This article explains how to vulcanize a conveyor belt by comparing two fundamentally different roles: rubber conveyor belt manufacturers and service providers. It breaks down full-belt factory vulcanization versus on-site hot splice vulcanization, clarifying process steps, time requirements, structural risks, and why splicing demands far higher process stability than factory curing in real industrial applications.

1. Introduction

Previously, I wrote an article about single conveyor belt vulcanization, in which I explained the vulcanization principle and the conveyor belt vulcanizing process in detail. This time, we will analyze conveyor belt vulcanization from the perspectives of a rubber conveyor belt manufacturer and a rubber conveyor belt service provider. These two roles adopt completely different approaches when dealing with rubber conveyor belt vulcanization.

Tiantie Industrial, as one of the top 10 conveyor belt manufacturers in China, vulcanizes entire conveyor belts during production. Therefore, our equipment and process flow are highly standardized and repeatable.

In contrast, professional service providers mainly focus on splicing conveyor belts by vulcanization between two long belts. They must develop customized strategies based on parameters such as belt thickness, number of fabric plies, and other technical specifications.

Next, we will examine how to vulcanize a conveyor belt from both perspectives. You can click the content table on the left to select your role and jump directly to the section you are interested in.

2. What Is Conveyor Belt Vulcanization?

Simply put, vulcanization uses a heated press that applies sufficient pressure and temperature according to the belt’s technical requirements. Through high temperature and high pressure, the “raw rubber” of the conveyor belt is transformed into “cured rubber.” This fundamental principle is the same for both manufacturers and service providers.

3. How to Vulcanize a Conveyor Belt in a Rubber Conveyor Belt Factory?

In this section, we list the vulcanization steps from a rubber conveyor belt manufacturer’s perspective.

Using Tiantie Industrial’s factory as an example: before vulcanization, we have already completed all processes including rubber mixing, calendering, and forming. Additionally, we use a 12-meter double-layer vulcanizing press. As a result, our vulcanization process and considerations are more complex than those of many other companies, but the advantage is significantly higher production efficiency.

Below, I will break down our conveyor belt vulcanization process step by step, starting from heating up the vulcanizing press:

- Step 1: Start the conveyor belt vulcanizing press and heat it to the production line’s target temperature, typically 140–160 °C.

- Step 2: Place two conveyor belts onto the production line and spread the belt surfaces flat at the same time.

- Step 3: Apply a silicone-based mold release agent to the belt surface. This is a very important step.

Tip: During vulcanization, rubber conveyor belts are typically processed at 145–155 °C and 1.5–3.0 MPa. At this stage, rubber exhibits high fluidity and tackiness. The silicone-based mold release agent forms an ultra-low surface energy separation film on the metal surface.

![]()

- Step 4: After completing the previous steps, the belt is ready for vulcanization. The vulcanization time is generally 15–20 minutes, depending on rubber properties, belt thickness, and other factors.

- Step 5: Once vulcanization is complete, the conveyor belt is pulled out by traction and then cooled. Currently, air cooling provides the best efficiency.

- Step 6: After cooling, conduct an initial surface inspection of the rubber conveyor belt to ensure product quality, checking for issues such as haze that may affect appearance.

- Step 7 – Moulded Edge Conveyor Belt: After cooling, because rubber flows during vulcanization, excess material overflows from the mold edges. Manual trimming is required to remove the excess rubber.

- Step 8 – Cut Edge Conveyor Belt: For cut-edge conveyor belts, no manual edge trimming is required. Before winding, the belt is sent directly into the edge-cutting machine and cut to the customer’s required width.

The above steps represent a comprehensive manufacturer’s perspective on how to vulcanize a conveyor belt. If you are preparing to start production or are learning the process, this can serve as an important reference.

4. How to Vulcanize a Conveyor Belt as a Service Provider?

Next, we look at vulcanization from the service provider’s perspective. As mentioned earlier, service providers do not vulcanize complete conveyor belts like manufacturers. Instead, their primary task is to achieve belt joints through vulcanization.

For many customers—whether end users or distributors—ocean shipping presents a major challenge. Due to container size limitations, it is impossible to ship a 2,000-meter conveyor belt in one piece. The belt must be divided into rolls of 200–300 meters. However, if the production line is 1,000 meters long, how can this be resolved?

The answer is conveyor belt vulcanized splicing, allowing the belt to run continuously on the production line.

How is this done? Here, we use the most common EP conveyor belt as an example:

- Step 1: Strip the cover rubber and fabric layers from both belt ends to be spliced, forming stepped joint surfaces. The two belt ends are aligned symmetrically along the center-line.

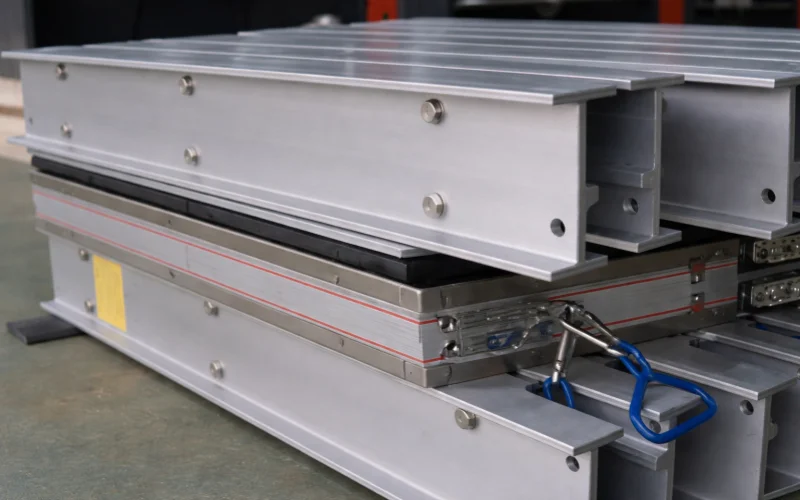

- Step 2: Due to site limitations, a portable small vulcanizing press is used. The service provider selects an appropriate vulcanization machine based on belt width.

- Step 3: Grind the stripped areas using an angle grinder or abrasive wheel. This step is difficult because the surface must be uniform without grinding through the fabric layers.

- Step 4: Apply bonding cement to the splicing surfaces, with at least two coats. The first coat allows penetration, and the second coat forms a surface film.

- Step 5: Align each fabric ply carefully and roll to expel trapped air. This is similar to the forming stage in manufacturing. If air is not removed, bulging may occur at the joint after vulcanization.

- Step 6: Lay the splice rubber and ensure proper filling of edge rubber.

- Step 7: Apply a silicone-based mold release agent, following the same principle as factory vulcanization, and then lay PTFE-coated fiberglass fabric.

- Step 8: Install the vulcanizing press. Portable presses are modular to accommodate different splice lengths and belt widths. Because belt joints are cut at an angle, many portable presses are installed diagonally.

- Step 9: After installation, set the pressure and temperature according to the belt’s manufacturing specifications. Professional rubber conveyor belt service providers can deliver complete and reliable service at this stage.

- Step 10: Unlike factory vulcanization, portable press splicing requires pressure holding after the target temperature is reached. After vulcanization, the press cannot be removed immediately; it must cool down gradually before demolding and removing the PTFE-coated fiberglass fabric.

The above outlines the vulcanization process from a service provider’s perspective. This approach is clearly more complex than the manufacturer’s process. As mentioned in my previous article How to Splice Conveyor Belt, hot vulcanized splicing alone can take up to one hour, including heating, pressure holding, and cooling. If you count from the initial cutting step, the total time far exceeds one hour. Among some distributors and service providers we work with, it is common for a single belt splice to take 3–4 hours. Belt thickness, tensile strength, and other factors all affect the final vulcanization outcome. Moreover, rework opportunities are extremely limited—each failure costs end users additional time and money.

Tip: Here, vulcanization time strictly refers to the heating, holding, and cooling cycle, while the total splicing operation includes preparation and setup.

5. Conclusion

When discussing how to vulcanize a conveyor belt, the determining factor is not merely whether vulcanization occurs in a factory or on-site, but more importantly, the purpose of the vulcanization.

For rubber conveyor belt manufacturers, vulcanization is an essential step in the production process. Its purpose is to transform the entire belt from raw rubber into a finished product. Therefore, factory vulcanization typically relies on large fixed equipment, constant pressure, repeatable vulcanization cycles, and appropriate temperatures to vulcanize the entire belt, ensuring consistent quality and high production efficiency.

For rubber conveyor belt service providers, the primary purpose of vulcanization is to achieve belt splicing. In this case, the object of vulcanization is a finished conveyor belt, and the parameters must be adjusted according to belt thickness, number of fabric plies, strength rating, and site conditions. As a result, hot vulcanized splicing must include heating, pressure holding, and a complete cooling process. A single splice vulcanization cycle can take around one hour, while the entire splicing operation often requires several hours.

6.FAQ

FAQ 1: Why does splice vulcanization require higher process stability than factory vulcanization?

Because splice vulcanization essentially rebuilds a new load-bearing structure. In full belt production, vulcanization acts on a continuous formed structure. In splice vulcanization, it must simultaneously achieve rubber crosslinking, interlayer bonding, and load redistribution. This combination significantly increases sensitivity to temperature uniformity, pressure distribution, and cooling control.

FAQ 2: Why can portable vulcanizing presses not fully replicate factory vulcanization results?

The limitation lies not in achievable temperature, but in the ability to maintain stable process conditions over time. Factory vulcanization relies on large, fixed systems with uniform pressure distribution, while portable presses must be repeatedly assembled under varying belt widths, splice lengths, and site conditions. This structural difference inherently affects pressure uniformity and thermal stability.

FAQ 3: Why is pre-treatment quality often more critical than vulcanization time in splice joints?

Because vulcanization can only cure an existing structure—it cannot repair structural defects. If issues exist during stripping, grinding, cement application, or air removal, even perfect vulcanization parameters cannot prevent weak interfaces within the joint. This is why splice failures often manifest as interlayer separation rather than overall tensile breakage.

FAQ 4: Why must vulcanization parameters in splice areas be set around “structure” rather than “material”?

In splice vulcanization, the process window is determined not by rubber formulation alone, but by the geometry of the splice structure. Step length, overlap configuration, and local thickness variations all affect heat transfer and stress distribution. Setting parameters solely based on material properties can easily result in non-uniform vulcanization at the splice.

FAQ 5: Why do splice vulcanization failures often appear as “delayed issues”?

Because most splice failures are structural rather than immediate breakages. After vulcanization, the splice may initially exhibit sufficient apparent strength, but under continuous load, thermal cycling, or impact, internal weak interfaces gradually propagate, eventually leading to separation or tearing. This is why splice quality often must be verified through actual operating time.