PVC Conveyor Belt Manufacturer

Tiantie Industrial PVC Conveyor Belt

With a legacy rooted in industrial craftsmanship since 2003, we’ve been at the forefront of light-duty conveying solutions. Our commitment to innovation shines through in our latest development – the Tiantie PVC Conveyor Belt Series, a fusion of durability and flexibility designed for modern industries.

Step into the future of material handling with our PVC belt range, meticulously engineered to enhance every process. Whether you’re in food processing or packaging logistics, our conveyor belts are your reliable partner. With over two decades of expertise, Tiantie Industrial delivers dependable quality and forward-thinking design trusted by factories worldwide.

Learn about our PVC Conveyor Belt

Designed for light-duty conveying in packaging, logistics, and food industries, this series combines reinforced fabric layers with precision PVC coatings for stable tracking and long-lasting integrity. Each belt is engineered for clean, reliable operation under continuous load, ensuring efficiency where consistency matters most.

With customizable cover compounds and excellent bonding strength, Tiantie’s PVC conveyor belts adapt to every working condition — from oil-resistant and anti-slip surfaces to abrasion or anti-static options. Backed by over two decades of manufacturing expertise, we build belts for real-world reliability, delivering durability and quality trusted by factories worldwide.

How Do Tiantie’s PVC Conveyor Belts Ensure Clean Operation?

Hygiene is critical in industries like food processing and pharmaceuticals. Tiantie’s PVC belts feature smooth, non-porous surfaces that prevent residue buildup and allow quick, water-based cleaning. This design minimizes bacterial growth and shortens downtime between production shifts — keeping your operation compliant and efficient.

PVC Conveyor Belt Key Features

Durable Construction

Tiantie’s PVC conveyor belts are built with robust multi-layer construction to handle long hours of continuous operation. Each belt is produced with uniform thickness and strong adhesion, ensuring stable performance under light-duty yet demanding conditions.

Flexible and Lightweight

Our PVC conveyor belts combine flexibility with dimensional stability. They run quietly, track precisely, and minimize pulley stress — making them ideal for compact conveyors and systems with frequent starts and stops.

Clean and Hygienic Design

Designed for hygiene-sensitive industries, our PVC belts have a non-porous structure that prevents residue buildup and allows quick water-based cleaning. This feature supports food safety compliance and efficient shift-to-shift operation.

Custom Surface Options

Different materials require different surfaces. Tiantie offers smooth, matte, or textured finishes — from anti-slip coatings for incline transport to glossy, easy-clean types for food and packaging lines. Each surface is designed to suit its specific application.

Oil and Chemical Resistance

For environments exposed to oils, lubricants, or mild chemicals, Tiantie provides optional resistant cover compounds. These prevent swelling, softening, and delamination, ensuring longer belt life and reduced maintenance costs.

Reliable Performance in All Conditions

Whether operating in humid warehouses, temperature-controlled plants, or outdoor logistics centers, Tiantie’s PVC conveyor belts maintain consistent grip and strength. They are engineered for stability, ensuring dependable conveying day after day.

Do Tiantie’s PVC Conveyor Belts Handle Moisture and Cleaning?

Moisture, oil mist, and frequent cleaning cycles often cause belt deformation or slippage in light-duty conveying lines. Tiantie’s PVC conveyor belts feature a non-porous surface that resists water absorption and layer swelling, keeping the belt stable even after repeated washing or humid exposure.

Our PVC belts are ideal for food, packaging, and pharmaceutical facilities where hygiene is critical. The smooth, easy-clean design prevents residue buildup and allows quick water-based cleaning without affecting surface quality — ensuring consistent performance, faster turnaround, and longer belt life.

PVC Conveyor Belt Datasheet

| No. | Type No. | Top Cover Color | Total Thickness (mm): | Top Cover Thickness (mm): | Weight (kg/m³): | Top Cover Hardness (ShoreA): | Breaking Load (N/mm): | 1% Elongation Strength | Minimum Pulley Dia.: | Contact Temperature Range (℃): | Max Production Width(mm): |

| Lohistics & Post | |||||||||||

| 1 | P25-14A | Green | 2 | 0.5 | 2.3 | 80 | 150 | 11 | 25 | -10/80 | 3000 |

| 2 | P25-15A | Green | 3 | 1 | 3.4 | 80 | 160 | 12 | 50 | -10/80 | 3000 |

| 3 | P22-37IHD | Nature Color | 2.5 | / | 2.9 | / | 150 | 10 | 40 | -10/80 | 3000 |

| 4 | P22-16/27-1 | Green | 5 | 3.3 | 4.1 | 60 | 160 | 11 | 90 | -10/80 | 3000 |

| 5 | P22-86/19D | Blue | 3.1 | 1.4 | 3.3 | 60 | 160 | 11 | 60 | -10/80 | 2000 |

| 6 | P32-14/1A | Green | 4 | 1.2 | 4.5 | 80 | 230 | 16 | 110 | -10/80 | 3000 |

| 7 | P32-74/OA | Dark Blue-Green | 4 | 0.9 | 4.6 | 80 | 240 | 17 | 110 | -10/80 | 3000 |

| 8 | P32-36H | Black | 7 | 3.3 | 8.4 | 80 | 260 | 18 | 200 | -10/80 | 3000 |

| 9 | P22-76/30D | Dark Blue-Green | 5 | 3.1 | 5.4 | 60 | 160 | 12 | 90 | -10/80 | 2000 |

| 10 | P22-74/24HDA | Dark Blue-Green | 2.6 | 1.1 | 2.7 | 60 | 150 | 11 | 50 | -10/80 | 2000 |

| 11 | PVK100-37 | Black | 2.8 | / | 3.3 | / | 210 | 15 | 100 | -10/80 | 3000 |

| 12 | PVK100B-37 | Black | 3.2 | / | 3.5 | / | 250 | 20 | 110 | -10/80 | 3000 |

| 13 | PVK120-37 | Black | 3.8 | / | 4.5 | / | 270 | 22 | 110 | -10/80 | 3000 |

| 14 | PVK125-37 | Black | 4 | / | 4.7 | / | 290 | 22 | 115 | -10/80 | 3000 |

| 15 | PVK150-37 | Black | 4.5 | / | 5.2 | / | 300 | 23 | 120 | -10/80 | 3000 |

| 16 | PVK22-37 | Black | 4 | / | 4.7 | / | 250 | 20 | 100 | -10/80 | 3000 |

| Automobile tires & Puching | |||||||||||

| 1 | P42-44/26 | Grey | 5 | 1.2 | 5.8 | 80 | 320 | 22 | 230 | -10/80 | 3000 |

| 2 | P42-16/3A-1 | Green | 8.5 | 3.9 | 8.6 | 60 | 340 | 23 | 260 | -10/80 | 3000 |

| 3 | P22-76/3AH | Dark Blue-Green | 4.8 | 3.1 | 4.1 | 60 | 160 | 12 | 90 | -10/80 | 3000 |

| 4 | P32-56/26H | Red | 7.5 | 4.2 | 8.7 | 80 | 270 | 18 | 180 | -10/80 | 3000 |

| 5 | P32-14HA | Green | 4.5 | 1.2 | 5.3 | 80 | 260 | 17 | 130 | -10/80 | 3000 |

| 6 | P32-94A | Orange Yellow | 4 | 1 | 4.6 | 80 | 260 | 17 | 110 | -10/80 | 3000 |

| 7 | P32-07 | Nature Color | 3 | / | 3.4 | / | 230 | 16 | 60 | -10/80 | 3000 |

| 8 | P23-07H | Nature Color | 2.6 | / | 3.4 | / | 180 | 20 | 30 | -10/80 | 3000 |

| Airport transportation | |||||||||||

| 1 | P32-74/7 | Dark Blue-Green | 5 | 2 | 5.6 | 80 | 250 | 17 | 110 | -10/80 | 3000 |

| 2 | P32-04/0HY | Lucency | 4.9 | 1.5 | 5.8 | 80 | 250 | 18 | 110 | -10/80 | 3000 |

| 3 | P22-26/27 | White | 5 | 3.3 | 4.1 | 65 | 160 | 12 | 80 | -10/80 | 2000 |

| 4 | P22-06/28 | Lucency | 4.3 | 2.6 | 4.2 | 65 | 150 | 12 | 80 | -10/80 | 2000 |

| 5 | P22-56/3D | Red | 5 | 3.3 | 4.2 | 60 | 160 | 12 | 80 | -10/80 | 3000 |

| 6 | P22-96/3A | Orange Yellow | 5 | 3.3 | 4.2 | 60 | 160 | 12 | 80 | -10/90 | 3000 |

| 7 | P21-471Z | Grey | 2 | / | 2.2 | / | 150 | 10 | 40 | -10/90 | 3000 |

| 8 | P31-34AHUV | Black | 4.8 | 1.3 | 5.6 | 75 | 300 | 22 | 60 | -10/90 | 3000 |

| Treadmill belt | |||||||||||

| 1 | S25/7A | Black | 2.5 | 0.75 | 2.5 | 75 | 150 | 12 | 40 | -10/80 | 3000 |

| 2 | S23/29A | Black | 2.3 | 0.65 | 2.4 | 75 | 150 | 12 | 35 | -10/80 | 2000 |

| 3 | S20/29A | Black | 2 | 0.5 | 2.2 | 75 | 140 | 11 | 35 | -10/80 | 2000 |

| 4 | S18/7A | Black | 1.8 | 1 | 1.8 | 75 | 60 | 6 | 30 | -10/80 | 3000 |

| 5 | P25-34/1DA | Black | 2 | 0.5 | 2.1 | 75 | 140 | 11 | 35 | -10/80 | 3000 |

| Food processing | |||||||||||

| 1 | U22-24/0A | White | 1.6 | 0.35 | 1.9 | 90 | 170 | 12 | 30 | -10/40 | 2000 |

| 2 | U22-26/28A | White | 3.1 | 1.6 | 2.6 | 90 | 180 | 12 | 50 | -10/40 | 2000 |

| 3 | U12-14/26IA | Green | 1 | 0.5 | 1 | 90 | 80 | 7 | 25 | -10/40 | 2000 |

| 4 | U22-14/0A | Green | 1.6 | 0.35 | 19 | 90 | 170 | 12 | 30 | -10/40 | 2000 |

| 5 | U22-24/0HA | White | 2.5 | 0.8 | 3 | 90 | 180 | 12 | 40 | -10/40 | 2000 |

| 6 | P32-24NA | White | 4 | 0.9 | 4.7 | 65 | 260 | 18 | 110 | -10/80 | 3000 |

| 7 | P25-24NA | White | 2.5 | 0.8 | 2.9 | 65 | 160 | 12 | 50 | -10/80 | 3000 |

| 8 | UP22-04HA | Lucency | 3.8 | 1.8 | 4.5 | 90 | 200 | 16 | 60 | -20/80 | 2000 |

| 9 | P25-25N | White | 3 | 1 | 3.5 | 65 | 180 | 12 | 50 | -10/80 | 3000 |

| 10 | P33-07 | Nature Color | 3 | / | 3.4 | / | 100 | 12 | 50 | -10/80 | 3000 |

| Tobacco processing | |||||||||||

| 1 | P22-04YC | Lucency | 2.6 | 0.9 | 3.1 | 80 | 150 | 11 | 60 | -10/80 | 3000 |

| 2 | P25-05YCM120 | Lucency | 3.6 | 1.8 | 3.7 | 80 | 180 | 12 | 85 | -10/80 | 2000 |

| 3 | E12-04A | Lucency | 1.2 | 0.6 | 1.4 | 90 | 120 | 10 | 40 | -10/40 | 3000 |

| 4 | E20-05A | Lucency | 3 | 0.9 | 3.6 | 90 | 230 | 18 | 80 | -10/40 | 3000 |

| 5 | SU22-07A | Lucency | 1.7 | 0.2 | 2 | 40 | 190 | 20 | 40 | -30/110 | 2000 |

| 6 | U12-64/25A | Sandy Beige | 1.2 | 0.7 | 1.1 | 90 | 60 | 6 | 25 | -10/40 | 2000 |

| Antistatic belt | |||||||||||

| 1 | P25-15/21A0 | Green | 3 | 1 | 3.4 | 75 | 160 | 12 | 50 | -10/80 | 3000 |

| 2 | P25-44/21A | Grey | 2 | 0.5 | 2.3 | 75 | 180 | 12 | 25 | -10/80 | 3000 |

| 3 | P22-41/21A | Grey | 2.2 | 0.7 | 2.4 | 75 | 170 | 11 | 25 | -10/80 | 3000 |

| 4 | U22-34/21A0 | Black | 1.6 | 0.3 | 1.9 | / | 160 | 12 | 30 | -10/40 | 2000 |

| 5 | U12-37/I21 | Black | 0.5 | / | 0.5 | / | 70 | 7 | 15 | -10/80 | 2000 |

| 6 | U12-34/0A21 | Black | 1 | 0.5 | 1.1 | 90 | 80 | 8 | 20 | -10/40 | 2000 |

| 7 | P22-17II21 | Black | 1.8 | / | 2 | / | 160 | 11 | 25 | -10/80 | 3000 |

| 8 | U22-34/21A0I | Black | 1.6 | 0.3 | 1.9 | 90 | 160 | 12 | 30 | -10/80 | 2000 |

| Wood processing | |||||||||||

| 1 | P22-31/18 | Black | 6 | 3.5 | 4.8 | 80 | 160 | 12 | 110 | -10/80 | 2000 |

| 2 | P32-46/13 | Grey | 9 | 6 | 8 | 55 | 250 | 16 | 130 | -10/80 | 2000 |

| 3 | P49-76/25 | Dark Blue-Green | 9 | 2.6 | 10 | 80 | 900 | 100 | 500 | -10/80 | 2000 |

| 4 | P49-86/34 | Blue | 13 | 6.6 | 12 | 55 | 900 | 100 | 450 | -10/80 | 2000 |

| 5 | P32-36/13 | black | 9 | 5.8 | 8.2 | 50 | 260 | 16 | 130 | -10/80 | 2000 |

| 6 | P39-76 | Dark Blue-Green | 6 | 1.4 | 7.2 | 80 | 750 | 65 | 250 | -10/80 | 3000 |

| 7 | P32-16/27 | Green | 7 | 1.6 | 5.1 | 60 | 260 | 17 | 160 | -10/80 | 2000 |

| 8 | P39-76/23 | Dark Blue-Green | 10 | 2.3 | 8.2 | 55 | 760 | 70 | 200 | -10/80 | 2000 |

| Load and unload gate seal | |||||||||||

| 1 | P12-89/1 | Light Blue | 2 | 0.7 | 2.1 | 80 | 80 | 8 | 10 | -10/80 | 3000 |

| 2 | P32-49/00 | Grey | 5 | 0.9 | 5.8 | 80 | 250 | 18 | 110 | -10/80 | 3000 |

| 3 | P12-29/0 | White | 2 | 0.7 | 2.3 | 80 | 80 | 7 | 10 | -10/80 | 3000 |

| 4 | P22-89/0Y | Blue | 3 | 0.7 | 3.4 | 85 | 160 | 12 | 50 | -10/80 | 3000 |

| 5 | P22-38/26 | Black | 2.3 | 0.5 | 2.5 | 80 | 150 | 12 | 30 | -10/80 | 2000 |

| Special belts | |||||||||||

| 1 | P10-06/29 | Cream | 1.7 | 1.1 | 1.8 | 60 | 40 | 5 | 15 | -10/80 | 2000 |

| 2 | P13-26/4 | White | 2 | 1.5 | 1.9 | 60 | 40 | 5 | 15 | -10/80 | 2000 |

| 3 | MP12-24 | White | 3.2 | / | 3.1 | / | 100 | 10 | 30 | -10/80 | 2000 |

| 4 | MP22-14G | Black | 4.2 | / | 4.3 | / | 150 | 13 | 55 | -10/80 | 2000 |

| 5 | P22-15/0AC | Full Color | 3 | 1 | 3.4 | 80 | 160 | 12 | 50 | -10/80 | 3000 |

| 6 | P22-35/OA | Black Blue | 3 | 1 | 3.4 | 80 | 160 | 12 | 50 | -10/80 | 3000 |

PVC Conveyor Belt Solution

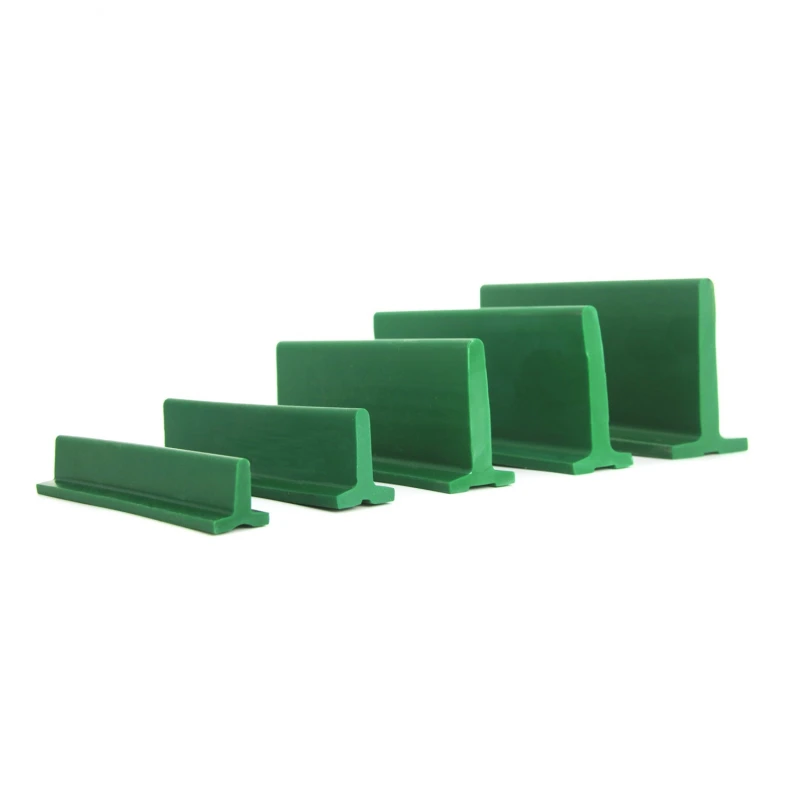

Versatile Joint Solutions

Not every PVC conveyor belt requires a fixed splice. Tiantie provides both heat-welded joints for continuous loops and mechanical fasteners for easy on-site assembly. Each option is selected to match belt strength, installation speed, and future maintenance convenience.

Dimensional Consistency

Each production batch is tightly controlled for uniform thickness, tensile strength, and flexibility. This consistency ensures stable belt tracking and easy interchangeability across multiple conveyor lines, improving operational reliability and reducing downtime.

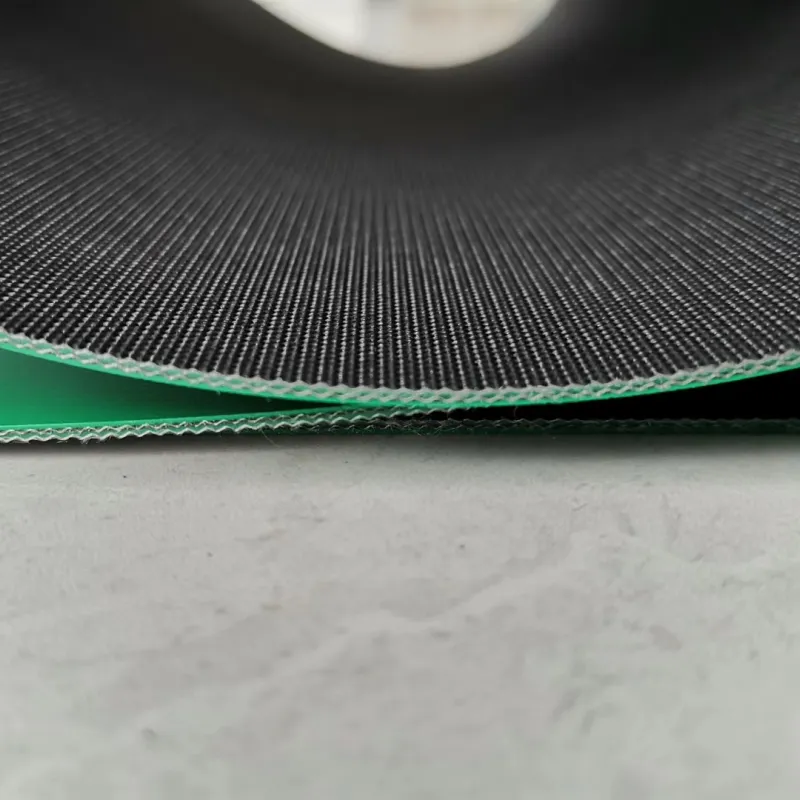

Controlled Friction Layers

Tiantie’s PVC belts use a dual-layer design: the drive side maintains high friction for secure torque transfer, while the running side has a low-friction finish that reduces drag on rollers or slider beds. This balance minimizes energy loss and surface wear.

Energy-Saving Operation

Lightweight carcass materials and low-drag surfaces reduce drive power requirements and heat buildup. Over time, this design lowers energy consumption and extends the lifespan of both the belt and the conveyor’s mechanical components.

PVC Conveyor Belt Usability and Performance

Our PVC conveyor belts are built for real factory conditions — easy to handle, highly visible, and made to last.

Can Tiantie’s PVC conveyor belts handle sharp or irregular materials?

Yes. The belt surface can be equipped with reinforced top layers or patterned profiles that prevent cuts and slipping when moving uneven or angular items, ensuring safe and steady transfer in complex material flows.

Are the belts resistant to color fading or surface wear?

Yes. Each PVC belt is manufactured with UV-stabilized and abrasion-protected coatings that retain color and texture even under strong lighting or extended operation. The surface stays uniform, preserving both appearance and function.

Are Tiantie’s PVC conveyor belts easy to align during installation?

Yes. The belt edges are precisely cut and finished to maintain straightness over long lengths. This simplifies alignment, reduces tracking adjustments, and helps achieve faster start-up during new system setups.

Do these belts perform well with lightweight packaging?

Absolutely. Tiantie’s PVC belts maintain smooth traction and prevent product shifting or rolling on the belt surface. This makes them ideal for carton handling, labeling, and precise packaging lines requiring consistent motion control.

Can the belts be used with metal detectors or weighing systems?

Definitely. Tiantie’s PVC conveyor belts can be produced with non-magnetic layers and controlled thickness tolerances, ensuring accurate readings for metal detection and check-weighing applications in food and logistics industries.

Do these belts support automated conveying systems?

Absolutely. Tiantie’s PVC conveyor belts integrate smoothly with sensors, diverters, and robotic pick-and-place systems. Their dimensional precision and stable motion ensure compatibility with automated equipment for modern smart factories.

Our PVC Conveyor Belts Are Built to Last

Smooth and Uniform Surface

Tear-Resistant Fabric Core

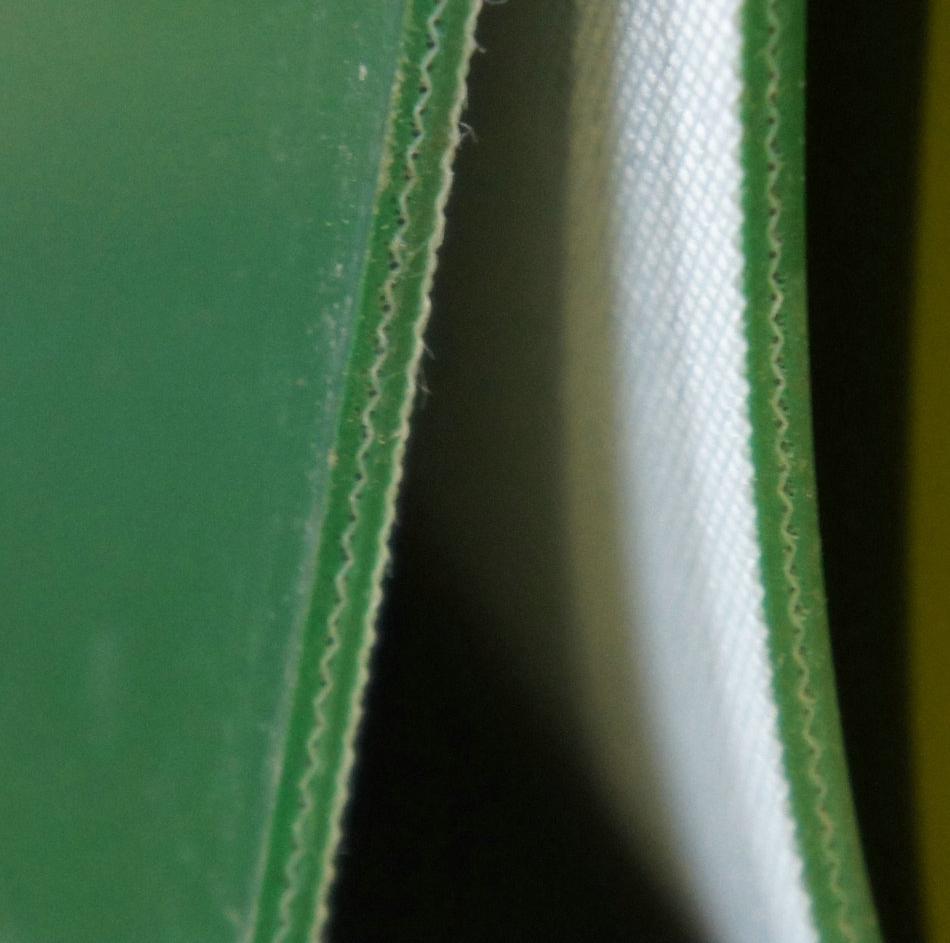

Precision Edge Processing

Surface Tuned for Real Work

Tiantie doesn’t just aim for laboratory perfection — we build for real working conditions. Each PVC coating is balanced between hardness and flexibility, keeping the surface smooth and preventing buildup or cracking. The result is clean, reliable conveying through long production hours.

Edge Strength Under Motion

Each belt edge is precision-cut and processed to endure continuous flexing, vibration, and directional change. The reinforced bond resists separation or distortion during long-term use, maintaining alignment and extending belt lifespan under demanding production cycles.

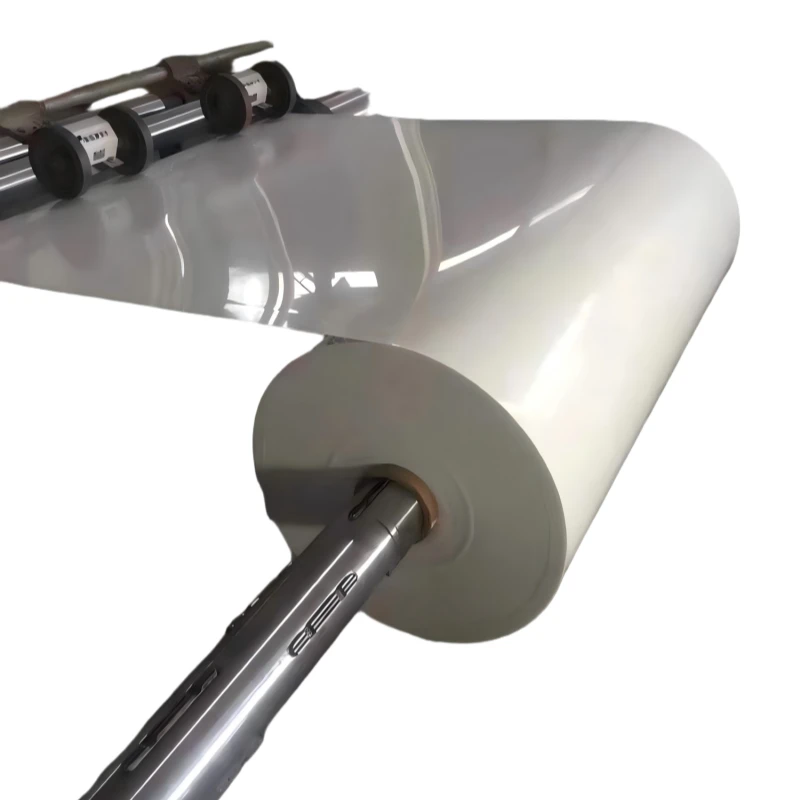

Fabric Specification That Delivers Strength

The reinforcement fabric forms the structural core of every belt. Tiantie selects polyester layers with optimized weave density and thermal stability, producing consistent tensile strength and minimal elongation. This balance ensures precise tracking and dependable motion across continuous lines.

Dimensional Stability Within Working Limits

Within the designed tension and load range, Tiantie’s PVC conveyor belts retain geometric accuracy and internal balance. Controlled layer lamination and cooling reduce stress concentration, preventing curl or warping while ensuring consistent operation across varied systems.

Accurate Belt Quality Monitoring

Precision Quality Tracking for Your Line

Accurate Production Metrics:

Monitor thickness, bonding, and elongation to ensure consistent performance every shift, reliably.

Holistic Performance Insights:

Review tracking, wear, and tension trends to schedule maintenance before issues arise.

PVC Conveyor Belt Reliability Assured

Produced through precise extrusion and lamination, Tiantie PVC conveyor belts deliver consistent quality and dependable performance in every order.

Controlled Production Process

Each PVC conveyor belt is produced with precise temperature and speed control during extrusion and lamination. This process guarantees smooth surface formation, stable coating adhesion, and consistent belt thickness across the entire width.

Surface and Thickness Accuracy

Continuous online measurement monitors coating uniformity and total thickness in real time. This ensures each belt roll remains within strict dimensional tolerance, providing predictable behavior and easy installation during replacement.

Uniform Fabric Alignment

The polyester fabric is tensioned and guided before lamination to ensure even alignment. This prevents surface waves or edge deviation, allowing the finished belt to track smoothly and maintain reliable performance in daily operation.

Reliable Production and Supply

Tiantie’s structured production planning and quality trace system ensure repeatable results for every batch. From small custom runs to bulk orders, every PVC conveyor belt is delivered on schedule and to the same verified specifications.

PVC Conveyor Belt Custom Solutions

Enhance your conveying efficiency with Tiantie’s customized PVC belt options. Tailor key parameters to your operation — including belt width, thickness, surface texture, and fabric structure — each designed for reliable performance in specific working environments.

Embrace precision that fits your system perfectly. From incline-resistant surfaces to antistatic and food-grade finishes, Tiantie builds every belt to match your process needs and maintain consistent quality across every run.

Request A Free Quote

We'd like to work with you

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 12 hours .