Conveyor Parts Supplier

Tiantie Industrial Conveyor Parts

With a legacy rooted in industrial craftsmanship since 2003, we’ve been at the forefront of precision conveyor component manufacturing. Our commitment to innovation shines through in the Tiantie Conveyor Parts Series — a seamless integration of strength and reliability engineered for today’s demanding industries.

Step into the future of material handling with our full range of conveyor parts, including idlers, pulleys, impact beds, and belt cleaners. Designed for durability and performance, our components keep systems running smoothly worldwide. With over two decades of expertise, Tiantie Industrial delivers trusted quality and engineering excellence that drives industries forward.

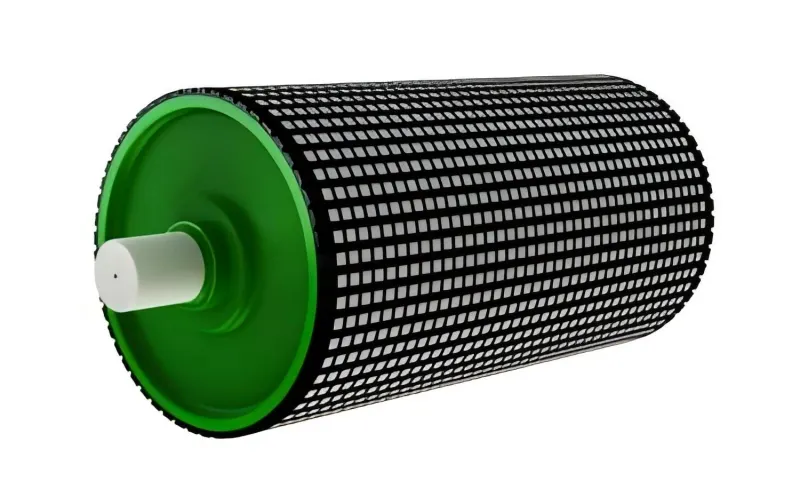

Learn about our Roller

Ensuring Smooth and Reliable Conveyor Performance

Conveyor rollers are the backbone of belt stability. Poor balance or sealing causes vibration and frequent failures. Tiantie Conveyor Rollers are precision-balanced to less than 0.5 mm run-out, ensuring quiet, stable rotation and reducing bearing temperature rise—keeping production lines operating longer between maintenance intervals.

Engineered for Long-Term Reliability

Each roller housing is machined from seamless steel tubing and undergoes stress relief treatment after welding. The bearings are heat-assembled and permanently lubricated, and sealed by a multi-stage labyrinth seal system, effectively blocking dust and moisture even in harsh, dusty environments, with a service life exceeding 30,000 hours.

Balancing and Quality Assurance

- Dynamic and static balance testing at up to 3 m/s belt speed ensures vibration-free operation.

- Pre-lubricated bearings reduce maintenance by 40%.

- Thick-walled shells resist impact and deformation.

- Sealing system prevents contamination in wet or dusty plants.

- Compatible with TDII / TD75 standard conveyors.

Technical Excellence

All rollers undergo full dimensional inspection and balance verification before shipment. Optional galvanized or powder-coated surfaces enhance corrosion resistance. Tight axial and radial tolerances guarantee low starting torque and consistent energy consumption across long conveying distances.

Applications

Used in mining, cement, steel, and port bulk-handling conveyors where long belt runs, high impact loading, and minimal downtime are critical. Tiantie rollers provide measurable reductions in power loss and wear, ensuring smoother, safer, and more efficient material handling operations.

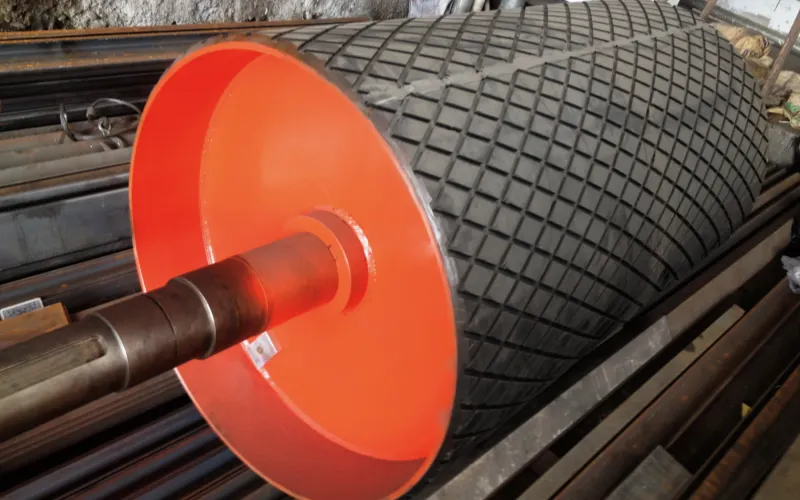

Learn about our Pulley

Reliable Power Transmission for Heavy-Duty Conveyors

Tiantie Conveyor Pulleys are designed to provide stable torque transmission and belt tracking in demanding bulk-handling systems. Each pulley is produced with strict manufacturing control to ensure accurate concentricity, strong load-bearing capacity, and long-term reliability under continuous operation.

Precision Manufacturing and Stress Relief

Each pulley shell is fabricated from seamless steel tubes and flame-cut for dimensional accuracy. The outer surface is machined on large-scale lathes to ensure uniform wall thickness and minimal radial deviation. Pulleys bearing more than 80 kN are subjected to internal stress relief to maintain structural integrity under high load.

Balancing and Quality Assurance

All pulleys designed for belt speeds above 2.5 m/s undergo static balance testing to ensure stable rotation and reduce belt vibration. Each shaft and hub assembly is precisely aligned, minimizing run-out and ensuring reliable power transmission throughout the entire conveying system.

Key Features and Advantages

- Seamless steel construction with precision machining for high concentricity.

- Stress-relieved design enhances strength and prevents deformation.

- Static balance testing ensures stable operation at high belt speeds.

- Suitable for drive, tail, and bend positions in TDII and TD75 conveyors.

- Optional rubber or ceramic lagging available for improved belt traction.

Applications

Widely used in mining, cement, steel, and port conveyor systems where torque stability, long service life, and continuous performance are essential. Tiantie pulleys deliver smooth power transfer and reduced downtime, ensuring efficiency in heavy-duty material-handling operations.

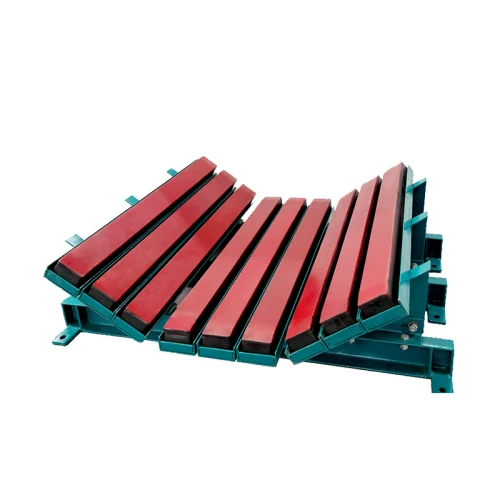

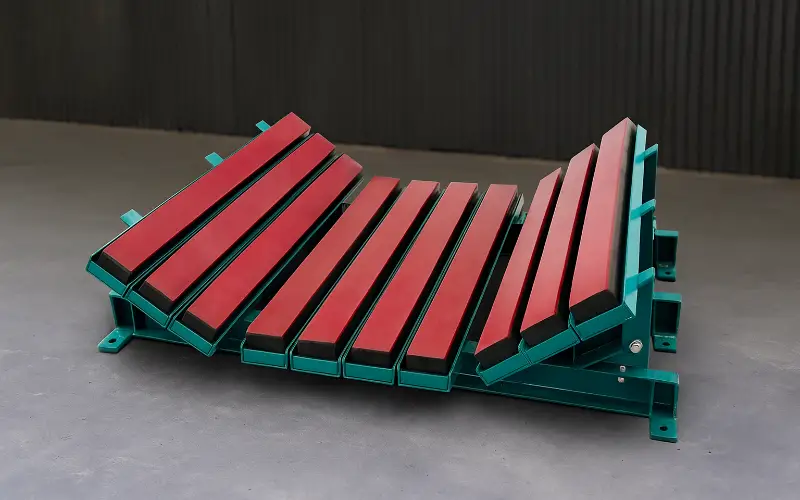

Learn about our Impact Bed

Protection and Stability at Conveyor Loading Points

Tiantie Impact Beds are designed to protect conveyor belts from damage at loading zones where falling materials cause strong impact. By replacing traditional idler sets, these impact beds provide continuous support across the belt width, reducing shock, vibration, and maintenance downtime.

Engineered Structure for Belt Protection

Each impact bed consists of UHMW-PE sliding bars bonded to energy-absorbing rubber layers. The bars are mounted on an aluminum alloy frame that provides both strength and flexibility. This structure absorbs impact energy efficiently while preventing belt sagging and surface wear under heavy loading conditions.

Precision and Reliability in Harsh Environments

The bed angle is adjustable between 35° and 45°, ensuring perfect belt contact and reduced spillage. All fasteners and brackets are corrosion-resistant, enabling long-term operation in wet, dusty, or corrosive environments such as ports, quarries, and coal terminals.

Key Features and Advantages

- UHMW-PE top surface ensures smooth belt sliding without friction damage.

- Rubber cushion blocks absorb material impact and extend belt service life.

- Modular design allows quick installation and easy replacement.

- Adjustable trough angle fits various conveyor widths.

- Strong aluminum alloy structure provides durability and reduced weight.

Applications

Tiantie Impact Beds are widely used at conveyor loading zones in mining, cement, steel, and port bulk-handling facilities. They effectively reduce belt damage, material spillage, and vibration—ensuring smoother operation, lower maintenance costs, and extended equipment lifespan.

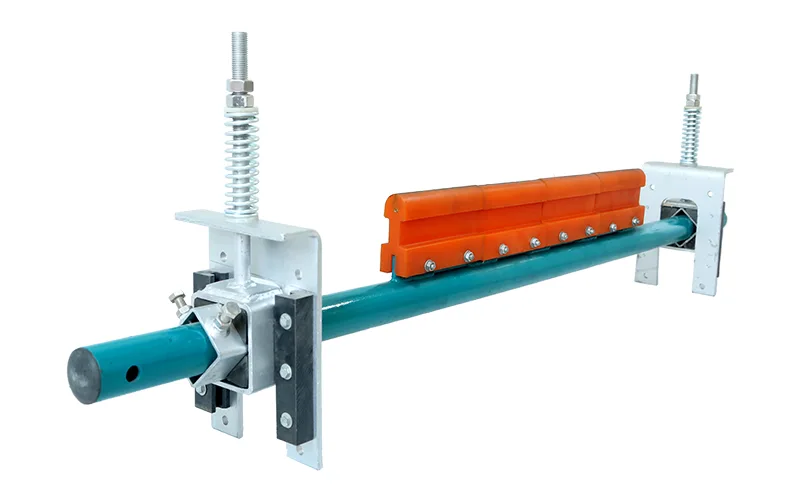

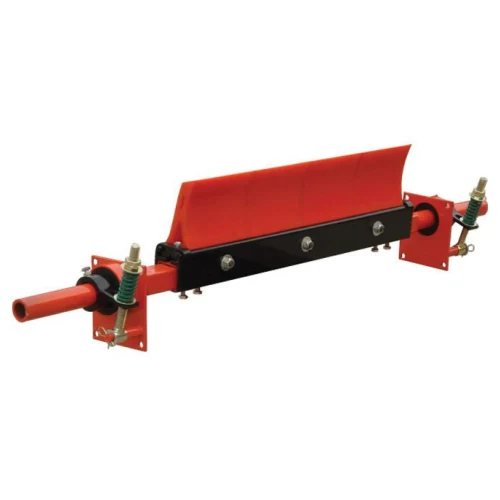

Learn about our Conveyor Belt Cleaner

Comprehensive Belt Cleaning Solutions

Tiantie Belt Cleaners provide complete cleaning solutions for modern conveyor systems. Designed to remove carryback and prevent material buildup, they maintain belt efficiency, reduce spillage, and extend belt service life across diverse industries and working environments.

Polyurethane and Brush Cleaning Options

Our product line includes high-performance polyurethane scrapers and heavy-duty brush cleaners. Polyurethane blades offer superior wear resistance for sticky or wet materials, while rotating brush cleaners effectively handle fine or powdery substances—providing reliable cleaning for every application type.

Engineered for Precision and Longevity

All cleaners are built with corrosion-resistant frames and self-adjusting tension systems to ensure consistent pressure and even blade or brush contact. The modular design allows easy installation and replacement, ensuring stable cleaning performance and minimal maintenance downtime.

Key Features and Advantages

- Polyurethane blades for high wear resistance and gentle belt contact.

- Rotating brush design ideal for fine, dry, or electrostatic materials.

- Adjustable tension system maintains uniform pressure and cleaning efficiency.

- Anti-corrosion steel structure ensures long-term reliability.

- Modular and replaceable parts simplify maintenance and reduce cost.

Applications

Tiantie Belt Cleaners are widely used in mining, cement, steel, port, and fertilizer conveyors where belt cleanliness is critical. Suitable for both return and discharge points, they provide efficient cleaning for wet, dusty, or abrasive materials, keeping conveyor systems running safely and continuously.

Request A Free Quote

We'd like to work with you

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 12 hours .