Conveyor Belt Cleaner

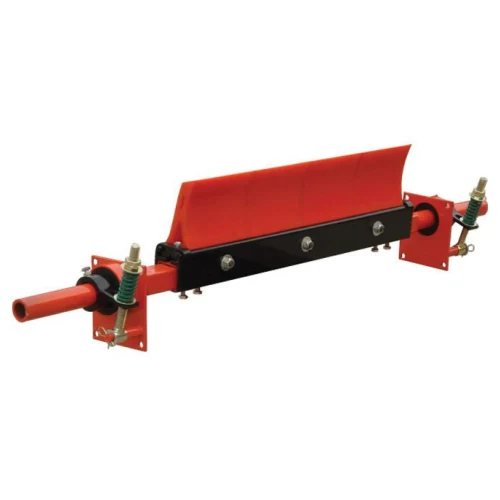

The conveyor belt cleaner is an essential device installed at the head and return pulleys of a conveyor system to remove residual material adhering to the belt surface. It improves conveyor efficiency, reduces material carryback, and protects the belt from premature wear.Our cleaner adopts wear-resistant polyurethane blades combined with heavy-duty tensioning mechanisms, providing long service life, stable performance, and excellent cleaning results under all operating conditions.

Details

A. Functional Significance

In continuous conveyor operation, fine material particles often stick to the belt surface, returning along the belt and contaminating the system.

The conveyor belt cleaner prevents:

Material carryback and spillage

Belt mis-tracking caused by material buildup

Premature belt and pulley wear

Additional cleaning and maintenance costs

According to CEMA Belt Cleaners Guidelines, properly installed primary and secondary cleaners can remove up to 90–95% of carryback material and reduce cleaning energy by 40%.

B. Our Product Features

High-Performance Polyurethane Blade

The cleaner blade is made of high-quality imported polyurethane with excellent elasticity, wear resistance, and chemical stability.

It maintains optimal cleaning contact even under high belt speeds and fluctuating loads.

The polyurethane hardness (85–95 Shore A) ensures balance between durability and belt protection.

Multiple Types Available

Primary Heavy-Duty Cleaner – Mounted on the head pulley to remove large residues.

Primary Common Cleaner – For standard material handling conveyors.

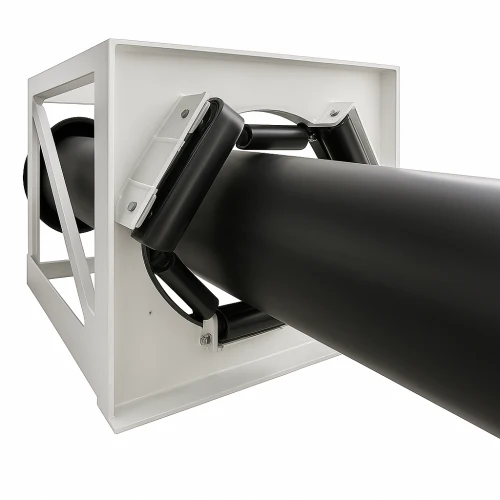

Secondary Cleaner – Installed behind the primary cleaner for fine cleaning.

V-Type Return Cleaner – Used on the return side to remove residual materials and water film.

Self-Adjusting Tension System

Equipped with a spring or torque arm tensioner to maintain constant contact pressure.

Automatically compensates for blade wear, ensuring consistent cleaning efficiency.

Modular and Easy Maintenance Design

The cleaner structure is simple and modular, with quick-release mechanisms for blade replacement.

Stainless steel or galvanized frames available for corrosion resistance.

Extended Service Life & Energy Efficiency

Laboratory tests (Flexco 2023 report) show polyurethane blades can last 3× longer than traditional rubber cleaners under identical abrasion conditions.

Reduced carryback lowers conveyor idler wear and belt friction losses.

Average belt cleanliness > 95% under proper alignment and tension.

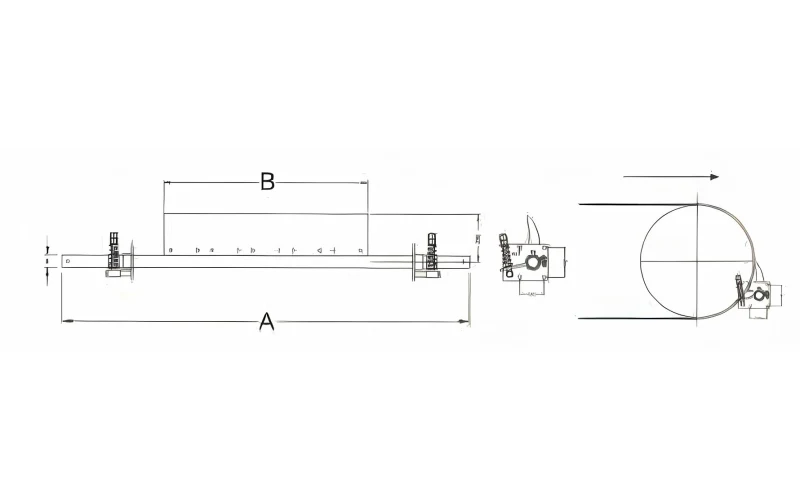

| Series | B=500 | B=650 | B=800 | B=1000 | B=1200 | B=1400 | B=1600 | B=1800 | B=2000 | B=2200 |

|---|---|---|---|---|---|---|---|---|---|---|

| A | 1500 | 1600 | 1800 | 2000 | 2200 | 2400 | 2600 | 2800 | 3000 | 3200 |

| B | 500 | 600 | 800 | 1000 | 1200 | 1400 | 1600 | 1800 | 2000 | 2200 |

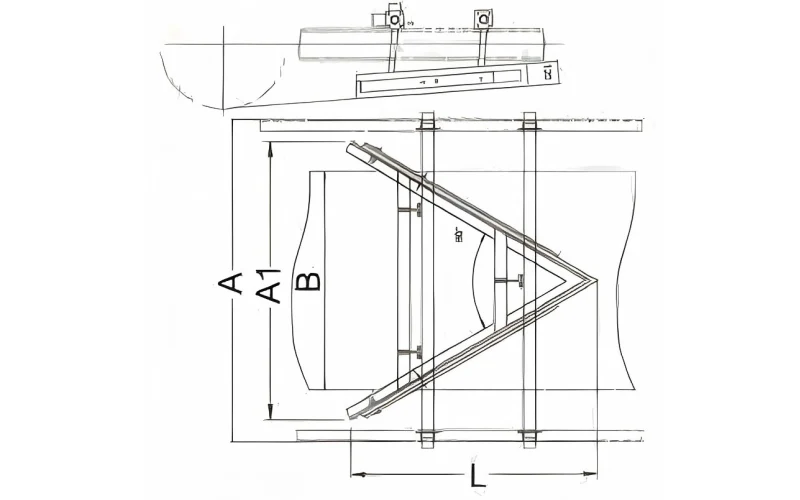

| B | A | A1 | L |

|---|---|---|---|

| 650 | 950 | 770 | 627 |

| 800 | 1150 | 970 | 800 |

| 1000 | 1350 | 1170 | 973 |

| 1200 | 1600 | 1420 | 1190 |

| 1400 | 1810 | 1630 | 1372 |

| 1600 | 2060 | 1880 | 1588 |

| 1800 | 2260 | 2080 | 1761 |

| 2000 | 2490 | 2290 | 1943 |

| 2200 | 2800 | 2610 | 2270 |

Application Scenarios

Mining, coal preparation, and aggregate conveyors

Cement plants, steel mills, and power stations

Port and bulk material handling systems

Fertilizer, chemical, and grain conveyors

Long-distance overland belt conveyors

Why Choose Our Conveyor Belt Cleaners

High-grade polyurethane with excellent wear life and belt compatibility

Multi-stage cleaning (Primary + Secondary + V-Type) available

Designed according to TDII / CEMA / DIN standards

Adjustable tension for maximum belt contact and cleaning efficiency

Factory-tested for belt speeds up to 3.5 m/s and load forces > 60 kN

Related Products

Why Choose Our Belts for Your Manufacturing Needs?

Discover how our innovative conveyor belt solutions enhance efficiency, reduce downtime, and provide reliable performance for all your industrial needs.

QUALITY ASSURANCE

Adopts high-strength double anilox rollers and tear-resistant materials to ensure product durability, safety and compliance with strict quality standards.Technological Innovation

Introduces lifetime replacement-free anilox roller coating technology and high-efficiency automated equipment to improve production efficiency and reduce maintenance costs.Professional Services

provides one-on-one technical support and quick response to customer needs to ensure smooth and worry-free use.Diversified Choices

provides a variety of industrial solutions and customized services to meet the specific needs of different customers.

Hello

Get Free Quote

Contact us today to receive a customized quote for your conveyor belt needs—fast, easy, and at no cost!

changjiang No.1 Office Building ,No.8 Tianshan Road, Xinwu District, Wuxi City, Jiangsu Province, China