Rubber sheets are the unsung heroes behind sealing, cushioning, and protection across industries. At Tiantie, we’ve spent decades perfecting rubber sheet manufacturing with advanced formulations and strict quality control. Our products prove that true durability comes from precision, not compromise. From factories to fitness floors, every sheet is built to last, resist wear, and perform under pressure. As industries evolve, Tiantie continues leading with reliability — shaping the future of smarter, longer-lasting rubber materials.

1. Introduction – What Is a Rubber Sheet and Why It Matters

If you’ve ever walked into a factory, a construction site, or even a gym, chances are you’ve already encountered a rubber sheet—quietly doing its job. But what is a rubber sheet, really? In simple terms, it’s a flat, flexible elastomeric sheet made from natural or synthetic rubber. Depending on its formulation, a rubber sheet can serve as a seal, vibration damper, insulation barrier, or protective lining—making it one of the most versatile materials in modern industry.

Think of it as the foundation material behind countless industrial and everyday products. In the automotive industry, rubber sheets are turned into gaskets and oil seals that keep engines leak-free. In manufacturing, they become vibration-absorbing pads under heavy machinery. In construction, they serve as roofing membranes and waterproof layers that protect buildings from the elements. Even in your home, that anti-slip floor mat might be an example of a thin industrial rubber sheet in disguise.

What makes the industrial rubber sheet so essential is its ability to combine flexibility with resilience. It resists wear, tolerates pressure, and adapts to extreme environments—from freezing warehouses to heat-intensive plants.

In this article, we’ll dive deep into the science and versatility of rubber sheeting—from its material composition and types, to its mechanical properties, manufacturing process, and the sustainability innovations shaping its future.

Rubber sheets aren’t just materials—they’re the silent backbone of modern engineering.

(Source: ASTM D2000 Standard Specification for Rubber Products ASTM International )

2. A Brief History of Rubber Sheeting – From Sap to Smart Material

To truly understand today’s rubber sheets, you need to look back—way back—to the tropical rainforests of South America. The story begins with Hevea brasiliensis, the rubber tree. Indigenous communities discovered that its milky sap, or latex, could be shaped and dried to create flexible, waterproof materials. This was the earliest chapter in the history of rubber sheet, long before industrialization gave it new meaning.

When explorers brought rubber to Europe in the 18th century, it fascinated scientists but frustrated engineers. Early rubber was sticky in the heat and brittle in the cold—useful for erasing pencil marks (hence “rubber”), but not much else. Then came Charles Goodyear in 1839, whose groundbreaking discovery of vulcanization—adding sulfur to rubber under heat—transformed it forever. Vulcanized rubber became stable, elastic, and resistant to temperature swings, paving the way for durable rubber sheets, tires, and industrial seals. (Source: Smithsonian Institution – National Museum of American History )

Fast forward to the 20th century, when synthetic rubber development took center stage. During World War II, shortages of natural rubber led to the invention of Neoprene (CR), Nitrile (NBR), and later EPDM, each engineered to solve specific industrial challenges like oil resistance, weathering, or chemical exposure.

Today, rubber sheets have evolved once again—blending traditional elastomers with recycled materials, bio-based polymers, and smart additives for sustainability and performance. From tree sap to engineered composites, the journey of the rubber sheet mirrors the evolution of modern material science itself.

3. The Material Science Behind Rubber Sheets

Let’s keep it simple — a rubber sheet isn’t just a piece of black material you roll out on the floor. It’s actually a carefully engineered product, made to stay flexible, strong, and durable in all kinds of environments.

At the heart of every rubber sheet is something called an elastomer — a long chain of molecules that can stretch like a spring and then bounce back. Before it’s treated, rubber feels sticky and soft, but once we heat it with a little sulfur (a process known as vulcanization), it changes completely. Sulfur creates tiny “bridges” between the molecular chains, locking them together. That’s what gives us a vulcanized rubber sheet — a tough, elastic material that can handle heat, pressure, and daily wear.

If you want an easy comparison:

Unvulcanized rubber = soft dough

Vulcanized rubber = baked bread

Both start from the same ingredients, but one is ready for real work.

Learn more about the history of vulcanization here:

Smithsonian Institution – The Story of Charles Goodyear

Now, when we make an industrial rubber sheet, it’s not just pure rubber. We create a rubber compound — a mix that includes fillers like carbon black for strength, oils to improve flexibility, and special chemicals that prevent aging and cracking. By adjusting these ingredients, we can make a rubber sheet softer, harder, more oil-resistant, or even suitable for extreme heat.

For example:

- EPDM handles sunlight, ozone, and outdoor weather perfectly.

- NBR is great for contact with oil or fuel.

- Silicone can work safely in food and medical industries because it’s clean and non-toxic.

So next time you see a rubber sheet under a machine, in a factory, or even as flooring, remember — it’s not just a flat piece of rubber. It’s the result of science, precision, and decades of engineering experience that make it one of the most reliable materials in the industrial world.

ASTM D412 – Standard Test Methods for Vulcanized Rubber and Thermoplastic Elastomers

4. Common Types of Rubber Sheets – Finding the Right One for Your Needs

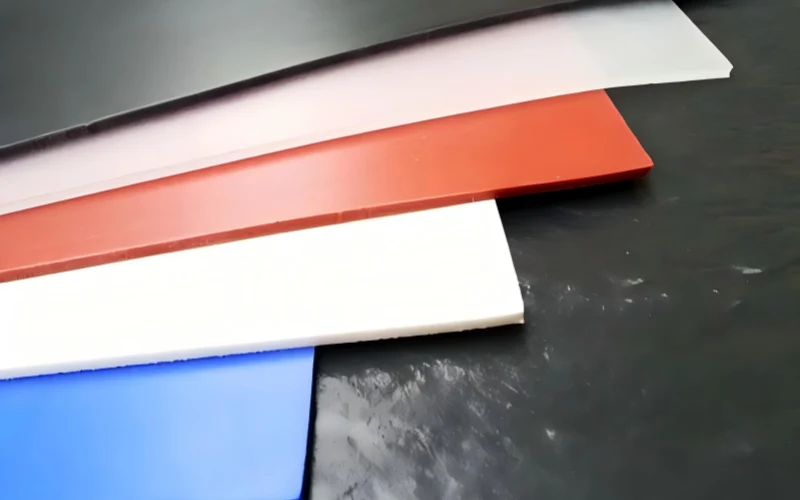

When people say “rubber sheet,” they might think it’s all the same — but in reality, there are many types of rubber sheets, each designed for a specific job. Some are made to resist oil, others for outdoor weather, and some for high heat or chemical exposure.

Let’s take a closer look at the most common rubber sheet types used in today’s industries.

4.1 Natural Rubber

Natural rubber comes directly from the sap of the Hevea brasiliensis tree. It’s famous for its superb elasticity, high tensile strength, and great abrasion resistance.

It’s ideal for anti-vibration pads, protective liners, industrial flooring, and machine mounts.

Limitations: It doesn’t like oil, sunlight, or ozone — so it’s best used indoors.

4.2 Styrene-Butadiene Rubber (SBR)

SBR Rubber is one of the most widely used synthetic rubbers. It offers excellent wear resistance and a lower cost compared to natural rubber.

Best for: conveyor belts, liners, flooring, and shock-absorbing pads.

Limitation: Not resistant to ozone or oil.

4.3 EPDM Rubber (Ethylene Propylene Diene Monomer)

EPDM is a star performer outdoors. It stands up to UV, ozone, water, and steam — that’s why it’s often used for roofing membranes, waterproof seals, and outdoor gaskets.

Limitation: Poor resistance to oil and fuel.

ASTM D2000 – Classification System for Rubber Products

4.4 Nitrile Rubber (NBR)

If your application involves oil, fuel, or grease, this is the one. NBR rubber sheets have excellent oil resistance and mechanical strength.

Used in: automotive gaskets, seals, hoses, and fuel systems.

Limitation: It becomes less flexible at very low temperatures.

4.5 Neoprene (CR)

Neoprene is known for its balanced performance — good oil resistance, weatherproofing, and even a bit of flame retardancy.

Applications: marine seals, electrical insulation, and general-purpose gaskets.

4.6 Silicone Rubber Sheet

The silicone rubber sheet stands out for its extreme temperature range (-60°C to +230°C) and non-toxic, odor-free nature.

Perfect for food processing, medical environments, and electronic insulation.

ISO 2230 – Rubber Products Storage and Shelf Life

4.7 Butyl Rubber (IIR)

This one’s great for air and gas sealing, thanks to its excellent impermeability.

Commonly used in tank linings, vacuum seals, and sound insulation panels.

4.8 Viton™ (FKM)

Viton Sheet A premium material for extreme conditions — high temperature, oil, and chemicals.

You’ll find it in aerospace, fuel systems, and chemical processing plants.

Downside: Higher cost, but unmatched performance.

4.9 Fabric-Reinforced Rubber

This type has layers of fabric inside the rubber to improve tensile strength and stability.

It’s perfect for high-pressure gaskets, diaphragms, and conveyor belts.

4.10 Recycled / Reclaimed Rubber

Made from used tires or rubber scraps, this type is eco-friendly and cost-effective.

It’s ideal for floor mats, sports areas, and impact-absorbing pads, but not for high-precision seals.

4.11 Quick Comparison Table – Rubber Sheet Types

Rubber Type | Temperature Range (°C) | Oil Resistance | Weather Resistance | Typical Applications |

Natural Rubber (NR) | -50 ~ +80 | Low | Low | Shock pads, liners, flooring |

SBR (Styrene-Butadiene) | -40 ~ +100 | Low | Medium | Conveyor belts, mats, liners |

EPDM Rubber | -50 ~ +150 | Poor | Excellent | Roofing, seals, outdoor gaskets |

NBR (Nitrile Rubber) | -30 ~ +120 | Excellent | Medium | Oil seals, hoses, gaskets |

Neoprene (CR) | -35 ~ +120 | Good | Good | Marine parts, insulation, covers |

Silicone Rubber | -60 ~ +230 | Good | Excellent | Food-grade, medical, electronics |

Butyl Rubber (IIR) | -40 ~ +130 | Fair | Excellent | Vacuum seals, linings, soundproofing |

Viton™ (FKM) | -20 ~ +250 | Excellent | Excellent | Aerospace, fuel systems, chemicals |

Fabric-Reinforced Rubber | -30 ~ +120 | Depends on base | Good | Conveyor belts, diaphragms, gaskets |

Recycled Rubber | -20 ~ +100 | Medium | Good | Flooring, sports mats, impact pads |

5. Key Physical and Mechanical Properties of Rubber Sheets

When people ask me what makes one rubber sheet better than another, I always say: “Look at the numbers — but understand what they mean.”

You don’t need to be an engineer to make sense of it. Here’s a quick and honest way to read the specs.

5.1 Tensile Strength

Think of this as the muscle of the material. It tells you how much pulling the sheet can take before it snaps.

A good industrial rubber sheet usually sits between 5 and 25 MPa.

Natural Rubber and NBR tend to be on the stronger side — that’s why they’re used for gaskets, anti-vibration pads, and conveyor liners.

Higher number, tougher sheet. Simple as that.

5.2 Elongation at Break

This one’s about stretch. Some rubbers can stretch four or five times their length and still bounce back.

If you need something that flexes under load — like a shock pad or a joint seal — go for a rubber with high elongation, such as NR or EPDM.

5.3 Hardness (Shore A)

Hardness is just how soft or stiff the rubber feels.

- 40-50 Shore A:soft, seals nicely, good for cushioning.

- 60-70 Shore A:the “just right” zone for most uses.

- 80-90 Shore A:firm and wear-resistant for heavy pressure.

Too soft? It’ll squish out. Too hard? It won’t seal properly. Pick the middle ground unless you have a special case.

5.4 Abrasion Resistance

If the rubber rubs against metal, concrete, or moving parts, you want it to last.

Good NR or SBR sheets hardly wear down even after years of contact.

Less dust, less replacement — more savings over time.

5.5 Temperature Range

Each rubber type handles heat and cold differently:

- Natural Rubber: -50 °C to +80 °C

- EPDM: -50 °C to +150 °C

- NBR: -30 °C to +120 °C

- Silicone: -60 °C to +230 °C

If your job site gets hot, or you’re near engines or outdoors, pay attention to this one.

5.6 Compression Set

A fancy term for how well rubber springs back after being squeezed.

Low compression set means the sheet keeps its shape — vital for gaskets that must stay tight year after year.

5.7 The Bottom Line

When you look at a spec sheet, here’s what to remember:

Strength keeps it together. Flexibility keeps it working. Hardness defines the feel. Wear resistance saves money. Recovery keeps it sealing.

Get those five right, and your rubber sheet will do its job quietly for a long, long time.

6. Surface Finishes and Functional Variations

If you’ve ever handled different kinds of rubber sheets, you’ve probably noticed they don’t all look or feel the same. That’s not random — the surface finish changes how the sheet behaves in real life. Le t me walk you through it in plain terms.

First, there’s the smooth surface. It’s clean, shiny, and seals like a dream. You’ll find it used for gaskets, tank liners, or insulation layers where a tight fit matters. Smooth rubber sheets are also easier to clean, which is why they’re common in factories and workshops. If you just need something practical and neat — this is the go-to.

Then we have textured or patterned surfaces — ribbed, diamond, or fabric-like. These are made for grip and traction. Think of anti-slip flooring in gyms, walkways, trucks, or loading zones. A textured industrial rubber sheet keeps people from slipping and helps drain water or oil faster. It’s the worker’s favorite — safe, solid, and durable.

Next up is cloth-inserted rubber. Basically, we sandwich fabric inside the rubber. That fabric layer adds strength and stops the sheet from stretching under pressure. It’s perfect for seals, diaphragms, or high-pressure gaskets that can’t afford to deform.

And sometimes, the surface gets a special coating. Maybe anti-static for electronics, flame-retardant for fire safety, or oil-resistant for workshops and machine areas.

Each surface tells you what the sheet was built for.

Smooth means sealing.

Textured means safety.

Reinforced means stability.

Coated means specialized.

Once you start seeing rubber this way, you realize — it’s not just a sheet. It’s a design choice made for a specific job.

7. How Rubber Sheets Are Manufactured

The rubber sheet manufacturing process is quite similar to how a rubber conveyor belt is made — the only difference is that rubber sheets skip the layer-forming step. Everything else, from mixing to vulcanization, follows nearly the same principles.

Many people imagine we just melt rubber and roll it flat. In reality, it’s a careful process that combines material science with hands-on craftsmanship. Every stage — from formulation to pressing — influences how the final sheet looks, feels, and performs.

It all begins with mixing.

We blend base rubber with various ingredients to achieve the right flexibility, hardness, and durability. Not every sheet is black — we produce colored rubber sheets too, like red, green, white, and even transparent ones. Each color comes from a different formulation, designed to match specific working environments. That’s why appearance can change, but quality always comes from precise mixing.

Next is calendering, where the rubber compound is rolled into a flat, uniform layer. This step defines the thickness and density but not the surface shine. The final appearance is decided later — during vulcanization.

The key step happens inside the vulcanizing press, the real heart of the process.

Here, rubber sheets are placed between heated steel plates under high pressure and temperature. The condition of these heating plates decides the surface finish. If the plates are smooth, clean, and well-maintained, the finished sheet comes out glossy and smooth. But if they’re scratched or not cleaned regularly, the surface looks foggy or dull. That’s why daily maintenance of the vulcanizing plates is a must for consistent quality.

Most surface patterns — such as diamond, fabric, or ribbed textures — are also created right here during vulcanization. The rubber isn’t “printed” later; it’s pressed between patterned molds that form the texture in one step. Once the rubber leaves the vulcanizing press, the pattern is permanent and wear-resistant.

Finally, the sheets are trimmed, cooled, and inspected. We check hardness, thickness, elasticity, and surface quality before packing. Every batch must meet performance standards before it goes out the door.

To put it simply: a rubber sheet isn’t made by accident. It’s shaped by formula, controlled by process, and perfected by experience. That’s what separates a low-cost sheet from a reliable, professional-grade one.

8. How to Select the Right Rubber Sheet

Selecting the right rubber sheet is more than comparing prices or colors — it’s about matching material performance to the job.

Different rubbers behave differently under oil, heat, pressure, or sunlight. The secret is to balance all these factors without overpaying or risking early failure.

1. Match the Working Medium

The first question to ask is: what will the rubber sheet touch every day?

- For oil, fuel, or lubricants, choose Nitrile Rubber Sheet (NBR)or Viton™ Rubber Sheet (FKM). Both resist oil swelling and keep their shape over time.

- For water, steam, or outdoor exposure, EPDM Rubber Sheetis the most reliable choice — excellent resistance to ozone, sunlight, and aging.

- If your environment involves chemicals or acids, Neoprene Rubber Sheet (CR)gives a safe balance between oil resistance and flame retardancy.

- For general mechanical protection or anti-vibration use, SBR Rubber Sheetis a cost-efficient option.

- And when you need the best elasticity and tear strength, nothing beats Natural Rubber Sheet (NR)— it’s more expensive, but in terms of rebound and flexibility, it’s in a league of its own.

2. Consider Temperature and Load

Every rubber sheet has a comfort zone.

EPDM works well up to 150°C; NBR handles oil up to 120°C; and Silicone stands out with its wide range from -60°C to +230°C.

If your system involves constant compression or vibration, use a cloth-reinforced rubber sheet — the fabric inside prevents stretching and makes it last longer under pressure.

3. Don’t Ignore Standards

Always check whether your rubber sheet meets industry requirements.

- Food and medical use:FDA-grade Silicone or EPDM.

- Fire safety:Flame-retardant Neoprene.

- Export projects:ROHS or REACH compliance.

These aren’t just formalities — they protect your product, your shipment, and your brand reputation.

4. Think Long-Term, Not Just Cost

A cheaper rubber sheet might look similar, but after a few months under oil or heat, it may crack or harden.

Paying slightly more for the right compound often means doubling the lifespan and cutting downtime — which is what your customer will remember.

5. If You’re Still Not Sure — Use the “Universal Formula”

Here’s my honest advice after years in production:

When you’re not sure which material to choose, EPDM Rubber Sheet is the safest all-rounder.

It performs well in water, steam, sunlight, mild chemicals, and most outdoor applications. It’s not the cheapest, and it’s not perfect for oil, but it covers nearly 80% of industrial needs without failure.

That’s why many buyers treat it as their “default” material when conditions are mixed or uncertain.

In short:

- Oil and fuel → NBR or FKM

- Weather and water → EPDM

- General use → SBR

- Premium elasticity → NR

- All-purpose fallback → EPDM

Choosing the right rubber sheet isn’t just a technical step — it’s the difference between stable production and unexpected shutdowns.

9. Applications Across Industries

The truth is — a rubber sheet is only as good as where it’s used.

Different industries face different challenges: oil, heat, vibration, weather, or hygiene. That’s why at Tiantie, we never recommend “one-size-fits-all.” Each sector demands a tailored approach, and some materials have clearly proven to outperform others.

9.1 Industrial & Manufacturing

In industrial plants, rubber sheets are everywhere — under machines, between flanges, around tanks. The main job here is to seal, cushion, and protect.

We’ve seen many factories still using cheap SBR sheets for everything, but that’s a costly mistake. SBR cracks quickly under oil and heat.

For workshops, chemical plants, and mechanical bases, the smarter option is Nitrile Rubber Sheet (NBR) or Neoprene Rubber Sheet (CR).

They can handle oil, grease, and vibration without losing shape. If heavy equipment is involved, go with cloth-reinforced rubber sheets — they stay dimensionally stable even under pressure.

Our recommendation: For most industrial environments, NBR Rubber Sheet is the most reliable choice — durable, oil-resistant, and easy to maintain.

9.2 Automotive & Aerospace

This is where material quality truly matters. A single rubber sheet failure in a car or aircraft can mean downtime, leakage, or worse.

Automotive manufacturers prefer NBR Rubber Sheets for gaskets and fuel seals, while EPDM Rubber Sheets are widely used for door seals, weather stripping, and vibration isolation.

For fuel systems or high-heat zones, Viton™ Rubber Sheet (FKM) is the premium choice — it resists both high temperature and aggressive chemicals.

Aerospace applications, on the other hand, often combine FKM and Silicone Rubber Sheets, especially in areas where weight reduction, heat resistance, and non-toxicity are critical.

Our recommendation: For automotive use — NBR for fuel and oil, EPDM for weather, FKM for high heat. Don’t mix materials; match them to the system.

9.3 Construction & Infrastructure

In construction, rubber sheets are like the silent foundation of safety. They stop leaks, absorb vibration, and create durable seals in concrete joints, roofs, and expansion gaps.

The clear winner here is EPDM Rubber Sheet — weatherproof, UV-resistant, and flexible even in freezing conditions. It’s the same material used in roof membranes and bridge joints across the world.

For cost-sensitive flooring or temporary cushioning, Recycled Rubber Sheets also perform well — especially in basements, walkways, and parking areas.

Our recommendation: Use EPDM Rubber Sheet for waterproofing and outdoor sealing; use Recycled Rubber Sheet only when budget outweighs longevity.

9.4 Marine & Offshore

Salt, sunlight, and pressure — the marine environment destroys weak rubber in months.

Here, Neoprene Rubber Sheet (CR) leads the pack. It resists seawater, oil, and weather, making it perfect for docks, boat decks, and ship seals.

For long-term resistance against both salt and UV, EPDM can also work, but Neoprene stays stronger in marine oil contact.

Our recommendation: Neoprene Rubber Sheet for marine environments — proven durability, stable in saltwater, and strong adhesion with metal.

9.5 Food & Medical Processing

Cleanliness and safety define this industry. Any rubber sheet used here must meet FDA or EU food-grade standards.

The top performer, hands down, is Silicone Rubber Sheet — non-toxic, odorless, and resistant to extreme temperatures. It can be sterilized, doesn’t leach chemicals, and stays flexible even after hundreds of cleaning cycles.

For steam or hot-water lines in food factories, EPDM Rubber Sheets also work well, especially the FDA-approved type.

Our recommendation: Use Silicone Rubber Sheet for direct food contact and EPDM Rubber Sheet for hot-water sealing and cleaning zones.

9.6 Sports & Fitness

In gyms, stadiums, or training areas, rubber sheets are used as flooring and shock pads.

The key here is impact absorption and slip resistance. SBR Rubber Sheets and Recycled Rubber Sheets dominate this field because they’re strong, affordable, and easy to replace.

EPDM is also popular for outdoor tracks and playgrounds due to its weather resistance and color flexibility.

Our recommendation: SBR Rubber Sheet for indoor flooring; EPDM Rubber Sheet for outdoor tracks and playgrounds.

Final Advice

Each industry has its best match, but if you want a single material that performs well in most environments, EPDM Rubber Sheet is the safest all-round choice.

It’s not the cheapest, and it’s not oil-proof, but for weather, temperature, and aging resistance — it simply wins.

10. Environmental & Sustainability Aspects

At Tiantie, we believe that real sustainability begins with quality.

A rubber sheet that performs well, resists wear, and lasts longer is far more environmentally responsible than one that needs frequent replacement.

Durability itself is the most practical form of sustainability.

10.1 Recycled and Reclaimed Rubber Sheets — The Reality

Many suppliers now promote recycled or reclaimed rubber sheets under the “green” label.

Yes, reusing materials does reduce waste and raw material consumption, but it also weakens the product’s mechanical strength.

When old rubber is ground or chemically processed for reuse, the internal structure becomes less stable.

This leads to higher abrasion loss, lower tensile strength, and significantly shorter service life.

These materials may work fine for simple flooring or temporary cushioning, but they are not suitable for heavy-duty sealing, industrial linings, or long-term mechanical use.

In our experience, when a recycled or reclaimed rubber sheet is used in demanding conditions, it tends to harden, crack, and wear out much faster.

So while it might seem cheaper at first, it actually increases maintenance frequency and overall waste in the long run.

That’s why at Tiantie, we focus on producing new, high-quality rubber sheets from carefully formulated compounds — because true sustainability means building something that doesn’t fail early.

10.2 Tiantie’s Commitment to Sustainable Quality

For us, sustainability has never been about using cheaper materials or chasing trends.

It’s about producing rubber sheets that perform longer, wear less, and protect equipment better.

We continue to use premium natural rubber as our main base material because it offers the best balance of elasticity, tensile strength, and abrasion resistance.

Our high-quality rubber sheets are engineered to deliver low wear rate, high mechanical stability, and long service life — traits that naturally reduce waste and resource use.

At Tiantie, we don’t cut corners for the sake of “green labels.”

We build sustainability through endurance.

A durable rubber sheet is not only better for your machinery — it’s better for the planet.

11. Rubber Sheets vs Other Materials

Every engineer has faced the same question: Why use a rubber sheet instead of plastic, polyurethane, or metal?

From years of experience in production and field feedback, we can say with confidence — rubber sheets simply achieve a better balance between flexibility, durability, and cost.

Plastic may look clean and light, but it cracks under impact and offers poor sealing when surfaces move or vibrate. Once deformed, it can’t recover.

Metal is strong, but it’s rigid, heavy, and expensive to process. It transmits vibration rather than absorbing it, which often leads to faster wear in connected parts.

Polyurethane (PU) is durable, yes, but it’s also costly, sensitive to temperature, and harder to cut or bond during installation.

A rubber sheet, on the other hand, adapts naturally to surfaces. It compresses under load and recovers when released — providing a tight seal, vibration damping, and consistent performance even under stress.

That’s why rubber remains the preferred choice for sealing, flooring, and protection across industries.

In simple terms:

If you want strength and flexibility, rubber beats plastic.

If you want resilience and economy, rubber outperforms PU.

And if you want protection with less weight and maintenance, rubber easily replaces metal.

At Tiantie, we don’t see rubber sheets as a low-cost substitute — we see them as the smarter material solution: adaptable, reliable, and proven in real industrial conditions.

12. Installation and Maintenance

A rubber sheet may look simple, but how it’s handled and maintained makes a big difference in how long it lasts.

Whether it’s used under a heavy machine or on a gym floor, proper handling ensures it performs as it should — safely, quietly, and reliably.

12.1 Cutting and Handling

The cutting method depends mainly on thickness, not size.

For thin rubber sheets (below 10 mm), a sharp utility knife or mechanical blade works perfectly.

For thicker sheets (10 mm and above), waterjet cutting or industrial cutters are recommended to ensure clean edges and prevent heat buildup that can harden the rubber surface.

When moving or placing large rubber sheets, avoid dragging them across rough concrete or sharp surfaces — it’s one of the most common causes of surface damage during installation.

12.2 Installation and Use

Installing a rubber sheet doesn’t require adhesives or complex preparation.

Most sheets are laid directly on flat or slightly textured surfaces.

In factories, they’re often fixed by pressure or edge framing; in daily use, they simply rely on weight and friction.

For industrial use, correct placement and even compression help maintain performance.

For lifestyle applications — such as gym floors, garage mats, playgrounds, or anti-slip areas — precision installation is less critical.

In these cases, the rubber sheet is usually replaced only after noticeable wear, cuts, or permanent dents appear.

12.3 Maintenance and Lifespan

Maintenance is straightforward.

Keep the rubber sheet clean by removing oil, sand, or metal debris that can cause localized wear.

Washing with mild detergent and water is enough; harsh chemicals aren’t needed.

In industrial applications, inspection every few months helps catch early signs of hardening or cracking.

High-quality rubber sheets can last three to five years in continuous operation — longer if used under moderate conditions.

In lifestyle or gym environments, lifespan varies more by usage intensity than by time.

If the sheet still feels elastic and the surface hasn’t worn thin, it can stay in use safely.

Once excessive wear or surface tearing appears, replacement is simple — and that’s usually all that’s needed.

At Tiantie, we always emphasize practicality:

A rubber sheet doesn’t need complicated care — just the right handling, the right environment, and periodic attention.

Do that, and it will quietly do its job for years, whether under a machine or beneath your feet.

13. FAQs

1. How long does a rubber sheet last?

That depends entirely on the environment.

In general industrial use, a high-quality rubber sheet lasts around 3–5 years.

However, in harsh conditions — such as constant oil exposure, heat, or strong mechanical stress — even the best materials may last only 1–3 years.

This isn’t a sign of poor quality; it’s the natural result of accelerated thermal and chemical aging.

Regular inspection and proper material selection are the keys to getting the most out of each sheet.

2. Why do outdoor applications require heat-resistant rubber?

Many people assume outdoor rubber only needs to resist sunlight or water,

but the real issue is surface heat buildup and oxygen aging.

Black rubber absorbs sunlight, and its surface temperature can easily rise above 70°C under direct sun — sometimes more on metal or concrete bases.

At that temperature, ordinary rubber hardens and cracks quickly.

That’s why EPDM rubber sheet is the most reliable choice for outdoor use.

It resists both UV light and high surface heat, preventing premature aging and keeping flexibility even after years of exposure.

So “heat resistance” in this case isn’t about fire — it’s about survival under sunlight and daily temperature swings.

3. Which rubber sheet is best for oil resistance?

For oil, fuel, or lubricant exposure, choose Nitrile Rubber Sheet (NBR).

For combined heat and chemical environments, use Viton™ (FKM).

Avoid SBR or Natural Rubber in oily areas — they’ll swell, soften, and lose strength fast.

4. Can rubber sheets be food-safe?

Yes — but only certified types.

Silicone Rubber Sheet and food-grade EPDM Rubber Sheet are FDA-approved and safe for direct or indirect food contact.

Standard industrial rubbers should never be used near food or potable water.

5. How do I choose the right hardness?

For sealing or cushioning, 60–70 Shore A is ideal.

For flooring or impact pads, 45–55 Shore A gives better shock absorption.

Harder grades (80+ Shore A) are suitable for load-bearing or structural uses.

The right hardness allows the rubber sheet to compress and recover correctly — that’s the difference between sealing and leaking.

6. Are recycled rubber sheets durable enough?

They work for low-demand flooring or gym mats, but not for high-stress industrial use.

Because recycled materials lose part of their elasticity and tear resistance, they wear out much faster.

If long-term performance matters, always choose new, high-quality rubber sheets — they cost slightly more but save far more over time.

14. Conclusion

In every industry, from manufacturing to construction to everyday flooring, the rubber sheet remains a quiet but essential material.

It seals, cushions, insulates, and protects — often without being noticed, yet always doing the heavy work.

After decades of development, the market is full of choices. But the truth is simple: not all rubber sheets are created equal.

The real difference lies in compound quality, production control, and performance consistency.

That’s where Tiantie continues to focus — producing high-durability rubber sheets built from premium natural rubber and refined formulas that deliver low wear, high elasticity, and stable service life.

In harsh industrial environments, durability is the most honest form of sustainability.

A sheet that lasts longer reduces waste, maintenance, and downtime — saving both cost and resources.

That’s why we never chase short-term trends or low-grade materials. Our commitment is to build products that last — stronger, safer, and more reliable.

If you need a rubber sheet that performs beyond the basics — whether for industrial sealing, flooring, or customized applications —

our team is ready to provide technical data, material samples, and tailored solutions based on real production experience.

Quality isn’t a promise — it’s what we produce every day.