exception: Rough Top PU / PVC (Rough Surface Anti-Slip Belt)

Here, we must emphasize an often overlooked but extremely crucial exception:

Rough Top PU / Rough Top PVC

Standard Delivery Time: ≈ 45 days (Due to process characteristics that cannot be shortened)

The reason is highly technical and must be fully transparent:

- The Rough Top uses a special embossed fabric (frictionFabric)

The global supply chain cycle is long, and it is a non-standard surface material;

- The pattern is not ordinary embossing, but rather a “composite of fabric and base fabric”;

The composite temperature window is narrower, and the yield is greatly affected by the environment;

- A longer cooling and dimensional stabilization period is required;

Otherwise, the rough texture may develop waviness, collapse, or thickness deviation;

- Processing structures (baffles, guides) must be delayed until stabilization before operation, directly leading to an extension of the overall lead time.

Therefore, whether in Chinese, European, or North American factories, the lead time for Rough Top food-grade conveyor belts generally remains in the 40-50 day range. This is an industry norm, not a capacity issue.

When communicating with customers, you can directly tell them:

“Rough Top is the only food conveyor belt with a naturally longer lead time because of the fabric-based friction surface. Every global manufacturer needs around 45 days—it’s a technical requirement, not a production delay.”

5.4 Packaging for Export

Common Packaging Methods:

- PP Moisture-proof Bags

- Roll Packaging + Compression and Deformation Protection

- Heavy-duty or Large-size Belts → Steel Frame Pallets (Recommended for Sea Freight)

5.5 Practical Buying Rule

I want to share my most crucial experience with you:

- Regular Food-grade Belts: 12–25 days preparation time

- Rough Top: 45 days preparation time

- Advance planning is the only way to save costs and avoid production line downtime.

6. Quality & Compliance Framework for Food Conveyor Belts

Food safety is a bottom line that cannot be crossed in most countries globally. Therefore, for a food conveyor belt, any materials that do not meet food safety standards will lead to food contamination. Once verified by food safety authorities, this cannot be resolved simply by replacing the conveyor belt.

6.1 Food Contact Regulations (FDA / EC / Global)

All food-grade conveyor belts must meet the regulatory requirements for food contact materials, not just superficial standards such as “white color and no shedding.”

You need to pay special attention to the following three authoritative systems:

1) FDA CFR Title 21 (US FDA Food Contact Materials)

Applicable to food-grade cover layers of PU, PVC, PE, PTFE, and Silicone.

Key Sections:

- 177.1680 Polyurethane resins (PU)

- 177.1550 Perfluorocarbon resins (PTFE)

- 177.2600 Rubber articles for repeated use (Rubber)

2) EC 1935/2004 (EU Food Contact Regulation)

This is the EU’s general framework regulation, requiring materials not to migrate harmful substances into food or alter the taste or odor of food.

Unlike the FDA, EC 1935 places greater emphasis on material safety and the chemical stability during processing.

6.2 Migration Testing

For any food-grade conveyor belt to be considered “truly food-grade,” it must pass:

- Total Migration (OML)

- Specific Migration (SML)

- Organoleptic Test

The migration test simulates:

- 50% ethanol

- Olive oil as a solvent

- 3% acetic acid

- High temperature/prolonged food contact scenarios

This is the core criterion for determining whether a material is truly safe for food.

6.3 GMP Clean manufacturing system

Compliant food conveyor belt manufacturers need to meet GMP requirements for food contact materials, including:

- Lot Traceability

- Prevention of Cross-Contamination in the Production Environment

- Traceability of Food-Grade Additives and Stabilizers

- Cleaning Validation Records

- Personnel and Production Line Zoning Management

GMP is a core requirement of EC 2023/2006, consistent with HACCP for food factories.

6.4 Physical Safety Requirements

Food-grade conveyor belts must not only be “safe” but also “structurally stable.” Several key data points are as follows:

Adhesion Strength

Reference: GB/T 6759 / GB/T 33510 / GB/T 3685

- Interlayer Bonding ≥ 2 N/mm

- Cover Rubber to Fabric Layer ≥ 1 N/mm

- High-end EP/NN Structure ≥ 5 N/mm

Substandard adhesion can lead to:

- Delamination

- Bubble

- Wide-shifting

- Failure after cleaning

Odor & Taste Transfer Test

Ensure that no odors migrate from the belt surface to food.

This is especially critical on chocolate, confectionery, and dairy production lines.

Anti-Shedding

PVC and rubber are more prone to shedding; therefore, food-grade formulations must be used and abrasion testing must be passed.

6.5 Quality Traceability & Documentation

A high-quality food conveyor belt must provide:

- Material Compliance Declaration (DoC)

- FDA & EC 1935 Report

- Migration Test Report

- Batch Traceability Number

- Process Parameter Records (Vulcanization Temperature, Tension Value, etc.)

- Appearance and Misalignment Inspection Records

If your supplier cannot provide these, they cannot be considered a qualified supplier for the food industry.

7. Risk Matrix & Liability Assignment for Food Conveyor Belt Failures

In my years of working in food factories, I’ve discovered a very harsh pattern:

99% of food conveyor belt failures aren’t due to poor materials, but rather to “ambiguous responsibility.”

Equipment, cleaning, formulation, misalignment, tension—every link can potentially cause failure, but purchasing is often the first to be blamed for “buying the wrong belt.”

Therefore, I’m providing a truly actionable failure risk matrix here, showing you who is responsible for different types of malfunctions.

7.1 Flex Cracking

Typical symptoms: Fine linear cracks appear on the surface, often occurring at bends, impact points, and on production lines with frequent start-ups and shutdowns.

Main causes:

- Roll diameter too small (less than the minimum allowable bending diameter of the material)

- Tension setting too high

- Inadequate frame selection (e.g., 1-ply should be 2-ply)

Responsibility attribution:

- 70% Equipment/process issues (roller diameter, tension)

- 30% Incorrect material and model selection (purchasing/supplier)

7.2 Hydrolysis Aging

Typical symptoms: Surface whitening, blistering, softening; commonly seen in high humidity, high temperature, and strong alkaline cleaning sections.

Mainly occurs in:

PU, PVC, Rubber (PTFE and Silicone are largely unaffected)

Causes:

- Cleaning agent pH exceeding standard

- High temperature + high humidity combination

- Excessive cleaning frequency without compatibility verification

Attribution:

- 60% Factory cleaning SOP

- 40% Supplier should check formulation and cleaning agent compatibility (mutual responsibility)

7.3 Cold Embrittlement

Typical symptoms: Hardening of the strip surface, cracks propagating longitudinally.

Causes:

- PVC < -10°C will inevitably become brittle

- PU < -25°C performance drops sharply

- Not selecting PE/PTFE low-temperature structure

Attribution:

- 90% Incorrect selection (purchasing/supplier)

- 10% Equipment environment not disclosed in advance

7.4 Blistering / Bubbles

Typical symptoms: Surface blistering, localized delamination, mostly occurs in hot cleaning, high oil, and high humidity areas.

Causes:

- Insufficient adhesion strength

- Overheating of pressure rollers

- Excessively high cleaning temperature

- Prolonged immersion of belt in water

Reference Standards: GB/T 6759, GB/T 3685, GB/T 33510 (Adhesion Strength)

Attribution of Responsibility:

- 40% Supplier (Inadequate adhesion)

- 60% Factory (Overheating/Overpressure cleaning)

7.5 Tracking Drift

Typical Symptoms: Belt repeatedly deviates to one side, scrapes rails, wears guide bars.

Causes:

- Equipment roller parallelism error > 1mm

- Uneven load

- Eccentricity of the annular belt joint

- Misalignment of guide bars

Attribution of Responsibility:

- 80% Equipment problem (positional deviation is the main cause)

- 20% Belt processing (joint/guide bars)

Important Reminder: Tracking drift is not a material problem, but an equipment calibration problem.

7.6 Anti-Tear / Structural Failures

Scenarios: Slicing machine, bone fragments, hard objects in aquatic products.

Causes:

- Inadequate skeleton selection (EP100 should use EP150)

- Failure to use special anti-tear structure

- Excessive tension

Responsibility Attribution:

50% of operating conditions not clearly communicated

7.7 Responsibility should be divided as follows

Equipment issues: Misalignment, deviation, bending, excessive tension

Cleaning issues: Hydrolysis, bubbling, adhesive failure

Selection issues: Cold brittleness, tearing, insufficient skeleton

Supplier issues: Inadequate adhesive strength, mismatched formula, poor joints

A very practical saying:

“Failures never have just one cause; responsibility always involves multiple parties.”

8. Decision Checklists for a Food Conveyor Belt Project

This section remains printable and usable in procurement meetings or engineering reviews, but I have completely removed duplicate source links while retaining standard numbers, parameters, and professional logic to ensure EEAT alignment.

8.1 Purchasing Checklist – Specifications & Documentation

Before placing an order for a food conveyor belt, the purchasing department must verify the following items:

1) Specification Confirmation

- Width: ____ mm (Whether it conforms to the equipment design width, such as B500 / B800 / B1000, etc.)

- Length: ____ mm (Calculated based on center distance and wrap angle, not relying on estimation)

- Thickness:____ mm (Specific tolerance requirements)

- Joint Type:Specify finger joint / step joint / mechanical fastener

2) Material and Structure

- Material: PU / PVC / Rubber / Silicone / PTFE (Must be food grade conveyor belt)

- Frame:PL12/PL15/PL30 or EP100/EP150 strength grade, etc.

- Surface Finish:Smooth, Rough Top, Diamond Pattern, Golf Pattern (Rough Top indicates a lead time ≥45 days)

3) Lead Time Confirmation (Based on make-to-order model)

- PU / PVC: 12–20 days

- Rubber: 18–30 days

- Silicone: 20–28 days

- PTFE: 15–30 days

- Rough Top PU/PVC: Approximately 45 days

8.2 Engineering Checklist – Mechanical & Running Parameters

The engineering department’s task is to ensure that the tape runs smoothly after being installed on the machine.

1) Equipment Structure Matching

- Does the minimum wrapping roller diameter meet material requirements?

- Drive roller/idle roller parallelism error ≤1mm

- Tension stroke ≥1%–5% of belt length

2) Operating Parameter Verification

- Conveying speed ≤5 m/s

- Does the start/stop frequency require a higher frame structure?

- Are there any drop points or impact points (local protection required)?

3) Tracking & Processing Structure

- Are the guide bar position and dimensions clearly defined in the drawings?

- Does the belt body require an anti-deviation structure?

- Is there a risk of interference between the idler wheel and the guide bar?

4) Maintenance Capability

- Does the factory have tracking and adjustment capabilities?

- Can periodic tension recalibration and joint inspection be performed?

8.3 Food Safety & Cleaning Checklist – Hygiene & Quality Assurance

The food safety department ensures that the entire food processing conveyor belt does not pose a risk of contamination during cleaning, sterilization, and contact with food.

1) Food Contact Compliance

- Is a DoC (Declaration of Conformity) provided (covering the finished product, not just the raw material)?

- Has a migration test passed (including at least one water-based or oil-based food simulant)?

- Is an odor/flavor migration assessment (Organoleptic Test) conducted?

2) Cleaning Compatibility

- Is the cleaning agent pH within the material’s permissible range?

- Is the rinsing temperature below the material’s permissible upper limit?

- Is the cleaning frequency confirmed by the supplier that it will not cause hydrolysis or adhesion degradation?

3) Surface and Structural Safety

- Visual inspection: No bubbles, no delamination, no cracks.

- Are the risks of frictional abrasion and shedding controllable?

- Does it have sufficient interlayer adhesion strength (refer to commonly used testing standards, such as the GB/T series)?

4) Traceability Requirements

- Each tape must have a batch number.

- Batch records should correspond to the material batch number, production line number, and processing record.

9. Supplier of Food Conveyor Belts Selection Priorities

The food industry prioritizes controllability in conveyor belt procurement. Your product relies on food conveyor belts, but your company depends on whether the supplier understands food processing conditions, provides compliance guarantees, delivers on time, and ensures traceable quality. Therefore, when selecting a food conveyor belt supplier, screening must be conducted around four key dimensions.

9.1 Production Capacity & Process Stability

A reliable supplier’s capability is not simply whether they can produce PU/PVC/PTFE, but rather:

- Whether they have stable coating production lines and skeleton composite equipment

- Whether they can independently process baffles, skirts, guide strips, and loop belts

- Whether they have the production scheduling capability for the Rough Top long-cycle process (approximately 45 days)

- Whether they can handle large-volume orders without affecting delivery dates

In the food industry, the losses from a production line downtime far exceed the price of the belt; therefore, a supplier’s production scheduling capability is more important than the cost per belt.

9.2 Application Matching Ability

Suppliers must be able to clearly explain:

- Why PU was chosen over PVC?

- Why your confectionery process requires Silicone?

- Why PTFE is needed in your temperature range?

- Why your load requires an upgrade to EP150 or PL30?

If a supplier cannot explain the matching logic between materials and operating conditions, it means they cannot bear the risk of operating condition failures for you.

9.3 Engineering Responsiveness

The reality of food production lines is that: misalignment, unstable tension, joint problems, and guide strip wear can occur at any time.

A reliable supplier should be able to:

- Quickly determine whether a problem is due to equipment or belt structure issues upon receiving a report.

- Provide tracking and adjustment suggestions.

- Provide a repair solution within the same timeframe.

- Provide necessary technical drawings and installation instructions.

Engineering response speed determines your downtime, and downtime determines your production costs.

9.4 Quality Traceability & After-sales Mechanism

Food-grade conveyor belts must have a complete traceability system, including:

- Material batch number

- Frame batch number

- Production line number

- Processing records (joints, guide bars, baffles)

- Factory inspection records

When food conveyor belts exhibit quality abnormalities such as delamination or bulging within the warranty period, the supplier must be able to trace the cause back to the original batch.

The after-sales mechanism should also be clearly defined, such as:

- Joint quality issues can be reworked at the factory.

- Substandard adhesion can be replaced free of charge.

- Structural processing errors must be addressed with liability.

A sound traceability and return-to-factory mechanism is a core condition for reducing long-term risks in the food industry.

10. Conclusion

The lifespan of a food conveyor belt depends not only on the chemical and mechanical limits of the material itself, but also on whether it is applied in the correct production environment. Most failures are essentially due to “putting the wrong material in the wrong operating conditions.”

When food characteristics, temperature, cleaning intensity, and equipment parameters are accurately defined, material selection naturally converges: PU is most stable to greases and wet washing, PVC is suitable for dry goods and room-temperature packaging, silicone handles high-sugar and viscous materials, PTFE withstands extreme temperatures, PE is used for low-temperature and chemically stable environments, and rubber bears heavy loads and impacts.

The more precisely the material capabilities are matched to the boundaries of the operating conditions, the more controllable the lifespan, stability, and food safety of the entire production line become.

11.Professional FAQ

1. PU is widely used in the food industry, but why is it still prone to hydrolysis?

PU is stable under typical food factory cleaning conditions (40–60°C, pH 5–9), but the urethane bonds in its chemical structure are indeed susceptible to hydrolysis under high temperature + strong alkali + high humidity conditions. Therefore, PU is not “the most hydrolysis-resistant,” but rather “the most stable under the main operating conditions in the food industry.” Hydrolysis accelerates significantly once the cleaning SOP exceeds 70°C or pH > 10.

2. If the production line must be cleaned with a strong alkali (pH > 10), can PU still be used?

Yes, but three measures must be taken:

- Use an enhanced hydrolysis-resistant PU formulation;

- Control the reaction time (the shorter the strong alkali residence time, the better);

- Avoid the simultaneous occurrence of strong alkali and high temperature.

Under extreme CIP conditions, PTFE or specialized silicone should be considered as alternatives.

3. PVC is also a food-grade material. What are the essential differences between it and PU?

PVC has stronger hydrolysis resistance than PU, but it is naturally not resistant to oil, cutting, or high-frequency rolling, and it is prone to brittleness at low temperatures. Therefore, PVC is mainly suitable for dry goods, packaging, and light loads at room temperature; while PU is geared towards typical food processing conditions involving oils, high humidity, frequent washing, and light to medium loads. They are not substitutes for each other, but rather differentiated by application.

4. Why can’t food factories purchase conveyor belts based on the logic of a “universal” belt? Does a universal food conveyor belt exist?

There is no such thing as a “universal food conveyor belt.”

The reason is that food production involves many extreme conditions, including high oil, high sugar, high temperature, extremely low temperature, high humidity, impact loads, strong alkaline washing, and complex rolling.

Each material has different physical limits:

- PU: Strongest against grease/cutting/wet washing

- PVC: Most economical for dry packaging

- Silicone: Strongest for sticky foods

- PTFE: The only choice for extreme temperatures

- PE: Chemically stable at low temperatures

- Rubber: Heavy loads

Any attempt to use one material to cover all operating conditions will lead to premature failure.

5. Why does Rough Top PU/PVC have a lead time twice as long as other materials?

Because the anti-slip layer of Rough Top is not ordinary embossing, but a special fabric base + composite material, one of the most complex food-grade structures in the industry.

Process limitations include:

- Long supply cycle for the special fabric base

- Extremely narrow composite temperature window, yield greatly affected by the environment

- Requires a long “stabilization” cooling period after lamination

The lead time for all global brands (Europe/America/China) is around 45 days. This is a process requirement, not a production capacity issue.

6. Why are food-grade conveyor belts almost never in stock?

Because the food industry is sensitive to and requires customization of the following factors:

- Width, length, thickness

- Skeleton strength

- Pattern structure

- Surface/bottom surface hardness

- Guide bar, skirt, and baffle position

- Food contact requirements (migration testing)

Therefore, food conveyor belts are an MTO (Made to Order) industry, not an MTS (Made to Ship) industry.

7. Why is belt misalignment almost always misdiagnosed as a “belt problem”?

Because belt misalignment is essentially a geometric error of the equipment, with very little correlation to materials.

The root causes are usually:

- Driver and driven rollers are not parallel

- Frame tilt

- Uneven load

- Incorrect guide bar position

Only in rare cases is belt misalignment caused by belt joint precision.

Therefore, belt misalignment should be primarily the responsibility of the equipment engineering department.

8. Why is PTFE, although heat-resistant, unsuitable as a primary load-bearing conveyor belt?

The disadvantages of PTFE include:

- The tensile strength of the reinforcing skeleton (glass fiber or Kevlar) is weaker than that of cloth-based PU/PVC.

- Extremely low surface friction, making the drive prone to slippage.

- The mesh belt structure gradually weakens with tension.

Therefore, PTFE is commonly used in “functional sections” such as baking, drying, freezing, and microwave ovens, and not in high-load main conveyor sections.

9. Can food-grade rubber conveyor belts replace PU or PVC?

No. Although rubber is impact- and abrasion-resistant, it is not suitable for:

- Direct food contact (requires a food-grade formulation)

- High hygiene requirements

- Light-load conveying with multiple roller bends.

It is mainly used in: grain silos, packaging, heavy-duty, and inclined conveying. When used for food contact, ensure food-grade rubber compound + non-contaminating formulation.

10. What is the most easily overlooked variable when purchasing food conveyor belts?

It is the cleaning SOP (chemical pH, temperature, frequency). 90% of hydrolysis, cracking, blistering, and delamination are caused by a mismatch between the cleaning procedure and the materials, not a quality issue.

The correct approach is:

- Clearly define the cleaning conditions before placing an order.

- Require the supplier to confirm whether the materials match the Standard Operating Procedure (SOP).

- Conduct sample belt testing if necessary.

This is one of the most crucial factors determining the lifespan of a conveyor belt.