Choosing the right conveyor belt joint types is more than a technical detail—it’s the key to safety, efficiency, and long-term performance. Studies by OSHA show that weak conveyor joints are a common cause of costly breakdowns and accidents. In this guide, I’ll break down the main joint methods for rubber and PVC belts, compare their strengths and limits, and share practical tips for real industries. By the end, you’ll know exactly how to match the right splice to your belt, your environment, and your business goals.

1.Why Conveyor Belt Joint Types Matter

Let’s be honest. Every conveyor belt is only as strong as its joint. You can buy the best rubber conveyor belt or the cleanest PVC conveyor belt, but if the splice is weak, your whole system is at risk. That’s why conveyor belt joint types really matter.

A poor joint means trouble. It tears. It slips. It stops production when you least expect it. And that costs money. Even worse, it puts people at risk. According to OSHA, conveyor systems cause dozens of workplace accidents every year, many linked to joint failures (OSHA ). Safety is not optional.

Different belts need different solutions. Heavy industries like mining or cement plants push a rubber conveyor belt to its limits. That’s where strong vulcanized joints shine. But in food factories, you need a smooth and hygienic splice. That’s where PVC conveyor belt joints come in, using cleaner conveyor belt joining methods.

So when I say conveyor belt joint types, I’m not just talking about splicing rubber. I’m talking about safety, efficiency, and keeping your line moving without surprises.

2.Rubber Conveyor Belt Joint Types

When we talk about rubber conveyor belt, strength matters. Heavy loads, high speed, and tough environments push the belt to its limits. That’s why the right conveyor belt joint types are critical. Let me walk you through the main options.

2.1 Hot Vulcanizing Splice

This is the gold standard. We heat, press, and fuse the layers until the joint becomes part of the belt. The splice can reach 80–90% of the belt’s original strength. That means long service life and fewer breakdowns. The downside? It needs skilled hands and expensive tools. But if you run a mine or a cement plant, this is the way to go. (Source: ContiTech)

2.2 Cold Bonding Splice

Here we use glue instead of heat. It’s fast and simple, perfect for quick fixes in the field. The trade-off is lower strength and shorter life. Still, it’s a practical choice for medium-duty rubber conveyor belts or emergency repairs.

2.3 Mechanical Fasteners

Think of metal clips, bolts, or teeth holding the belt together. It’s quick. It’s cheap. It works in emergencies. But it’s also the weakest option. You’ll see more wear, more noise, and more maintenance. It’s a temporary fix, not a long-term solution.

So for rubber conveyor belt, you’ve got three clear conveyor belt joining methods. If you want reliability, go vulcanized. If you want speed, go with cold bonding or fasteners. That’s the reality of conveyor belt joint types in heavy industry.

3.PVC Conveyor Belt Joint Types

When we deal with a PVC conveyor belt, the demands shift. You don’t just need strength—you also need smoothness, hygiene, and the ability to work with small pulleys. That’s why the conveyor belt joint types for PVC are designed differently from rubber belts.

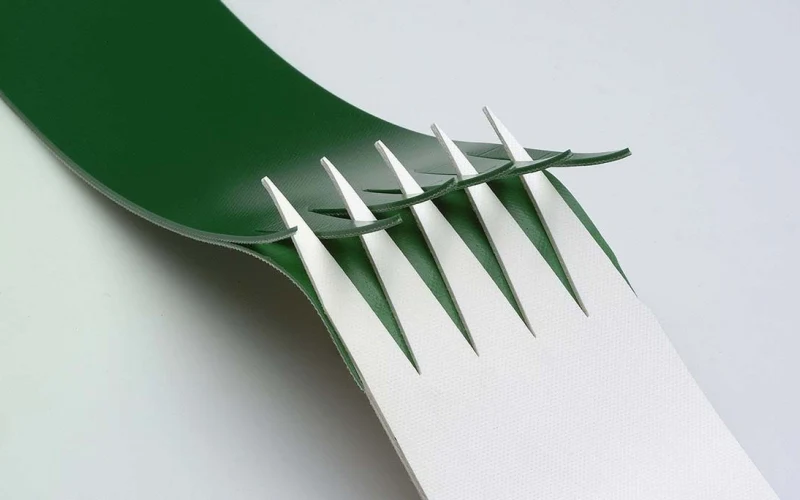

3.1 Finger Splice (Hot Press)

This is the premium method. I cut the ends into “fingers,” then fuse them with heat and pressure. The splice becomes flat, strong, and flexible. It looks clean and runs quietly.

Strength usually reaches 70–80% of the belt’s original tensile capacity, which is more than enough for most light-duty operations. More importantly, the joint bends around small pulleys without creating bumps. That’s critical in food, pharma, and electronics industries, where belts must stay smooth and hygienic.

The only challenge? You need special tools and trained operators. The process takes more time. But in sensitive industries, it’s the only method that meets hygiene standards like FDA or EHEDG (FDA , EHEDG ).

3.2 Overlap Splice

This method is simpler. The belt ends are overlapped, skived, and pressed together. It costs less and installs quickly. Many factories choose it for short conveyors or low-speed lines.

The drawback is clear: the splice is thicker and less flexible. That makes it unsuitable for small-diameter pulleys or high-speed logistics. Strength is also lower, typically 60–70% of the belt’s capacity. Still, for light packaging lines or budget-limited projects, it works.

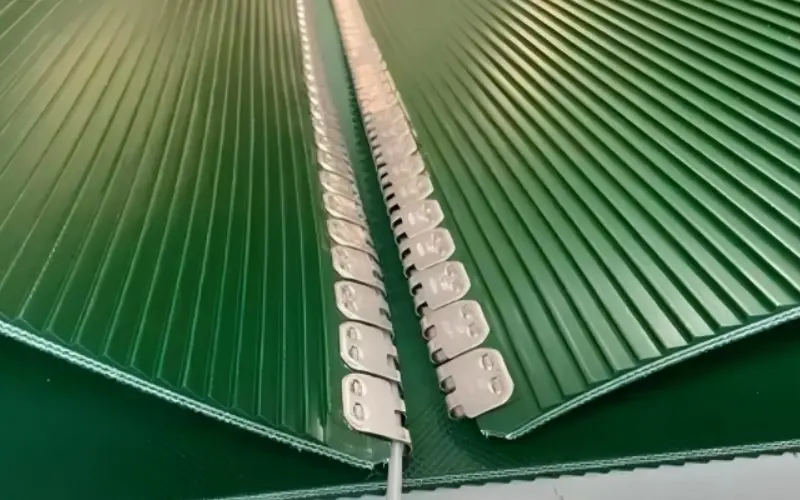

3.3 Mechanical Fasteners

Yes, even PVC conveyor belts can be joined with clips or fasteners. The benefit is speed. One worker can install a joint in minutes. It’s perfect for emergencies or temporary lines.

But this comes at a cost. The joint is weaker, noisier, and hard to clean. Gaps and metal parts trap dirt, which violates hygiene rules. That’s why you almost never see fasteners in food or clean industries. Instead, they are used in low-end logistics or emergency repairs where hygiene doesn’t matter.

So, when it comes to PVC conveyor belt joining methods, the finger splice is the best long-term solution. Overlap splices make sense for lighter use, and mechanical fasteners remain the emergency choice. That’s the real picture of conveyor belt joint types in clean and light-duty industries.

4.Comparison of Conveyor Belt Joint Types

Here’s a clear overview of the main conveyor belt joint types. This table compares their strength, cost, and best applications. Use it as a guide when choosing the right conveyor belt joining methods for your industry.

Joint | Suitable Belt | Joint Strength | Lifespan | Cost | Typical Industries | Advantages | Limitations |

Hot Vulcanizing | Rubber | ★★★★★ (80–90%) | Long | High | Mining, Cement, Power Plants | Strongest splice, long service life, smooth run | High cost, needs skilled technicians & equipment |

Cold Bonding | Rubber | ★★★★ (60–70%) | Medium | Medium | General Factories, Maintenance | Easy to apply, no hot press needed | Weaker, affected by humidity & temperature |

Mechanical Fasteners | Rubber / PVC | ★★ (40–50%) | Short | Low | Emergency Repairs, Logistics | Very fast to install, low cost | Weak, noisy, traps dirt, poor hygiene |

Finger Splice (Hot Press) | PVC | ★★★★★ (70–80%) | Long | Medium | Food, Electronics, Logistics | Flat, flexible, hygienic, small pulley friendly | Needs special press & tools |

Overlap Splice | PVC | ★★★ (60–70%) | Medium | Low | Packaging, Light-Duty Conveyors | Quick, low-cost, easy to make | Thicker joint, less flexible, shorter lifespan |

5.How to Choose the Right Conveyor Belt Joint Types

By now, you’ve seen the main conveyor belt joint types and how they compare. But the real question is simple: which one should you choose for your line?

5.1 Look at the Belt Material

If you use a rubber conveyor belt, go for hot vulcanizing when possible. It gives you the longest life and the strongest splice. If you need a quick repair, cold bonding or fasteners will get you running, but they won’t last as long.

If you run a PVC conveyor belt, hygiene and smoothness matter. That’s why finger splices are the smart choice. They bend well and meet food industry standards. For lighter use, overlap splices are fine. Fasteners only make sense for emergencies.

5.2 Consider the Material You’re Moving

Moving ore, coal, or cement? You need strength and durability. That means vulcanized joints.

Moving food, medicine, or electronics? You need hygiene and smooth surfaces. That means finger splices.

5.3 Think About the Environment

Harsh, dusty, or wet conditions? Go stronger. Hot vulcanizing holds up better.

Clean and controlled environments? PVC splicing methods work best.

5.4 Don’t Forget Maintenance

Ask yourself: do you have trained staff and tools for vulcanizing? If not, cold bonding or overlap splices may be more practical. OSHA warns that poorly maintained conveyor joints are a common cause of accidents and downtime . A good splice is not just stronger—it’s safer.

picking the right conveyor belt joint types depends on your belt, your material, your environment, and your people. Use conveyor belt joining methods that match your reality, not just the “strongest” option. That’s how you balance cost, safety, and uptime.

6.Why Conveyor Belt Joint Types Decide Your Success

At the end of the day, conveyor belt joint types decide how reliable your system really is. The belt itself may look strong, but the splice is where everything comes together—or falls apart.

Choose the wrong joint, and you face breakdowns, delays, and higher costs. Choose the right one, and your line runs smoother, safer, and longer. That’s the power of good conveyor belt joining methods.

If you work with rubber conveyor belts, hot vulcanizing is your strongest bet, while cold bonding and fasteners cover repairs and emergencies. If you run PVC conveyor belts, finger splices give you hygiene and flexibility, overlap splices save time and cost, and fasteners only step in when you need a quick fix.

In our factory, we help customers match the splice to their reality—whether that’s mining, cement, logistics, or food processing. We don’t just sell belts. We provide solutions that keep your business moving.

So remember this: the right choice of conveyor belt joint types is not a detail. It’s the difference between constant downtime and steady production.

7.FAQ on Conveyor Belt Joint Types

Q1: What is the strongest conveyor belt joint type?

Hot vulcanizing is the strongest. It restores 80–90% of the belt’s strength and lasts the longest. That’s why it’s the top choice for mining, cement, and power plants.

Q2: Which conveyor belt joining methods are best for food-grade belts?

Most food-grade belts today are PU conveyor belts, not PVC. PU is cleaner, more durable, and meets FDA and EU food safety standards. The best splice here is usually a finger splice, because it’s flat, hygienic, and flexible. PVC belts are still used in light logistics and packaging, but not as much in direct food contact.

Q3: Can I use mechanical fasteners on both rubber and PVC belts?

Yes, but they are only a temporary fix. They are quick and cheap, but weaker, noisier, and less hygienic. For food or pharma belts, avoid them. For logistics or emergency use, they can be useful.

Q4: How do I know if my joint type meets international standards?

Check for certifications like ISO, DIN, or FDA compliance. For example, ISO 9856 sets testing standards for belt tensile strength, while FDA covers food-grade PU belts.

Q5: How can I extend the life of my conveyor belt joint?

Pick the right splice for your industry, and maintain it regularly. OSHA reminds us that poor maintenance is a key factor in conveyor belt accidents . A well-chosen and well-maintained joint saves money and prevents downtime.