1. What are drive belts?

What are drive belts? In a nutshell, drive belts are the key components for transmitting power through a system of pulleys, which are widely used in machinery and industrial systems. This type of drive relies on elastic materials to transmit power through friction or gear synchronization. Typically, they are used in mechanical systems that transmit low to medium power, such as automobiles, household appliances, and industrial equipment.

From an engineering perspective, drive belts are an integral part of modern mechanical equipment. Not only does it provide a flexible power transmission solution, but it can also help companies achieve more efficient production. Drive belts are becoming increasingly important in equipment across a wide range of industries, showing great value whether they are used in large industrial machines or precision equipment.

The advantages:

Cost-effective: Drive belts are widely used first and foremost because of their low cost. According to statistics, companies that use drive belts as the main transmission method in industrial drive systems can save about 20% of their initial equipment costs. This makes them an extremely economical choice for long running equipment.

Less noise: drive belts produce less noise during operation than other types of drives such as chain drives. The low noise characteristics of drive belts are particularly critical in scenarios where noise is critical, such as in the textile and food processing industries.

High energy absorption: drive belts are designed to absorb energy efficiently during operation, reducing shock loads in mechanical systems. This feature helps extend the life of mechanical equipment. According to equipment maintenance data, systems using drive belts have a 10% increase in average equipment life over other drives.

Ease of maintenance: drive belts are easier to maintain than chain or gear drive systems. Simply adjusting the tension and checking for wear on a regular basis will ensure stable long-term operation.

Disadvantages:

Slipping phenomenon: Since drive belts mainly transmit power through friction, under high load or high torque conditions, slipping phenomenon may occur, resulting in a decrease in transmission efficiency. This is a problem that cannot be ignored when high precision drives are required.

Limited service life: Although the maintenance of drive belts is relatively simple, their service life is still limited. Especially in harsh working environments, such as high temperatures or corrosive environments, the materials of drive belts are prone to aging, thus affecting their durability.

Lower transmission accuracy: drive belts have a lower transmission accuracy than gear or chain drives. This makes them less suitable for high-precision machinery and equipment, such as numerical control equipment, which requires extremely high transmission accuracy.

Since drive belts are used in such a wide range of applications, are there unique specifications and standards for each drive belt design and usage scenario? How does each industry and machine choose the right type of drive belt for its different needs?

2. Basic types and structures of drive belts

Drive belts in industrial applications can be categorized into a variety of types based on their design features and functions, each of which offers different advantages and excels in specific application scenarios. To ensure optimal performance of your mechanical system, it is important to understand the basic types and internal structure of drive belts.

Basic types of drive belts:

① Flat Belts:

Flat belts are one of the simplest and oldest types of drive belts and are primarily used in low-speed, high-power drive systems. Because of their large contact area, flat belts perform well in long-distance drives and low-friction applications. However, its slippery characteristics limit its use in high load environments, and it is more commonly used in light industry or some simple agricultural machinery.

② V-Belts:

V-belts are one of the most widely used types of drive belts in industrial and mechanical systems. With a V-shaped cross-section, this design effectively increases the contact area with the pulley, thereby increasing friction and reducing slippage. v-belts are suitable for mechanical systems with medium loads and speeds, and have high transmission efficiency, and are commonly used in automobile engines, industrial equipment and agricultural machinery.

③ Narrow V-Belts:

Narrow V-belts offer higher power density and efficiency than conventional V-belts through optimized cross-section design. Their narrow cross-section not only allows them to transmit higher torque in a limited space, but also accommodates high RPM operating environments. This type of drive belt is widely used in high-efficiency industrial drive systems and automotive transmissions.

④ Timing Belts:

Timing belts, due to their tooth structure design, can be perfectly matched with the tooth grooves on the pulleys to achieve precise transmission without slippage. Timing belts are suitable for high-precision power transmission needs and are commonly used in automation equipment, precision machinery and automobile engines. Its main advantages are low noise, high transmission accuracy and synchronization of power transmission.

⑤ Multi-Ribbed Belts:

Multi-Ribbed Belts consist of several wedge-shaped ribs arranged in parallel and are suitable for use at high speeds and low noise levels. This design not only reduces operating noise, but also provides excellent transmission efficiency in a compact space. Multi-wedge belts are commonly used in household appliances, automobile engines and some high-efficiency industrial equipment.

⑥ Double V-Belts / Hexagonal Belts:

The hexagonal cross-section of double-sided V-belts allows them to transmit power in two directions simultaneously, making them suitable for mechanical systems with complex drive paths. Agricultural machinery and industrial equipment are common application scenarios for double-sided V-belts, which can meet the demand for two-way driving force while ensuring smooth operation of the system.

Components of drive belts:

The performance of a drive belt is not only determined by its type, but also by its composition. Drive belts typically consist of three layers, each of which has a direct impact on durability, drive efficiency and service life.

① Cover Layer:

The outer layer is the outermost layer of the drive belt and is usually made of highly abrasion-resistant rubber or synthetic material, whose main function is to protect the internal structure of the drive belt from damage caused by the external environment. This layer can effectively resist mechanical wear, chemical corrosion and temperature fluctuations, and is a key part of extending the service life of the drive belt.

② Tensile Member/Core:

The core is the core of the drive belt and is usually made of high-strength materials such as steel wire, nylon or fiberglass. It is responsible for carrying the tensile strength of the drive belt and determines the flexibility and pressure resistance of the belt. A high quality core ensures that the belt maintains stable transmission performance under high loads.

③ Compression Layer:

The friction layer is located on the inner side of the belt and is in direct contact with the pulley. Its main function is to increase the friction between the belt and the pulley to ensure that the drive belt can run stably in the power transmission process. The high performance friction layer effectively reduces slippage, ensures efficient power transmission and extends the service life of the drive belt.

Each layer is designed to provide durability and performance, especially in high-intensity industrial applications where the structural design of the drive belt is critical.

An understanding in the type and construction of drive belts is necessary, which will also pave the way for key factors in how you select a drive belt. Choosing the right drive belt is not only about its type, but also about the needs of the equipment and the operating environment. So what are the key factors to prioritize when choosing a drive belt?

3. Key factors in selecting drive belts

When selecting the right drive belts, a number of factors need to be taken into account to ensure that the drive belts are able to operate effectively in different mechanical systems. The wrong choice can lead to inefficiency, drive slippage and even early wear, so a thorough understanding of the key factors in drive belt selection is essential to the overall performance of your equipment. Here are some key factors to prioritize when selecting a drive belt:

① Torque Transmission:

The primary function of a drive belt is to transmit torque, so it is important to consider the torque required by the equipment when selecting one. If the equipment needs to transmit a higher torque, a belt type with higher strength and friction should be selected. For example, V-belts perform well under moderate loads, while narrow V-belts and timing belts are suitable for high-torque, high-speed drive systems.

② Speed of Rotation:

The speed of rotation of a drive belt determines its ability to transmit power efficiently. High-speed equipment requires drive belts that remain stable at high rotational speeds to avoid slipping or wearing out too quickly. For example, multiribbed belts excel in high-speed equipment because of their flexible design, while timing belts are suitable for high-precision, high-speed drive systems.

③ Center Distance:

The length of a drive belt depends on the distance between the pulleys, also known as the center distance. Too short or too long a center distance can affect the choice of drive belt. Short-distance drive systems usually require more flexible belts, while longer-distance systems require higher tensile strength and wear-resistant belt types, such as flat belts or V-belts.

④ Transmission Ratio:

The transmission ratio of a drive belt is a key measure of how efficiently it can transmit power at different speeds. A large transmission ratio requires that the belt be able to maintain stable power transmission at different speeds. Narrow V-belts are suitable for use in applications requiring a large transmission ratio because of their high power density.

⑤ Temperature and Environmental Conditions:

The operating environment has a significant impact on the service life and performance of drive belts. In high or low temperature environments, drive belt materials must be able to withstand extreme temperature changes. For example, high-temperature rubber or silicone materials are typically used in high-temperature industrial environments, while cold-resistant polyurethane drive belts are suitable for use in low-temperature conditions. In addition, drive belts need to be resistant to corrosion, especially when used in the chemical or food processing industries.

⑥ Load Capacity:

Different equipment has different load requirements. High-load systems often require drive belts with higher load capacity and abrasion resistance to ensure consistent performance over long periods of time. For example, narrow V-belts and timing belts perform well under high load conditions, while spaghetti belts are suitable for medium duty equipment.

⑦ Durability and Maintenance:

The durability and maintenance costs of drive belts are important considerations in the long-term operation of equipment. High-quality drive belts not only reduce maintenance frequency, but also extend replacement intervals, thereby reducing overall operating costs. When selecting a drive belt, choose a type of belt that is highly abrasion-resistant and easy to maintain according to the frequency of operation and the environment in which the equipment is used.

⑧ Noise Level:

Noise is a key consideration in some application scenarios. Low noise drive belts are often used in equipment that requires high noise control in the working environment. For example, synchronous belts or spaghetti belts are often used in textile machinery and food processing equipment to reduce noise levels.

These factors should be taken into account in the selection of drive belts to ensure efficient and stable operation of the equipment under different working conditions. Different types of drive belts vary in construction and design, so understanding the specific needs of the equipment and operating conditions can help make a more informed choice.

Ignoring any of the key factors in drive belt selection can lead to inefficient operation of the drive system. Whether it’s load, speed or operating conditions, choosing a belt that matches the needs of your equipment will ensure optimum performance.

4. Material selection: materials suitable for different working conditions

Selecting the appropriate material is undeniably one of the key factors that significantly impacts the performance of drive belts. Different working environments, load conditions and transmission requirements have different requirements for drive belt materials. An incorrect choice of material can result in a belt that is unable to withstand the load of the equipment, wear prematurely or fail in extreme environments. Therefore, understanding the characteristics of each material and the scenarios in which it is used is key to ensuring efficient drive belt operation.

Common Drive Belt Materials

① Rubber:

Rubber is one of the most common materials used in drive belts and is characterized by excellent elasticity and abrasion resistance. Natural rubber is suitable for moderate temperatures and loads, and is commonly used in industrial machinery and automotive drivelines. In more extreme environments, synthetic rubbers such as neoprene and silicone perform better. Neoprene is widely used in the automotive industry because of its excellent resistance to high temperatures and chemicals. Another advantage of rubber materials is their ability to maintain a stable transmission under high loads, making them the material of choice for many industrial applications.

② Polyurethane:

Polyurethane is commonly chosen for applications demanding high strength and precision in drives, thanks to its superior resistance to abrasion and oil.Polyurethane materials have excellent resistance to low temperatures and are therefore widely used in refrigeration equipment, food processing and the pharmaceutical industry. In addition, polyurethanes are highly resistant to chemicals and grease, making them particularly suitable for use in wet or oily environments. Polyurethane timing belts are widely used in precision transmission systems because their tooth structure ensures high precision transmission without slippage.

③ Nylon:

Nylon is another option for drive belt material, and is commonly used in small to medium-sized machinery because of its light weight, flexibility and high tensile strength. Nylon drive belts are typically utilized in equipment that demands high flexibility and fast transmission speeds, such as in textile and packaging machinery.Nylon has good fatigue resistance, suitable for frequent operation of the equipment, and can effectively reduce the transmission belt in the use of fatigue rupture phenomenon.

④ Steel Cord or Fiberglass:

In high-strength and high-load drive systems, steel wire or fiberglass is often used as the core material, and these high-strength materials provide excellent tensile properties for drive belts. For example, steel-core drive belts are widely used in mining and heavy industry, where they are able to withstand extreme tensile forces and torque and maintain stable performance over long periods of time. Fiberglass, on the other hand, is both strong and lightweight, and is often used in light industrial equipment to ensure that the belt does not stretch at high speeds.

⑤ Teflon:

Teflon is a high-temperature and chemical-resistant, high-performance material that is often used in drive belt applications in extreme temperature environments. Because of its excellent self-lubricating properties, PTFE drive belts are often used in equipment that requires low friction and high heat resistance, such as dryers, chemical equipment and high-temperature industrial furnaces. Although this material is more expensive, there is no substitute for its durability and stability in specific areas.

Material selection and application scenarios

According to different working conditions, the material selection of drive belt should try to match the working environment. For example, drive belts operating in high-temperature environments should be made of high-temperature-resistant materials such as neoprene or PTFE, while polyurethane and nylon drive belts are more advantageous in low-temperature and humid environments. For heavy equipment that is subjected to high torque and high loads, steel core or fiberglass materials are the best choice.

Below is an analysis of several common application scenarios and applicable materials:

① High-temperature environments:

In high-temperature operations, drive belts need to be able to resist heat while maintaining their physical properties. Materials such as neoprene, silicone and PTFE are widely used in metallurgy, drying equipment and high-temperature production lines for their excellent heat resistance.

② Low-temperature or freezing environments:

Polyurethane and nylon materials are often used in low-temperature environments, such as food cold chains and refrigeration equipment, because of their cold resistance. Polyurethanes are especially good in frozen food lines, ensuring smooth and efficient operation at low temperatures.

③ Chemical and humid environments:

Polyurethane drive belts perform particularly well in environments that require resistance to chemicals and grease. Their chemical and oil resistance makes them one of the most common materials used in chemical equipment, food processing plants and the pharmaceutical industry.

④ High load and mining equipment:

Steel-core drive belts are able to withstand heavy loads on heavy equipment due to their high tensile strength, and excel in high-strength applications such as mining and metallurgy. Fiberglass materials, on the other hand, are suitable for use in some light industrial equipment in high-torque, sustained-load operations, providing good tensile strength and durability.

Each material has its own specific advantages and disadvantages, and choosing the right material for the operating conditions of the equipment will effectively improve the service life and transmission efficiency of the drive belt. Therefore, in the scientific selection of materials, we provide a reliable guarantee for the long-term stable operation of equipment.

5. Special needs and application cases in different industries

Different industries have different needs for drive belts, and specific application scenarios also put forward different requirements for the characteristics of drive belts. Whether it is high load, precision control, or corrosion resistant, high temperature applications, different industries have unique standards and specifications for the performance of drive belts. Understanding the specific needs and success stories of different industries will help you make more targeted decisions during equipment selection and optimization.

① Food processing industry

Strict hygiene standards in the food processing industry place high demands on drive belts. In this sector, drive belts are not only required to transmit power, but also to ensure that there is no contamination of the food. Food-grade drive belts are typically constructed of chemical-resistant polyurethane or Viton materials that are capable of maintaining stable operation in wet and high humidity environments. These drive belts are designed with ease of cleaning and antimicrobial properties in mind to ensure compliance with the high hygiene standards of the food industry.

② Mining and heavy industry

Equipment in the mining and heavy industry is often exposed to high loads and harsh working conditions. The use of steel core drive belts is key to meeting these challenges. Mining machinery must maintain high load carrying capacity and durability over long periods of operation, and the strength and abrasion resistance of steel core drive belts make them the ideal choice. These drive belts excel in heavy equipment, withstanding high loads in harsh environments while reducing maintenance frequency.

③ Textile industry

The high speeds of textile machinery make it essential for drive belts to be highly flexible and wear-resistant. Unlike other industries, drive belts in the textile industry need to be smooth and slip-free at high speeds. Nylon and polyurethane drive belts are ideal for textile equipment due to their lightweight, flexible design. These drive belts resist friction over long periods of time while maintaining precise drive performance at high speeds.

④ Logistics and automation

In modern logistics systems and automated production lines, drive belts are not only required to transfer materials quickly, but also to ensure precision and reliability. Synchronized drive belts excel in these highly efficient automation systems due to their ability to drive without slipping. By means of a precise gear structure, synchronous drive belts ensure the precise transfer of materials in automated warehousing and transportation systems and ensure efficient operation. The logistics industry’s demand for high precision and low error drives the widespread use of synchronous drive belts.

⑤ Pharmaceutical industry

Similar to the food industry, the pharmaceutical industry requires high hygiene standards for drive belts. Drive belts must be resistant to chemicals and used in a sterile environment. Drive belts made of polyurethane and PTFE are widely used in pharmaceutical equipment due to their chemical resistance and sterility. These drive belts ensure precise transmission while remaining clean and contamination-free in harsh production environments.

The need for drive belts varies from industry to industry, and the success of these applications is a testament to the importance of choosing the right drive belt. From food processing to pharmaceutical production, choosing the right drive belts for your equipment not only improves productivity, but also ensures long-term stability. As technology advances, the use of drive belts in various industries will become more widespread and specialized.

6. Considerations when purchasing

Selecting and purchasing the right drive belts is an important part of ensuring the stable operation of the equipment. In the procurement process, in addition to specifying the specific needs of the equipment, it is also important to consider various factors such as the supplier’s reputation, contract terms and potential hidden costs. These considerations not only help buyers avoid possible risks, but also ensure that the best transmission results in actual use.

① Define equipment requirements

Before purchasing drive belts, first of all, we should clarify the specific needs of the equipment, including the load that the drive belt needs to withstand, the operating speed, the working environment, etc., for details, see the above text. Different equipments have different performance requirements for drive belts. For example, high load equipment requires the use of steel wire core or other high-strength material drive belt, while high-speed operation of the system may be more suitable for the choice of synchronous belt. This link is crucial, and directly determines whether the drive belts purchased can meet the long-term needs of the equipment, and will even affect whether the mechanical equipment can be used normally.

② Supplier reputation

Choosing suppliers with good reputation can reduce the risk of procurement. In the first two years, due to the influence of COVID-19, many purchasers could not inspect the suppliers on the spot, so many purchasers were deeply hurt by the scammers in the previous years. However, the qualification of the supplier, the evaluation of past customers and the guarantee of the quality of the products they provide are all the elements that need to be emphasized when purchasing. Trusted suppliers not only provide high-quality drive belts, but also usually provide timely after-sales service to ensure that equipment problems can be quickly resolved. In addition, the examination of the supplier’s industry experience and technical support capabilities is also one of the important factors in the purchasing decision, and it is best to be able to personally visit the supplier’s factory, at least if the supplier’s goods have a problem, you will be able to know what his factory is located, and can find him through the location.

③ Contract terms

Purchasing contract is an important legal document to protect the rights and interests of buyers, in recent years, many people in order to minimize the trouble or due to the convenience of various countries for international trade, many orders have become by the PI instead of the contract, but the PI can not really replace the contract, so it is recommended to sign a formal contract as well. And the contract should be clear drive belts specifications, delivery date, price and after-sales service and other key terms. Particular attention should be paid to the fact that the contract should set out some after-sales terms of drive belts, so that in the event of product quality problems can be timely maintenance of rights and interests. Purchasers should also ensure that the terms of the contract is fair and reasonable, to avoid unnecessary trouble in the event of a dispute.

④ Hidden costs

When purchasing drive belts, not only should we pay attention to the initial purchase price of the product, we should also consider the hidden costs that may exist. Including the transportation and installation costs of drive belts, as well as future maintenance and replacement costs, are important expenses that may be overlooked, especially rubber products, if only a small number of purchases may not be very obvious shipping costs, but along with the more quantities, the weight data of the rubber products will be in the form of unexpected. If a poor quality drive belt is selected, the frequency of subsequent maintenance and replacement will increase, bringing unnecessary additional burden to the enterprise. Therefore, the procurement should be comprehensive consideration of the cost-effectiveness of the product, to avoid higher late costs due to greed for cheaper.

⑤ Supply cycle and inventory

For some equipment that requires long-term operation, timely delivery and adequate inventory is an important factor to ensure smooth production. Buyers in the purchase of drive belts, should be communicated with the supplier supply cycle, to ensure that in need of rapid access to the required drive belts. In addition, the supplier’s inventory capacity also affects the company’s response time when it comes to equipment maintenance. Especially in emergency situations, timely delivery can effectively reduce production downtime.

⑥ Counterfeit products

There are a large number of counterfeit drive belts on the market, which often attract buyers with low prices, but the quality cannot be guaranteed. Buyers should be wary of underpriced products when purchasing, especially if the difference between the price of the product and the average market price is too large, they must carefully consider its authenticity. In order to avoid purchasing counterfeit products, buyers can ask suppliers to provide relevant quality certifications and test reports, and purchase through regular channels.

⑦ Technical support and training

In international trade, it is especially important to establish technical support and training services with suppliers, especially when purchasing key components such as drive belts, technical support can significantly improve the efficiency of equipment operation. But we are here to talk about technical support, not only for the buyer in the use of the process may encounter problems to answer, but also to provide for the user’s daily use of the product process needs to be used, including product maintenance and other advice, as much as possible to improve the use of the product cycle.

During the procurement process, buyers should consider various factors such as equipment requirements, supplier reputation, contract terms and hidden costs to ensure that the drive belts purchased can meet the operational requirements of the equipment and have a high cost-effective. By choosing the right suppliers and products, companies can reduce the maintenance and downtime brought about by improper procurement, thus ensuring the long-term stable operation of the equipment.

7. Drive Belt Installation and Maintenance Guidelines

Even if the right drive belts are selected, errors in installation or maintenance can lead to reduced efficiency of the equipment, premature wear of the drive belts or system failure. Therefore, proper installation and routine maintenance are key factors in ensuring the longevity of your drive belts. The following is a detailed guide to the installation and maintenance of drive belts to help keep your equipment running efficiently for a long time. This is only for regular products, please contact the company for details of special specifications.

① Proper Tension Adjustment

The tension of a drive belt has a direct impact on its performance and life. Too much or too little tension can lead to premature wear of the belt and a reduction in drive efficiency. drive belts must be installed with proper tension adjustment. Overly tight drive belts increase friction and lead to increased wear between the belt and the pulley, while overly loose belts tend to slip and reduce transmission efficiency. Therefore, a tension meter can be used during installation to ensure that the drive belt tension is in the correct range.

Tension adjustments should be checked periodically, as prolonged use may cause the drive belt to slacken. When the drive belt slips or makes noise, it is usually a sign of insufficient tension, which should be adjusted immediately. Proper tension not only extends the life of the drive belts, but also ensures stable operation of the equipment.

② Importance of alignment

In order to avoid excessive wear on the edges of the drive belts, the alignment between the drive belts and the pulleys must be precise. A drive system that is not aligned causes the belt to tilt during operation, which increases wear and shortens its service life. To ensure that drive belts are aligned correctly, it is recommended that specialized tools be used to ensure that the drive belt is parallel to the pulleys.

Alignment problems not only affect the life of the drive belt, but also reduce the efficiency of the entire drive train. An unaligned driveline increases the energy consumption of the equipment and can lead to unwanted noise and vibration. Therefore, checking the alignment of the driveline on a regular basis is a part of maintenance that should not be overlooked.

③ Routine maintenance and inspection

In order to extend the service life of drive belts, regular maintenance and inspection is essential. Drive belts should be inspected regularly for signs of wear, cracks or other damage during use. At the first sign of any abnormality, drive belts should be replaced immediately to prevent system failure.

Routine maintenance should also include cleaning the drive belt to prevent the buildup of dust, oil and other contaminants and to avoid damage to the friction layer and core of the drive belt. In addition, the friction layer between the drive belt and pulley should be kept dry during use to prevent transmission efficiency from being reduced due to slippage.

For high-precision drive belts such as multi-wedge belts and synchronous belts, more detailed inspection is required. Especially for synchronous belts, if there is a problem with the meshing between the gears, it may lead to poor transmission, and in serious cases, it may even cause equipment shutdown. Regularly checking the wear and tear of the drive system can detect potential problems in advance and take timely measures to avoid more serious equipment failures.

④ Drive belt replacement and storage

Drive belts wear out over time, even with good maintenance, so replacing them is an unavoidable part of routine maintenance. When replacing, must use with the original equipment to match the model and specifications of the drive belts, to ensure that the transmission effect and stability of the equipment, so for the supplier of the drive belt if not necessary, usually not recommended to change, if the previous supplier for what reason you have to change, in your replacement of the new supplier, make sure to require parameters, materials and so on must be.

In addition, the storage conditions of the drive belts are equally important. Unused drive belts should be stored in a cool, dry environment, avoiding direct sunlight and high temperature and humidity. Drive belts should avoid contact with grease, chemicals or other corrosive substances during storage to prevent material deterioration.

⑤ Regular inspection and record

In order to ensure the long-term efficient operation of the drive belt, it is necessary to establish detailed maintenance records. Each maintenance and inspection job should record the use, wear and tension adjustment of the drive belt. This data helps to predict belt replacement intervals and allows for timely adjustments to the maintenance program based on the equipment’s operating conditions.

By establishing a regular maintenance and inspection process, companies can effectively reduce equipment downtime and minimize production interruptions due to drive belt failures. Recorded data can also help technicians understand the overall health of the drivetrain and perform preventive maintenance as appropriate to avoid sudden equipment failure.

By following these installation and maintenance guidelines, you can significantly extend the life of your drive belts and ensure consistent driveline operation. Correct tensioning, alignment checks and routine maintenance are key to the efficient operation of the equipment, while regular replacement and proper storage of the drive belts are also important measures to extend their service life. A standardized maintenance process not only reduces downtime, but also lowers long-term operating costs.

8. Criticality and importance of after-sales service for Drive Belts

The stability and service life of the drive belts in use play a key role in the efficiency of the entire production system. Choosing the right drive belts is the first step to ensure the smooth operation of the equipment, while a strong after-sales service guarantees the long-term maintenance of the equipment and the continuous operation of the drive belts. Whether it is installation guidance, maintenance services, or product customization, a comprehensive after-sales service system can significantly reduce equipment downtime and ensure the normal operation of enterprises.

① Importance of warranty and guarantee period

When purchasing drive belts, buyers should pay special attention to the warranty and guarantee terms. These terms usually specify the warranty period for the drive belts under certain conditions of use. The length of the warranty period is not only a measure of product quality, but also an important reference in managing maintenance costs.

Drive belts with reasonable warranty period can help enterprises reduce the risk of accidental damage, and in the event of quality problems, enterprises can obtain free repair or replacement services through after-sales service. For long-term high-load operation of the equipment, these terms are extremely important protection measures.

② Installation guidance and technical support

In many cases, the correct installation of drive belts requires specialized technical support. The supplier should provide detailed installation instructions and technical consulting services to ensure that the drive belts are used correctly in the equipment. Improper installation can lead to early wear, slippage or even breakage of the drive belt, so technical support from the supplier is essential to ensure that the drive system works properly.

Technical support is not limited to the installation phase, but should also cover technical consulting services during the operation of the equipment. The supplier should answer any problems encountered by the buyer in a timely manner, especially in the event of abnormal wear and tear or other problems with the drive belt, and be able to provide appropriate solutions.

③ Maintenance and replacement services

As wearing parts, drive belts need to be maintained and replaced regularly. A well-developed after-sales service system should provide regular maintenance and inspection services to ensure that the transmission system of the equipment is always in the best working condition. The supplier should have the ability to provide replacement service to the customer when necessary, especially for some special models or customized drive belts, timely supply and replacement service is especially important.

Maintenance services focus on preventing potential problems and reducing the likelihood of equipment downtime by regularly checking and adjusting the tension, alignment and wear of drive belts. For high-precision drive belts such as multi-wedge belts and synchronous belts, the maintenance requirements are even higher and the supplier should have the appropriate technical expertise.

④ Customized solutions

With the development of production technology, the needs of enterprises for drive belts are constantly changing. Suppliers should be able to provide customized drive belts solutions according to customers’ special needs. Different types of equipment or specific production environments may require special materials or designs of drive belts, and suppliers should have the ability to customize their products to ensure that the drive belts are perfectly matched to the operational needs of the equipment.

Customized services can not only improve the efficiency of the equipment, but also according to the customer’s specific application scenarios, to provide suitable for the special conditions of the drive belt, thus helping companies to optimize the production process and reduce long-term operating costs.

⑤ Preventive maintenance program

Preventive maintenance is a key service that helps companies anticipate potential equipment problems and avoid sudden breakdowns. By working with a supplier, companies can develop a detailed preventive maintenance program to inspect and evaluate drive belts on a regular basis. The program typically includes tension adjustments, alignment checks and regular monitoring of drive belt wear.

Preventive maintenance helps to extend the service life of drive belts, avoiding unnecessary downtime and saving the company significant repair costs. This service is particularly suited to high-intensity operating environments and ensures that the equipment remains in optimum condition during extended periods of operation.

9. Frequently Asked Questions (FAQs) about Drive Belts Procurement

When purchasing and using drive belts, technical questions are often encountered. To help customers better select and use drive belts, the following are frequently asked questions and solutions about drive belts.

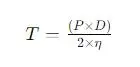

Calculation of drive belt tension needs to take into account the load, torque, speed and friction of the equipment. You can refer to the following formula for calculation:

T represents the drive belt tension (in Newtons), and

P is the required power in watts or kilowatts, and

D is the diameter of the drive pulley in meters.

η is the efficiency of the system, usually between 0.9 – 0.98.

With this formula you can calculate the theoretical tension, but at the same time measure it on site with a tool such as a tensiometer to ensure that it meets the requirements of the equipment.

Improperly aligned drive belts can accelerate edge wear and lead to reduced efficiency. To optimize alignment, it is recommended to use a laser alignment tool to ensure that the angle of the drive belt to the pulley remains accurate. Regularly checking alignment can effectively reduce drive belt deflection and unnecessary wear, thus increasing the life of the drive belt and the transmission efficiency of the equipment.

High speed rotation will cause vibration of the drive belt, which will reduce the transmission efficiency. To minimize vibration problems, choose a higher tension drive belt material and make sure the pulleys are round and balanced. Insufficient belt tension or high pulley eccentricity can cause system vibration. Regularly check drive belt tension and replace worn or deformed drive belts as necessary to maintain smooth operation.

The choice of drive belt material is particularly important in extreme temperature conditions. At high temperatures, silicone or Teflon coated belts offer excellent heat resistance; at lower temperatures, polyurethane and cold resistant rubber are good choices. By choosing the right material for your equipment’s operating temperature range, you can ensure stable and efficient operation in extreme environments.

The service life of a drive belt depends not only on the operating conditions of the equipment, but also on the material of the belt and how it is maintained. By using a preventive maintenance strategy and regularly checking wear conditions, companies can anticipate when drive belts should be replaced. By using monitoring tools to record tension changes, wear levels and fatigue points, you can better control the condition of your belts and avoid costly equipment downtime.

10. Summary

Drive belts may not get as much attention as other components in the operation of industrial equipment, but they are certainly a key force in keeping the system running smoothly. With the right drive belts, equipment is like a reliable “engine” that is not only more efficient, but also much more stable.

For the unique needs of each industry, drive belts have their own application scenarios. Whether it’s dealing with extreme temperatures or high speed rotating loads, choosing the right material and type is key to keeping your equipment running. And those who are concerned about the long-term stability of their equipment can keep their drive belts working long and efficiently with regular maintenance and adjustments, reducing downtime due to malfunctions.

When you’re sourcing drive belts, finding a reliable supplier is like finding a dependable ally. Not only can they help you meet your immediate challenges, but they can also provide ongoing support for the future operation of your equipment. Whether it’s a customized solution or a long-term relationship, make sure your production line is always in tip-top shape.

Drive belts, though seemingly simple, are a vital part of keeping the entire industrial world moving at high speed. Use them well, maintain them well, and the productivity of your business will naturally follow.