PVC Conveyor Belt

PVC Conveyor Belt is a commonly used industrial conveyor belt material, which is widely used in logistics, food processing, packaging, electronics, agriculture and other industries.Made of high quality polyvinyl chloride (PVC) material with excellent abrasion, tear, oil and chemical resistance, PVC conveyor belts are the preferred choice for many industrial conveyor solutions due to their cost-effective, lightweight and easy-to-install nature and good conveying performance.

Details

- Max-Width:

- Max-Width: The maximum width of PVC conveyor belt can be up to 3400MM, depending on the thickness.The maximum width of conveyor belt with thickness of 2-3MM is 3200MM, and the maximum width of conveyor belt with thickness of more than 4MM can reach 3400MM.

- Material & Structure:

- Cover Material: Optional materials include PVC (Polyvinyl Chloride), PE (Polyolefin), PU (Polyurethane), TPE (Polyester) and SI (Silicone) to meet different requirements for durability, flexibility and chemical resistance.

- Fabric Layers: Depending on the usage requirements, PVC conveyor belts can be customized with different layers of fabric construction to enhance its strength and durability.

- Fabric Types:

- A wide range of fabric types are available including:

- Non-Lateral Stability: polyester gauze, polyester fabrics.

- Lateral stability: polyester fabrics (e.g. 100N/mm and 80N/mm strength), high strength polyester fabrics.

- Composite fabrics: cotton/polyester composite fabrics, cotton/polyester yarn composite fabrics.

- Special function fabrics: low noise fabrics, cotton fabrics, etc., adapting to different industrial application scenarios.

- A wide range of fabric types are available including:

- Surface Coating Colors:

- PVC conveyor belts are available in a wide range of color options such as clear, green, white, black, grey, red, beige, blue-green, blue and orange to meet different visual and functional needs.

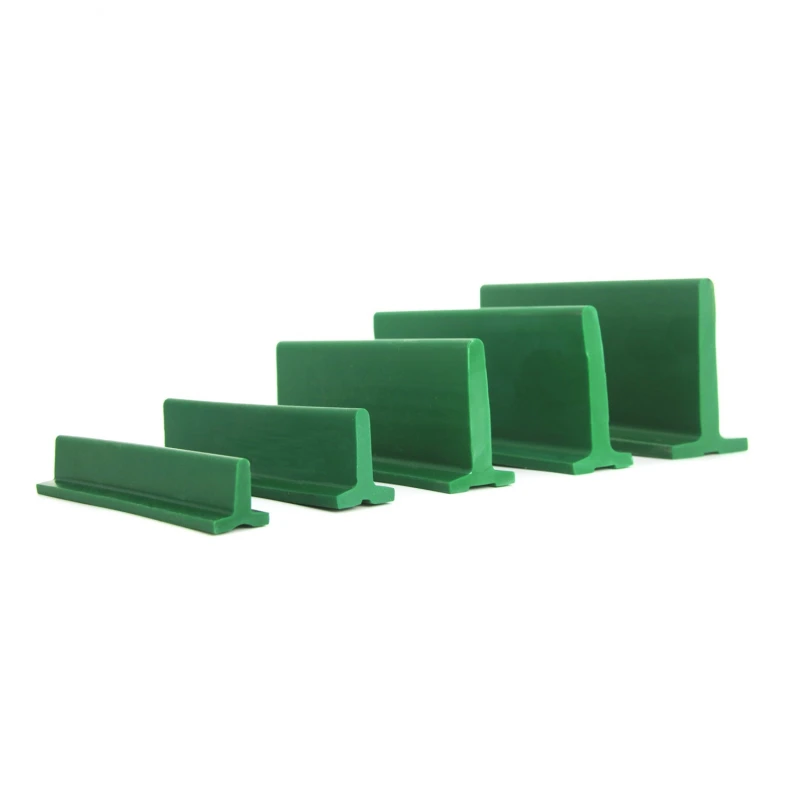

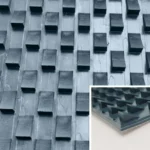

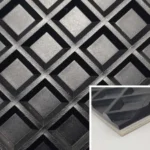

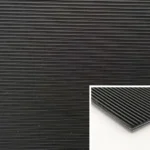

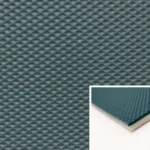

- Top-covered/bottom-covered profiles:

- Multiple combinations of surface coatings and patterns are available to ensure optimum friction and stability during material handling.Common options include:

- Normal thickness, medium thickness and extra thick coatings.

- Various patterns such as diamond patterns and fabric patterns to suit different working environments and needs.

- Multiple combinations of surface coatings and patterns are available to ensure optimum friction and stability during material handling.Common options include:

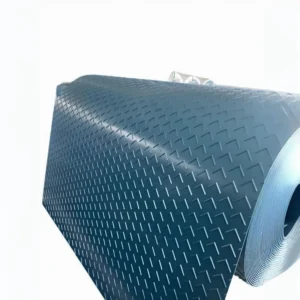

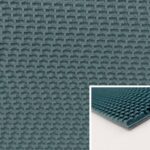

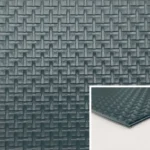

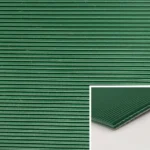

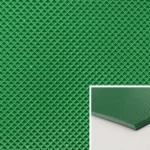

- Surface Pattern Options:

- A wide variety of surface patterns are available to enhance the efficiency and reliability of material handling, including matte, diamond, high friction, dot, serrated, golf ball, mesh, pinstripe, antistatic, large chevron, raised tooth, twill, corrugated, and more.

- Applicable industries and uses:

- Logistics and warehousing: for efficient conveying of parcels and goods, providing excellent wear resistance and long-term reliability.

- Food Processing: Meets food grade requirements, can be used in the production and conveying process of bread, pastry, candy and other foodstuffs to ensure hygiene and material safety.

- Packaging industry: It is suitable for all kinds of packaging production lines, preventing materials from sliding or shifting and ensuring the stable operation of the production line.

- Electronic manufacturing: used in the transportation of electronic parts and products, with anti-static properties, reduce static electricity accumulation.

- Agriculture: in the process of sorting and conveying of agricultural products, to prevent material damage and pollution, suitable for vegetables, fruits, grains and so on.

- Product Advantage:

- HIGH DURABILITY AND VERSATILITY: Able to be customized according to specific needs, offering a wide range of colors, materials, structures and pattern combinations to adapt to different industrial applications.

- Easy to clean and maintain: the material has a smooth, chemical-resistant surface that is easy to clean, reducing maintenance costs and downtime.

- Versatility: Suitable for a wide range of industrial applications, from light food processing to heavy-duty logistics and transportation, providing reliable and efficient conveying solutions.

- Max-Width:

| PVC Conveyor Belt Date Sheet | |||||||||||

| No. | Type No. | Top Cover Color | Total Thickness (mm): | Top Cover Thickness (mm): | Weight (kg/m³): | Top Cover Hardness (ShoreA): | Breaking Load (N/mm): | 1% Elongation Strength | Minimum Pulley Dia.: | Contact Temperature Range (℃): | Max Production Width(mm): |

| Lohistics & Post | |||||||||||

| 1 | P25-14A | Green | 2 | 0.5 | 2.3 | 80 | 150 | 11 | 25 | -10/80 | 3000 |

| 2 | P25-15A | Green | 3 | 1 | 3.4 | 80 | 160 | 12 | 50 | -10/80 | 3000 |

| 3 | P22-37IHD | Nature Color | 2.5 | / | 2.9 | / | 150 | 10 | 40 | -10/80 | 3000 |

| 4 | P22-16/27-1 | Green | 5 | 3.3 | 4.1 | 60 | 160 | 11 | 90 | -10/80 | 3000 |

| 5 | P22-86/19D | Blue | 3.1 | 1.4 | 3.3 | 60 | 160 | 11 | 60 | -10/80 | 2000 |

| 6 | P32-14/1A | Green | 4 | 1.2 | 4.5 | 80 | 230 | 16 | 110 | -10/80 | 3000 |

| 7 | P32-74/OA | Dark Blue-Green | 4 | 0.9 | 4.6 | 80 | 240 | 17 | 110 | -10/80 | 3000 |

| 8 | P32-36H | Black | 7 | 3.3 | 8.4 | 80 | 260 | 18 | 200 | -10/80 | 3000 |

| 9 | P22-76/30D | Dark Blue-Green | 5 | 3.1 | 5.4 | 60 | 160 | 12 | 90 | -10/80 | 2000 |

| 10 | P22-74/24HDA | Dark Blue-Green | 2.6 | 1.1 | 2.7 | 60 | 150 | 11 | 50 | -10/80 | 2000 |

| 11 | PVK100-37 | Black | 2.8 | / | 3.3 | / | 210 | 15 | 100 | -10/80 | 3000 |

| 12 | PVK100B-37 | Black | 3.2 | / | 3.5 | / | 250 | 20 | 110 | -10/80 | 3000 |

| 13 | PVK120-37 | Black | 3.8 | / | 4.5 | / | 270 | 22 | 110 | -10/80 | 3000 |

| 14 | PVK125-37 | Black | 4 | / | 4.7 | / | 290 | 22 | 115 | -10/80 | 3000 |

| 15 | PVK150-37 | Black | 4.5 | / | 5.2 | / | 300 | 23 | 120 | -10/80 | 3000 |

| 16 | PVK22-37 | Black | 4 | / | 4.7 | / | 250 | 20 | 100 | -10/80 | 3000 |

| Automobile tires & Puching | |||||||||||

| 1 | P42-44/26 | Grey | 5 | 1.2 | 5.8 | 80 | 320 | 22 | 230 | -10/80 | 3000 |

| 2 | P42-16/3A-1 | Green | 8.5 | 3.9 | 8.6 | 60 | 340 | 23 | 260 | -10/80 | 3000 |

| 3 | P22-76/3AH | Dark Blue-Green | 4.8 | 3.1 | 4.1 | 60 | 160 | 12 | 90 | -10/80 | 3000 |

| 4 | P32-56/26H | Red | 7.5 | 4.2 | 8.7 | 80 | 270 | 18 | 180 | -10/80 | 3000 |

| 5 | P32-14HA | Green | 4.5 | 1.2 | 5.3 | 80 | 260 | 17 | 130 | -10/80 | 3000 |

| 6 | P32-94A | Orange Yellow | 4 | 1 | 4.6 | 80 | 260 | 17 | 110 | -10/80 | 3000 |

| 7 | P32-07 | Nature Color | 3 | / | 3.4 | / | 230 | 16 | 60 | -10/80 | 3000 |

| 8 | P23-07H | Nature Color | 2.6 | / | 3.4 | / | 180 | 20 | 30 | -10/80 | 3000 |

| Airport transportation | |||||||||||

| 1 | P32-74/7 | Dark Blue-Green | 5 | 2 | 5.6 | 80 | 250 | 17 | 110 | -10/80 | 3000 |

| 2 | P32-04/0HY | Lucency | 4.9 | 1.5 | 5.8 | 80 | 250 | 18 | 110 | -10/80 | 3000 |

| 3 | P22-26/27 | White | 5 | 3.3 | 4.1 | 65 | 160 | 12 | 80 | -10/80 | 2000 |

| 4 | P22-06/28 | Lucency | 4.3 | 2.6 | 4.2 | 65 | 150 | 12 | 80 | -10/80 | 2000 |

| 5 | P22-56/3D | Red | 5 | 3.3 | 4.2 | 60 | 160 | 12 | 80 | -10/80 | 3000 |

| 6 | P22-96/3A | Orange Yellow | 5 | 3.3 | 4.2 | 60 | 160 | 12 | 80 | -10/90 | 3000 |

| 7 | P21-471Z | Grey | 2 | / | 2.2 | / | 150 | 10 | 40 | -10/90 | 3000 |

| 8 | P31-34AHUV | Black | 4.8 | 1.3 | 5.6 | 75 | 300 | 22 | 60 | -10/90 | 3000 |

| Treadmill belt | |||||||||||

| 1 | S25/7A | Black | 2.5 | 0.75 | 2.5 | 75 | 150 | 12 | 40 | -10/80 | 3000 |

| 2 | S23/29A | Black | 2.3 | 0.65 | 2.4 | 75 | 150 | 12 | 35 | -10/80 | 2000 |

| 3 | S20/29A | Black | 2 | 0.5 | 2.2 | 75 | 140 | 11 | 35 | -10/80 | 2000 |

| 4 | S18/7A | Black | 1.8 | 1 | 1.8 | 75 | 60 | 6 | 30 | -10/80 | 3000 |

| 5 | P25-34/1DA | Black | 2 | 0.5 | 2.1 | 75 | 140 | 11 | 35 | -10/80 | 3000 |

| Food processing | |||||||||||

| 1 | U22-24/0A | White | 1.6 | 0.35 | 1.9 | 90 | 170 | 12 | 30 | -10/40 | 2000 |

| 2 | U22-26/28A | White | 3.1 | 1.6 | 2.6 | 90 | 180 | 12 | 50 | -10/40 | 2000 |

| 3 | U12-14/26IA | Green | 1 | 0.5 | 1 | 90 | 80 | 7 | 25 | -10/40 | 2000 |

| 4 | U22-14/0A | Green | 1.6 | 0.35 | 19 | 90 | 170 | 12 | 30 | -10/40 | 2000 |

| 5 | U22-24/0HA | White | 2.5 | 0.8 | 3 | 90 | 180 | 12 | 40 | -10/40 | 2000 |

| 6 | P32-24NA | White | 4 | 0.9 | 4.7 | 65 | 260 | 18 | 110 | -10/80 | 3000 |

| 7 | P25-24NA | White | 2.5 | 0.8 | 2.9 | 65 | 160 | 12 | 50 | -10/80 | 3000 |

| 8 | UP22-04HA | Lucency | 3.8 | 1.8 | 4.5 | 90 | 200 | 16 | 60 | -20/80 | 2000 |

| 9 | P25-25N | White | 3 | 1 | 3.5 | 65 | 180 | 12 | 50 | -10/80 | 3000 |

| 10 | P33-07 | Nature Color | 3 | / | 3.4 | / | 100 | 12 | 50 | -10/80 | 3000 |

| Tobacco processing | |||||||||||

| 1 | P22-04YC | Lucency | 2.6 | 0.9 | 3.1 | 80 | 150 | 11 | 60 | -10/80 | 3000 |

| 2 | P25-05YCM120 | Lucency | 3.6 | 1.8 | 3.7 | 80 | 180 | 12 | 85 | -10/80 | 2000 |

| 3 | E12-04A | Lucency | 1.2 | 0.6 | 1.4 | 90 | 120 | 10 | 40 | -10/40 | 3000 |

| 4 | E20-05A | Lucency | 3 | 0.9 | 3.6 | 90 | 230 | 18 | 80 | -10/40 | 3000 |

| 5 | SU22-07A | Lucency | 1.7 | 0.2 | 2 | 40 | 190 | 20 | 40 | -30/110 | 2000 |

| 6 | U12-64/25A | Sandy Beige | 1.2 | 0.7 | 1.1 | 90 | 60 | 6 | 25 | -10/40 | 2000 |

| Antistatic belt | |||||||||||

| 1 | P25-15/21A0 | Green | 3 | 1 | 3.4 | 75 | 160 | 12 | 50 | -10/80 | 3000 |

| 2 | P25-44/21A | Grey | 2 | 0.5 | 2.3 | 75 | 180 | 12 | 25 | -10/80 | 3000 |

| 3 | P22-41/21A | Grey | 2.2 | 0.7 | 2.4 | 75 | 170 | 11 | 25 | -10/80 | 3000 |

| 4 | U22-34/21A0 | Black | 1.6 | 0.3 | 1.9 | / | 160 | 12 | 30 | -10/40 | 2000 |

| 5 | U12-37/I21 | Black | 0.5 | / | 0.5 | / | 70 | 7 | 15 | -10/80 | 2000 |

| 6 | U12-34/0A21 | Black | 1 | 0.5 | 1.1 | 90 | 80 | 8 | 20 | -10/40 | 2000 |

| 7 | P22-17II21 | Black | 1.8 | / | 2 | / | 160 | 11 | 25 | -10/80 | 3000 |

| 8 | U22-34/21A0I | Black | 1.6 | 0.3 | 1.9 | 90 | 160 | 12 | 30 | -10/80 | 2000 |

| Wood processing | |||||||||||

| 1 | P22-31/18 | Black | 6 | 3.5 | 4.8 | 80 | 160 | 12 | 110 | -10/80 | 2000 |

| 2 | P32-46/13 | Grey | 9 | 6 | 8 | 55 | 250 | 16 | 130 | -10/80 | 2000 |

| 3 | P49-76/25 | Dark Blue-Green | 9 | 2.6 | 10 | 80 | 900 | 100 | 500 | -10/80 | 2000 |

| 4 | P49-86/34 | Blue | 13 | 6.6 | 12 | 55 | 900 | 100 | 450 | -10/80 | 2000 |

| 5 | P32-36/13 | black | 9 | 5.8 | 8.2 | 50 | 260 | 16 | 130 | -10/80 | 2000 |

| 6 | P39-76 | Dark Blue-Green | 6 | 1.4 | 7.2 | 80 | 750 | 65 | 250 | -10/80 | 3000 |

| 7 | P32-16/27 | Green | 7 | 1.6 | 5.1 | 60 | 260 | 17 | 160 | -10/80 | 2000 |

| 8 | P39-76/23 | Dark Blue-Green | 10 | 2.3 | 8.2 | 55 | 760 | 70 | 200 | -10/80 | 2000 |

| Load and unload gate seal | |||||||||||

| 1 | P12-89/1 | Light Blue | 2 | 0.7 | 2.1 | 80 | 80 | 8 | 10 | -10/80 | 3000 |

| 2 | P32-49/00 | Grey | 5 | 0.9 | 5.8 | 80 | 250 | 18 | 110 | -10/80 | 3000 |

| 3 | P12-29/0 | White | 2 | 0.7 | 2.3 | 80 | 80 | 7 | 10 | -10/80 | 3000 |

| 4 | P22-89/0Y | Blue | 3 | 0.7 | 3.4 | 85 | 160 | 12 | 50 | -10/80 | 3000 |

| 5 | P22-38/26 | Black | 2.3 | 0.5 | 2.5 | 80 | 150 | 12 | 30 | -10/80 | 2000 |

| Special belts | |||||||||||

| 1 | P10-06/29 | Cream | 1.7 | 1.1 | 1.8 | 60 | 40 | 5 | 15 | -10/80 | 2000 |

| 2 | P13-26/4 | White | 2 | 1.5 | 1.9 | 60 | 40 | 5 | 15 | -10/80 | 2000 |

| 3 | MP12-24 | White | 3.2 | / | 3.1 | / | 100 | 10 | 30 | -10/80 | 2000 |

| 4 | MP22-14G | Black | 4.2 | / | 4.3 | / | 150 | 13 | 55 | -10/80 | 2000 |

| 5 | P22-15/0AC | Full Color | 3 | 1 | 3.4 | 80 | 160 | 12 | 50 | -10/80 | 3000 |

| 6 | P22-35/OA | Black Blue | 3 | 1 | 3.4 | 80 | 160 | 12 | 50 | -10/80 | 3000 |

Related Products

Why Choose Our Industrial Adhesive Solutions for Your Manufacturing Needs?

Discover how our innovative conveyor belt solutions enhance efficiency, reduce downtime, and provide reliable performance for all your industrial needs.

QUALITY ASSURANCE

Adopts high-strength double anilox rollers and tear-resistant materials to ensure product durability, safety and compliance with strict quality standards.Technological Innovation

Introduces lifetime replacement-free anilox roller coating technology and high-efficiency automated equipment to improve production efficiency and reduce maintenance costs.Professional Services

provides one-on-one technical support and quick response to customer needs to ensure smooth and worry-free use.Diversified Choices

provides a variety of industrial solutions and customized services to meet the specific needs of different customers.

Hello

Get Free Quote

Contact us today to receive a customized quote for your conveyor belt needs—fast, easy, and at no cost!

changjiang No.1 Office Building ,No.8 Tianshan Road, Xinwu District, Wuxi City, Jiangsu Province, China