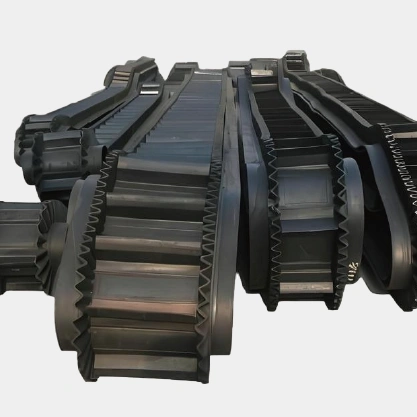

Roller

Our conveyor belt idlers and idler sets are built to support and guide rubber conveyor belts in heavy-duty bulk material handling systems. We offer both the older TD75 standard idler series and the modern TDII standard series, providing superior bearing life, lower rolling resistance, strict concentricity control, and customisable assemblies for high-impact, heavy-load and long-distance conveyors.

Details

A. Functional Significance

In a belt conveyor system, idlers play a critical role in:

Supporting the loaded belt in the carrying section, maintaining the trough shape so that material is conveyed smoothly.

Supporting the empty belt in the return section, reducing belt sag and preventing material accumulation.

Guiding and centring the belt to avoid mis-tracking and edge damage.

Absorbing impact loads (in impact idlers or idler sets) at loading points, reducing shock to the belt and frame.

A well-selected idler assembly significantly improves system reliability, minimises downtime, lowers maintenance cost and optimises energy consumption.

B. Our Product Features

Standard Compatibility

Supports the legacy TD75 idler series for retrofits and older equipment.

Supports the current mainstream TDII idler series, with enhanced construction and longer life.

Precision Manufacturing & Component Quality

Premium bearings, precision shafts and sleeves ensure concentricity and reduce eccentric shaft forces.

Roller shell thickness and outer diameter are processed with large turning machines to ensure uniformity and reduced radial run-out.

For high radial loads (e.g., >50 kN in TD75, >80 kN in TDII) we perform internal stress relief and static balancing tests.

Sealing & Durability Enhancements

Advanced sealed bearing systems (e.g., labyrinth + contact seals) prevent ingress of dust and water—extending service life. According to CEMA-rated idler guidelines, larger diameter rolls reduce RPM and thereby extend operational life.

Heat-fitted bearings or pre-lubricated sealed units reduce installation damage and increase mean time between failure.

Heavy-Duty Suitability & Energy Efficiency

Our idler designs conform to CEMA or equivalent heavy duty classifications. Larger diameters and optimal spacing can reduce maintenance and energy cost.

Versatile Configurations

Available in carrying idlers, return idlers, impact idlers, troughing sets and custom assemblies.

Customisable shaft ends, diameters and mounting to match specific conveyor frames or retrofit requirements.

C. Technical Data Snapshot

Below is a summary of technical reference data for idlers and idler sets derived from third-party industry sources (note: for guidance only).

| Parameter | Typical Value / Range | Source & Notes |

|---|---|---|

| Roller diameter (light duty) | 63.5 mm | “Common conveyor roller metric dimensions” table for light-duty applications. |

| Roller diameter (heavy duty) | 133–159 mm | Heavy duty mining idlers for belt widths 1000–1600 mm. |

| Shaft diameter | 20–40 mm steel spindle | Based on HIC Universal load carrier idler data. |

| Bearing life design (L10) | 30,000 h for CEMA B/C; 60,000 h for D/E | From PPI Idler Selection Guide. |

| Max recommended belt speed per idler size | 4” idler ~ 534 ft/min, 5” ~ 654 ft/min, 6” ~ 758 ft/min | PPI guide’s table. |

| Typical idler spacing – carrying | 4–5 ft (for belt widths ≤ 48”) | PPI spacing table. |

| Typical idler spacing – return | 8–10 ft | Same source. |

Related Products

Why Choose Our Belts for Your Manufacturing Needs?

Discover how our innovative conveyor belt solutions enhance efficiency, reduce downtime, and provide reliable performance for all your industrial needs.

QUALITY ASSURANCE

Adopts high-strength double anilox rollers and tear-resistant materials to ensure product durability, safety and compliance with strict quality standards.Technological Innovation

Introduces lifetime replacement-free anilox roller coating technology and high-efficiency automated equipment to improve production efficiency and reduce maintenance costs.Professional Services

provides one-on-one technical support and quick response to customer needs to ensure smooth and worry-free use.Diversified Choices

provides a variety of industrial solutions and customized services to meet the specific needs of different customers.

Hello

Get Free Quote

Contact us today to receive a customized quote for your conveyor belt needs—fast, easy, and at no cost!

changjiang No.1 Office Building ,No.8 Tianshan Road, Xinwu District, Wuxi City, Jiangsu Province, China