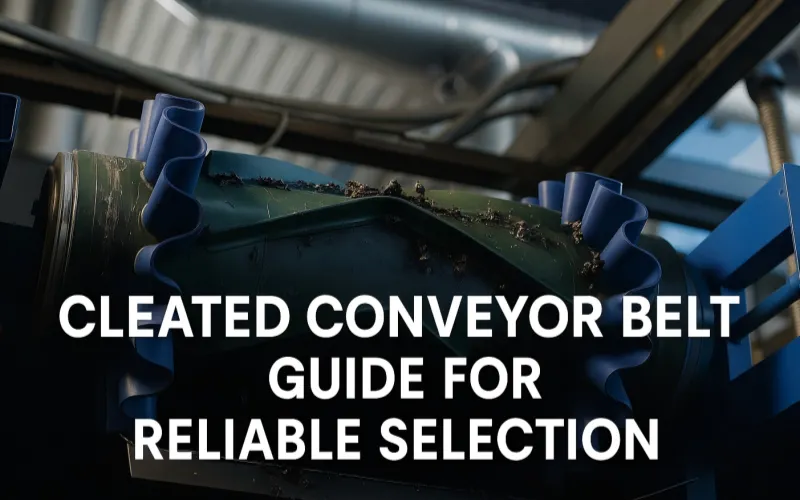

If you’ve ever struggled with material slippage on slopes, this guide will show you why a cleated conveyor belt is more than just a belt with cleats—it’s an engineered solution for angle control and material stability. Backed by Tiantie Industrial’s production strength and years of real-world application experience, every recommendation in this article comes from tested engineering logic, not assumptions. You’ll see how structure, material, and cleat design work together to define performance and lifespan. By the end, you’ll know exactly how to choose the right system—and how to avoid the costly mistakes most buyers never notice.

1. What is a Cleated Conveyor Belt?

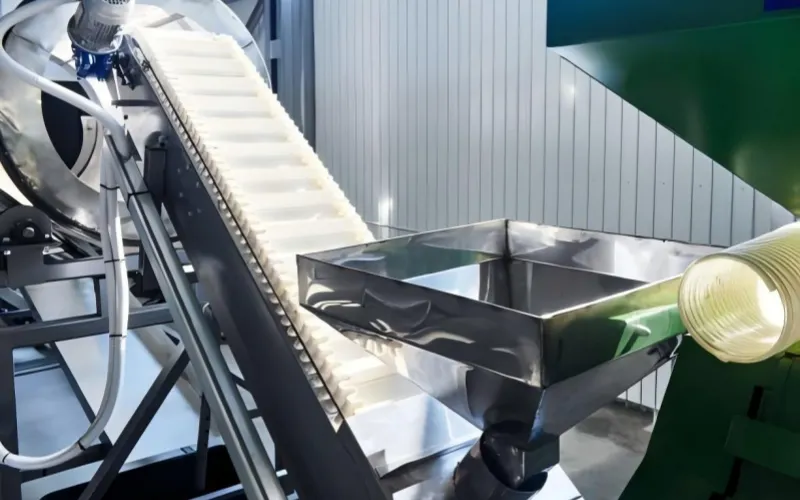

The most striking feature of a cleated conveyor belt is the rows of cleates standing on its surface. As one of the engineers at Tiantie Industrial, deeply involved in the conveyor belt industry, I often tell our clients: if you consider a regular conveyor belt as a “flat road,” then a cleated conveyor belt is like having rows of “steps” built on that road, allowing materials to steadily ascend even in inclined environments.

The essence of a cleated conveyor belt is to add cleats of different shapes and heights to the surface of the conveyor belt for different applications, preventing materials from slipping on slopes.

Whether you’re conveying sand, grain, gravel, packaging boxes, or even food particles, as long as there’s an incline, gravity will cause the material to slide down. The cleats exist to counteract this gravity, “supporting” the material.

In actual working conditions, the cleats serve three core functions:

- First, anti-slip (blocking). This is the most basic function of all cleated conveyor belts. The higher the cleat, the more goods can be transported per unit area. However, it cannot be chosen arbitrarily, as incorrect height selection will reduce conveying efficiency.

- Second, it prevents backflow. Material rushing backwards when climbing inclines is a common loss point. cleats can stabilize the material, reducing spillage and waste.

- Third, it increases the conveyable angle and conveying efficiency. Ordinary flat belts typically reach their limit at around 18°, but with a properly structured cleat, the angle can be increased to 40°. Using a corrugated skirted belt can further increase this.

When understanding cleated conveyor belts, it is essential to distinguish between two systems: the structural system and the material system.

The structural system determines the conveying height, angle, and material residence method; the material system determines the applicable industries, abrasion resistance, hygiene level, and temperature performance of the belt.

There are two structural systems:

1) Straight-plate cleat belt: Flat belt + cleats. Different heights are available depending on the requirements, with common heights ranging from 6mm to 150mm, suitable for slopes of 20-40°.

2) Corrugated Sidewall Conveyor Belt: Base belt + corrugated skirt + crossbeams, suitable for steep inclines of 40-70°.

Currently, there are three main material systems: Rubber (heavy-duty), PVC (light-duty), and PU (food-grade).

These three types are the most widely used and applicable materials in my experience.

However, material does not determine structure, and structure does not change material selection; both need to be matched.

In essence, the core value of a cleated conveyor belt lies in ensuring that materials remain controllable, do not slip, and do not flow back in inclined conveying environments. Regardless of the industry or whether the load is light or heavy, if the conveying angle exceeds the limits of a standard flat belt, a cleat belt is usually a more direct and effective solution.

2. Why are cleated conveyor belts needed?

In the conveying industry, the value of cleated conveyor belts becomes increasingly apparent whenever inclination angles, space constraints, or material stability are involved. Tiantie Industrial has long provided conveyor belt selection advice for various working conditions, and we have observed some common patterns in numerous practical cases.

First, the effective conveying angle of ordinary flat belts is relatively limited.

Conventional rubber or PVC flat belts are prone to material slippage between approximately 16-18°, a normal phenomenon determined by the coefficient of friction and material stress. When the system requires a larger inclination angle, friction alone is insufficient. In this case, cleat structures provide additional support points, improving material retention stability. Besides cleats, for angles between 16-22°, if the cleat height is less than 6mm, we also recommend our users use Chevron conveyor belts, which are also a cost-effective option.

Second, the larger the inclination angle, the more pronounced the effects of backflow and spillage.

Materials such as powders, granules, crushed stone, and packaging boxes tend to slide backward towards the less supportive sections due to the component of gravity on inclined sections. cleats provide a blocking surface for the material, making it more controllable during inclined conveying and reducing the risk of spillage, stockpiling, or decreased efficiency.

Third, increasing the inclination angle is a common strategy when factory space is limited.

Factors such as equipment layout, material drop location, and floor height restrictions limit the length of the conveyor line’s incline. Increasing the inclination angle becomes a common choice, and cleat structures can expand the system’s operational range in terms of space planning, allowing for a more compact layout.

Fourth, the demand for cleat belts increases with the change in inclination angle.

Industry experience typically refers to the following ranges:

- Approximately 18-40°: Cleated conveyor belts generally perform more stably;

- Approximately 40-70°: Corrugated sidewall conveyor belts offer better support in many operating conditions;

- Beyond this range, some companies consider bucket elevators or other vertical conveying methods.

This isn’t a fixed rule, but rather an empirical value based on common material behavior, system efficiency, and maintenance costs.

Fifth, there are indeed situations where cleat belts are unsuitable.

Because the cleats of cleated conveyor belts are typically made of pure rubber or PVC without an impact-resistant reinforcing layer, the cleats can be more prone to damage than the conveyor belt itself under certain conditions.

For example:

- Sustained high temperatures exceeding 200°C

- High impact, large-piece material drops

- Highly corrosive environments

- Complex routes involving repeated material unloading

These scenarios usually require additional structural protection or comparison with other lifting methods.

In conditions of limited space, inclined lifting, and easy material slippage, the role of cleat belts becomes increasingly apparent, and this is the fundamental reason why cleated conveyor belts are needed.

3. Two Major Structural Systems of Cleated Conveyor Belts

3.1 Straight-Plate Cleated Conveyor Belt Structure

(1) Structural Composition

The straight-plate cleated conveyor belt consists of:

a flat belt + conveyor belt cleats.

The cleats are arranged at intervals along the running direction to improve the stability of the material at inclines.

(2) Applicable Inclination Angle Range

Common engineering applications are approximately 18-40°.

The actual range needs to be confirmed based on material particle size, flowability, angle of repose, and belt speed.

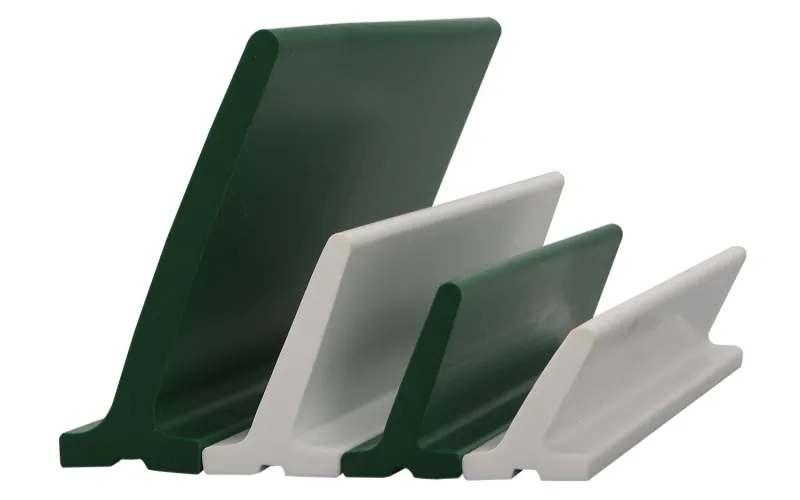

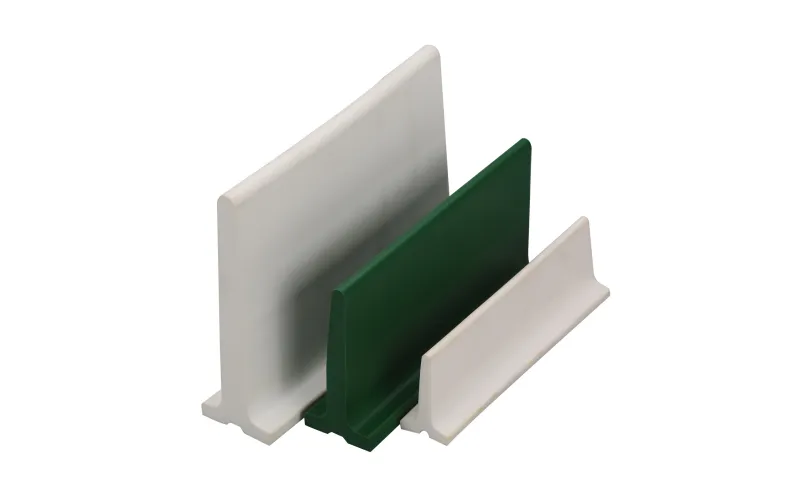

(3) Main Conveyor Belt Cleat Types

- L-type: Light load, small incline

- T-type: Powder

- C-type: Particulate matter, mixture

- Reinforced cleated belt:Large-sized, high-impact materials

These are all structural forms and are unrelated to the material.

(4) Structural Boundaries of Cleat Height

The cleat height of a straight-plate cleated conveyor belt generally does not exceed approximately 100 mm. Beyond this height, the bending stability of the cleat decreases, and a switch to a corrugated sidewall conveyor belt structure is typically evaluated.

(5) cleat Spacing Design Principles

The commonly used range is approximately 200-600 mm, depending on:

- Material particle size

- Angle of repose

- Conveying capacity

- Belt speed

- Sensitivity to spillage

It is not selected based on simple experience, but rather on engineering logic calculations.

(6) Typical Application Scenarios

Straight-plate cleated conveyor belts are widely used in:

- Grain conveying

- Light industrial packaging

- Industrial bulk materials

- Logistics sorting

- Medium-angle lifting

(7) Structural Advantages and Limitations

Advantages: Simple structure, convenient installation and maintenance, strong adaptability.

Limitations: Greater influence from material characteristics at angles approaching 40°, requiring additional assessment of load-bearing capacity.

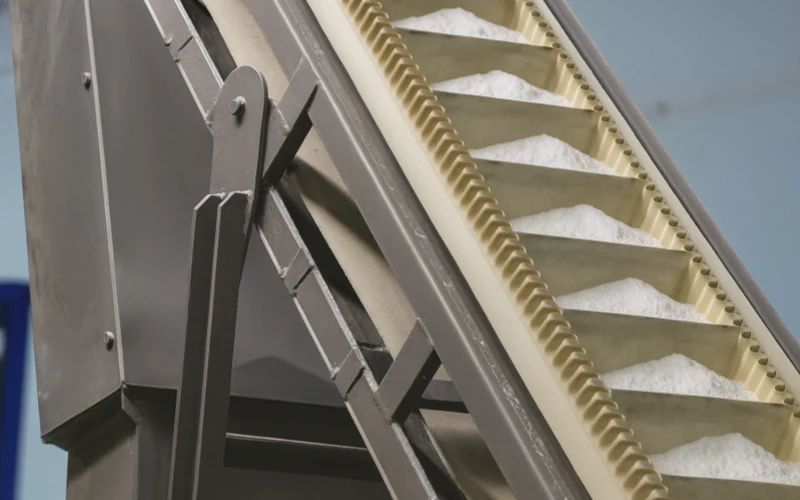

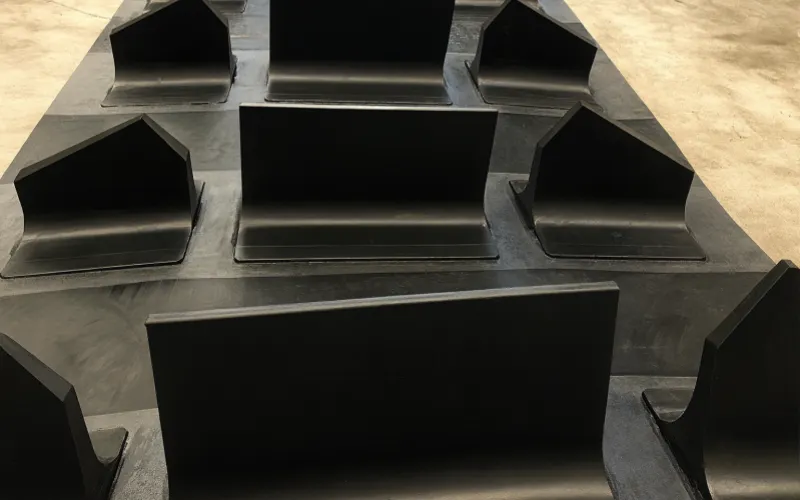

3.2 Corrugated Sidewall Conveyor Belt

(1) Structural Composition

It consists of three parts:

- Base belt

- Corrugated skirt

- Dividers (fixed to the base belt, not to the skirt)

These three components together constitute a “complete large inclination angle conveyor structure”.

(2) Applicable Inclination Angle Range

Commonly used for conveying angles of approximately 40-70°, suitable as a high-inclination angle supplementary structure to cleated conveyor belts.

(3) Structural Operation Logic

- Corrugated skirt: Provides lateral closure and flexible bending capability

- Dividers: Support material

- Base belt: Bears tensile force and provides structural support

The overall support method is similar to “stepped container lifting”.

(4) Typical Application Scenarios

- Space-constrained layout

- High-level material drop and docking

- Large-angle conveying of heavy-duty bulk materials

- Working conditions requiring reduced drop impact

(5) Structural Advantages and Limitations

Advantages: Large inclination range, strong load-bearing capacity, saves equipment space.

Limitations: High structural complexity, strict requirements for the bonding process of the skirt and cross diaphragm.

4. Cleated Conveyor Belt Material Selection

4.1 Rubber

Rubber is suitable for medium to heavy-duty bulk material conveying, exhibiting stable performance in applications requiring specific wear resistance, impact resistance, and temperature resistance.

(1) Performance Characteristics

- High wear resistance:Commonly used cover rubber grades can achieve abrasion resistance of 90 mm³, 70 mm³, or lower, suitable for highly abrasive bulk materials.

- Good impact resistance:Capable of withstanding large drops or impacts, and not easily fatigued or torn.

- Wide temperature range:Standard formulations are suitable for 80-120°C; heat-resistant formulations for 150-180°C; instantaneous temperatures up to approximately 200°C (according to GB/T 33510 requirements).

- Oil-resistant, flame-retardant, and cold-resistant formulations can be added depending on the operating conditions.

(2) Industry Adaptation Logic

In heavy industries such as mining, cement, sand and gravel, and power plants, rubber cleated conveyor belts are not the primary conveying method because these industries prefer flat belts, steeply inclined corrugated sidewall conveyor belts, or bucket elevators.

Rubber cleated conveyor belts are more suitable for the following situations:

- Local lifting sections of 18-40°

- Small height differences between equipment

- Areas where space is insufficient to extend the slope

- Slight inclines in underground mines or narrow tunnels

- Slight lifting at loading/unloading points or buffer sections

In summary, rubber cleated conveyor belts are used locally in heavy industries, rather than as the main line equipment.

(3) Inapplicable Situations

- Long-distance main conveyor lines

- Materials subjected to sustained temperatures exceeding 200°C

- Food industries with strict hygiene requirements

- Extra-large pieces of material with extremely high drops without reinforced structural treatment

4.2 PVC

PVC is a lightweight, room-temperature, and easy-to-clean material, suitable for processes in light industry requiring angled installations, anti-slip properties, or fixed distances.

It should be noted that the applicable industries for PVC flat conveyor belts are far greater than those for PVC cleated conveyor belts; their usage scenarios should not be confused.

(1) Performance Characteristics

- Applicable temperature: approximately 80°C (Our actual recommendation is to discontinue use of this material above 60°C)

- Dense material surface, non-absorbent, easy to clean

- Good flexibility, suitable for small diameter rollers

- Can be customized with oil-proof, anti-static, and food contact grades as needed

(2) Industry Compatibility

PVC cleated conveyor belts are mainly used in light-load applications requiring “climbing, anti-slip, and fixed-distance” operation, such as:

- Food packaging lifting section: The feeding section before small packaged food enters the weighing machine, batching machine, and packaging machine

- Lightweight bulk material climbing: Such as nuts, coffee beans, pet food, and small granular raw materials

- Equipment height difference transition: Local climbing of 20-40° is required between different equipment

- Express small package anti-slip section: Low-angle section to prevent packages from slipping back

- 3C small parts fixed-distance conveying: Screws, connectors, and small plastic parts require cleats Position Control

- Small Inclined Sections in Cold Chain Sorting: Prevents Slippage of Small Packaged Frozen Foods at Height Changes

In short:

PVC cleated conveyor belts are suitable for light loads, normal temperatures, and locations requiring slight support or lifting, but not all light industrial sectors.

(3) Inapplicable Situations

- Medium to Heavy Load Bulk Materials

- High Temperature Conditions

- High Impact, Sharp Materials

- Heavy Industrial Main Conveying

4.3 PU

PU is a high-hygiene, lightweight conveyor material widely used in the food and pharmaceutical industries.

Compared to PVC, PU performs more reliably with oily, sticky, or highly hygienic materials.

(1) Performance Characteristics

- Meets FDA/EU food-grade requirements

- Dense surface, does not breed bacteria

- Oil resistance and cut resistance are superior to PVC

- Good flexibility, suitable for small roller diameters and complex circuits

(2) Industry Compatibility

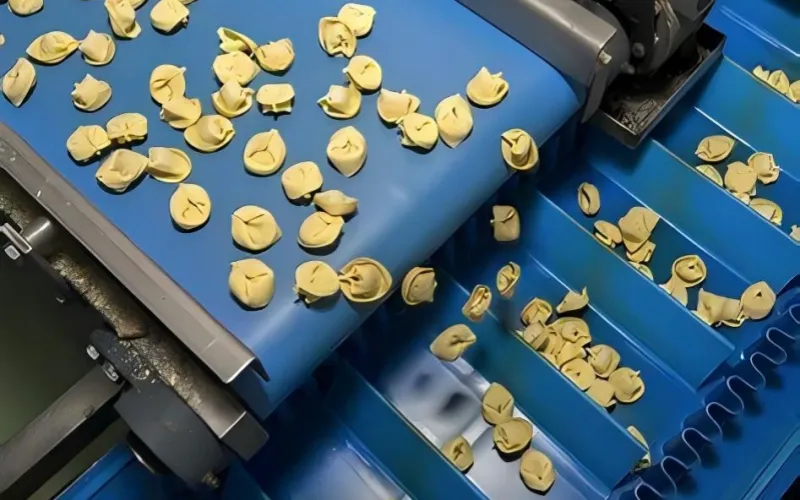

PU cleated conveyor belts are commonly used in light industrial food processes that require both hygiene standards and load-bearing capacity, such as:

- Meat processing:light lifting and anti-slip for frozen and fresh meat loading

- Oil and fat products:fried foods, nuts, and semi-finished oil products

- Dairy products, pre-baking stages

- Pharmaceutical production lines:strict requirements for material cleanliness

- Food fixed-distance conveying: production lines requiring cleats for positioning, such as dough and dough blanks

(3) Inapplicable Situations

- Cost-sensitive mass light industrial industries

- High-temperature conditions

- Medium-to-heavy load bulk material high-impact areas

4.4 Engineering Judgment for Material Selection

- Rubber: Heavy load, wear-resistant, temperature-resistant → Selected when strength is required in local lifting sections.

- PVC:Light load, normal temperature, slight incline → Main material for lifting sections in the light industry.

- PU:Food grade, oil resistant → Small angle lifting and positioning processes in the food and pharmaceutical industries.

5. Key Factors Affecting the Lifespan of Cleated Conveyor Belts: Manufacturing Process

For cleated conveyor belts, the quality of the base belt is crucial. However, under the same base belt conditions, lifespan differences often stem from the design and manufacturing process of the cleats themselves: how they are made, how they are fixed, the rationality of the root transition, and their compatibility with different material systems. This chapter focuses solely on the manufacturing process of cleats and crossbars.

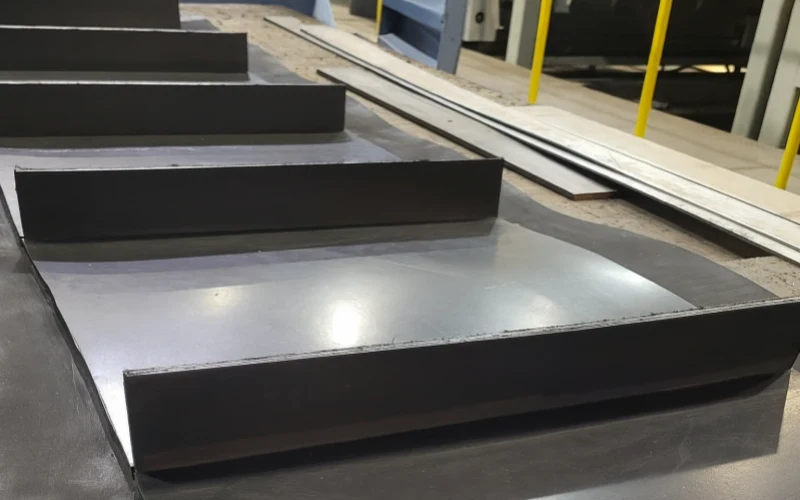

5.1 Key Manufacturing Points for Rubber Cleats

Rubber cleats are primarily used in medium-to-heavy load applications, with lifting angles typically ranging from 18° to 40°. The key here is not how the rubber is molded into a belt, but rather how the cleats are integrated with the rubber base belt.

(1) Small Height Cleats (≤ Approximately 6 mm)

These small protrusions or shallow cleats are usually integrally molded directly from the rubber base belt during vulcanization. They are more akin to anti-slip patterns, used for small inclination angles, anti-slip, and guidance, rather than as the main support structure bearing heavy loads.

There are only two key control points:

- Mold precision and rubber flow to ensure consistent geometric dimensions;

- No sharp corners should appear in the transition area with the base strip to avoid stress concentration and cracking.

(2) Medium-High Rubber Cleats

Once the cleats reach the actual “supporting material” zone, they are usually not completed in one step during base strip vulcanization. Instead,

- Cleaats are vulcanized separately;

- Base strip is vulcanized separately;

- Cleaats are bonded to the base strip using a special adhesive and hot-press curing.

The key process points here are:

- Sufficient effective bonding area at the bottom of the cleats;

- A smooth transition adhesive layer at the root, rather than a 90° right angle;

- One or more reinforcing fabric layers are added to the bottom of the cleats depending on the working conditions to disperse the peeling force;

- The bonding interface must be free of bubbles, impurities, and oil stains.

In short, the process goal of rubber cleats is: under conditions of repeated material impact and periodic loading, to ensure that the failure point of the cleats occurs as late as possible after the normal lifespan of the base belt, rather than being ripped off from the root after only a few months of operation.

5.2 Key Processing Points of Cleats in Corrugated Sidewall Conveyor Belt

This article focuses only on the parts directly related to cleats for corrugated sidewall conveyor belts.

(1) Skirt and Base Belt

The skirt is generally made of rubber material. Through surface treatment, adhesive bonding, and vulcanization pressure, it forms a high-strength bond with the rubber base belt, not simply by gluing it on. This relates to lateral sealing capability and overall structural stability, but it is still only an “environmentally supportive structure.”

(2) Connection Method of Cleats and Skirt

The cleats here are essentially also a type of cleat, but they work in conjunction with the skirt to form a “grid” or “bucket-like” support structure. There are three key points:

- The diaphragms cannot be directly “welded” to the skirt through vulcanization. In actual engineering, mechanical connections are commonly used: bolts, rivets, plate clips, etc.

- During connection, pressure plates, gaskets, and other structures are used to firmly clamp the diaphragms to the skirt and/or the skirt reinforcement layer;

- The diaphragms are not necessarily vertical in design; sometimes they are tilted forward or backward to better adapt to the material flow state, inclination angle, and loading method.

(3) Process details requiring special attention

- The bolt hole positions must be symmetrical, and the bolt preload must be kept stable to avoid loosening after operation;

- The rubber thickness in the contact area between the diaphragm and the skirt should not be too thin to avoid local “cutting” by the bolts;

- The spacing and angle of the diaphragms need to match the inclination angle and material particle size; otherwise, material accumulation, jamming, or premature tearing may occur.

In other words, the quality of the crossbar construction on a corrugated sidewall conveyor belt determines whether the system can stably support materials at an inclination angle of 40-70° over a long period.

5.3 Welding Process of PVC/PU Cleats

PVC and PU cleats do not use a vulcanization system; they are thermoplastic materials. The most common cleat fixing methods are high-frequency welding or hot air welding.

(1) Basic Logic of High-Frequency Welding/Hot Air Welding

- The base belt and cleats are made of the same PVC or PU material;

- The contact area is heated by a high-frequency electric field or hot air, causing its surface to “melt”;

- Cooling is performed under a certain pressure, allowing the two to re-bond into one unit.

Advantages:

- Smooth seams, easy to clean, suitable for food, packaging, and other applications;

- No extra foreign matter layer between materials, good overall flexibility, suitable for small roller diameters;

- Mature process, suitable for mass standardized production.

(2) Common Failure Modes and Process Correlation

- Insufficient welding temperature → cleats gradually lift and curl at the edges during operation;

- Excessive temperature → Material becomes brittle, yellows, and hardens on the surface;

- Uneven pressure → One side of the cleats is well welded, while the other side has a weak weld, leading to skewed stress.

In PVC/PU systems, an empirical judgment is:

If the edges of the cleats start to turn white and lift under normal load, it is mostly due to unstable welding process or process window control, rather than a problem with the material itself.

5.4 Direct Impact of Cleats Process on the Lifespan of Cleated Conveyor Belts

To make the key points clearer, the impact of the cleats process on lifespan can be understood as three inspection lines:

(1) Whether the connection method matches the material system

- Rubber → vulcanization molding + vulcanization bonding;

- PVC/PU → high-frequency welding or hot air welding;

- Corrugated sidewall conveyor belt partitions → mainly mechanical connection.

If the material system and connection method are mismatched, the lifespan is often uncontrollable.

(2) Does the root design avoid stress concentration?

- Does the rubber cleats have rounded corners and a reinforcing layer at the root?

- Are the welds on the PVC/PU cleats wide enough?

- Is the adhesive layer thickness at the crossbeam connection reasonable?

A poor root design is most typically a case of “breaking from the root.”

(3) Can the process stability cover real-world working conditions?

- Load, impact, tilt angle, temperature, and speed all fluctuate;

- Cleats need to maintain a “firm fit and stable shape” over a long period amidst these fluctuations.

As long as the cleats process is conservative, the service life of the entire cleated conveyor belt will be closer to the upper limit that the base belt can withstand, rather than being prematurely worn down by the cleats.

6. Cleated Conveyor Belt Selection: Correct Selection Based on Working Conditions

Selecting a cleated conveyor belt cannot be based solely on the inclination angle or the material. The correct approach is: first, consider the working conditions; then determine the structure; once the structure is determined, decide on the material; finally, refine the height, spacing, and shape of the cleats.

The following selection logic is presented in three dimensions: inclination angle, material, and industry, avoiding the use of incorrect solutions for different scenarios.

6.1 Selecting the Structure Based on Inclination Angle Range

The first criterion for selecting a cleated conveyor belt is always the inclination angle. The following structures are suitable for different tilt angle ranges:

(1) 0–18°: Flat belt or low cleats (Rubber / PVC / PU)

- Basically no supporting structure is needed.

- If the material is prone to rolling or slight slippage, low cleats (≤30 mm) can be used.

- Commonly used in packaging, conveyor line height fine-tuning, and light-load food processing.

(2) 18–30°: Medium cleats

- Suitable for Rubber, PVC, and PU materials.

- Cleats height is usually in the 40–60 mm range.

- Commonly used for light-load loading, food packaging entering weighing machines, and light bulk material lifting.

(3) 30–40°: High cleats (mainly Rubber)

- Rubber cleats have higher adaptability.

- Mainly used for local lifting of medium-load bulk materials.

- Cleats height is mostly in the 60–100 mm range.

- If it reaches 38–40°… Upper limit, root structure needs to be strengthened

(4) 40–70°: Corrugated Sidewall Conveyor Belt

- Cleats can hardly provide enough support space, requiring a skirt + diaphragm structure

- Suitable for light loads, medium loads and some heavy loads of bulk materials

- If the inclination angle exceeds 60°, the larger the material particle size, the greater the need for the diaphragm spacing

(5) 70–90°: Bucket elevator or special structure should be evaluated

- Clated conveyor belt is not a standard solution

- Specific structures are only used under very specific and light load conditions

The overall logic is very clear:

18–40° use cleated conveyor belt; 40–70° use corrugated sidewall conveyor belt; above 70° consider bucket elevator structure.

6.2 Select cleats type according to material characteristics

The inclination angle determines the structure, and the material determines the shape and spacing of the cleats. The following classifications are commonly used in engineering:

(1) Powders (pulverized coal, cement powder, starch, food powder)

Suitable cleats types: T-type, light bucket-shaped, transverse beam structure

Reason: Powders are easily flowable and require a basic support surface to prevent them from flowing away through the cleats.

Recommended cleat height:

- 40–60 mm (18–30°)

- 60–80 mm (30–40°)

(2) Granular materials (grains, coffee beans, pelleted feed, small packaged bulk materials)

Suitable cleats types: T/C type

Granular materials are relatively stable, so the crossbeam structure can be reduced appropriately.

Recommended cleat height:

- 40–70 mm

Applicable to: Rubber, PVC, PU; select materials according to industry.

(3) Large materials (ore, large coal, aggregate)

Suitable cleats type: C-type, reinforced cleats

Due to high load and strong impact, cleats with higher structural strength are required.

Recommended cleats height:

- 70–100 mm (Rubber)

If higher than 100 mm, a corrugated sidewall conveyor belt structure should be used.

(4) Irregular, easily rolling materials

Suitable cleats type: T-type + appropriately increased height and density

Commonly used for bagged items, small boxes, and small hardware components in food packaging.

6.3 Material and cleats type combination by industry

Different industries have completely different requirements for cleated conveyor belts.

(1) Food Packaging Industry (Light Load)

Applicable: PVC cleated conveyor belt / PU cleated conveyor belt

Typical Applications:

- Bagging and small packaged food being lifted to weighing machines

- Biscuits and candies entering packaging machines

- Cold chain small package inclines

Cleats Height: 20–50 mm

Material Rationale: Light load, easy to clean, food grade.

(2) Light Manufacturing / 3C / Small Parts Conveying

Applicable: PVC cleated conveyor belt

Typical Applications:

- Stabilized distance conveying of small parts

- Small angle lifting of electronic components

Cleats Type: Low cleats or guide cleats

Material Rationale: Good flexibility, suitable for small roller diameters.

(3) Logistics / Express Transit

Applicable: PVC cleated conveyor belt

Typical Applications:

- Slight inclines for small packages

- Low angle anti-slip sections

Cleats are mostly low cleat structures (15–40 mm).

(4) Mining, Aggregates, Cement (Local Lifting Section)

Applicable: Rubber cleated conveyor belt or corrugated sidewall conveyor belt

Typical Applications:

- 18–40° local lifting due to space constraints

- Short-distance material loading before entering the screening or storage system from the main line

Cleaats are mostly reinforced C-type or T-type.

Ruber cleats are used locally, not on the main line; for angles exceeding 40°, they default to a corrugated sidewall conveyor belt structure.

(5) Oily Foods, Meat, Pharmaceuticals (High Hygiene Standard)

Applicable: PU cleated conveyor belt

Oil and grease resistant, does not breed bacteria, meets food-grade requirements.

6.4 Basic Calculation Logic of Cleats Height and Spacing (Commonly Used in Engineering)

To ensure more accurate selection, the most commonly used cleats parameter determination methods are given here:

(1) Height (H) Calculation Logic

H selection is determined by the following factors:

- Larger inclination angle → Higher cleats

- Larger material → Higher cleats

- Easier material to roll → Higher cleats

Common empirical values:

- 18–25°: 40–50 mm

- 25–35°: 50–70 mm

- 35–40°: 70–100 mm

Exceeding 100 mm → Switch the structure to corrugated sidewall conveyor belt.

(2) Spacing (P) Calculation Logic

P depends on:

- Material particle size

- Flowability

- Theoretical conveying capacity of the equipment

Common empirical values:

- Powder: 200–300 mm

- Particles: 250–400 mm

- Large pieces: 400–600 mm

Too large a spacing → Material backflow

Too small a spacing → Decreased volumetric efficiency

7. On-site Inspection Guidelines: 10 Must-Check Items for Cleated Conveyor Belts

The key points for inspecting cleated conveyor belts, besides the base belt itself, are:

whether the cleats are secure, whether the structure is symmetrical, whether the connections are stable, and whether the belt body meets the necessary operating conditions.

The following 10 items apply to rubber, PVC, and PU cleats, as well as the crossbeam structure of corrugated sidewall conveyor belts, and are all based on “factory inspection,” avoiding the erroneous logic of “observation only after operation.”

7.1 Is the interface between the cleats and the strip intact? (Inspection methods differ depending on the material)

Rubber:

- Check if the adhesive layer at the base of the cleats is “full, without hollow areas, and without sharp edges.”

- Focus on the continuity of the adhesive interface.

PVC/PU:

- Check if the weld seam is continuous, without gaps, warping, or whitening.

- Check if the welded area is flat and free from overheating and scorching.

In short: Don’t look at “whether there is glue,” but rather at “whether the interface is continuous, uniform, and without defects.”

7.2 Are there any deformations, damages, or defects in the cleats themselves? (Applicable to all materials)

Key inspection points include:

- Are the cleats straight and without twisting?

- Are there any indentations or dents on the surface?

- Are there any micro-cracks (rubber) on the edges?

- Are there any warping at the top? (Insufficient welding in PVC/PU can cause this.)

Despite the different materials, the geometry of the cleats themselves must be consistent and free of defects.

7.3 Are the cleats arranged parallel, equidistant, and without skewing?

This can be checked without operating the equipment.

You can determine if the cleats exhibit the following by visual inspection and a ruler:

- Front-to-back offset

- Left-to-right skewing

- Inconsistent spacing

- Not straight in rows

Incorrect arrangement will lead to uneven support and localized wear during operation.

7.4 Are the joints of the cleated conveyor belt correctly positioned to avoid cleat areas?

The joint is the most vulnerable point on the entire cleated conveyor belt.

Inspection should confirm:

Rubber:

- Hot-vulcanized joints are aligned, without steps or bubbles.

PVC/PU:

- Finger joints are of sufficient length and flat.

Key inspection point: The joint should not fall in an area with dense cleats; otherwise, the cleats will cause excessive localized stress at the joint.

7.5 Is the belt surface uniform and free of exposed reinforcement? (This applies to all materials, but the description must be precise.)

Rubber:

- No exposed fabric layers.

- No pits or inclusions.

PVC/PU:

- The surface must be complete and continuous.

- The internal reinforcement layer must not be visible; there should be no “through-weave”.

- No damage or wear marks.

Your reminder is correct: It’s not “partial exposure,” it’s “no reinforcement should be exposed.”

7.6 Does the belt’s geometric accuracy (straightness, width, thickness) meet standards?

This can be checked at the factory and does not require operation.

Check:

- Are the belt edges straight? (Not “worn out,” but “skewing during manufacturing”).

- Is the width consistent on both sides?

- Is the thickness uniform?

This relates to whether the cleated conveyor belt can be properly tensioned and aligned on-site.

7.7 For corrugated sidewall conveyor belts: Are the bolt connections of the diaphragms correct?

Based on the key principle you pointed out: The diaphragms must be mechanically fixed, not vulcanized.

Required Inspection:

- Are all bolts fully installed?

- Are gaskets (yellow or black) installed as designed? (Color varies by brand; not all are yellow.)

- Are bolts symmetrically arranged?

- Are bolt holes free of tears?

- Is the crossbeam angle consistent with the design? (Can be tilted forward or backward; verticality is not required.)

This is a critical safety check for corrugated sidewall conveyor belts.

7.8 Are there any potential interferences between cleats and the skirt/belt body? (Can be determined without operation)

Must Confirm:

- Cleats will not touch the skirt at bends.

- Cleats will not extend beyond the edge of the belt body at transition sections.

- Cleat height will not exceed the allowable space of the matching equipment.

This is a “precautionary check” and does not require equipment startup.

7.9 Are cleat height and spacing consistent with the order? (To avoid manufacturing deviations)

On-site inspection must include measurements:

- Cleat height

- Cleat spacing

- Cleat width

- Designed quantity of cleats

These are the basic requirements for the qualification of a cleated conveyor belt.

7.10 Are the materials of the cleats, partitions, and skirts consistent with the order?

Including:

- Are the cleats made of the correct material (Rubber / PVC / PU)?

- Are the partitions made of the specified hardness?

- Are the skirts the required height and hardness?

- Is the entire cleated conveyor belt manufactured with the correct material and structure?

Material errors are a major quality issue.

8. Cost and Lifespan: Why is the Overall Cost of a Cleated Conveyor Belt Higher?

A cleated conveyor belt is essentially a structurally reinforced conveyor system, not a simple variation of a regular conveyor belt. However, in actual procurement, many users mistakenly believe that a cleated conveyor belt is simply a combination of a regular conveyor belt and several cleats, thus assuming its cost should be similar to a flat belt.

This misconception is one of the most common misconceptions about cleated conveyor belts.

From an engineering perspective, the cost and lifespan of a cleated conveyor belt are affected by the materials, structure, fastening method, operating load, and failure risk of the cleats, all of which are significantly higher than those of a regular conveyor belt. The following explains from an engineering perspective why the actual cost of a cleated conveyor belt is higher over its lifespan.

8.1 The cleats of a cleated conveyor belt are the core of the structure, not “additional components.”

The reason why cleated conveyor belts are often mistakenly believed to “should be cheaper” is not due to the product itself, but rather to an underestimation of the structural complexity by the purchasing party. Many users view cleats as “a few extra pieces of material glued on,” leading to incorrect price expectations. However, from an engineering perspective, cleats are not accessories, but rather the high-stress core structure of the entire cleated conveyor belt, directly affecting:

- Support capacity

- Upper angle limit

- Impact resistance

- Strength distribution in the frame

- Operating stability

- Failure modes

Whether it’s the vulcanization bonding of rubber cleated conveyor belts, the high-temperature welding of PVC/PU cleated conveyor belts, or the use of corrugated sidewall conveyor belts for high-angle diaphragm structures, cleats require independent molding, processing, and fixing, and have high structural requirements.

Therefore, the core cost of a cleated conveyor belt does not come from the base belt, but from the cleats themselves:

- Material consumption

- Molding and pressing costs

- Bonding/welding/mechanical fixing costs

- Mechanical requirements and fatigue life design

From an engineering manufacturing perspective, the complexity of cleated conveyor belts is significantly higher than that of flat belts, which is the fundamental reason why their cost is higher than that of ordinary conveyor belts.

8.2 The presence of cleats complicates the stress patterns of the entire cleated conveyor belt.

While flat belts experience relatively uniform stress, cleated conveyor belts endure the following during operation:

- Periodic impacts

- Instantaneous material ballast

- Repeated tensile stress on the root of the cleats due to bending fatigue

- Continuous thrust of material on the top of the cleats

- Shear loads at large angles of inclination

In heavy-duty applications, especially rubber cleated conveyor belts or corrugated sidewall conveyor belts, cleats are the components most prone to fatigue.

This mechanical complexity means:

- Cleats require higher material costs

- Cleats require more sophisticated bonding or welding processes

- The lifespan of a cleated conveyor belt depends on the cleats, not the base belt

Complex structure → High manufacturing costs → Harsh operating conditions → Higher lifespan management requirements.

8.3 The connection method of cleats directly affects the life cycle cost of a cleated conveyor belt.

The cleat fixing method of a cleated conveyor belt determines the life cycle structure of the entire system:

- Rubber cleats: Vulcanized bonding (hot vulcanization)

- PVC/PU cleats: High-temperature welding

- Corrugated sidewall conveyor belt: Cross cleats must be mechanically fixed

These fixing methods are inherently high-cost processes, and cleat failure will lead to:

- Lower local support capacity

- Material backflow

- Increased overload risk

- In corrugated sidewall conveyor belts, it may even cause the entire conveyor system to stop.

This means that the life cycle cost of a cleated conveyor belt is highly dependent on the structural strength of the cleats, and the more complex the cleat manufacturing process → the higher the cost → the greater the impact on life cycle.

8.4 Cleats alter the energy consumption and equipment load of a conveyor system.

Cleated conveyor belts generate higher operating resistance than ordinary conveyor belts due to the following reasons:

- Cleats need to push material, not just carry it.

- Increased contact resistance between the material and the cleats.

- Cleats experience more reverse pressure at angles.

- Cleats generate additional air resistance and idler friction at return points.

In actual engineering calculations, under the same specifications:

The energy consumption of cleated conveyor belts is typically 5–15% higher than that of ordinary conveyor belts.

This difference in energy consumption directly affects long-term operating costs and is closely related to the height, number, spacing, and material of the cleats.

8.5 Cleats have a higher failure risk than the base belt, therefore, the downtime costs of cleated conveyor belts are higher.

Clitors are the core supporting components of a cleated conveyor belt. Their failure directly leads to:

- Reduced conveying capacity

- Material slippage

- Material backflow and accumulation

In contrast, ordinary conveyor belts can continue operating even with localized wear, while cleat failure will prevent the entire system from lifting materials properly, or significantly reduce the lifting effect.

8.6 The Total Cost of Ownership (TCO) of a cleated conveyor belt is directly linked to the cost of cleats.

TCO includes:

- Initial purchase cost

- Assembly and installation cost

- Cleats’ structural and material costs

- Operating energy consumption

- Downtime and maintenance costs

- Replacement costs after cleats fatigue failure

- Overall lifespan

In the TCO model for cleated conveyor belts, the impact of cleats is far greater than that of the base belt because cleats determine:

- Inclination capability

- Operating stability

- Failure modes

- Maintenance cycles

This makes the lifespan cost of a cleated conveyor belt much higher than that of a seemingly similar ordinary conveyor belt.

9. 12 Key Parameters You Must Confirm Before Placing an Order (Essential for Procurement)

Selecting a cleated conveyor belt is unlike selecting a regular conveyor belt, where bandwidth, length, and strength are sufficient for ordering.

Because cleats are highly structured components, any incorrect parameter may be can lead to:

- Insufficient tilt angle

- Material backflow

- Cleats twisting or tearing

- Operational interference

- Insufficient conveying capacity

- Complete cleated conveyor belt scrapping

To avoid these situations, every procurement engineer, equipment engineer, or OEM must confirm the following 12 parameters before placing an order.

The following applies to rubber cleated conveyor belts, PVC cleated conveyor belts, PU cleated conveyor belts, and corrugated sidewall conveyor belts.

9.1 Material Selection (Rubber / PVC / PU) – The most important parameter to confirm.

The material determines the operating limits of the cleated conveyor belt:

Rubber:

- Medium-load, heavy-load, abrasion-resistant, impact-resistant

- High temperature ≤160°C (special formulations can reach 200°C)

- Suitable for mining, aggregate, cement, and energy industries.

PVC:

- Light load, normal temperature, inclined lifting

- Light industrial use below 80°C

- Packaging, logistics, food packaging, small-item inclines

PU:

- Food-grade, oil-resistant, grease-resistant, cut-resistant

- High hygiene requirements

- Meat, oily foods, pharmaceuticals, cold chain

Once the material is determined, the structure, cleats shape, height, and spacing become meaningful.

9.2 Structural Options (Cleated Conveyor Belt / Corrugated Sidewall Conveyor Belt)

These two structures cannot be used interchangeably:

- Cleated conveyor belt: Suitable for lifting angles of 18–40°

- Corrugated sidewall conveyor belt: Suitable for large inclination angles of 40–70°

If the inclination angle exceeds 40°, it must be specified that:

A skirted + diaphragm structure is required; straight cleats are no longer acceptable.

9.3 Belt Width

Must be matched to the equipment space, roller width, and material particle size.

Common range:

300–2200 mm (varies slightly depending on the material)

A belt that is too small will cause material spillage; a belt that is too large will interfere with the frame.

9.4 Total Conveyor Length

Required:

- Center Distance

- Tension Stroke

- Allowance

- Field Joint Required

Special Note: Corrugated sidewall conveyor belts are more sensitive to length errors.

9.5 Inclination Angle

Determines the structure type and cleats height.

Basic Engineering Logic:

- 18–30°: Medium cleats

- 30–40°: High cleats (primarily rubber)

- 40–70°: Corrugated sidewall conveyor belt

- 70°+: Bucket Elevator Recommended (not within the scope of cleated conveyor belts)

Inclination angle information must be accurate.

9.6 Capacity

Capacity affects the spacing and height of cleats and cannot be omitted.

Please provide:

- t/h or m³/h

- Belt speed (if unavailable, we can calculate it)

Without conveying capacity data, the effective volume of the cleats cannot be calculated.

9.7 Material Size

Affects cleat cross-section type:

- Powder: T-type

- Particles: T-type or C-type

- Large blocks: Reinforced cleats or cross-sections

Larger particle size and larger spacing require more reinforcement at the cleat root.

9.8 Bulk Density

Higher density results in greater stress on the cleats.

Common classifications:

- <0.8 t/m³: Light load

- 8–1.6 t/m³: Medium load

- 6 t/m³: Heavy load

Used to determine if the cleats need thickening or reinforcement.

9.9 Material Temperature

Temperature determines material properties:

- PVC: ≤80°C

- PU: ≤100°C

- Rubber: ≤160°C (heat resistant up to 200°C)

Accuracy is crucial; otherwise, cleats will age prematurely.

9.10 Material Characteristics (Oil Content, Corrosiveness, Stickiness)

Determine material formulation:

- Oil Content:PU is preferred

- Corrosiveness:Requires a special rubber formulation

- High Stickiness:Requires higher cleats or reduced spacing

Using PVC cleats in oily conditions will cause premature delamination in the welded area.

9.11 Cleats Parameters (Height / Pitch / Type)

Most critical structural data:

- Cleats Height (H)

- Cleats Spacing (P)

- Cleats Shape (L / T / C / Reinforced)

- Whether cleats require reinforcement layers

If it’s a corrugated sidewall conveyor belt, the dimensions of the crossbeams need to be added.

9.12 Application Scenario

Application scenarios are used to refine the engineer’s selection direction:

Typical examples:

- Light-load loading for food packaging

- Small-item logistics ramping

- Local lifting in mines

- Auxiliary lifting in cement plants

- Rapid feed pellet ramping

- Cold chain small-package lifting

Application scenarios will influence the final selection of materials, structure, and cleats values.

9.13 Belt Thickness

Applicable to all materials:

Rubber:

- top-Cover thickness affects abrasion resistance.

- bottom-cover thickness affects return life.

- Insufficient thickness → cleats are more prone to tearing at the root.

PVC / PU:

- Cover thickness determines tensile and deformation resistance.

- Too thin and it cannot withstand the cyclic load of cleats.

- Small roller diameters also need to be matched.

Insufficient cover thickness will significantly reduce the overall lifespan of the cleated conveyor belt.

9.14 Tensile Strength (EP / NN / ST)

These are the core safety parameters for cleated conveyor belts:

EP / NN (Light load, medium load, multi-purpose)

ST (Wire rope construction, suitable for heavy-duty applications)

The strength rating determines:

- The material pressure that cleats can withstand

- The tensile force in inclined sections

- The fatigue life of the entire conveyor belt

Low strength rating → Cleats are prone to tearing

High strength rating → Can withstand greater lifting loads

9.13 Required Information Submission Checklist

The following is a list of standard parameters recommended by Tiantie Industrial. Only the 6 most basic items need to be filled in; our engineers will handle the professional selection for the rest:

【Cleated Conveyor Belt Product Selection Checklist】

1. Material: | Rubber / PVC / PU |

2.Basic Belt Width (mm): | |

3.Basic Belt Thickness(mm): | |

4.Basic Belt Tensile Strength: | |

5. Total Length (m): | |

6. Inclination Angle (°): | |

7. Conveying Capacity (t/h or m³/h): | |

8. Application Scenarios (Please briefly describe): |

After submitting the above information, Tiantie Industrial’s technical team will provide you with a complete selection solution for cleated conveyor belts or corrugated sidewall conveyor belts, including structural options, material recommendations, cleats height, spacing, and cross-sectional type, based on your working conditions.

10. Let Cleated Conveyor Belts Go Back to Their Essence—Solving Your Working Conditions

If we were to condense this entire article into a single core logic, it would be: Choosing the right cleated conveyor belt isn’t about the cleats, but about ensuring stable and controllable material handling at different angles.

Only three things truly matter:

First, the working conditions determine the structure.

Once the angle of inclination, space, and material shape are clear, you can determine:

- Is a straight cleated conveyor belt necessary?

- Or do you need a corrugated sidewall conveyor belt?

Second, the material determines the boundaries.

Ruber, PVC, PU—regardless of industry, consider temperature, load, and hygiene requirements.

Choosing the right material provides the foundation for lifespan and stability.

Third, parameters are derived from engineering logic, not guesswork.

The base belt strength, thickness, cleats height, and spacing must all be based on your:

- Angle of inclination

- Conveying capacity

- Material particle size and density

This isn’t based on experience, but on engineering calculations.

For you, the most crucial thing is to clearly describe your operating conditions: bandwidth, total length, inclination angle, conveying capacity, material characteristics, and application scenario.

The rest we’ll handle.

Tiantie Industrial’s engineers can transform this field data into a complete cleated conveyor belt selection solution.

You don’t need to be an expert; you just need to clearly explain your requirements.

A matched cleated conveyor belt will be more cost-effective, durable, and stable than an incorrectly specified one.

That’s the value of the entire system.

1. When should I use a cleated conveyor belt instead of a flat belt or bucket elevator?

2. How do I choose between Rubber, PVC, and PU cleated conveyor belts?

PVC: For light loads at normal temperatures (≤60–80°C), such as packaging, logistics ramps, and small-parts conveying where cleanliness and flexibility matter.

PU: For food, meat, oily products, and pharmaceuticals where hygiene and oil resistance are critical. Once the working conditions (load, temperature, hygiene requirements) are clear, the material choice becomes straightforward.

3. How do I determine the proper cleat height and spacing?

Spacing is usually 200–600 mm depending on whether the material is powder, granular, or large lumps. Too large a spacing leads to backflow, and too small reduces volumetric efficiency and raises cost.

4. Why is a cleated conveyor belt more expensive than a standard flat belt?

- Extra material consumption and molding

- Vulcanization bonding (rubber) or high-frequency/hot-air welding (PVC/PU)

- More complex stress management at the root and in bending zones

Cleated belts also increase energy consumption (typically 5–15% higher) and have higher downtime risk if cleats fail, so their total cost of ownership (TCO) is inherently higher than a simple flat belt.

5. What key parameters must I confirm before ordering a cleated conveyor belt?

- Material (Rubber / PVC / PU)

- Belt width

- Belt thickness and tensile strength (EP/NN/ST rating)

- Total length and inclination angle

- Conveying capacity (t/h or m³/h) and material size/density

- Application scenario (industry, position in the line, special hygiene or temperature requirements)

Based on these, engineers can then define the correct structure (cleated vs corrugated sidewall), cleat height, spacing, and cleat type to avoid slippage, backflow, and premature cleat failure.