- Tiantie Industrial

- Continental AG

- Bridgestone Corporation

- Fenner Dunlop

- Sempertrans

- Goodyear Rubber Products, Inc.

- Habasit AG

- Mitsuboshi Belting Ltd.

- Bando Chemical Industries, Ltd.

- Ammeraal Beltech

- Trelleborg

- Intralox

- Metso

- Gates Corporation

- Forbo Siegling

1.Why Choosing Top Conveyor Belt Manufacturers Is Crucial for Your Business

As a practitioner with many years of experience in the conveyor belt industry, I know the importance of conveyor belt Manufacturers in modern industry. The conveyor belt is not only a key equipment connecting major industries, but also the cornerstone of improving production efficiency. From mining to food processing to automobile manufacturing, industrial conveyor belt manufacturers provide solutions everywhere, supporting the high-speed operation of various industries.

Globally, the conveyor belt market is huge and over the next few years I think the conveyor belt industry will continue to grow. This growth is mainly due to the rapid development of science and technology, the continuous advancement of automation technology, the acceleration of infrastructure construction, and the growing demand for efficient transmission systems in various industries.

Especially in the Asia-Pacific region, with the rapid development of manufacturing and mining industries, the demand for mining conveyor belt Manufacturer has increased significantly. At the same time, the North American and European markets are also expanding steadily, pushing rubber conveyor belt manufacturers to continue to move forward on the road of innovation and development.

Among the many conveyor belt Manufacturers, many industry leaders have ensured steady improvement in quality and maintained strong market competitiveness by continuously introducing new production equipment or completely new data-based factory transformations.

These manufacturers not only focus on product durability and reliability, but also actively promote environmentally friendly and sustainable production methods to meet increasingly stringent environmental standards and customer needs. As a practitioner for many years, I have also witnessed how many companies have won the trust and support of customers around the world through excellent products and services.

In the following article, I will conduct an in-depth analysis of the top 15 conveyor belt Manufacturers in the world and explore their influence in the market and their unique competitive advantages. Whether you are new to the industry or a veteran, this article will provide you with valuable insights to help you make an informed decision when choosing the right conveyor belt Manufacturers.

2.Conveyor Belt Manufacturers and Key Applications

The wide application and importance of conveyor belt Manufacturers in various industries is self-evident. Conveyor belt Manufacturers are not just companies that produce conveyor belts, they are also the core force in promoting industrial automation and efficiency improvement. However, different Manufacturers target completely different markets and fields, and their main products are also different. Let’s discuss them together next.

2.1Global Conveyor Belt Manufacturers Market Size and Growth

According to the latest report from Market Research Future (MRFR), the global market size of conveyor belt manufacturers has reached approximately US$30 billion in 2022 and is expected to grow to US$40 billion by 2027, with a compound annual growth rate (CAGR) of approximately 6% . This significant growth is mainly due to the rapid development of automation technology, the acceleration of infrastructure construction, and the increasing demand for efficient logistics systems in various industries.

Especially in the Asia-Pacific region, with the rapid expansion of manufacturing and mining industries, the demand for mining conveyor belt Manufacturer has risen significantly. In addition, the North American and European markets are also developing steadily, promoting the continuous progress of rubber conveyor belt manufacturers in technological innovation and product diversification.

2.2Main Driving Area

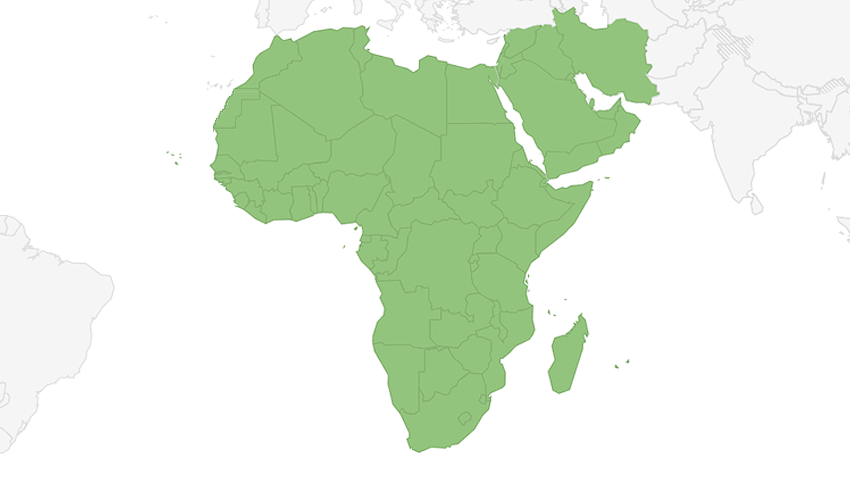

The demand of conveyor belt Manufacturers shows obvious regional characteristics on a global scale. The Asia-Pacific region has become an important market for industrial conveyor belt manufacturers due to its large manufacturing base and rapidly growing mining industry. North America and Europe, with their advanced technology and strict quality standards, have driven the demand for high-performance conveyor belts. In the Middle East and Africa, the advancement of infrastructure construction and industrialization has also brought new growth opportunities to conveyor belt Manufacturers.

2.3Market dynamics of conveyor belt Manufacturers

The growth of the conveyor belt Manufacturers market is driven by various factors. Among them, the advancement of automation technology has made the conveyor belt system more intelligent and efficient, meeting the needs of modern industry for fast response and high-precision operation. The concept of sustainable development is also driving conveyor belt Manufacturers to adopt environmentally friendly materials and energy-saving production processes to reduce the impact on the environment.

In addition, industrial expansion and globalization require conveyor belt Manufacturers to continuously improve their production capabilities and technical levels to cope with increasingly fierce market competition.

2.4Key application areas

Conveyor belt Manufacturers’ products are used across a number of key sectors, each with its own unique needs and challenges.

2.4.1 Mining: The perfect combination of strength and durability

In the mining industry, the conveyor belts provided by mining conveyor belt Manufacturers must have extremely high wear resistance and strength. These heavy-duty conveyor belts transport ore and other minerals efficiently, ensuring reliability in harsh environments.

2.4.2 Logistics and warehousing: Improving automation and efficiency

Industrial conveyor belt manufacturers design conveyor systems in the logistics and warehousing industry to significantly improve the efficiency of sorting and transporting goods. With the rapid development of e-commerce, the demand for automation in warehouse management continues to increase. An efficient conveyor system speeds up cargo handling and improves overall operational efficiency.

2.4.3 Food processing: the guardian of hygiene and safety

The food processing industry places extremely high hygiene and safety standards on conveyor belts. The conveyor belts produced by rubber conveyor belt manufacturers must comply with strict hygiene regulations to ensure the safety and hygiene of food during the production process. These conveyor belts are typically made from non-toxic, easy-to-clean materials with anti-slip and anti-bacterial properties to meet high food safety standards.

2.4.4 Other industries: perfect response to diverse needs

In addition to the above fields, conveyor belt Manufacturers’ products are also widely used in chemical, construction and packaging industries. Each industry has its specific needs. For example, the chemical industry requires corrosion-resistant conveyor belts, the construction industry requires conveyor belts that can adapt to complex construction environments, and the packaging industry requires high-speed and precise conveyor belts. By providing customized solutions, conveyor belt Manufacturers meet the diverse needs of different industries and help them achieve excellence.

3.Selection Criteria For The Top 15 Conveyor Belt Manufacturers In The World

In order to ensure that the top 15 conveyor belt manufacturers in the world we list are truly competitive in their respective fields, we have developed a comprehensive and rigorous selection criteria. These criteria cover multiple key aspects to ensure that the selected companies have excellent performance in technology, quality, market coverage, etc. The following are our main selection criteria:

3.1 Innovation

Innovation is the core indicator for measuring the competitiveness of conveyor belt manufacturers. We evaluate the R&D investment and results of each manufacturer in new technologies and advanced materials (such as high-temperature conveyor belts, oil-resistant conveyor belts, etc.). Continuous R&D investment and technological breakthroughs not only improve product performance, but also promote the overall progress of the industry. Manufacturers who can continuously launch innovative products with high performance and durability are usually able to maintain a leading position in the market.

3.2 Quality Control

Quality is a key factor in selecting conveyor belt manufacturers. We examine whether the manufacturer maintains consistent manufacturing standards during the production process and whether it has obtained international quality certifications (such as ISO certification, etc.). High-quality conveyor belts not only extend the service life, but also reduce maintenance costs and improve customer satisfaction. Manufacturers with strict quality control can ensure that their products perform stably in various application environments and meet the high standards of customers.

3.3 Global Reach

Global reach reflects the market influence and distribution capabilities of conveyor belt manufacturers. We evaluate manufacturers’ production bases and distribution networks in multiple regions to ensure that they can provide timely services and support to global customers. Manufacturers with a wide global footprint usually have stronger market adaptability and resource integration capabilities, and can quickly respond to market needs and changes in different regions.

3.4 Customer Feedback

Customer feedback is an important basis for measuring the reputation of conveyor belt manufacturers. We collect and analyze reviews from customers in various industries, including customer satisfaction, product performance feedback, and after-sales service experience. Good customer reputation and high satisfaction scores indicate that manufacturers perform well in meeting customer needs. Positive customer feedback not only enhances the company’s market reputation, but also provides a solid foundation for its continued development.

3.5 Sustainability

Sustainability has become an important trend in modern manufacturing. We examine conveyor belt manufacturers’ practices in environmentally friendly production methods, material recycling, and sustainable development commitments. Manufacturers that actively promote environmental protection and sustainable development not only comply with global environmental regulations, but also meet customer demand for green products. Sustainable companies are more competitive in the market and are more likely to gain long-term trust from customers.

3.6 Manufacturing Capacity

Production capacity determines whether conveyor belt manufacturers can meet large-scale orders and urgent needs. We evaluate manufacturers’ production scale, equipment advancement, and ability to handle large contracts. Manufacturers with high production capacity are better able to cope with market fluctuations and customer needs, ensure supply chain stability and timely product delivery, and improve customer satisfaction and trust.

3.7 Product Diversification

Product diversification is the key to measuring the flexibility and adaptability of conveyor belt manufacturers. We examine the types of products provided by manufacturers, including PVC conveyor belts, rubber conveyor belts, wire rope conveyor belts, modular conveyor belts, etc. Diversified product lines can meet the specific needs of different industries and application scenarios, and enhance customer flexibility. Manufacturers with diversified products can better adapt to market changes and meet the changing needs of customers.

Through the above strict selection criteria, we ensure that the top 15 conveyor belt manufacturers in the world are not only excellent in technology and quality, but also have significant advantages in global market coverage, customer satisfaction and sustainable development. These manufacturers have set benchmarks in their respective fields and provided reliable and efficient conveying solutions for global customers.

However, it should be pointed out that the above selection is based on my personal opinions and selection criteria and is for reference only. Before making a final decision, it is recommended that you have a deep understanding of the specific advantages and market performance of each

4.Top 15 Conveyor Belt Manufacturers In The World Revealed

Company Name | Website |

| Tiantie Industrial | https://conveyorbeltchn.com |

| Continental AG | https://www.continental.com/en/ |

| Bridgestone Corporation | https://www.bridgestone.com/ |

| Fenner Dunlop | https://fennerdunlopamericas.com/ |

| Sempertrans | https://conveyor-belts.semperitgroup.com/ |

| Goodyear Rubber Products, Inc. | https://goodyearrubberproducts.us/ |

| Habasit AG | https://www.habasit.com/ |

| Mitsuboshi Belting Ltd. | https://www.mitsuboshi.com/english/ |

| Bando Chemical Industries, Ltd. | https://www.bandogrp.com/eng/ |

| Ammeraal Beltech | https://www.ammeraalbeltech.com/ |

| Trelleborg | https://www.trelleborg.com/en |

| Intralox | https://www.intralox.com |

| Metso | https://www.metso.com/ |

| Gates Corporation | https://www.gates.com/ |

| Forbo Siegling | https://www.forbo.com/movement/en-gl/ |

When choosing the right conveyor belt manufacturers, it is essential to understand the top companies in the market and their advantages. Globally, many industrial conveyor belt manufacturers have established their industry leadership through technological innovation, excellent product quality and extensive service network. Here is a detailed introduction to the top 15 conveyor belt manufacturers in the world to help you make an informed decision among the many choices.

1. Tiantie Industrial

Company Business Profile:With more than 15 years of professional experience, Tiantie Industrial has become a leading supplier of high-quality conveyor belt manufacturers. They focus on producing a variety of conveyor belts, covering PVC and rubber conveyor belts to meet the needs of different industries. The company is committed to providing customers with customized solutions to adapt to various complex application environments and ensure efficient and reliable conveying performance.

Innovation:Tiantie Industrial continues to invest in the research and development of new technologies and advanced materials, launching heat-resistant and oil-resistant conveyor belts to improve product performance. They use the latest manufacturing processes to ensure that their products still perform well under extreme conditions.

Quality Control:The company strictly follows international quality standards and has obtained multiple ISO certifications to ensure the high quality and reliability of each conveyor belt. By implementing a comprehensive quality management system, Tiantie Industrial ensures that products are strictly inspected and tested before leaving the factory.

Global Reach:Tiantie Industrial’s products are sold to Southeast Asia, the Middle East, Africa and South America, with a wide international market coverage. They have established a strong distribution network to ensure that global customers can get the required products and services in a timely manner.

Customer Feedback:Customers generally feedback that its products are durable and timely after-sales service, which has won a good market reputation. Tiantie Industrial has gained a high degree of trust and satisfaction from customers with its efficient customer support and technical services.

Sustainability:The company is committed to environmentally friendly production, using recyclable materials and implementing energy-saving production processes to promote sustainable development. Tiantie Industrial actively participates in environmental protection projects to reduce carbon footprint and waste emissions during production.

Manufacturing Capacity:With advanced production equipment and efficient production lines, Tiantie Industrial is able to meet large-scale orders and urgent needs. They ensure that products are delivered on time and of stable quality by optimizing production processes.

Product Diversification:Tiantie Industrial offers a variety of conveyor belt types, including PVC, rubber and modular conveyor belts, to meet the specific needs of different industrial applications. Tiantie Industrial’s product line is flexible and diverse, adapting to a variety of complex conveying environments and operating conditions.

2. Continental AG

Company Business Profile:As an industry leader, Continental AG is known for its advanced technology and extensive product line, serving heavy industries such as mining and logistics. They provide high-performance conveyor belt solutions, covering a variety of types such as high temperature resistance, oil resistance and fire resistance, to meet the needs of different industrial applications.

Innovation:The company continues to invest in R&D to develop high-durability and high-performance conveyor belts to maintain technological leadership. Continental AG continuously improves the performance and reliability of its products through innovative materials and intelligent manufacturing technology.

Quality Control:Continental AG strictly controls the production process to ensure that all products meet international quality standards and pass multiple quality certifications. They use advanced quality testing equipment to ensure that each conveyor belt undergoes rigorous performance testing before leaving the factory.

Global Reach:With production bases and distribution networks all over the world, Continental AG is able to provide timely service and support to customers around the world. They have multiple branches in major markets such as North America, Europe, and Asia to ensure efficient operation of the global supply chain.

Customer Feedback:Customers have rated their products as having excellent performance, stable operation in high-demand environments, and high satisfaction. Continental AG has won the trust and loyalty of customers around the world with its reliable products and high-quality customer service.

Sustainability:The company pays attention to environmental protection, adopts sustainable materials and environmentally friendly production processes, and is committed to reducing environmental impact. Continental AG actively promotes green manufacturing and develops environmentally friendly conveyor belts to meet global environmental regulations and customer demand for green products.

Manufacturing Capacity:With large-scale production capabilities, it can handle large contracts and emergency orders to ensure a stable supply chain. Continental AG ensures that it can respond quickly to market needs by optimizing production processes and improving production efficiency.

Product Diversification:Provides diversified products including high-temperature resistant, oil-resistant and fire-resistant conveyor belts to meet the needs of different application scenarios. Continental AG has a wide range of product lines, covering various conveying needs from light industry to heavy industry.

3. Bridgestone Corporation

Company Business Profile:Bridgestone Corporation is a giant in the rubber industry, providing a variety of conveyor belts for various industrial applications. Their products are widely used in mining, logistics and manufacturing industries, and are known for their high durability and excellent performance, ensuring stable operation under extreme conditions.

Innovation:The company continues to launch conveyor belts with high durability and excellent performance, using the latest materials and advanced technologies to improve product quality. Bridgestone has developed high-performance conveyor belts that can adapt to various complex environments through technological innovation.

Quality Control:Bridgestone ensures that every conveyor belt meets the high standards of customers through a strict quality control process. They implement a comprehensive quality management system to ensure that products meet the highest quality standards during the production and testing stages.

Global Reach:The products are sold to many countries and regions around the world, with a strong international distribution network covering a wide range of markets. Bridgestone has multiple production bases and sales offices around the world to ensure that products can be quickly delivered to customers everywhere.

Customer Feedback:Customers highly evaluate the stability and durability of its products under extreme conditions and have high satisfaction. Bridgestone has won the high trust of global customers with its high-performance conveyor belts and excellent customer service.

Sustainability:The company actively promotes environmentally friendly production, uses renewable materials and implements energy-saving processes, and is committed to sustainable development. Bridgestone reduces carbon emissions and resource consumption in the production process through green manufacturing and environmental protection projects.

Manufacturing Capacity:With advanced production facilities and efficient production processes, Bridgestone is able to meet the needs of large-scale and customized orders. The company ensures efficient production capacity by optimizing production lines and improving automation levels.

Product Diversification:Provides a variety of conveyor belts, including rubber conveyor belts, wire rope conveyor belts and modular conveyor belts to meet different industrial needs. Bridgestone’s product line is flexible and diverse, and can adapt to various complex conveying environments and operating conditions.

4. Fenner Dunlop

Company Business Profile:Fenner Dunlop focuses on providing high-performance conveyor belts for mining and heavy-duty applications, and is known for its excellent technical capabilities and comprehensive after-sales service. The company is committed to developing conveyor belt solutions that adapt to harsh environments to ensure efficient and safe material transportation.

Innovation:The company continues to innovate in high-performance materials and advanced designs to develop conveyor belt products that adapt to harsh environments. Through technological research and development, Fenner Dunlop continues to improve the durability and performance of conveyor belts to meet the special needs of mining and heavy industries.

Quality Control:Fenner Dunlop strictly follows international quality standards to ensure the reliability and durability of its products in various harsh environments. They implement a comprehensive quality management system to ensure that every conveyor belt undergoes strict quality inspections before leaving the factory.

Global Reach:The products are widely used in mining and heavy industries around the world and have a strong international market influence. Fenner Dunlop has established a global distribution network to ensure that its products can be quickly delivered to customers everywhere.

Customer Feedback:Customers have reported that its conveyor belts perform well under high-load conditions, improving production efficiency and safety. Fenner Dunlop has won high satisfaction and trust from customers around the world with its high-performance conveyor belts and excellent customer service.

Sustainability:The company is committed to environmental protection, using recyclable materials and optimizing production processes to reduce environmental impact. Fenner Dunlop actively promotes green manufacturing and develops environmentally friendly conveyor belts to meet global environmental regulations and customer demand for green products.

Manufacturing Capacity:With large-scale production capabilities and flexible production lines, it can meet the needs of large projects and emergency orders. Fenner Dunlop ensures that it can respond quickly to market demand by optimizing production processes and improving production efficiency.

Product Diversification:Provide a variety of high-performance conveyor belts, including wear-resistant, high-temperature resistant and anti-static conveyor belts, to meet different industrial needs.

5. Sempertrans

Company Business Profile:As part of the Semperit Group, Sempertrans specializes in conveyor belts for mining and industrial applications. They are well-known in the global market for reliability and innovation, and continue to launch high-quality conveyor belts that meet different needs to ensure efficient and safe material transportation.

Innovation:Sempertrans continues to develop high-quality conveyor belts that meet different needs, using advanced materials and technologies to improve product performance. Through technological innovation, the company launches new products with high durability and high performance to meet the special needs of the mining and industrial fields.

Quality Control:The company strictly controls the production process to ensure that all products meet international quality standards and provide highly reliable conveying solutions. Sempertrans implements a comprehensive quality management system to ensure that products meet the highest quality requirements at all stages of production.

Global Reach:Products are distributed in multiple markets around the world, with an extensive distribution network and production bases, which can provide timely support to global customers. Sempertrans ensures that its conveyor belts can be quickly delivered to customers around the world through a global layout.

Customer Feedback:Customers are generally satisfied with the high reliability and quality service of its products, and Sempertrans has established a good market reputation. With its excellent product performance and high-quality customer service, Sempertrans has won the high trust and loyalty of customers around the world.

Sustainability:The company pays attention to environmental protection, adopts sustainable production methods and material recycling, and promotes green manufacturing. Sempertrans is committed to reducing carbon footprint and resource consumption in the production process, actively participates in environmental protection projects, and fulfills social responsibilities.

Manufacturing Capacity:With strong production capacity and advanced production equipment, it can handle large-scale and complex order requirements. Sempertrans ensures efficient production capacity and timely product delivery by optimizing production processes and improving automation levels.

Product Diversification:Provides a variety of conveyor belt products, including wear-resistant, high-temperature resistant and modular conveyor belts to meet the needs of different industrial applications. Sempertrans’s product line is flexible and diverse, and can adapt to various complex conveying environments and operating conditions.

6. Goodyear Rubber Products, Inc.

Company Business Profile:“Goodyear Rubber Products, Inc.”Provides diversified conveyor belts for industries such as automotive, agriculture and material handling. With high quality and durability, they have become a trusted partner for global customers and are committed to providing efficient and reliable conveying solutions for different industries.

Innovation:The company continues to invest in new materials and innovative designs to develop high-performance conveyor belts that meet different industrial needs. “Goodyear Rubber Products, Inc.” Through technological innovation, it continuously improves the durability and performance of its products to meet the diverse needs of the market.

Quality Control:“Goodyear Rubber Products, Inc.” strictly follows quality control standards to ensure the high quality and consistency of each conveyor belt. The company implements a comprehensive quality management system to ensure that the products meet the highest quality standards during the production and testing stages.

Global Reach:With a large production capacity and global distribution network, its products cover multiple international markets and can respond quickly to customer needs. “Goodyear Rubber Products, Inc.” has multiple production bases and sales offices around the world to ensure that its products can be quickly delivered to customers everywhere.

Customer Feedback:Customers highly value the durability and high performance of its products, and have high satisfaction and loyalty. “Goodyear Rubber Products, Inc.” has won high trust and satisfaction from customers with its efficient customer support and technical services.

Sustainability:The company is committed to environmental protection, using renewable materials and energy-saving production processes to promote sustainable production methods. “Goodyear Rubber Products, Inc.” actively participates in environmental protection projects to reduce carbon footprint and resource consumption in the production process.

Manufacturing Capacity:With advanced production equipment and efficient production processes, “Goodyear Rubber Products, Inc.” is able to meet the needs of large-scale and customized orders. The company ensures efficient production capacity and timely product delivery by optimizing production lines and improving automation levels.

Product Diversification:Provides a variety of conveyor belts, including rubber conveyor belts, PVC conveyor belts and modular conveyor belts to meet the needs of different industrial applications. “Goodyear Rubber Products, Inc.”‘s product line is flexible and diverse, adapting to various complex conveying environments and operating conditions.

7. Habasit AG

Company Business Profile:Habasit AG is a global leader in modular conveyor belts, power transmission belts and conveying solutions, especially in the food processing and packaging industries. They are committed to providing customers with highly customized and precise conveyor belt solutions to improve production efficiency and operational reliability in various industries.

Innovation:The company continues to innovate in technology, develops highly customized and precise conveying solutions, and improves product performance and adaptability. Habasit AG continuously optimizes product design to meet the specific needs of customers by introducing advanced materials and intelligent manufacturing technologies.

Quality Control:Habasit AG strictly controls the production process to ensure that all products meet international quality standards and provide highly reliable conveyor belt products. The company implements a comprehensive quality management system to ensure that every conveyor belt undergoes strict quality inspections before leaving the factory.

Global Reach:The products are sold to many countries and regions around the world, with an extensive international distribution network, which can provide timely service and support to global customers. Habasit AG ensures that its conveyor belts can be quickly delivered to customers everywhere through its global layout.

Customer Feedback:Customers generally report that its conveyor belts have high performance and reliability in the food processing and packaging industries, and have high satisfaction. Habasit AG has won the high trust and loyalty of customers with its excellent product quality and excellent customer service.

Sustainability:The company pays attention to environmental protection, adopts sustainable materials and energy-saving production processes, and is committed to reducing environmental impact. Habasit AG actively promotes sustainable development and fulfills social responsibility through green manufacturing and environmental protection projects.

Manufacturing Capacity:With efficient production capacity and advanced production equipment, Habasit AG can meet the needs of large-scale and customized orders. Habasit AG ensures efficient production capacity and timely product delivery by optimizing production processes and improving automation levels.

Sustainability:Provides diversified conveyor belt products, including modular conveyor belts, power transmission belts and special conveyor belts to meet the specific needs of different industries. Habasit AG’s product line is flexible and diverse, adapting to various complex conveying environments and operating conditions.

8. Mitsuboshi Belting Ltd.

Company Business Profile:“Mitsuboshi Belting Ltd.” is well-known for its high-quality conveyor belt products in multiple industries, especially in the automotive and logistics fields. They have a strong manufacturing base in Asia and are gradually expanding their market share in other regions, committed to providing efficient and reliable conveying solutions to customers around the world.

Innovation:“Mitsuboshi Belting Ltd.” continues to invest in new materials and advanced manufacturing technologies to develop high-performance and durable conveyor belts to meet the needs of different industries. Through technological research and development, the company continuously improves the durability and performance of its products to maintain its technological leadership.

Quality Control:The company strictly implements international quality standards, and all products pass strict quality inspections to ensure high consistency and reliability. “Mitsuboshi Belting Ltd.” ensures that its products meet the highest quality requirements in both production and testing stages through a comprehensive quality management system.

Global Reach:“Mitsuboshi Belting Ltd.”‘s products are sold to many countries and regions around the world, and it has a strong international distribution network that can quickly respond to customer needs. The company’s global layout ensures that its conveyor belts can be quickly delivered to customers everywhere.

Customer Feedback:Customers highly appreciate the high quality and excellent performance of its conveyor belts, especially in the automotive and logistics industries, where customer satisfaction is extremely high. “Mitsuboshi Belting Ltd.” has won a high degree of trust and satisfaction from customers with its efficient customer support and technical services.

Customer Feedback:The company is committed to environmental protection, using renewable materials and energy-saving production processes to actively promote sustainable development and reduce environmental impact. “Mitsuboshi Belting Ltd.” fulfills its social responsibility and complies with global environmental regulations through green manufacturing and environmental protection projects.

Manufacturing Capacity:With advanced production facilities and efficient production processes, “Mitsuboshi Belting Ltd.” is able to meet the needs of large-scale and customized orders and ensure the stability of the supply chain. The company ensures efficient production capacity and timely product delivery by optimizing production lines and improving automation levels.

Product Diversification:Providing a variety of conveyor belts, including PVC conveyor belts, rubber conveyor belts, wire rope conveyor belts and modular conveyor belts, to meet the diverse needs of different industrial applications. “Mitsuboshi Belting Ltd.”‘s product line is flexible and diverse, adapting to various complex conveying environments and operating conditions.

9. Bando Chemical Industries, Ltd.

Company’s Business Profile:Bando Chemical Industries is a key player in providing industrial conveyor belts to a variety of industries, including automotive, agriculture and logistics. With innovation and excellent customer service as their core competitiveness, they continue to develop new materials and technologies to meet the growing needs of customers.

Innovation:Bando Chemical Industries continues to innovate in technology and develops conveyor belts with high durability and performance to meet the special needs of different industries. The company improves the overall performance and adaptability of conveyor belts by developing new materials and optimizing product design.

Quality Control:The company strictly controls the production process to ensure that all products meet international quality standards and provide highly reliable conveyor belt solutions. Bando Chemical Industries ensures that products meet the highest quality requirements in both production and testing stages through a comprehensive quality management system.

Global Reach:Bando Chemical Industries has a wide distribution network and production bases around the world, which can provide timely service and support to global customers. The company ensures that its conveyor belts can be quickly delivered to customers in various places through a global layout.

Customer Feedback:Customers highly appreciate the high performance and quality service of its products, and have established a good market reputation and customer loyalty. Bando Chemical Industries has won a high degree of trust and satisfaction from customers with its excellent product quality and high-quality customer service.

Sustainability:The company pays attention to environmental protection, adopts sustainable materials and energy-saving production processes, and actively promotes green manufacturing to reduce environmental impact. Bando Chemical Industries fulfills its social responsibility and complies with global environmental regulations through environmental protection projects and sustainable production methods.

Manufacturing Capacity:With advanced production equipment and efficient production processes, it can meet the needs of large-scale and customized orders and ensure the stability of the supply chain. Bando Chemical Industries ensures efficient production capacity and timely product delivery by optimizing production lines and improving automation levels.

Product Diversification:Provides diversified conveyor belt products, including rubber conveyor belts, PVC conveyor belts and modular conveyor belts to meet the needs of different industrial applications. Bando Chemical Industries’ product line is flexible and diverse, adapting to various complex conveying environments and operating conditions.

10. Ammeraal Beltech

Company’s Business Profile:Ammeraal Beltech focuses on modular conveyor belts in the fields of food processing, logistics and industrial automation, and is known for its product customization and innovative conveying solutions. They are committed to providing customers with high-quality conveyor belt products, improving production efficiency and operational reliability through flexible design and efficient production processes.

Innovation:The company continues to develop innovative conveying solutions, using the latest technologies and materials to improve product performance and adaptability to meet the needs of different industries. Through technological research and development, Ammeraal Beltech has launched intelligent and efficient conveyor belt systems to improve customers’ production efficiency.

Quality Control:Ammeraal Beltech strictly follows international quality standards to ensure that all products are of high quality and reliability to meet the high standards of customers. The company implements a comprehensive quality management system to ensure that products meet the highest quality standards during the production and testing stages.

Global Reach:The products are sold in many countries and regions around the world, and have an extensive international distribution network to provide timely service and support to global customers. Ammeraal Beltech’s global layout ensures that its conveyor belts can be quickly delivered to customers everywhere.

Customer Feedback:Customers are generally satisfied with the high performance and customized solutions of its conveyor belts, especially in the food processing and logistics industries, where customer satisfaction is extremely high. Ammeraal Beltech has won a high degree of trust and loyalty from customers with its excellent product quality and excellent customer service.

Sustainability:The company is committed to environmental protection, using sustainable materials and energy-saving production processes to actively promote green manufacturing and reduce environmental impact. Ammeraal Beltech fulfills its social responsibility and complies with global environmental regulations through environmental projects and sustainable production methods.

Manufacturing Capacity:With advanced production facilities and efficient production processes, Ammeraal Beltech is able to meet the needs of large-scale and customized orders and ensure the stability of the supply chain. The company ensures efficient production capacity and timely product delivery by optimizing production lines and improving automation levels.

Product Diversification:A variety of conveyor belt types are available, including modular conveyor belts, PVC conveyor belts and rubber conveyor belts, to meet the diverse needs of different industrial applications. Ammeraal Beltech’s product line is flexible and diverse, adapting to various complex conveying environments and operating conditions.

11. Trelleborg

Company’s Business Profile:Trelleborg is well-known in the mining and heavy industry for its advanced rubber products and conveyor belts, focusing on sustainable practices and environmentally friendly solutions. They are committed to providing high-performance conveyor belt products through technological innovation and environmentally friendly materials to meet the needs of modern industry for green production.

Innovation:The company continues to innovate in technology and develop high-performance and environmentally friendly conveyor belt products to meet the needs of modern industry for green production. Trelleborg improves the durability and environmental performance of conveyor belts through the research and development of new materials and intelligent manufacturing technologies.

Quality Control:Trelleborg strictly controls the production process to ensure that all products meet international quality standards and provide highly reliable conveyor belt solutions. The company implements a comprehensive quality management system to ensure that products meet the highest quality requirements in both production and testing stages.

Global Reach:With products sold in many countries and regions around the world, Trelleborg has an extensive international distribution network and production bases, providing timely service and support to customers around the world. Through its global layout, Trelleborg ensures that its conveyor belts can be quickly delivered to customers everywhere.

Customer Feedback:Customers highly appreciate the high performance and environmental protection characteristics of its conveyor belts, especially in mining and heavy industry, where customer satisfaction is extremely high. Trelleborg has won the high trust and loyalty of customers with its excellent product quality and excellent customer service.

Sustainability:The company pays attention to environmental protection, adopts sustainable materials and energy-saving production processes, and actively promotes green manufacturing to reduce environmental impact. Trelleborg fulfills its social responsibility and complies with global environmental regulations through environmental protection projects and sustainable production methods.

Manufacturing Capacity:With advanced production equipment and efficient production processes, Trelleborg is able to meet the needs of large-scale and customized orders and ensure the stability of the supply chain. The company ensures efficient production capacity and timely product delivery by optimizing production lines and improving automation levels.

Product Diversification:Provides a variety of conveyor belt products, including high-temperature conveyor belts, oil-resistant conveyor belts and modular conveyor belts to meet the needs of different industrial applications. Trelleborg’s product line is flexible and diverse, adapting to various complex conveying environments and operating conditions.

12.Intralox

Company Business Profile: Founded in the 1970s and headquartered in Louisiana, USA, Intralox is a global leader in modular plastic conveyor belts and intelligent conveying solutions. Known for inventing and marketing modular plastic conveyor belts that provide efficient, reliable and easy-to-maintain conveyor solutions for a wide range of industries, including food processing, beverage packaging, logistics, e-commerce, postal sorting, and automotive manufacturing, Intralox has a strong technical development team and industry experience that is dedicated to delivering higher productivity and lower total cost of ownership for its customers.

Innovation: Intralox continues to optimize the design structure, material and surface characteristics of its modular plastic belts through continuous R&D investment and patented technological innovations to provide customers with higher transport efficiency and product handling precision. The company actively applies advanced intelligent control systems and automation technologies, and develops customized solutions to meet customer needs, maintaining an industry-leading position in conveyor layout, picking efficiency and line flexibility.

Quality Control: Intralox strictly adheres to international quality standards and provides customers with rigorously tested conveyor belts with high durability and stability. A comprehensive quality management system is in place, from raw material sourcing, through manufacturing to final shipment, to ensure that our products excel in a wide range of industrial applications.

Global Reach: Intralox operates a network of factories, technical centers and sales offices around the world, covering major markets in North America, Europe, Asia and South America. The company’s global presence provides localized technical support and responsive after-sales service to customers in different regions, ensuring fast product delivery and helping customers improve line efficiency.

Customer Feedback: Intralox’s modular conveyor belts are highly regarded by customers for their stability, ease of cleaning and ease of maintenance. Many food processing plants, beverage filling plants and e-commerce warehousing centers have adopted Intralox’s solutions to significantly reduce line downtime and improve picking and conveying efficiency, resulting in improved overall operational performance.

Sustainability: Intralox focuses on environmental protection and sustainable development, continuously optimizing product design and material selection to reduce energy consumption and waste generation. By extending belt life and improving resource efficiency, the company helps customers optimize line performance while reducing environmental impact.

Manufacturing Capacity: Equipped with state-of-the-art manufacturing equipment and efficient production processes, the company is able to respond quickly to high-volume and customized orders. Thanks to automation and digitalization, Intralox not only guarantees high quality and fast delivery, but also has the flexibility to adapt its production capacity to the needs of its customers.

Product Diversification: Intralox has a diverse product portfolio that includes modular plastic belts in a wide range of sizes, materials and surface configurations, as well as associated sorting, diverting and merging equipment. The product line is designed to meet the needs of applications ranging from food sanitation scenarios to highly abrasive heavy industrial environments, helping customers find the optimal solution for specific line conditions.

13.Metso

Company’s Business Profile:Metso Outotec is a leading global supplier of mining and metalworking equipment, providing efficient and sustainable solutions to support the production needs of the global mining and metalworking industries.

Innovation:Metso Outotec is constantly developing advanced crushing, grinding and sorting technologies to increase productivity and automation.

Quality Control:Our strict adherence to international quality standards ensures the reliability and durability of all our equipment in demanding environments.

Global Reach:We have multiple manufacturing facilities and service centers around the world, covering key markets in North America, Europe, Asia Pacific and Africa.

Customer Feedback:Customers have commented on the high performance of their equipment, which has helped to significantly increase productivity and reduce operating costs.

Sustainability:Committed to the environment, we support our customers’ sustainability goals through energy-efficient equipment and renewable materials.

Manufacturing Capacity:State-of-the-art production facilities and efficient manufacturing processes ensure timely delivery of large-scale and customized orders.

Product Diversification:We offer a diverse product line of crushers, grinding equipment, sorting systems and automated control systems to meet the needs of different industries.

14. Gates Corporation

Company’s Business Profile:Known for its high-performance conveyor belts used in multiple industries including transportation, food processing and automotive, Gates Corporation specializes in providing efficient and long-lasting conveying solutions. They continuously develop new technologies to improve the performance and durability of conveyor belts to meet the diverse needs of customers.

Innovation:The company continues to develop new technologies to improve the performance and durability of conveyor belts, meet the diverse needs of customers, and maintain technological leadership. Through technological innovation, Gates Corporation launches high-efficiency and intelligent conveyor belt systems to improve the overall performance of the product.

Quality Control:Gates Corporation strictly follows international quality standards to ensure that all products are of high quality and reliability, providing excellent conveyor belt solutions. The company implements a comprehensive quality management system to ensure that products meet the highest quality requirements during both the production and testing stages.

Global Reach:Our products are sold to many countries and regions around the world, and we have a strong international distribution network that can provide timely service and support to customers around the world. Through its global presence, Gates Corporation ensures that its conveyor belts can be quickly delivered to customers everywhere.

Customer Feedback:Customers generally speak highly of the efficiency and durability of its conveyor belts, with high satisfaction and loyalty. Gates Corporation has earned a high degree of trust and satisfaction from its customers for its superior product quality and excellent customer service.

Sustainability:The company is committed to environmental protection, using sustainable materials and energy-saving production processes, actively promoting green manufacturing and reducing environmental impact. Gates Corporation fulfills its social responsibilities and complies with global environmental regulations through environmental projects and sustainable production methods.

Manufacturing Capacity:With advanced production facilities and efficient production processes, Gates Corporation is able to meet large-scale and customized order needs, ensuring the stability of the supply chain. The company ensures efficient production capacity and timely product delivery by optimizing production lines and improving automation levels.

Product Diversification:Provides various types of conveyor belts, including high temperature resistant conveyor belts, oil resistant conveyor belts and modular conveyor belts, to meet the diverse needs of different industrial applications. Gates Corporation’s product lines are flexible and diverse, adaptable to a variety of complex conveying environments and operating conditions.

15. Forbo Siegling

Company’s Business Profile:Forbo Siegling is a leading global conveyor belt manufacturer specializing in high quality conveyor belt solutions for the food, packaging, pharmaceutical and logistics industries. Their products are known for their high performance, durability and environmentally friendly design and are used in a wide range of production lines and logistics facilities.

Innovation:Forbo Siegling continually invests in research and development to develop new materials and advanced manufacturing processes to enhance the performance and adaptability of their conveyor belts. They are committed to introducing lighter and more wear-resistant conveyor belts to meet their customers’ increasing demands for efficient and sustainable production.

Quality Control:Forbo Siegling’s high standards of quality control ensure the reliability and durability of its products in demanding environments, with a comprehensive quality management system that ensures that every conveyor belt undergoes rigorous inspection and testing.

Global Reach:Forbo Siegling has manufacturing facilities and distribution networks in many countries around the world, enabling them to respond quickly to customer needs and provide timely product supply and technical support. Their global presence ensures fast delivery and efficient service.

Customer Feedback:Customers speak highly of Forbo Siegling’s conveyor belts, especially in terms of performance stability, durability and environmentally friendly design. The company has gained widespread market recognition and customer loyalty for its quality products and excellent customer service.

Sustainability:Forbo Siegling is committed to environmental protection and sustainability, using renewable materials and energy-efficient production processes to reduce their environmental impact. They promote green manufacturing by optimizing production processes and recycling to comply with global environmental regulations and their customers’ sustainability goals.

Manufacturing Capacity:With state-of-the-art manufacturing equipment and efficient production processes, Forbo Siegling is able to meet large-scale and customized orders. By optimizing production lines and increasing automation, the company ensures efficient production capacity and just-in-time product delivery.

Product Diversification:Forbo Siegling offers a wide range of conveyor belts, including rubber, PVC and modular belts, to meet the diverse needs of different industrial applications.Forbo Siegling’s product line is flexible and adaptable to a wide range of complex conveying environments and operating conditions.

The top 15 conveyor belt manufacturers in the world introduced above have their own characteristics. They have become the leaders in the industry with their outstanding performance in innovation, quality control, global reach, customer feedback, sustainability, manufacturing capacity and product diversification. No matter what industry you are in, these top manufacturers can provide high-quality conveyor belt solutions that meet your needs. By choosing the right conveyor belt manufacturers, you will be able to improve production efficiency, optimize logistics management, and occupy a favorable position in the fierce market competition.

5.Importance and technological innovation of mining conveyor belt manufacturers

Among the many application fields for conveyor belt manufacturers, mining is undoubtedly the most challenging and critical one. Mining conveyor belt Manufacturers play a vital role in mining production. They not only ensure the efficient transportation of ore and other minerals, but also directly affect the efficiency and safety of the entire mining production.

5.1 Importance of Mining Conveyor Belt Manufacturers

Mining production involves the transportation of large amounts of materials, and the heavy-duty conveyor belt systems provided by Mining Conveyor Belt Manufacturer are central to achieving this goal. The environment in mining areas is usually harsh and the terrain is complex. Conveyor belts need to have extremely high wear resistance and strength to cope with continuous wear and high-load transportation tasks. High-quality conveyor belts can not only significantly improve the efficiency of ore transportation, but also reduce the frequency of equipment maintenance and replacement, reducing operating costs. In addition, the stability and reliability of the mining conveyor belt system are directly related to the safe production of the mining area, ensuring the continuity of operations and the safety of workers.

5.2 Technological innovation drives the development of mining conveyor belts

In order to meet the high standard needs of mining production, mining conveyor belt Manufacturer has invested a lot of resources in technological innovation. They continuously develop new materials and advanced manufacturing processes to improve the performance and durability of conveyor belts. The following are several key technological innovations that are currently widely used:

5.2.1 High-strength synthetic materials

In recent years, in order to make the conveyor belts stronger, mining conveyor belt manufacturers have begun to choose to use high-strength synthetic materials, such as Kevlar fiber, to replace traditional rubber core materials. These high-strength materials not only improve the wear and tear resistance of the conveyor belt, but also extend its service life and reduce the frequency of maintenance and replacement.

5.2.2 Anti-slip and anti-static coating

In order to maintain the stability of the conveyor belt in the slippery and dusty mining environment, the mining conveyor belt Manufacturer applies anti-skid and anti-static coatings to the surface of the conveyor belt. These coatings can effectively prevent ore and other materials from sliding on the conveyor belt, reduce the falling and accumulation of materials, and improve transportation efficiency and safety.

5.2.3 Modular design

The modular conveyor belt design allows the belt to quickly replace damaged modules in the event of a belt failure without having to replace the entire belt. This design greatly shortens maintenance time, reduces the risk of production interruption, and improves the continuity and efficiency of mining production.

5.2.4 Intelligent monitoring system

With the development of Internet of Things (IoT) technology, mining conveyor belt Manufacturer begins to integrate intelligent monitoring systems into conveyor belt systems. By installing sensors and monitoring equipment to monitor the operating status, temperature, tension and wear of the conveyor belt in real time, potential problems can be warned in advance, maintenance and repair can be carried out in a timely manner, and production interruptions and safety accidents caused by equipment failure can be avoided.

5.2.5 Heat resistant and chemical resistant materials

heat resistant and chemical resistant are often present in the mining environment. Mining Conveyor Belt Manufacturer has developed heat resistant and chemical resistant conveyor belt materials to ensure that the conveyor belt can still maintain its physical properties and transmission efficiency under extreme conditions. These special conveyor belts are widely used in ore processing and refining processes, significantly improving production efficiency and equipment reliability.

5.2.6 Environmentally friendly production process

Driven by the global environmental protection trend, mining conveyor belt Manufacturer actively adopts environmentally friendly production processes, such as reducing the use of harmful chemicals and improving energy efficiency. By optimizing the production process and using renewable materials, they reduce the environmental impact in the production process and promote the green transformation of mining production.

Through these practical technological innovations, mining conveyor belt Manufacturer not only improves the performance and durability of conveyor belts, but also promotes the development of mining production in a more efficient, smarter and more environmentally friendly direction. The application of these innovative technologies not only meets the high standards of mining production, but also brings significant economic benefits and safety guarantees to mining companies.

6.Performance of the world’s top 15 conveyor belt manufacturers in major import markets

Understanding the market performance of conveyor belt manufacturers in different regions can help companies better choose partners and optimize supply chain layout. The world’s top 15 conveyor belt manufacturers have performed well in major import markets. They have won a wide market share by adapting to regional needs, optimizing distribution networks and providing customized solutions. The following will deeply analyze the performance and strategies of these manufacturers in major import markets such as North America, Europe, and Asia Pacific.

6.1 North American market: technology-driven and efficient logistics demand

As an important industrial and logistics center in the world, North America continues to grow in demand for conveyor belt manufacturers. Industrial conveyor belt manufacturers mainly serve the mining, manufacturing and logistics industries in the North American market. With the popularization of automation technology and the advancement of intelligent manufacturing, the demand for high-performance and high-efficiency conveyor belt systems in the North American market continues to increase.

Continental AG and Bridgestone Corporation have performed particularly well in the North American market. By introducing intelligent monitoring systems and high-strength materials, they provide conveyor belt solutions that adapt to various complex working conditions and meet customers’ needs for high reliability and low maintenance costs. In addition, the North American market’s emphasis on environmental protection and sustainable development has also driven these manufacturers to adopt environmentally friendly materials and energy-saving production processes to enhance the market competitiveness of their products.

6.2 European Market: High Standard Quality and Environmental Protection Requirements

The European market is known for its strict quality standards and environmental regulations, and has placed higher requirements on conveyor belt manufacturers. Habasit AG and Trelleborg occupy an important position in the European market. They have won the trust of customers by providing conveyor belt products that meet EU environmental standards.

Habasit AG focuses on the food processing and packaging industries, providing high-performance conveyor belts that meet hygiene and safety standards to meet the European market’s demand for high quality and high reliability. Trelleborg, through its advanced rubber technology and environmentally friendly production processes, provides high-temperature and chemical-resistant conveyor belts to meet the European industry’s requirements for green production.

In addition, the European market’s demand for modular and intelligent conveyor belt systems is also increasing. Industrial conveyor belt manufacturers provide flexible and efficient conveying solutions through technological innovation and product diversification, further consolidating their leading position in the European market.

6.3 Asia Pacific Market: Rapid Growth and Infrastructure Construction

The Asia Pacific region has become an important growth point for conveyor belt manufacturers due to its huge manufacturing base and rapidly growing infrastructure construction projects. Tiantie Industrial and Mitsuboshi Belting Ltd. have performed particularly well in the Asia Pacific market, and they have quickly captured market share by expanding production bases and optimizing distribution networks.

Tiantie Industrial meets the diverse needs of conveyor belts in different industries in the Asia Pacific region with its diverse product lines and flexible customized services. Mitsuboshi Belting Ltd. serves multiple industries such as automotive manufacturing, logistics and mining through its high-quality and high-performance conveyor belt products, and has won wide customer recognition.

In addition, the demand for smart manufacturing and industrial automation in the Asia Pacific region has driven industrial conveyor belt manufacturers to invest in technological innovation and product research and development, providing more efficient and intelligent conveyor belt systems, further promoting the rapid growth of the market.

6.4 Middle East and Africa Market: Infrastructure Construction and Resource Development

The demand for conveyor belt manufacturers in the Middle East and Africa is also growing rapidly due to its abundant natural resources and ongoing infrastructure construction projects. Fenner Dunlop and Sempertrans have performed well in these markets by providing high-durability and high-performance conveyor belts to meet the special needs of the mining and construction industries.

Fenner Dunlop focuses on providing high-performance conveyor belts for mining and heavy-duty applications, ensuring reliability and efficiency in harsh environments. Sempertrans serves the mining and industrial markets in the Middle East and Africa with its advanced production technology and customized solutions, helping customers improve production efficiency and reduce operating costs.

In addition, the demand for environmental protection and sustainable development in the Middle East and African markets is also increasing. Conveyor belt manufacturers have improved their competitiveness in these markets by using environmentally friendly materials and energy-saving production processes to meet customers’ demand for green products.

7. Market challenges and opportunities

Global Conveyor Belt Manufacturers are facing multiple challenges in the course of development and are also witnessing a number of opportunities. Fluctuating raw material prices have a direct impact on manufacturers’ production costs and profit margins, forcing them to find more flexible strategies for sourcing and cost control. At the same time, the growing demand for environmentally friendly and sustainable products is requiring manufacturers to innovate in material selection and production processes to meet customer expectations for greener products.

Increased competition is also an important issue for manufacturers to deal with. Intense competition from local and international suppliers makes it imperative for companies to continuously improve their core competencies and stand out by offering differentiated products and excellent customer service. Especially customer service, in this economic climate of an overall downturn, the degree of difference in the quality of everyone’s products is actually not that great, and can’t just be a matter of branding and quality as well as fast service response.

At the level of new technology, the combination of smart conveyor belts and the Internet of Things (IoT) is opening up new directions for manufacturers. By integrating sensors and intelligent control systems in conveyor belts, companies can realize real-time monitoring and data analysis to improve transportation efficiency and reduce downtime, but this approach requires companies to replace the overall accessories and equipment, which can cause cost pressure.

This is where new materials may become the best option for companies without replacing large machinery and equipment. Advances in material science make conveyor belts more durable and energy-saving, and the application of new high-strength synthetic materials not only extends the product life, but also reduces maintenance costs to meet the market demand for high-performance conveyor belts.

For example, as mentioned above, more and more customers have started to look for Kevlar as the core layer of rubber conveyor belts. Along with the continuous development of technology, the cost of Kevlar will continue to decrease, which will further reduce the price of conveyor belts with this material as the core layer, and this may be a virtuous cycle for end customers.

Rapid industrialization and infrastructure development in emerging economies have also brought vast market space for conveyor belt manufacturers. As the demand for high-quality conveyor belts increases in these regions, manufacturers have the opportunity to rapidly capture market share and expand globally by expanding their production bases and optimizing their distribution networks.

The promotion of environmentally friendly production processes is also an important trend. By using renewable materials and optimizing production processes, manufacturers are reducing their environmental impact and enhancing their corporate social responsibility image. This not only complies with global environmental regulations, but also strengthens customers’ trust and loyalty to the brand.

In such a market environment, surveyor belt Manufacturers need to be flexible and responsive to change, continuously investing in R&D and innovation, and improving the quality of their products and services, in order to maintain a competitive edge and capitalize on new opportunities for growth.

8.Future Trends and Industry Outlook

Against the backdrop of global industrial transformation and technological innovation, the conveyor belt manufacturing industry is witnessing new opportunities and trends. The following is my outlook on the future development of the industry, which I hope will provide you with valuable reference.

8.1 Customer demand-driven personalized customization

Increased market competition and diversified customer demands have prompted conveyor belt manufacturers to offer more personalized products and services. Customization will definitely become the ultimate process of the industry, especially for large-scale conveyor belt projects. By working closely with customers and gaining an in-depth understanding of their specific needs, manufacturers can offer tailor-made conveyor solutions that enhance customer stickiness and market competitiveness.

8.2 Expansion in Emerging Markets

Changes in the global economic landscape and the rise of emerging markets have brought new growth points to the industry. Especially in regions such as Southeast Asia, Africa and Latin America, the accelerated process of infrastructure construction and industrialization, as well as the extensive exploitation of mineral resources, has brought about a huge demand for high-quality conveyor belts. Conveyor belt manufacturers need to develop effective market expansion strategies that may include agency partnerships and customized marketing programs to better serve local customers.

8.3 Supply chain flexibility and risk management

Recent global events, such as trade frictions, have highlighted the importance of supply chain risk management. In the future, conveyor belt manufacturers will pay more attention to supply chain flexibility and sustainability. By working with multiple and stable suppliers, companies can reduce the risk of supply chain disruptions and ensure continuity of production and delivery, but this is a very difficult item.

8.4 Service-oriented business model shift

In addition to providing the product itself, future conveyor belt manufacturers are likely to shift more towards service-oriented business models. For example, offering value-added services such as full lifecycle maintenance services and predictive maintenance.

9.Conveyor Belt Manufacturers: Ensuring Efficiency and Reliability

Conveyor belt Manufacturers play a key role in the production process of various industries. Through strict quality control, they provide reliable conveyor systems to meet the diverse needs of the mining industry, logistics, food processing and other fields.

In the face of fluctuating raw material prices and fierce market competition, manufacturers maintain strong market competitiveness by optimizing the supply chain and improving production efficiency. Meanwhile, the requirements of environmental protection and sustainable development have prompted them to adopt green materials and energy-saving processes, further enhancing the market attractiveness of their products.

Looking ahead, the conveyor belt manufacturing industry will continue to focus on providing high-quality and reliable conveying solutions. Choosing the right Conveyor belt Manufacturers not only enhances a company’s productivity, but also ensures the long-term stability of the conveyor system.

Through continuous optimization and dedication to quality, Conveyor belt Manufacturers will continue to provide trusted conveyor belt products to a wide range of industries, helping companies to achieve their efficient production and operational goals.