A flame retardant conveyor belt must be tested because its real behavior only appears once heat is removed. Field incidents show that small mechanical faults often ignite belt material faster than expected. Standardized flame testing proves how the rubber decomposes, chars, and self-extinguishes under controlled conditions. These results help engineers judge risk, compare compounds, and plan safer conveyor operation in confined or high-hazard environments.

1. Why a Flame Retardant Conveyor Belt Must Undergo Proper Flame Testing

A flame retardant conveyor belt is only as trustworthy as its behavior once the heat source is removed, and anyone who has worked long enough around heavy conveyors knows how misleading appearances can be. Most belt fires do not start with open flames; they start with minor mechanical problems that escalate quietly. A seized idler generating 240–260°C surface temperature, a belt edge rubbing steel for an hour, or carry-back accumulating on a hot pulley are enough to push rubber into pyrolysis. Once volatile gases form, even a weak spark can ignite the material. In an enclosed gallery or mine decline, the flame moves upward along the belt’s length, assisted by natural convection.

That is exactly why standardized flame testing exists. A flame retardant conveyor belt is designed to self-extinguish, not to withstand unlimited heat. Flame testing verifies the belt’s ability to stop burning without operator intervention. In real fires, the ignition phase is rarely the problem. The danger comes afterward—whether the belt continues burning after the heat source is gone, whether the char layer collapses, and whether ventilation airflow causes re-ignition. The vertical flame test in GB/T 3685–2017 is engineered to expose these failure modes. A belt that looks acceptable under normal operation may behave unpredictably under actual heat load unless tested in a controlled, repeatable way.

2. Material Behavior That Determines How a Flame Retardant Conveyor Belt Burns

To evaluate a flame retardant conveyor belt, you must understand how rubber behaves under heat. Rubber doesn’t combust instantly. It undergoes thermal decomposition beginning around 180–220°C. Polymer chains break apart, releasing hydrocarbons. If oxygen is present, these vapors ignite. The engineering question is not “does it burn?” but “does it continue burning once ignition stops?”

A well-designed flame retardant conveyor belt controls decomposition rate. The retarded compound forms a dense, coherent char layer that shields the underlying carcass. If the char is brittle or porous, or if it blisters during heating, oxygen finds its way back into the rubber, and the flame keeps feeding. That is why the flame test heavily emphasizes “after-flame time” rather than ignition temperature. Ignition tells you little. Self-extinguishing behavior tells you everything.

Vertical positioning in the test matters. A belt in service rarely burns horizontally. Flames climb, assisted by convection and by the belt’s surface angle. A proper flame test places the flame retardant conveyor belt sample vertically to maximize upward flame spread potential. If the material can extinguish itself in this worst-case geometry, its behavior in plant conditions becomes predictable.

Another important factor is directional behavior. A belt burns differently along warp and weft directions. Rubber thickness also influences flame progression. Worn covers, especially when the remaining top cover drops below 1.5 mm, behave as if retarding additives barely exist. Many belts that pass testing when new lose self-extinguishing capability after months of abrasion. That is why removing the cover for certain specimens is required—it reveals what the carcass alone contributes to the flame behavior.

3. Specimen Preparation Before Testing a Flame Retardant Conveyor Belt

Most test failures I’ve seen were not due to compound defects but due to poor specimen preparation. GB/T 3685–2017 eliminates ambiguity by prescribing strict preparation rules. A flame retardant conveyor belt specimen must be cut at least 50 mm from the belt edge. Edge zones have tapering thickness, exposed fibers, and uneven rubber geometry. Testing those areas gives misleading results.

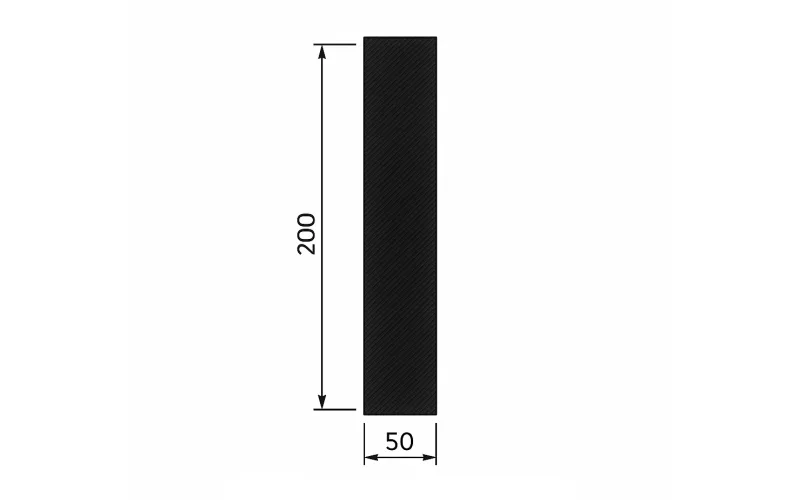

Specimen size is fixed at 200 mm × 25 mm. This dimension ensures consistent flame exposure and comparable heat flux across all labs. Fabric belts require twelve specimens—three longitudinal with cover, three transverse with cover, three longitudinal without cover, and three transverse without cover. These combinations reveal directional flame behavior and whether removing the cover exposes unacceptable flammability in the carcass.

Steel-cord belts need six specimens, each including two cords. Engineers insist on this because the cords influence internal heat conduction. A cord-containing specimen simulates actual belt behavior; a plain rubber strip does not. Removing the cover to expose cords must be done carefully—over-grinding introduces heat damage, artificially increasing burn tendency.

Conditioning is another step engineers take seriously. All specimens must stabilize in controlled temperature and humidity (GB/T 30691). Moisture trapped in the fabric, or samples taken fresh from cold storage, distort combustion. A flame retardant conveyor belt should be tested under true material conditions, not influenced by weather. Labs that skip conditioning often produce inconsistent results.

4. Standard Procedure for Testing a Flame Retardant Conveyor Belt (GB/T 3685–2017 / ISO 340)

The flame test procedure is not arbitrary; every number results from decades of incident investigations. The test evaluates whether a flame retardant conveyor belt can achieve controlled charring and stop burning after heat removal.

4.1 Burner Calibration

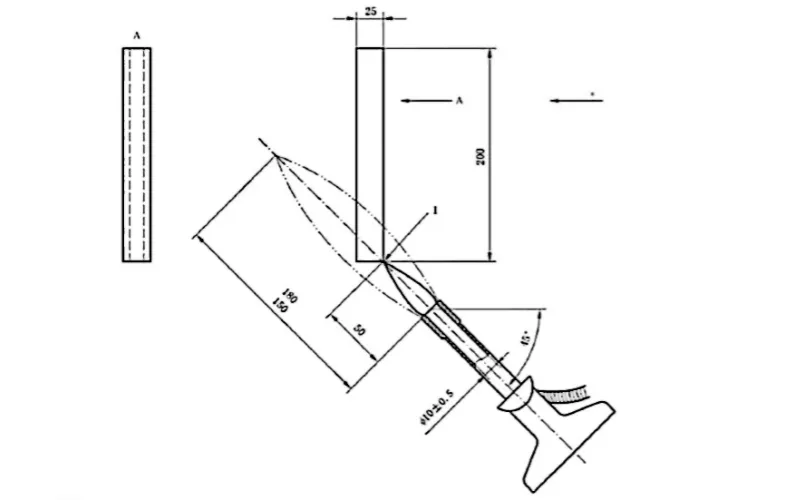

A Bunsen burner with a 10 ± 0.5 mm nozzle is used. Flame height must be 150–180 mm, with the inner blue cone at about 50 mm. A NiCr–NiAl thermocouple confirms flame temperature at 1000°C ± 20°C. Engineers rely heavily on this calibration. A flame even 30°C cooler produces slower decomposition, falsely suggesting better performance.

4.2 Test Setup

The sample is fixed vertically with ≥20 mm of clearance behind it to avoid reflected heat. The burner is held at a 45° angle, with the nozzle tip 50 mm below the specimen’s lower edge. This simulates real flame movement, where heat always rises along the belt path.

4.3 Ignition Phase (45 Seconds)

The burner is brought close to the sample at approximately a 45-degree angle to the horizontal and released for 45 seconds. This window is long enough to generate pyrolysis gases but short enough to reflect realistic ignition events, like a jammed roller heating a small area. A poor-quality flame retardant conveyor belt typically shows inconsistent charring or bubbling during this stage.

4.4 After–flame Recording

Once the burner is pulled away—without extinguishing it—engineers record how long the specimen continues burning. This “after-flame time” reveals whether the compound can control its own decomposition. Flame climbing upward after burner removal is an indicator that volatile gases continue feeding the flame.

4.5 Forced-Air Re-Ignition Test

After 60 ± 5 seconds, a 1.5 m/s airflow is applied for one full minute. This is the most revealing stage. Conveyor galleries often have unpredictable ventilation patterns. A belt that self-extinguishes in still air but reignites under airflow is a dangerous belt. A genuine flame retardant conveyor belt must withstand this airflow without flame reappearance.

5. Visual and Mechanical Indicators After Testing a Flame Retardant Conveyor Belt

When the flame goes out, most people think the evaluation is over. In reality, that’s when the real analysis starts. The post-burn condition of a flame retardant conveyor belt tells an engineer more about the compound than the after-flame time alone. I’ve seen belts with low after-flame times but catastrophic internal damage, and I’ve seen belts with longer after-flame but stable char that resists oxygen intrusion. You learn to look at the residues, not just the stopwatch.

A proper flame retardant conveyor belt forms a dense, continuous char layer. The char should cling to the carcass like a ceramic skin. If the char crumbles with finger pressure or breaks into flaky pieces, it means the rubber decomposed too quickly. Fast decomposition releases volatile, and volatile feed flame. A belt like that might pass the numerical limit but still be unsafe in an actual conveyor line, especially in upward airflow environments.

Another indicator is char geometry. A flame retardant conveyor belt that curls aggressively after burning usually has uneven thermal shrinkage between cover and carcass. Excessive curl indicates internal stresses in the compound; areas of the belt may contract while others expand. These internal stresses can propagate cracking during real fires. If you see spiral curling, especially when the cover is thin, it’s often a sign of under-vulcanized rubber.

The discoloration pattern also matters. A flame retardant conveyor belt with a clean transition between charred and uncharred zones usually has predictable heat transfer properties. But when the transition is smeared or fades gradually, the belt may have inconsistent compound mixing. Poor mixing creates micro-zones of different burn behavior. You typically see this in belts with high filler content or recycled rubber—materials that appear normal in tensile tests but perform poorly in flame tests.

Engineers also examine the carcass. After removing the char, look for exposed warp or weft fibers. In a well-designed flame retardant conveyor belt, the carcass should remain intact. If the fabric melts or shows brittle ash residues, the test has revealed deeper structural weakness. When the carcass fails, the splice will fail next. Flame safety is not just about stopping the fire; it’s about preserving belt integrity long enough to prevent mechanical failure during an emergency shutdown.

For steel-cord belts, a separate inspection is required. The insulation rubber around each cord in a flame retardant conveyor belt must remain elastic after cooling. If the insulation becomes glass-hard or cracks when bent gently, the heat penetrated too deeply. Many belts pass surface flame tests but silently fail in core structure. That’s why steel-cord belts require cautious post-burn analysis—internal smoldering does not always show on the surface.

Finally, forced-air re-ignition behavior leaves clues. If a flame retardant conveyor belt produces glowing embers after the airflow test, even without visible flame, that is still a failure condition. Embers indicate incomplete char formation and oxygen-permeable carbon residue. A belt like that can reignite when airflow changes in underground operations.

6. Common Failure Modes Seen During Flame Testing

I’ve watched countless flame tests, and failure patterns repeat themselves across plants, labs, and suppliers. A flame retardant conveyor belt rarely fails randomly. It fails in very repeatable ways that point directly to formulation or process errors.

The most common failure is excessive volatile release. When additives are unevenly dispersed, pockets of material release combustible vapors at different rates. You see rapid bubbling, followed by erratic flame jets. A flame retardant conveyor belt exhibiting this behavior was usually mixed poorly. You can’t fix that in the field; it’s a compounding flaw.

The second common failure mode is char collapse. During the airflow stage, a flame retardant conveyor belt with weak char loses its surface layer, exposing new rubber underneath. The incoming oxygen ignites the fresh layer instantly. This usually happens when the rubber hardness is too low or the formulation overuses plasticizers. Soft compounds burn unpredictably.

Another failure mode is caused by cover thickness. Many belts marketed as “flame resistant” barely meet minimum cover thickness. Once the cover wears below 1.5 mm, the belt essentially stops functioning as a flame retardant conveyor belt because the carcass is much more flammable. In the lab, the thin samples burn quickly, often leading to re-ignition during airflow.

For steel-cord belts, thermal conduction causes a unique failure pattern. Heat travels along the cords faster than expected. A flame retardant conveyor belt with insufficient cord insulation may pass the after-flame stage but fail internally. The cords heat up, damage the core rubber, and compromise the belt’s load-carrying ability. I’ve seen belts that looked acceptable externally but failed in service due to splice blowouts caused by hidden heat damage.

Another frequent problem is incorrect specimen preparation. If the cover removal overheats the sample, the flame retardant conveyor belt is no longer in a natural state. Burned fibers and pre-damaged rubber ignite faster, causing false test failures. Conversely, specimens cut too close to the belt edge make the belt look worse than it is because edge zones burn faster.

Finally, insufficient vulcanization leads to inconsistent flame behavior. Under-cured belts bubble, produce irregular char, and show flame trails that climb unpredictably. A flame retardant conveyor belt with this flaw usually comes from poor process control—wrong press temperature, uneven heating, or insufficient dwell time.

7. How to Ensure Reliable Flame Test Performance

Engineers know that passing the flame test once does not guarantee long-term safety. A flame retardant conveyor belt needs predictable behavior throughout its service life, not just in the factory. Ensuring that starts with verifying cover thickness on delivery. Many belts arrive with nominal thickness printed on the documentation but show measurable deviations across the width. Thin zones are weak links in flame exposure.

Routine inspection of mechanical components is essential. A flame retardant conveyor belt can only self-extinguish if ignition events remain localized. When idlers seize or scrapers jam, the heat transfer overwhelms the belt’s retardant mechanism. Engineering teams should track bearing temperatures and belt drift weekly, not just during shutdowns.

Contamination control is equally important. Oil contamination undermines flame performance by softening the rubber and changing decomposition chemistry. A flame retardant conveyor belt contaminated with hydraulic oil can burn like a standard belt. Plants using hydraulic drives or wet lubrication must treat oil drips as flame hazards, not housekeeping issues.

Aging is another factor. Rubber loses flame-retardant properties over time, especially under UV or ozone exposure. Engineers should periodically remove small samples from the flame retardant conveyor belt and run degradation checks—not full flame tests, but mechanical and visual inspections. Belts in long open-air conveyors degrade faster than enclosed belts.

For critical applications—mining declines, power-plant conveyors, grain terminals—the safest approach is batch testing. A flame retardant conveyor belt order spanning multiple production batches should not rely on a single certificate. Each batch may differ in compound quality. Proper quality assurance requires random sampling.

Finally, engineers should understand the limits. A flame retardant conveyor belt is not designed to survive continuous flame. It is designed to extinguish when the heat source is removed. Prolonged direct exposure—like a belt dragging on a red-hot pulley—will defeat any retardant system. Good maintenance and early detection are as critical as the belt itself.

8. Field-Level Safety Implications When Using a Flame Retardant Conveyor Belt

People who have never dealt with an actual belt fire often misunderstand what a flame retardant conveyor belt can and cannot do. In an experimental chamber, the flame source is steady, airflow is controlled, dust concentration is negligible, and the sample is small. But once you walk an underground conveyor during a fire drill or inspect scorch marks on a 2-km decline, you realize the lab test is only a baseline. Real conditions are harsher, faster, and far less predictable.

The biggest real-world factor is airflow. Mines and tunnels rarely have stable airflow. A flame retardant conveyor belt may self-extinguish under still air but reignite when ventilation direction shifts. I’ve seen flames rekindle at only 1.2–1.8 m/s, which is well within normal ventilation speeds. That is why the forced-air stage in GB/T 3685–2017 exists—to replicate how fire interacts with moving air. If a belt cannot withstand airflow in the lab, it certainly will not behave safely on the conveyor.

Dust is another amplifier. A clean flame retardant conveyor belt behaves one way; a dust-covered belt behaves another. Fine coal dust, grain dust, or limestone fines accumulate on the cover, increasing both fuel load and insulation. During a real fire event, the flame may travel along the dust layer even when the rubber underneath is self-extinguishing. This is a field-proven phenomenon that the flame test cannot fully reveal. Belts in dust-heavy environments require more frequent inspection because dust can mask early signs of heat damage.

Heat sinks within structures also matter. Conveyor trusses, steel galleries, and chutes can conduct heat backward. A flame retardant conveyor belt tested for surface burn rate might still fail when adjacent steel members transfer heat to the belt edge. In long declines, I’ve seen hotspots at bottom curves where heat rises and gets trapped under the belt.

Then there’s the issue of belt tension. A belt running near its tension limit generates more friction heat during drift or misalignment. Even a well-formulated flame retardant conveyor belt can become vulnerable if tension spikes during a jam or emergency stop. Engineers understand that safety is a combination of belt formulation, system design, and maintenance discipline—not just the test certificate.

One more subtle field implication is splice behavior. Splices degrade differently from the parent belt. A flame retardant conveyor belt may pass testing, but if the splice uses incompatible rubber or if vulcanization was under-cured, the splice becomes the ignition point. Splice rubber often contains less retardant additive than the main cover, making it a weak link during fire.

This is why engineers never rely solely on a test report. They evaluate how the belt behaves inside an actual conveyor system—under dust, tension, airflow, contamination, and thermal cycling. The flame test is a prerequisite, not a guarantee.

9. Practical Checklist for Anyone Working With a Flame Retardant Conveyor Belt

In the field, operators rarely have time for exhaustive evaluation. They need a structured checklist that reveals the real condition of a flame retardant conveyor belt in minutes, not hours. Below is a condensed engineering checklist based on decades of site audits.

9.1 Cover Thickness Verification

Measure actual top cover thickness across the width. If the cover is thinner than spec, the flame retardant conveyor belt will not perform as its certificate suggests. Thin covers burn faster and fail the airflow stage sooner.

9.2 Carcass Behavior After Heating

Cut a small section from a retired belt and expose it to controlled heat. A real flame retardant conveyor belt maintains carcass integrity even when charred. If fabric melts or delaminates under low heat, the belt has limited safety margin.

9.3 Splice Inspection

Check splice rubber hardness, cracks, and discoloration. A poorly made splice may not behave like the parent flame retardant conveyor belt. Many real fires start at the splice because its thermal resistance is lower.

9.4 Mechanical Hazard Areas

Inspect return rollers, snub pulleys, and transfer points. A flame retardant conveyor belt cannot compensate for a seized idler. The test only evaluates self-extinguishing behavior, not friction hazards.

9.5 Contamination Audit

Look for oil, grease, or hydrocarbon residues. Oil contamination undermines retardant chemistry. A contaminated flame retardant conveyor belt may burn like a regular belt.

9.6 Dust and Fines Accumulation

If dust layers exceed a few millimeters, they become additional fuel. Even the best flame retardant conveyor belt cannot prevent dust-layer ignition.

9.7 Certificate and Batch Validation

Confirm that the belt delivered matches the tested batch. Some suppliers run a single test and reuse the certificate. Each batch of a flame retardant conveyor belt can vary, especially when compounding controls are weak.

9.8 Post-Incident Review

After any heating event—whether a roller jam or chute contact—inspect the belt for char pattern, surface hardness, and internal cracking. A flame retardant conveyor belt can degrade invisibly on the inside after repeated heat cycles.

This checklist is not optional; it’s how you verify that flame-test results still match real-world behavior months or years after commissioning.

10. Critical Engineering Notes on Safe Use of Flame Retardant Conveyor Belts

There are realities every engineer must acknowledge, no matter how well a flame retardant conveyor belt performs in the lab. The belt’s flame behavior is not static; it changes with age, wear, and contamination.

A key limitation is that no flame retardant conveyor belt is designed for continuous flame exposure. The test applies a 45-second flame. Real fires can expose belts to heat for minutes. If a belt remains in contact with a jammed pulley or steel edge long enough, even retardant compounds lose control of decomposition.

Another important note: heat-damaged zones rarely look dramatic. I’ve inspected belts that visually appeared fine but became brittle internally after a minor heating event. When bent, the surface cracked like painted wood. A flame retardant conveyor belt with internal micro-cracking loses its ability to form a stable char. The next heating event will escalate faster than the first.

Environmental factors also degrade performance. UV exposure, ozone, and thermal cycling slowly reduce the retardant additives’ effectiveness. A flame retardant conveyor belt used on outdoor overland conveyors ages differently from one used in a closed gallery. Aging reduces char cohesion. Belts that passed tests when new may behave less predictably years later.

Another critical point is operational complacency. Facilities sometimes assume that installing a flame retardant conveyor belt eliminates the need for preventive maintenance. In reality, flame properties are just one layer of protection. Early detection—temperature sensors, belt drift switches, bearing monitors—is still essential. Flame retardant design cannot compensate for mechanical neglect.

Finally, engineers must recognize when a belt is no longer safe. If the char from a small heating event becomes powdery, or if the belt repeatedly shows internal hardening near splices, it is no longer acting like a flame retardant conveyor belt. Continued use becomes a risk, regardless of what the certificate says.

The safest plants are not the ones with the best certificates; they are the ones where engineers treat a flame retardant conveyor belt as a safety component that requires ongoing evaluation, not a set-and-forget item.