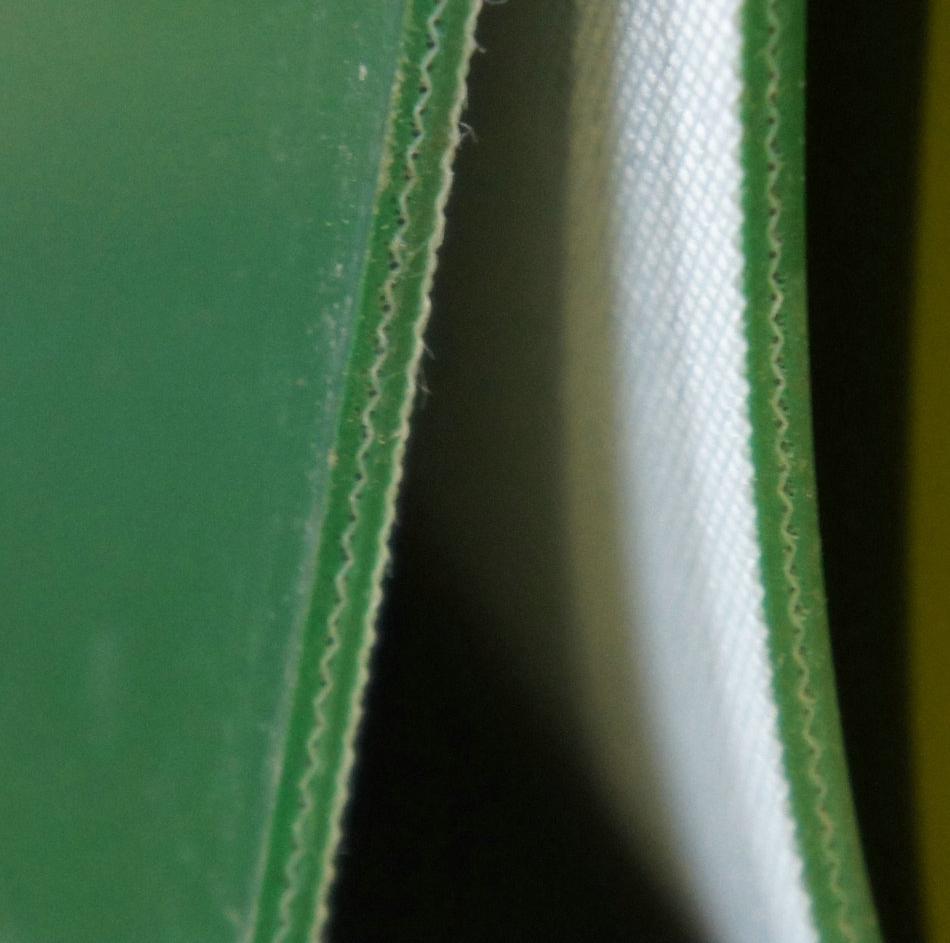

Low Static Type Antistatic PVC Conveyor Belt

Low static type anti-static PVC conveyor belts effectively inhibit static build-up in environments with low static control needs through advanced static dissipation technology.Its robust structural design and abrasion resistance are suitable for material transportation in high-speed production lines, especially for electronics manufacturing, automated assembly lines and light industrial production.The belt’s low maintenance costs and excellent anti-static properties make it ideal for use in these industries.

Details

Usage Scenario:

Low Static Type Antistatic PVC Conveyor Belt is mainly suitable for those environments where static control is required but strict anti-static protection is not necessary.This conveyor belt is widely used for material handling in electronics manufacturing, automated assembly lines, packaging operations and light industry.In these applications, static control is critical to prevent material buildup or equipment damage.By applying a surface treatment to the conveyor belt, this belt effectively reduces static build-up and ensures the stability and safety of the production process.

Product Features:

- Static electricity suppression: The surface of the conveyor belt is made of special anti-static material, which maintains the surface resistance between 10^7 – 10^9 Ω through static dissipation technology, effectively reducing the accumulation of static electricity and avoiding the damage of electrostatic discharges (ESD) to electronic components.

- Excellent tensile properties: The use of high-strength PVC composite material is able to maintain stable deformation and ductility under frequent loading conditions, providing a tensile strength of 120N/mm – 200N/mm, ensuring structural integrity over long periods of use.

- High abrasion resistance: The belt’s surface layer has been specially treated to increase resistance to friction and cuts, extending service life, making it suitable for high-speed automated equipment and reducing the frequency of belt replacement due to wear and tear.

- Lightweight design, easy to install and maintain: Compared with traditional conveyor belts, low-static anti-static PVC conveyor belts are lighter in weight, simplifying the installation process and reducing the energy consumption of the equipment.The surface is easy to clean and has shorter maintenance intervals, which further enhances the operational efficiency of the production line.

- Stable friction coefficient: The surface friction coefficient is controlled between 0.4 – 0.5, which can ensure the smooth movement of materials in the conveying process, and will not lead to the increase of equipment load or material damage due to excessive friction.

Applicable environment:

- Electronic manufacturing industry: In the production and assembly process of precision electronic components, preventing static electricity accumulation can reduce the damage and defects caused by electrostatic discharge of components and improve the product qualification rate.

- Packaging and automated assembly line: suitable for automated production and sorting systems that require anti-static, to ensure that the material will not stick or shift due to electrostatic influences in the high-speed transmission process.

- Light Industry and Precision Manufacturing: Used in lightweight materials or production scenarios that require a certain level of static control to ensure the normal operation of materials and equipment.

Product Advantage:

- Efficient static suppression: Through precise anti-static treatment, it effectively reduces the interference of static electricity on the production process, especially suitable for industrial environments that require stable static control.

- Excellent durability: Made of abrasion-resistant PVC material with excellent anti-wear performance, it is suitable for high-frequency operation environment, prolonging the service life of the conveyor belt and reducing the cost of downtime and maintenance.

- Flexible application scenarios: the conveyor belt can not only be used in static-sensitive environments, but also meet a variety of light industrial needs, suitable for a wide range of industrial applications, with high applicability and cost-effective.

| Parameter | Description | Range |

| Thickness | Total thickness of the conveyor belt (in mm) | 1.5mm – 3.0mm |

| Tensile strength | Maximum tensile strength of conveyor belt material (in N/mm) | 120N/mm – 200N/mm |

| Static electricity suppression value | Static suppression factor for conveyor belt surfaces (in Ω) | 10^7 – 10^9 Ω |

| Applicable temperature range | Operating temperature range that the belt can withstand (in °C) | -10°C to +70°C |

| Coefficient of friction | Coefficient of friction between conveyor belt surface and material for anti-slip properties (unitless) | 0.4 – 0.5 |

| Weight | Weight per square meter of conveyor belt (in kg/m²) | 2.5kg/m² – 4.0kg/m² |

| Surface treatment | Conveyor belt surface treatment determines material sliding characteristics | Smoothness |

| Conveying speed | Recommended maximum conveying speed (unit: m/s) | 1.5m/s – 2.5m/s |

Related Products

Why Choose Our Industrial Adhesive Solutions for Your Manufacturing Needs?

Discover how our innovative conveyor belt solutions enhance efficiency, reduce downtime, and provide reliable performance for all your industrial needs.

QUALITY ASSURANCE

Adopts high-strength double anilox rollers and tear-resistant materials to ensure product durability, safety and compliance with strict quality standards.Technological Innovation

Introduces lifetime replacement-free anilox roller coating technology and high-efficiency automated equipment to improve production efficiency and reduce maintenance costs.Professional Services

provides one-on-one technical support and quick response to customer needs to ensure smooth and worry-free use.Diversified Choices

provides a variety of industrial solutions and customized services to meet the specific needs of different customers.

Hello

Get Free Quote

Contact us today to receive a customized quote for your conveyor belt needs—fast, easy, and at no cost!

changjiang No.1 Office Building ,No.8 Tianshan Road, Xinwu District, Wuxi City, Jiangsu Province, China