1.The Guardians of the Conveyor Belt – Why Maintenance is Crucial

In the busy stage of modern industry, conveyor belt is like an invisible assistant, silently sending every part and material to the correct location to ensure the smooth operation of the production line. Whether in the manufacturing, logistics or food processing industries, the role of conveyor belt cannot be underestimated. Proper conveyor belt maintenance can not only improve production efficiency, but also significantly reduce operating costs.

When it comes to downtime, businesses don’t want to deal with this “hot potato.” Studies show that once a production line is shut down, it may lead to losses of thousands or even millions. This not only damages immediate profits, but also may cause the trust of customers to collapse. When equipment breaks down, the process of restoring production is often maddeningly long, and waiting for hours can feel like torture. Just imagine, orders are coming in like snow flakes, but the machines remain motionless due to minor problems. The corporate image and customer relations face a double test.

To make downtime a thing of the past, companies need to develop an effective conveyor belt maintenance strategy. Regular inspections and maintenance are like “vaccination” for equipment, ensuring that problems are not blocked before they appear. Checking key parts of the conveyor belt, such as tension, wear and alignment, is like performing routine maintenance on a sports car to ensure it is always in top condition. According to the recommendations of the American Society for Testing and Materials (ASTM), maintenance frequency should be at least once a week, so that small problems can avoid becoming “big troubles”, allowing companies to save a lot of maintenance costs, and allowing employees to work hard in a safe and stable environment.

Let’s talk about safety. Good maintenance is definitely the “talisman” for employees. According to the Occupational Safety and Health Administration (OSHA), accidents caused by equipment failure are frequent and often put employees’ lives at risk. Strengthening the maintenance of conveyor belt safety is like building a safety barrier for employees to protect them from harm at work. This is not only the responsibility for the equipment, but also the responsibility of the enterprise as a member of society. In such an environment, employees will feel more at ease and their work efficiency will naturally increase.

Finally, conveyor belt maintenance has an unexpected benefit, which is extending the service life of the equipment. Equipment wear and tear is inevitable, but through reasonable maintenance, this process can be significantly slowed down and money spent on replacing equipment can be saved. Just imagine, if every link operates efficiently under good maintenance, the smoothness of the production line will be greatly improved, and the company’s profits will also spring up like mushrooms after a rain.

Maintaining the conveyor belt is not only responsible for the equipment, but also a wise investment in the future of the enterprise. By establishing an effective maintenance system, companies can survive the fierce market competition and lay a solid foundation for the next successful stage.

2.Maintenance Strategy Overview

In today’s fast-paced industrial world, equipment maintenance is not only “icing on the cake”, but also “a timely help”. For enterprises, ensuring the efficient operation of conveyor belts is like giving a luxury car regular maintenance, which not only improves performance but also extends its service life. According to the report of the International Society for Materials Management (ISM), improper equipment maintenance may cause the global manufacturing industry to lose billions of dollars each year (Source: ISM Report). Therefore, enterprises are in urgent need of a scientific conveyor belt maintenance strategy to cope with the dual challenges of equipment aging and changing market demand.

First, regular inspection and maintenance are the “golden key” to any maintenance plan. Imagine that regular inspections are like a “heart shot” for the equipment, helping enterprises to detect hidden dangers in time before problems surface. According to the use of the equipment and the working environment, enterprises should develop personalized maintenance plans. For example, many industries recommend a detailed inspection once a week to ensure that the conveyor belt is running in the best condition and avoid small problems from turning into “big troubles”, which can be said to be prepared for a rainy day.

Second, lubrication and cleaning are the “lubricants” that keep the conveyor belt running smoothly. Proper lubrication not only reduces friction and prolongs equipment life, but also improves overall production efficiency. Studies have shown that proper lubrication can reduce equipment failure rates by 40% (Source: Lubrication Study). In addition, cleaning equipment is also crucial. Removing dirt and debris can prevent unexpected failures. Therefore, companies should establish a systematic cleaning procedure to ensure that each conveyor belt is kept clean and tidy to avoid “diseases from the mouth”.

The introduction of monitoring technology is the “black technology” of modern maintenance strategies. By installing sensors and monitoring systems, companies can obtain equipment operation data in real time. Data analysis can not only help predict potential failures, but also issue warnings before problems occur. For example, companies using IoT technology can convert equipment operation conditions into visual data, so that decisive action can be taken when necessary. This strategy is like installing “clairvoyance” for companies, allowing them to gain an advantage in the ever-changing market.

Finally, another unexpected benefit of conveyor belt maintenance is that it extends the service life of equipment. Equipment wear is inevitable, but through reasonable maintenance, this process can be significantly slowed down and money can be saved on replacing equipment. Imagine that if every link is well maintained and operates efficiently, the smoothness of the production line will be greatly improved, and the company’s profits will spring up like mushrooms after rain.

Maintaining the conveyor belt is not only responsible for the equipment, but also a wise investment in the future of the company. By establishing an effective maintenance system, the company can easily cope with the fierce market competition and lay a solid foundation for the next stage of success.

Strategy 1: Regular Inspections and Maintenance

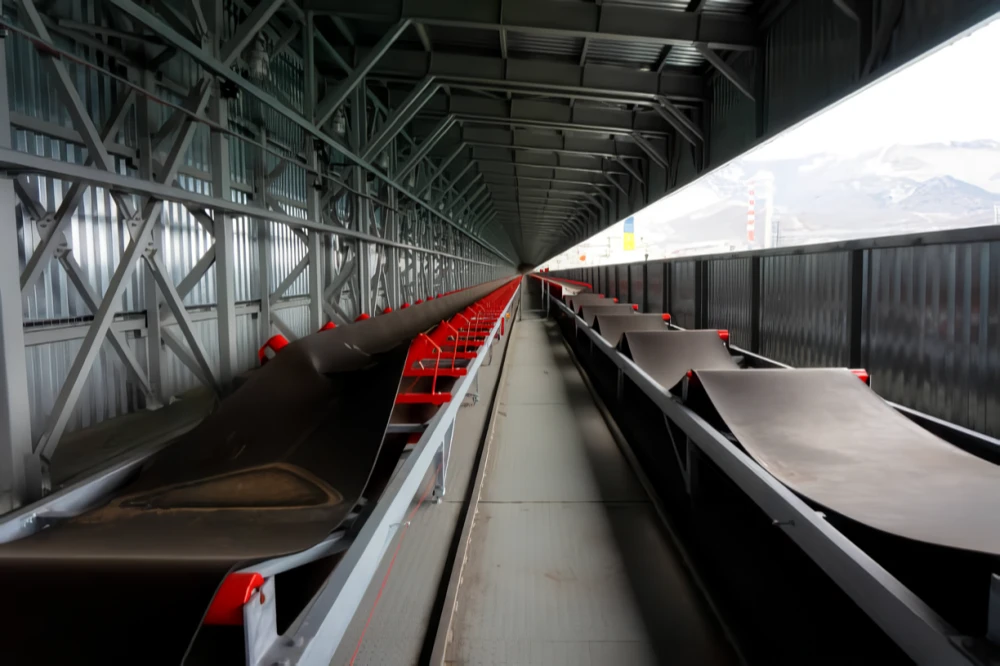

When it comes to conveyor belt maintenance, regular inspections and maintenance are the key to ensuring the continuous operation of the equipment. If the company’s production line is compared to a complex machine, the conveyor belt is the transmission device in it, and regular maintenance is equivalent to a “health check” for this machine. Regular inspections of conveyor belts are essential.

First of all, regular inspections can help companies detect problems as early as possible. Many large companies, due to their long conveyor belt machinery, will specially configure multiple daily conveyor belt inspectors to ensure that there are no foreign objects stuck during the operation of the conveyor belt, causing permanent damage to the conveyor belt, and confirm the working status of the conveyor belt. For example, in terms of tension, too tight or too loose will cause wear on the conveyor belt. Through routine inspections, technicians can adjust the tension in time to ensure that the conveyor belt is in the best condition. According to the standards of the American Society for Testing and Materials (ASTM), monthly inspections of the tension and alignment of the conveyor belt are basic requirements. In addition, the inspection should include the wear of the conveyor belt, especially when the conveyor belt is used frequently or in a harsh environment. This process not only prolongs the life of the equipment, but also prevents sudden failures and reduces production downtime.

Secondly, regular maintenance can significantly reduce equipment wear. During the operation of the conveyor belt, friction and tension will inevitably cause wear on its surface, and this problem can be effectively alleviated through reasonable maintenance. The choice of lubricant is particularly important here. Using a suitable lubricant according to the material and properties of the conveyor belt can not only reduce friction, but also provide additional protection for the conveyor belt in harsh environments such as high temperature and high humidity. Choosing the wrong lubricant may be counterproductive, causing material degradation or increased friction. Therefore, companies should carefully select the appropriate lubricant according to the material and working environment of the conveyor belt.

The frequency of regular inspections varies depending on the industry and workload. For example, the conveyor belt in the food processing industry needs to be cleaned frequently, so it is recommended to conduct a comprehensive inspection once a week; in some more stable environments, monthly or quarterly inspections may be more suitable. In the case of a gravel yard or coal mine, the inspection frequency of the conveyor belt may need to be higher. In any case, the biggest benefit of regular maintenance is that it can avoid sudden failures. Statistics show that regular inspection and maintenance can reduce the failure rate of conveyor belts by more than 30%, which is undoubtedly the result that every company hopes to see.

In addition to the conveyor belt itself, companies should also conduct routine inspections on other related equipment, such as rollers, transmission devices and motors. Many times, the problem is often not the failure of a single device, but a chain reaction caused by the damage of related components. Therefore, companies should include the entire conveyor system in the regular maintenance plan to prevent problems before they occur.

Maintenance is not a one-time process, but a continuous commitment. As the old saying goes, “A journey of a thousand miles begins with a single step.” Regular inspection and maintenance pave the way for the long-term development of the production line for companies. Ignoring this process is tantamount to playing “unboxing”, and what awaits you may be an unexpected downtime accident.

Strategy 2: Lubrication and Cleaning Practices

In conveyor belt maintenance, lubrication and cleaning are like the “golden partners” for maintaining equipment. Lubrication is more than just friction reduction; in fact, it is a key factor in improving the energy efficiency of the entire system. In today’s context of rising energy prices, optimizing the energy consumption of equipment has become crucial. High-performance lubricants not only reduce friction but also significantly reduce energy consumption. Studies show that by using optimized lubricants, equipment energy consumption can be reduced by up to 15% . For any business, this is not only maintenance of equipment, but also an investment in the future of the business.

At the same time, cleaning equipment is not only about appearance, but also affects the smoothness of internal operations. Although traditional cleaning methods are effective, they are not efficient and prone to leakage problems. Automated cleaning systems, such as those equipped with dirt monitoring sensors, allow companies to monitor the cleaning status of conveyor belts at any time and automatically trigger cleaning procedures when needed. This intelligent approach not only improves accuracy but also avoids human errors. With the advancement of technology, this smart cleaning system is gradually becoming the new standard in the industry, improving overall operational efficiency while also reducing the workload of workers.

Companies should also pay attention to environmental factors when choosing lubricants and cleaners. Choosing lubricating products that meet environmental standards not only reduces the impact on the environment, but also wins a good social responsibility image for the company. In recent years, many environmentally friendly lubricants have performed well, remaining stable in harsh environments while being safer for workers and equipment. Working with suppliers to find environmentally friendly products that suit their business needs is a key step toward sustainable development.

Additionally, maintenance strategies for lubrication and cleaning cannot be static. Enterprises should maintain a “continuous improvement” mentality and constantly review whether current practices are achieving the best results. Through regular data analysis, companies can evaluate the impact of lubrication and cleaning on equipment life, energy consumption, and overall production efficiency, and continuously adjust according to actual needs. This flexible management method not only keeps the equipment in optimal condition, but also provides a strong guarantee for the enterprise in future market competition.

Lubrication and cleaning are no longer maintenance tasks in the traditional sense, but are key means for enterprises to improve their competitiveness. Through intelligent and environmentally friendly methods, companies can not only ensure the continuous and efficient operation of equipment, but also move forward steadily in the increasingly fierce market competition. As Edison said: “Success is one percent inspiration and ninety-nine percent perspiration.” In equipment maintenance, that ninety-nine percent comes from the continuous investment and continuous investment in lubrication and cleaning. Innovation.

Strategy 3: Implementing Monitoring Technologies

When it comes to regular inspections and lubrication cleaning, we have seen how to extend the life of conveyor belts through routine maintenance. However, relying solely on traditional methods, companies may miss early signs of potential equipment failure. At this time, intelligent monitoring technology comes on the scene, providing a new solution for conveyor belt maintenance, just like installing a “clairvoyant” for the conveyor belt, so that no small problem can escape the monitoring sight.

Through the combination of sensors and data acquisition systems, companies can obtain key data of equipment in real time. Small changes in conveyor belt speed, tension, temperature, and even noise levels are often a sign of impending equipment problems. Using this data, operators can compare historical operating conditions and quickly identify abnormal conditions. Just like doctors can find health risks in advance through physical examination reports, companies can also intervene early and prevent failures through data analysis.

Internet of Things (IoT) technology has further changed the way equipment is managed. Today, every detail of the conveyor belt can be captured, analyzed, and uploaded to the central monitoring system. Through this network, operators can not only monitor the status of equipment in real time, but also control it through remote devices, so that they can always grasp the pulse of the production line no matter where they are. For example, in a logistics center, operators can use IoT devices to view the operating status of the conveyor belt in real time from their mobile phones or tablets, reducing the frequency of manual inspections and greatly improving management efficiency.

Predictive maintenance is the “killer weapon” of intelligent monitoring technology. By analyzing past operating data and current status, the system can predict when the equipment may fail and provide early warning. Imagine if the tension of the conveyor belt has gradually increased over the past few weeks, which may indicate that the transmission components need to be adjusted or replaced. The system will issue an alarm in advance, giving the company enough time to take action and avoid sudden downtime. Studies have shown that companies that implement predictive maintenance can reduce equipment failure rates by up to 20% , which is extremely valuable for any manufacturing company.

Intelligent monitoring not only makes maintenance more efficient, but also provides operators with a new basis for decision-making. The system can automatically identify problems and propose specific solutions. Even novice operators can make correct judgments under the guidance of the system. This technological advancement not only reduces the risk of human misjudgment, but also significantly shortens maintenance time and reduces losses caused by production interruptions.

In the future, conveyor belt maintenance will rely more on intelligent technical support. With the continuous maturity of equipment automation management systems, enterprises are expected to achieve a comprehensive “zero failure” goal and completely get rid of the frequent downtime problems in traditional maintenance. Monitoring technology has undoubtedly opened up new prospects for equipment management, allowing enterprises to improve production efficiency while also laying a solid foundation for long-term sustainable development.

Strategy 4: Enhancing Employee Training Programs

It is important to introduce advanced monitoring technology and optimized maintenance strategies, but in the end, the implementation of maintenance work still depends on operators. The core of conveyor belt maintenance is not only technology, but also skilled employees. As mentioned earlier, intelligent technology and data analysis provide companies with tools, but these tools can only really work in the hands of fully trained employees.

Enhancing employee training is not only to improve their operating skills, but also to make every employee a “guardian” of the conveyor belt. Equipment maintenance involves many details, from daily operations to emergency fault handling, each step requires employees to have solid knowledge and practical experience. Many conveyor belt failures are caused by the accumulation of small problems, and a trained employee can quickly judge the severity of the problem and deal with it in time by observing the subtle changes in the equipment. This ability is crucial to preventing failures.

According to a study on enterprise equipment management, employees who receive regular equipment maintenance and safe operation training have significantly improved their ability to detect faults and prevent accidents. Data shows that trained teams can reduce equipment failure rates by up to 25%. This not only effectively prevents the frequency of downtime, but also greatly reduces the company’s expenses on equipment maintenance.

The training content should include two cores: one is the training of daily maintenance operations of conveyor belts, and the other is the training of equipment safety operating procedures. Through the training of basic conveyor belt maintenance procedures, employees can master core skills such as how to correctly adjust tension, check wear, and identify potential faults. At the same time, safe operation training can ensure that employees have sufficient protection awareness and operating skills when handling complex or dangerous equipment to avoid personal accidents.

However, practical opportunities are not common in many companies, especially for key equipment such as conveyor belts, where the opportunity to stop for training may be very limited. Therefore, companies need to conduct practical training through experienced engineers combined with on-site operations. Engineers with many years of experience can not only impart their valuable experience accumulated in actual work, but also answer the complex problems encountered by young employees in actual operations. The teaching model can help employees better combine theory with practice, and these instructions will also provide great help for them when they face equipment failures in the future.

In addition, companies should also create a “everyone is responsible” equipment maintenance culture. Employees are not only individuals who operate equipment, but also a link in the entire production chain. Through training, companies can inspire employees’ sense of responsibility and make them aware of their important role in equipment operation. Only when every employee regards the normal operation of the equipment as their own responsibility can the company’s equipment maintenance work be truly implemented.

In the battlefield of equipment maintenance, science and technology are powerful weapons, and well-trained employees are the core force to master these weapons. Through continuous training, companies can not only improve their employees’ skills, but also build an efficient and responsible equipment maintenance team. Ultimately, such a team will become an important guarantee for companies to cope with future challenges and maintain their competitiveness.

Strategy 5: Timely Replacement of Critical Components

No matter how perfect the conveyor belt maintenance plan is, it cannot prevent the aging of equipment due to long-term use, especially those critical components that are running under high-intensity loads. When performing conveyor belt maintenance, whether these critical components can be accurately identified and replaced in time is the key to maintaining the efficient operation of the conveyor belt system. Even if daily maintenance is meticulous, if the regular replacement of critical components is neglected, the entire system may be shut down due to an inconspicuous minor problem, causing unexpected losses and delays.

The core components of the conveyor belt, such as drive rollers, rollers, bearings and fasteners, have been subjected to tremendous pressure and friction for a long time. These components are the basis for the smooth operation of the system. However, it is precisely because they are under high load all year round that they wear faster than other components. If not replaced in time, the conveyor belt may deviate, wear severely, or even cause the equipment to shut down completely. According to statistics, failure to replace critical components in time is one of the main causes of unexpected downtime, which may cause thousands of dollars in losses each time .

How to judge whether key components need to be replaced is a skill that every conveyor belt maintenance team must master. Although some component failures are obvious, more often, problems are latent and need to be identified by regular inspections and monitoring systems. For example, excessive wear of bearings is often manifested by increased temperature or increased vibration. By introducing intelligent monitoring technology, companies can track the operating status of these components more accurately and determine in advance when to replace them based on data analysis. This not only avoids sudden shutdown of equipment due to failure, but also allows companies to plan downtime and reduce the impact on production progress. This is an indispensable part of modern conveyor belt maintenance.

Timely stocking management of replacement parts is also another important part of the key component replacement strategy in conveyor belt maintenance. An effective strategy is to accurately predict the service life of key components through historical usage data and equipment maintenance records, and reasonably set reorder points. For example, if the expected life of a drive roller is two years, the company should start planning stocking at about one and a half years to ensure that the parts are ready when they are actually needed. This approach can avoid unnecessary emergency procurement costs while reducing downtime. There is another method that is relatively simpler. Even if you get relevant information from the supplier, the supplier may be more clear about the operation of spare parts in a certain environment. You can save more trouble by directly asking the supplier for advice on the replacement cycle.

Some companies have also adopted the “old for new” conveyor belt maintenance strategy. That is, as mentioned above, after the relevant accessories have been used for a certain period of time, even if some parts do not show obvious signs of failure, they will be actively replaced within the scheduled time. Although this strategy increases maintenance costs in the short term, in the long run, it can effectively reduce the risk of sudden downtime and overhaul, and ultimately save a lot of time and money for the company. This “preventive replacement” strategy has been widely used in many industrial fields, especially in production lines with extremely low tolerance for downtime.

Replacing key components is not only to repair problems, but also to keep the entire system in the best working condition at all times. For conveyor belt maintenance, the health of key components determines the efficiency and safety of the entire production line. By developing clear replacement plans, using intelligent monitoring systems and inventory management strategies, companies can not only reduce the risk of unexpected downtime, but also ensure that the conveyor system is in the best condition at all times, providing solid protection for the company’s continued production and development.

3.Maintenance Tips – Keep Your Conveyor Belt Running

Every company wants its production line to run like clockwork, efficiently and without pause. To achieve this goal, it is essential to maintain high standards of conveyor belt maintenance. From regular inspections and maintenance, to timely lubrication and cleaning, to the introduction of advanced monitoring technology and employee training, each link is an indispensable puzzle piece that together form a seamless operation picture.

By implementing the five strategies discussed above, companies can not only significantly reduce the risk of unexpected downtime, but also extend the life of equipment and maximize production efficiency. Especially in the face of natural wear and inevitable aging of equipment, preventive maintenance and intelligent monitoring will become the company’s “line of defense” to help companies take action before problems occur. Whether it is meticulous maintenance or precise component replacement, it ultimately points to one goal: to keep the conveyor belt system running continuously and efficiently.

However, relying solely on technology and strategy is not enough. The success of equipment maintenance also depends on the construction of corporate culture and the initiative of employees. Only by establishing an atmosphere of “everyone participates in maintenance” and regarding the health of equipment as a collective responsibility can every employee contribute to the normal operation of the equipment. As an equipment maintenance expert said: “The stable operation of the conveyor belt is not only a technical issue, but also a collective commitment.”

The knowledge listed above is only the most basic. The conveyor belt maintenance process varies from company to company due to the different nature of the product. Combining the experience of employees and product performance can not only ensure the stability of the equipment, but also improve the continuity and safety of production. Maintenance is not only an important part of ensuring the normal operation of equipment, but also a core means for companies to maintain their competitiveness in a highly competitive market. By strictly implementing conveyor belt maintenance, companies can effectively reduce unexpected downtime and improve the stability and efficiency of production lines. Reasonable maintenance can not only extend the life of the equipment, but also avoid the cost and time loss caused by production interruptions. Through continuous attention and precise maintenance, companies can move forward steadily in the market, enhance the reliability of overall operations, and take the lead in future opportunities.