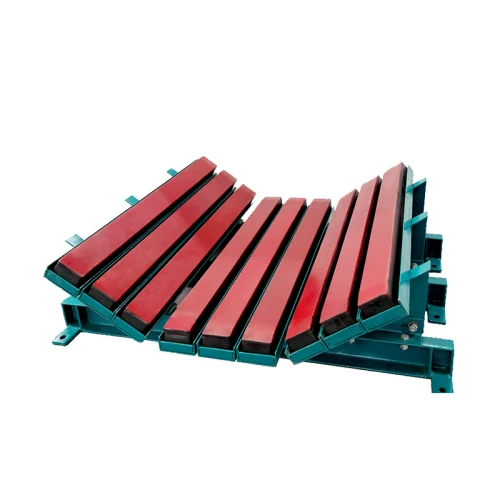

Impact Bed

The impact bed is designed to replace traditional impact idlers at conveyor loading points. It provides continuous belt support, reduces belt damage caused by material impact, and prevents material spillage. The structure consists of self-lubricating UHMW-PE (Ultra High Molecular Weight Polyethylene) sliding bars bonded with high-elastic rubber pads, ensuring excellent shock absorption and wear resistance. It is an ideal solution for heavy-duty conveyor loading zones in mining, quarrying, cement, and port bulk-handling systems.

Details

A. Functional Significance

At the material loading point of a conveyor system, the belt often suffers from impact, tearing, or sagging due to falling material.

The Impact Bed is engineered to:

Absorb the impact energy and reduce belt damage.

Provide stable, continuous belt support to prevent sagging.

Replace conventional impact rollers, reducing maintenance needs.

Prevent material spillage by keeping the belt stable under impact.

Studies by manufacturers such as Martin Engineering show that impact beds can reduce belt puncture and splice damage by up to 70%, and extend belt life by 2–3 times compared with impact rollers.

B. Our Product Features

High-Performance Impact Structure

Each bed uses a combination of UHMW-PE wear strips and vulcanized rubber shock-absorbing layers.

The UHMW-PE surface offers low friction, reducing belt wear and resistance.

The rubber layer provides high rebound and excellent impact absorption.

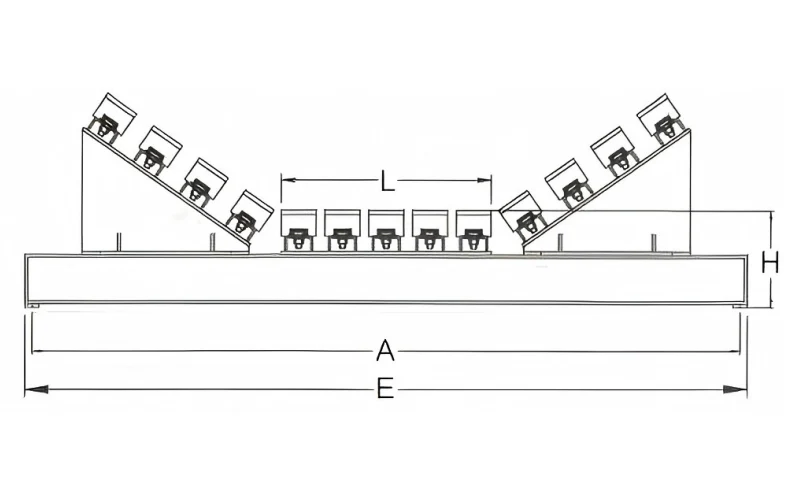

Aluminum Alloy Slide Frame Design

Modular aluminum alloy frame makes installation and maintenance easier.

Adjustable groove angle allows fine-tuning according to the actual conveyor troughing angle.

Durability & Safety

All components are corrosion-resistant, suitable for wet or dusty environments.

Designed to reduce vibration and belt deviation, improving overall system stability.

Customisation Options

Available for belt widths from 500 mm to 2000 mm.

Optional galvanized or stainless-steel frame.

Custom impact bar thickness, spacing, or color available upon request.

Maintenance Advantages

Unlike impact idlers, there are no rotating parts, eliminating bearing failures.

The replaceable UHMW-PE bars simplify periodic maintenance and reduce downtime.

| Belt Width (BW) | A (mm) | E (mm) | L (mm) | H (mm) | Number of Impact Bars |

|---|---|---|---|---|---|

| BW = 500 | 740 | 800 | 200 | 169 | 6 |

| BW = 650 | 890 | 950 | 250 | 169 | 6 |

| BW = 800 | 1090 | 1150 | 315 | 169 | 7 |

| BW = 1000 | 1290 | 1350 | 380 | 204 | 9 |

| BW = 1200 | 1540 | 1600 | 465 | 208 | 10 |

| BW = 1400 | 1740 | 1810 | 530 | 228 | 12 |

| BW = 1600 | 1990 | 2060 | 600 | 268 | 13 |

| BW = 1800 | 2190 | 2260 | 670 | 268 | 15 |

| BW = 2000 | 2420 | 2490 | 750 | 268 | 16 |

C.Applications

Mining and quarrying conveyor systems

Cement, steel, and power plants

Port and terminal bulk handling systems

Loading, transfer, and material-receiving points of long-distance belt conveyors

D.Why Choose Our Impact Bed

Proven design aligned with TDII conveyor structure standards.

Factory-tested for static load >80 kN and belt speed up to 3.0 m/s.

Manufactured with high-quality materials for heavy-impact applications.

Custom designs available for OEM and replacement projects.

Related Products

Why Choose Our Belts for Your Manufacturing Needs?

Discover how our innovative conveyor belt solutions enhance efficiency, reduce downtime, and provide reliable performance for all your industrial needs.

QUALITY ASSURANCE

Adopts high-strength double anilox rollers and tear-resistant materials to ensure product durability, safety and compliance with strict quality standards.Technological Innovation

Introduces lifetime replacement-free anilox roller coating technology and high-efficiency automated equipment to improve production efficiency and reduce maintenance costs.Professional Services

provides one-on-one technical support and quick response to customer needs to ensure smooth and worry-free use.Diversified Choices

provides a variety of industrial solutions and customized services to meet the specific needs of different customers.

Hello

Get Free Quote

Contact us today to receive a customized quote for your conveyor belt needs—fast, easy, and at no cost!

changjiang No.1 Office Building ,No.8 Tianshan Road, Xinwu District, Wuxi City, Jiangsu Province, China