Choosing the right conveyor belt rubber material determines whether a conveyor system remains stable or gradually fails. This article explains how rubber formulation, aging behavior, and consistency shape real performance, using engineering logic and field-proven failure patterns. It offers a clear framework for making long-term, reliable material decisions.

1.What is true conveyor belt rubber material? — Let’s clarify the concept first.

The term “conveyor belt rubber material” is often mistakenly understood as natural rubber raw material. If you think so too, we must first correct this misconception, otherwise all subsequent selection decisions will be misguided.

1.1 Conveyor belt rubber is not “ordinary conventional rubber.”

Some end-users mistake conveyor belt rubber for general industrial rubber. Rubber conveyor belts need to withstand continuous friction from sharp materials, heavy impact loads, and high-temperature environments of 100-300℃.

Therefore, the carbon black content in conveyor belt rubber material formulations is as high as 50-60 phr (compared to about 30-40 phr for ordinary rubber), and a special vulcanization system and anti-aging formula are used to achieve a tensile strength of 18-25 MPa and a wear rate controlled below 200 mm³.

The ISO 188:2023 standard verifies the material’s performance retention rate under extreme working conditions through accelerated aging tests at 70℃/100℃ for 168 hours, providing a reliable basis for judging conveyor belt quality.

1.2 Rubber material and rubber grade are not the same thing.

Many suppliers will directly tell you, “This is a certain grade of rubber.” But you need to know:

Rubber grade is a classification of test results, while rubber material is the formulation system itself.

Two conveyor belts with the same nominal grade can have vastly different lifespans if their rubber formulations differ. This is why relying solely on grade often leads to problems.

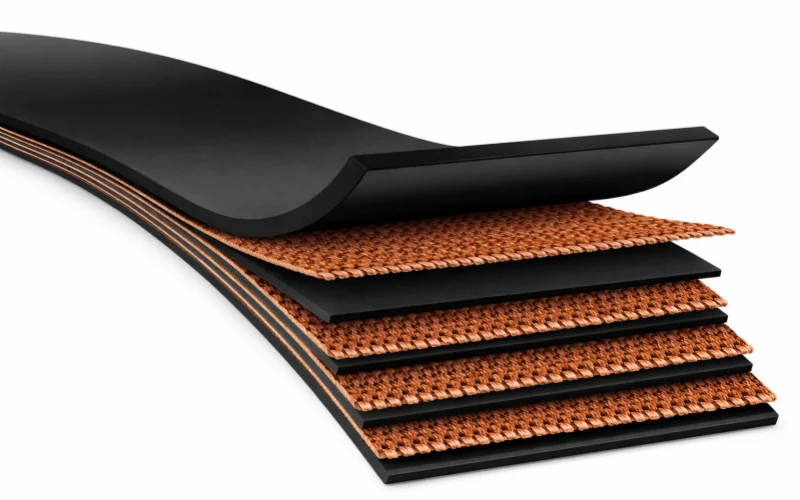

1.3 The True Role of Rubber in the Conveyor Belt Structure

A conveyor belt is a system: rubber + fabric layers or steel wire rope skeleton + interlayer adhesive structure. The rubber material is not just the “outer shell”; it also protects the skeleton, disperses impact, and maintains adhesive stability. Focusing only on skeleton strength without considering the rubber material is essentially gambling.

1.4 Why Rubber Material is More Crucial Than Thickness

I can say with certainty: poor-quality conveyor belt rubber material, no matter how thick, is useless.

The material system determines the performance ceiling; thickness merely amplifies or diminishes this result. What truly differentiates lifespan is never “how thick it looks,” but whether the rubber itself can withstand the dual tests of time and operating conditions.

The conveyor belt rubber material is the foundation of the conveyor belt’s performance, not a decorative layer.

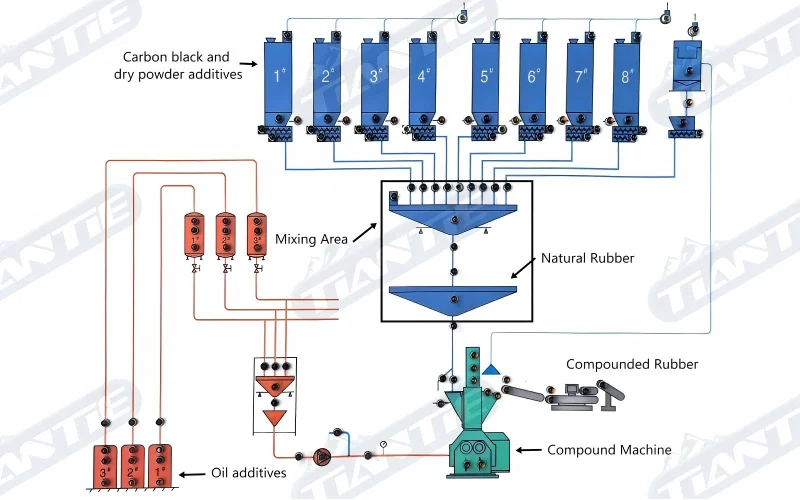

2.The True Composition Logic of Conveyor Belt Rubber Materials – A Reinterpretation of Conveyor Belt Rubber Material

To truly understand conveyor belt rubber materials professionally, it’s essential to separate them into three levels: the rubber itself → the rubber system → and the synergistic effects of additives. Any exaggerated or isolated description will mislead decision-making.

2.1 Natural Rubber is the “Mechanical Foundation” of Conveyor Belt Performance

The conclusion is: without high-quality natural rubber, there is no highly reliable conveyor belt rubber material.

Natural rubber plays the most fundamental and irreplaceable role in conveyor belt materials—dynamic strength, fatigue resistance, and structural toughness. The repeated bending, impact absorption, and load rebound during long-term operation of conveyor belts essentially rely on the molecular structure characteristics of natural rubber. This is why, under high-impact and high-wear conditions, the natural rubber content is always the determining factor for the lower limit of performance.

2.2 Synthetic Rubber Provides Performance Reinforcement Within the “Stable Range”

Synthetic rubber is not intended to replace natural rubber, but rather to correct its shortcomings. For example, heat resistance, oil resistance, and performance consistency are all weaknesses of natural rubber. By appropriately incorporating synthetic rubber, engineers can control the properties of conveyor belt material within a more stable and predictable range, rather than gambling on raw material fluctuations.

2.3 Why Industrial Conveyor Belts Must Use a Hybrid Rubber System

The reality is harsh: a single type of rubber cannot simultaneously meet all operational requirements.

The significance of a hybrid formulation is not to pursue “high-end,” but to achieve an engineering balance—finding a long-term operational intersection between wear resistance, tear resistance, and aging resistance. This is the fundamental reason for the emergence of different types of conveyor belt materials.

2.4 Chemical additives are not the main players, but rather “amplifiers.”

It must be clarified here: additives do not determine the upper limit, but they significantly widen the gap.

Assuming the quality of natural and synthetic rubber meets standards, the vulcanization system, carbon black type, and anti-aging system determine whether performance can be stably released and maintained long-term. The value of the additive system is to prevent the correct rubber system from being rapidly consumed by time and the environment, rather than replacing the rubber itself.

The essence of conveyor belt rubber material is never a “material term,” but an engineering system that respects the laws of materials.

3.How Rubber Materials Directly Determine Conveyor Belt Performance – A Reassessment of Conveyor Belt Rubber Material Based on Similar Products

To clarify this, let’s consider a more meaningful premise: conveyor belts of the same physical form, such as those with similar heat resistance, the same number of structural layers, similar thickness, and cover rubber design. Under this premise, the difference in lifespan and reliability almost entirely stems from the engineering differences in the conveyor belt rubber material itself.

3.1 Where Does the Difference Begin When They’re Both Heat-Resistant?

At the factory level, our first focus isn’t on the word “heat resistance,” but rather: what properties remain after heat resistance? What truly determines lifespan isn’t how good the initial data is, but whether the rubber can maintain sufficient tensile strength, elongation, and structural toughness after heat aging. This is why the industry emphasizes “performance changes before and after aging” in heat resistance testing—because field failures almost always begin with performance degradation, not instantaneous breakage.

3.2 Tear Resistance and Cut Resistance: Material and Structure Must Both Be Achieved Simultaneously

In similar products, tear resistance primarily depends on the crack control capability of the rubber material. High-quality conveyor belt material properties can slow the propagation rate of cracks by dissipating energy within the material as soon as they appear.

It’s important to objectively assess that while core structures like breaker layers can significantly inhibit tear propagation, they address the problem “after the crack has already occurred.” If the rubber material itself lacks sufficient cut resistance and the crack initiation frequency is too high, even the strongest structure can only delay failure, not fundamentally solve it.

3.3 Heat resistance, oil resistance, and aging resistance are not just concepts, but rather “failure path control.”

In the same type of conveyor belt, different rubber formulations will push the material towards completely different degradation paths.

- Some formulations harden rapidly at high temperatures, leading to a dense formation of surface microcracks;

- Some swell in oil or chemical media, resulting in decreased strength and increased cut sensitivity;

- Others continue cross-linking in a hot and oxygen-rich environment, causing the rubber to become brittle, and the bonded areas fail first.

3.4 Let’s clarify the differences from a materials perspective:

Under the same physical conditions, the lifespan difference is typically amplified by the combined effects of three factors:

1.Rubber matrix selection (the ratio of natural to synthetic rubber, determining dynamic strength and fatigue baseline);

2.Crosslinking system design (determining whether the material steadily degrades or rapidly collapses under heat and time);

3.Additive system synergy (determining whether the above properties can be maintained long-term, rather than just showing good short-term performance).

These three factors collectively determine the performance of different types of conveyor belt materials under real-world conditions, and are the most easily underestimated yet most critical difference in conveyor belt material selection.

What conveyor belt rubber material determines is never “whether it’s heat-resistant,” but rather: under the same heat resistance, which one can truly run longer and more stably.

4.Matching Rubber Materials for Different Working Conditions – The Selection Logic of Conveyor Belt Rubber Material That Truly “Understands the Site”

If the previous sections discussed the “material itself,” this section puts conveyor belt rubber material back into the field. Because in the real world, materials never work in isolation; they only have meaning within specific working conditions. This time, I’ll guide you through a different perspective on selection logic, refreshing your understanding.

4.1 Mining and Gravel Production Conditions: Consider the “Method of Failure” First, Then Lifespan

In mining and gravel production lines, my primary focus isn’t on the abrasion resistance index itself, but rather on the source of the damage.

- Large blocks, high drops → Impact + cutting coexist

- Many sharp edges → Extremely high cracking frequency

- Dusty environment → Continuous surface wear

In these conditions, the core of conveyor belt rubber material isn’t “lowest abrasion value,” but whether the rubber can maintain structural continuity after repeated cutting. The proportion of natural rubber, cut resistance, and whether tear-resistant structures are needed are often more critical than simply increasing the abrasion resistance rating. Choosing the wrong material usually doesn’t result in “faster wear,” but rather sudden tearing, localized adhesive failure, and non-linear failure.

4.2 Cement and Clinker Conveying: Heat Resistance ≠ Durability

Cement and clinker lines are typical examples of scenarios “misled by heat resistance labels.” Many problems aren’t due to insufficient heat resistance, but rather a collapse in performance after heat treatment.

In these conditions, the focus of conveyor belt material selection should be:

- Whether the rubber hardens rapidly after heat aging

- Whether the cover rubber develops early cracks under thermal cycling

- Whether interlayer adhesion significantly decreases after high temperatures

Even with heat-resistant belts, if the rubber formulation only meets initial heat resistance requirements while neglecting the retention of toughness after aging, the actual service life will be significantly shortened.

4.3 Ports and Bulk Terminals: Material Failure is Often Not “Wear-Off”

Port conditions may seem mild, but they are actually very “hidden.”

- Salt spray and damp heat → accelerate aging

- Diverse materials → localized oil and chemical contamination

- Long-distance continuous operation → extremely high requirements for rubber fatigue stability

Here, if the conveyor belt rubber material’s anti-aging system is insufficient, it is easy to encounter a situation where “it looks okay overall, but its performance has already collapsed”: surface hardening, increased cutting sensitivity, and gradual failure of the adhesive zone. These problems often erupt concentratedly after a period of operation, rather than gradually appearing.

4.4 The Real Consequences of Choosing the Wrong Rubber Material

The most dangerous aspect of choosing the wrong rubber material is not that it “cannot be used,” but that it is used unstably:

- Unpredictable lifespan

- Uncontrollable failure modes

- Downtime often occurs at the most inopportune times

From an engineering perspective, this type of risk is far greater than simply “short lifespan.”

4.5 Returning to the Essence: Working Conditions to Determine the Material

The truly professional selection logic for conveyor belt materials must be:

First, analyze the main failure mechanisms of the operating conditions → Then, match the failure paths of the rubber material → Finally, decide whether the structure needs reinforcement.

This is why engineers who truly understand the field never ask about the price first, but rather clarify the working conditions.

The value of conveyor belt rubber material lies not in the specifications, but in whether it is truly “suitable for the field.”

5.How Industry Standards Define Rubber Material Performance—Understanding Conveyor Belt Rubber Material Through Engineering Logic

In the conveyor belt industry, standards aren’t about “proving how good the material is,” but rather answering a more practical question: After the rubber material is continuously consumed by real-world working conditions, can it still maintain acceptable performance?

This is why understanding conveyor belt rubber material requires focusing on “testing logic” rather than just “indicator tables.”

5.1 What Do DIN/ISO/GB Standards Really Constrain?

Whether it’s DIN, ISO, or the equivalent GB standard, they almost never concern themselves with “what formulation was used” in the rubber.

What standards truly constrain is the change in material behavior after undergoing specified treatments.

Therefore, you’ll see three types of combined testing logic repeatedly appearing in the standard system:

- Treatment conditions (e.g., heat aging, hot air aging, media aging)

- Evaluation methods (physical tests such as tensile, elongation, hardness, and adhesion)

- Change judgment (the range of performance changes before and after aging, not a single numerical value)

Standards aren’t “testing rubber,” but rather simulating the state of the material after use.

5.2 What are the roles of tensile, aging, and adhesion tests?

- Aging tests are the destructive condition, the “cause.”

- Tensile, elongation, and hardness tests are evaluation methods, the “effect.”

Only after a material has undergone aging treatment, and then compared before and after through tensile and other tests, can we determine whether irreversible degradation of the rubber molecular structure has occurred. This is why standards emphasize performance retention rather than a specific initial strength value.

The same logic applies to interlayer adhesion testing. Adhesive strength itself is not the goal; whether adhesion can still be maintained after aging or use is the engineering risk.

5.3 Abrasion testing does not reflect “on-site wear.”

Many people understand abrasion testing as “simulating on-site wear,” which is inaccurate.

The engineering significance of abrasion testing lies in whether the material’s structure is stable and whether wear is controllable under continuous frictional energy input.

It is more used to distinguish which types of conveyor belt material are more likely to enter a state of uncontrolled wear during long-term use, rather than predicting a specific lifespan.

5.4 Why Standard Data is More Meaningful than “Abrasion-Resistant Rubber”

Terms like “abrasion-resistant,” “high-end,” and “reinforced” cannot be verified or used to assign blame.

Standardized test data, however, possesses at least three engineering values:

1.Clear Premise: Test conditions and processing methods are clearly defined.

2.Comparable Results: Different materials can be compared under the same logic.

3.Assessable Risk: It reveals whether performance is stable, not just whether it’s “good enough.”

In conveyor belt material selection, this “assessability” is far more important than a single performance indicator.

5.5 Standards are not answers, but tools for judgment.

Finally, it must be emphasized: Standards define the baseline, not the optimal solution.

Truly professional judgment involves understanding the logic of standard testing and, in conjunction with operating conditions, interpreting the failure trends hidden behind the data.

The reliability of conveyor belt rubber material is never about “passing the standard,” but rather:Whether it exhibits sufficient stability under the failure paths defined by the standard.

6.Common Misconceptions about Conveyor Belt Rubber Material and How to Communicate Effectively with Suppliers

In actual projects, problems with rubber materials rarely stem from “technical limitations,” but rather from issues in the understanding and communication stages. Many failures are not due to the material itself being bad, but rather to asking the wrong questions from the outset.

6.1 Misconception 1: Treating Conveyor Belt Rubber Material as a “Separate Option”

A common practice in procurement communication is:

“What kind of rubber is used in this belt? Is it more wear-resistant?”

The problem is that conveyor belt rubber material never exists in isolation.

It is inextricably linked to the core structure, adhesive system, and failure modes under operating conditions. Discussing “whether the rubber is good or bad” in isolation, without considering the operating conditions and structure, yields answers with almost no value.

6.2 Misconception 2: Assuming “General-Purpose Configuration” is Always Safer

Many procurement professionals subconsciously believe:

“General-purpose = More Use = More Reliable”

But the reality is quite the opposite.

The significance of a general-purpose configuration is to cover as many lower limits as possible under operating conditions, not to achieve optimal matching for your specific operating conditions. In certain special environments, general-purpose conveyor belt rubber material may actually be more prone to problems appearing earlier, although the failure mode may be slower and less obvious.

6.3 Misconception 3: Using “it worked fine this time” as a long-term judgment criterion

The biggest risk with rubber materials is not during the first use, but during repeated use.

Many materials perform normally on the first or second conveyor belt, but as batches change, performance fluctuations become amplified, and problems gradually emerge. This situation is essentially not due to accidental material failure, but rather insufficient quality control capabilities.

7.how can you determine if a supplier truly understands rubber materials?

The following judgment methods do not require you to ask any professional testing terms, but are very effective.

7.1 Can they provide “boundary-based recommendations” based on operating conditions?

Suppliers who truly understand conveyor belt rubber material usually do not offer a “one-size-fits-all” solution from the outset.

They will repeatedly confirm the operating conditions and then proactively eliminate unsuitable material configurations, rather than offering a “what can be used for everything” approach.

This ability to “know what is unsuitable for” is often more important than “knowing what can be used for.”

7.2 Does the supplier’s recommendation logic revolve around operating conditions, rather than price?

A very practical way to judge this is: When you adjust the description of the operating conditions (e.g., temperature, material properties, operating mode), does the supplier’s material recommendation logic change accordingly, rather than simply increasing thickness, downgrading specifications, or changing the name?

If the core logic of conveyor belt material selection remains unchanged, it indicates that the recommendation is not based on material understanding but on a sales template.

7.3 Does the supplier prioritize consistency, not just single-batch performance?

In a procurement context, instead of discussing whether “performance is stable and controllable,” it’s more important to directly examine the reliability of quality control:

- Do they emphasize batch consistency?

- Do they pay attention to performance fluctuations after long-term supply?

- Are they willing to discuss “how to handle changes in subsequent batches”?

These kinds of questions often reflect a supplier’s true capabilities more than any parameter table.

7.4 Are they willing to highlight risks, rather than just emphasizing advantages?

A team with sufficient knowledge of rubber materials will be aware of the risks associated with certain materials under certain operating conditions.

If you only hear “no problem,” “it’s all fine,” and “many customers use it” during communication, without any clear boundaries, you need to be extremely cautious.

The choice of conveyor belt rubber material is not essentially about choosing the “best rubber,” but rather about choosing a material system that is controllable in the long term, has clear risks, and whose quality is reproducible under your working conditions.

8.Reflections on Conveyor Belt Rubber Material – Putting Complex Issues Back in Their Right Place

At its core, conveyor belt rubber material is never a matter that can be simply labeled. It’s not about “what kind of rubber to use,” nor “whether the parameters are high enough,” but rather whether this material system is controllable and its behavior predictable under specific operating conditions.

The truly valuable judgments often occur before the parameters:

- Do you understand the main failure modes of the operating conditions?

- Do you realize that material failure is a process, not an instant?

- Do you treat material selection as an engineering decision, not just a procurement action?

When you begin to understand conveyor belt rubber material from the perspectives of structure, operating conditions, quality consistency, and risk boundaries, many seemingly complex issues become clear.

Understanding rubber materials is not about pursuing the “best configuration,” but about making the least error-prone choice under realistic conditions.

9.FAQs

FAQ 1

Why does the drive power of a conveyor belt gradually increase under constant rated load?

This is usually related to the elastic decay or increased internal friction of the conveyor belt rubber material. After aging or structural fatigue, the energy consumed per unit cycle increases, and even if the appearance is intact, the system efficiency will continue to decline.

FAQ 2

Why do different batches of conveyor belts exhibit different operational stability under the same tension setting?

This is a typical issue of batch consistency in rubber materials. When the formulation window or process control is unstable, the rubber modulus and elongation response will shift, directly affecting the tension-deformation relationship.

FAQ 3

Why do conveyor belts tear or fail locally before reaching their designed wear level?

This usually indicates that the main cause of failure is not wear, but rather insufficient resistance to cutting or crack propagation control of the conveyor belt rubber material. The main failure mechanism assumed in the design is inconsistent with actual operating conditions.

FAQ 4

Why do heat-resistant belts crack or peel prematurely after long-term operation without significant wear?

Heat resistance does not equate to structural stability after aging.

When rubber hardens or loses toughness under heat, stress redistributes between the cover rubber and the core layer, often leading to failure first in the bonding area or surface layer.

FAQ 5

Why does the frequency of conveyor belt maintenance increase significantly, but individual problems are not considered “serious”?

This is a typical signal that the material is entering an accelerated degradation phase.

At this point, the performance fluctuations of the conveyor belt rubber material increase. Although catastrophic failure has not yet occurred, system stability has significantly decreased.

FAQ 6

Why are laboratory test results合格 (qualified), but the field life is still significantly shorter?

Because laboratory tests verify a single failure path, while field operations often involve multiple failure mechanisms. When material design goals are overly focused on a single indicator, the overall lifespan will be reduced. It is recommended to confirm the datasheet with the supplier to further increase the controllability of the lifespan.

FAQ 7

Why does the conveyor belt perform stably in the initial stage of operation, but problems occur concentratedly in the middle and later stages?

This is a typical case of insufficient performance retention after rubber aging.

The material remains within a safe range in the early stages, but as aging progresses, key mechanical properties cross critical thresholds, and the probability of failure increases rapidly.

FAQ 8

Why is there a significant difference in lifespan between different suppliers for the same structure and operating conditions?

The difference usually stems from the maturity of the conveyor belt rubber material formulation and quality control capabilities, rather than the structural design itself. Structure determines the lower limit, while material determines the lifespan curve. Some companies choose recycled rubber for secondary processing to save costs, which introduces more impurities and leads to quality control issues.

FAQ 9

Can insufficient material selection be compensated for by adjusting tension or operating parameters?

This can only provide limited relief, not a fundamental solution.

Adjusting operating parameters cannot change the aging path or crack propagation mechanism of the rubber material; incorrect selection will ultimately manifest as problems in another form.

FAQ 10

What is the most critical engineering signal for determining whether a rubber material is suitable for long-term use?

Under the same operating conditions, does the conveyor belt maintain stable operation over a long period, rather than becoming increasingly reliant on manual adjustments?

Specifically, focus on three points:

- Is the tension adjusted frequently?

- Is the drive load continuously increasing?

- Is the maintenance frequency significantly increasing?

If these three aspects remain stable over a long period, it indicates that the conveyor belt rubber material is mature, controllable, and suitable for long-term use; conversely, even if the appearance is intact, it means that the material is gradually becoming uncontrollable.