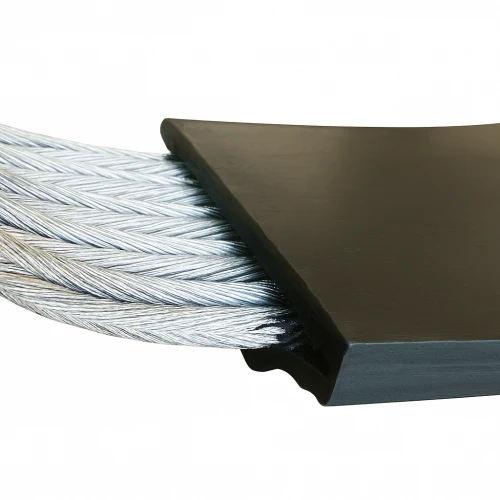

Rough Top Conveyor Belt

Rough Conveyor Belt is designed for the transportation of light materials such as bags, boxes and parcels at an inclined angle of up to 35 degrees.The upper rubber surface of the belt is made of abrasion-resistant, non-slip rubber, which provides cushioning, vibration damping and stabilization of the material being transported, and is particularly good at non-slip performance, ensuring safety and stability during transport.

Details

Usage:

Rough Conveyor Belt is suitable for the transportation of light materials at an inclined angle, such as bags, boxes, parcels and so on.Thisconveyor belt is mainly used in logistics, express delivery, warehousing, food processing and other industries that require non-slip performance, especially in slopes or inclined transportation environments.especially in slopes or inclined transportation environments.

Product Features:

- ANTI-SLIP DESIGN: The rough upper rubber surface increases friction and ensures that the material does not slide during conveyance.

- Excellent abrasion resistance: The upper rubber layer is made of abrasion-resistant material, which can withstand long time use and heavy friction.The upper rubber layer is made of abrasion-resistant material, which can withstand long time use and heavy friction.

- Cushioning and shock-absorbing function: The design of the conveyor belt can effectively absorb the impact of the material transportation process, protecting the material and the conveyor belt itself.The design of the conveyor belt can effectively absorb the impact of the material transportation process, protecting the material and the conveyor belt itself.

- High Stability: Provides excellent anti-slip and anti-shock functions to ensure that the material remains stable during transportation atLightweight and flexible: Suitable for the transportation of various lightweight materials, especially suitable for the scenarios where the material is transported at an inclined angle.

- Lightweight and flexible: Suitable for the transportation of various lightweight materials, especially suitable for the scenarios whereSuitable for the transportation of various lightweight materials, especially suitable for the scenarios where materials need to be changed frequently.

Suitable for the environment.

- Logistics and warehousing industry: for the transportation of parcels, boxes and other materials on inclined conveyor systems.

- Food processing industry: Ideal for the transportation of lightweight materials such as food boxes, bags of food, etc.

- Courier and distribution centers: Ensure safe and fast transfer of parcels and boxes in automated sorting systems.

Application Advantages.

- Efficient anti-slip: The unique design of the rough rubber surface provides excellent anti-slip properties and ensures stability duringtransportation on slopes.

- Cost Savings: Wear-resistant material extends the life of the conveyor belt, reducing maintenance and replacement frequency.

- Simple to operate: Easy to install and maintain, no special tools or equipment modifications required.

| Properties | Detailed Description | Common Data Ranges/Standards |

| Surface Material | Rough, non-slip rubber that provides excellent slip and abrasion resistance. | Highly abrasion-resistant synthetic rubber (e.g. NBR) |

| Applicable Angle | Ideal for incline angle transportation up to 35°. | 0° – 35° (typical slope transportation angle) |

| Coefficient of Friction | High coefficient of friction to prevent material slippage. | Coefficient of dynamic friction ≥ 0.6 (depending on material and surface treatment) |

| Thickness range | Total thickness of the conveyor belt. | 5mm – 12mm (according to specific application requirements) |

| Width range | Standard or customized widths. | 300mm – 2000mm |

| Load capacity | The maximum load that a conveyor belt can carry. | Depending on belt width and angle (e.g. 50 kg/m² – 200 kg/m²) |

| Abrasion resistance | High abrasion resistance for frequent use in transportation environments. | Conforms to DIN 22102: ≤ 90 mm³ (excellent abrasion resistance class) |

| Wear volume | The volume lost when a material wears out, usually measured using the DIN standard. | DIN 53516 test: 50 – 150 mm³ (the lower the value the more wear-resistant) |

| Cushioning performance | Provides excellent shock absorption and cushioning to minimize material damage. | Superior vibration damping design (corrugated surface or specialty materials) |

| Service life | Expected service life under normal operating conditions. | 3 – 5 years (depending on conditions of use and environment) |

| Temperature resistance | Stable operation at different temperatures. | -10°C to +60°C (conventional operating temperature range) |

| Applicable speed | Applicable operating speed of the conveyor belt. | 1 – 3 m/s (depending on specific application and transportation conditions) |

| Connection method | Connection method of the conveyor belt. | Hot vulcanized joint, cold bonded head |

| Applicable industries | Typical application industries for conveyor belts. | Logistics, warehousing, express delivery, food processing and other industries |

| Ageing resistance | Resistance to aging under long-term use. | Conforms to ISO 4649 |

| Color Options | Color options are available to suit different applications. | Black, brown, gray (common industrial colors) |

| Abrasion rating | Classification of a material’s ability to resist abrasion. | DIN Y, DIN X, DIN W and other standard classifications |

| Tensile strength | The tensile strength of the conveyor belt material determines the maximum load it can withstand. | 800 N/mm – 2500 N/mm (depending on the number of plies and material) |

| Elongation at break | Maximum elongation of the belt before stretching to break. | ≤ 20% (according to ISO 283) |

| Tear resistance | The ability of a material to resist tearing when subjected to an external impact. | Conforms to ISO 15236 |

| Wear Thickness Variation | The change in thickness of a material during use, reflecting its durability. | ≤ 0.1 mm (depending on specific application and material selection) |

| Oil resistance properties | Stability and resistance of the material in oily environments. | Conforms to ISO 1817 |

| Flame retardant grade | Self-extinguishing properties in the presence of fire, reducing the risk of fire. | Conformity to ISO 340 or DIN 22103 |

Related Products

Why Choose Our Belts for Your Manufacturing Needs?

Discover how our innovative conveyor belt solutions enhance efficiency, reduce downtime, and provide reliable performance for all your industrial needs.

QUALITY ASSURANCE

Adopts high-strength double anilox rollers and tear-resistant materials to ensure product durability, safety and compliance with strict quality standards.Technological Innovation

Introduces lifetime replacement-free anilox roller coating technology and high-efficiency automated equipment to improve production efficiency and reduce maintenance costs.Professional Services

provides one-on-one technical support and quick response to customer needs to ensure smooth and worry-free use.Diversified Choices

provides a variety of industrial solutions and customized services to meet the specific needs of different customers.

Hello

Get Free Quote

Contact us today to receive a customized quote for your conveyor belt needs—fast, easy, and at no cost!

changjiang No.1 Office Building ,No.8 Tianshan Road, Xinwu District, Wuxi City, Jiangsu Province, China