Rubber Conveyor Belt

EP Rubber Conveyor Belt

- Excellent dimensional stability thanks to low elongation polyester warp yarns

- Custom widths ranging from 300mm to 3500mm are available, depending on the required thickness and roll length.

- Various cover grades allow EP belts to perform reliably in harsh environments — from -60℃ freezing conditions to 300℃ heat, and in contact with oily, flammable, or abrasive materials.

- Its low stretch properties deliver exceptional stability and operational consistency.

- Strong interlayer bonding and superior adhesion between cover and fabric layers enhance belt integrity.

EP Conveyor Belt Specification

| Carcass | Carcass Structure | Carcas s Type | Carcass Thickness (mm/p) | Strength(N/mm) | Cover Thickness (mm) | Width (mm) | ||||||

| Warp | Weft | 2ply | 3ply | 4ply | 5ply | 6ply | top cover | bottom cover | ||||

| EP | Polyester | Nylon | EP100 | 1 | 200 | 300 | 400 | 500 | 600 | 1.5-30 | 1.5-20 | 300-3500 |

| EP125 | 1 | 250 | 375 | 500 | 625 | 750 | ||||||

| EP150 | 1.1 | 300 | 450 | 600 | 750 | 900 | ||||||

| EP200 | 1.2 | 400 | 600 | 800 | 1000 | 1200 | ||||||

| EP250 | 1.4 | 500 | 750 | 1000 | 1250 | 1500 | ||||||

| EP300 | 1.6 | 600 | 900 | 1200 | 1500 | 1800 | 2-30 | 2-20 | ||||

| EP350 | 1.7 | 700 | 1050 | 1400 | 1750 | 2100 | ||||||

| EP400 | 1.9 | 800 | 1200 | 1600 | 2000 | 2400 | ||||||

| EP500 | 2.1 | 1000 | 1500 | 2000 | 2500 | 3000 | ||||||

| EP630 | 2.6 | 1260 | 1890 | 2520 | 3150 | 3780 | ||||||

| Adhesion Strength and Elongation | |||||||||||||

| Carcass Type (EP/NN) | Adhesion | Elongation | |||||||||||

| Between Plies N/MM | Between Rubber and Carcass N/MM | Longitudinal Elongation At Break At All Thckness of Belt %≥ | Longitudinal Reference Tensile Rate at All Thickness of Belt %≤ | ||||||||||

| Cover Thickness (0.8-1.5mm) | Cover Thickness >1.5mm | ||||||||||||

| Mean Value | ≥ 4.5 | ≥3.2 | ≥3.5 | 10 | 2 | ||||||||

| Lowest Data | ≥3.9 | ≥2.4 | ≥2.9 | 10 | 2 | ||||||||

EP Conveyor Belt Construction

- Top Rubber Cover: Protects the belt surface from wear, impact, and chemicals; customizable for heat, oil, or abrasion resistance.

- EP Fabric: Core layer made of polyester and nylon, offering high strength and low stretch for stable.

- Skim Rubber: Bonding layer between plies that enhances adhesion and impact resistance.

- Bottom Rubber Cover: Shields the underside from pulley wear and external abrasion.

- Rubber Moulded Edge: Seals the edges to prevent moisture and dust ingress, extending belt lifespan.

EP Conveyor Belt Tensile Strength Test

In this video, we put our Rubber Conveyor Belt to the test—literally.

To verify the tensile strength of the belt, we secure both ends of a prepared sample using a calibrated clamping fixture.

The testing machine gradually applies increasing force until the belt finally breaks.

At the moment of rupture, the computer records the peak load, giving us the precise tensile strength of the material.

This process ensures our conveyor belts meet the mechanical performance standards required for heavy-duty industrial applications.

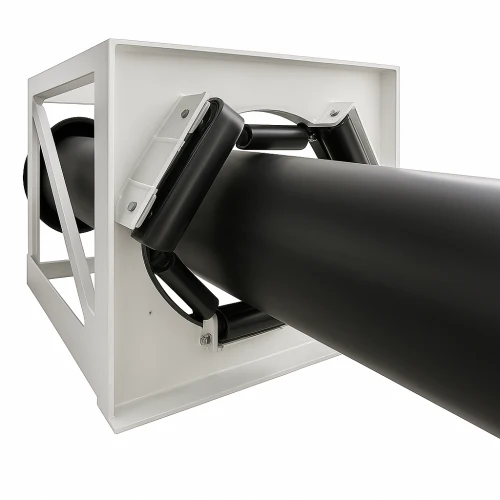

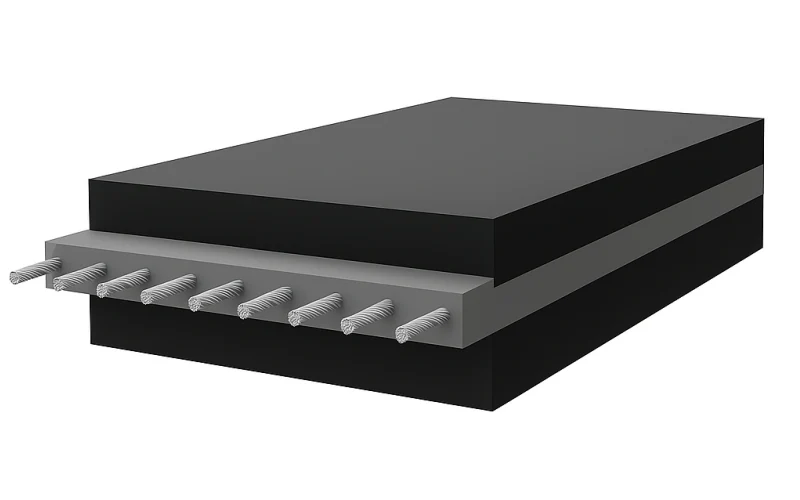

ST Rubber Conveyor Belt

- ST Rubber Conveyor Belt offers strength from ST630 to ST5400 for all-duty applications.

- Cord diameter ranges 3–11.3 mm, making ST Rubber Conveyor Belt highly customizable.

- ST Rubber Conveyor Belt features pitch options from 10 to 17±1.5 mm for stability.

- Cover thickness 5×5–9×9 mm enhances ST Rubber Conveyor Belt wear resistance.

- ST Rubber Conveyor Belt supports pulley diameters from 500 mm to 1800 mm.

- ST Rubber Conveyor Belt delivers strength and durability even under extreme load.

ST(Steel Cord) Conveyor Belt Specification

Strength:ST630-7100N/mm

Width(mm):400-2500

| Item | ST630 | ST800 | ST1000 | ST1250 | ST1600 | ST2000 | ST2500 | ST3150 | ST3500 | ST4000 | ST4500 | ST5000 | ST5400 |

Tensile strength(N/mm) | 630 | 800 | 1000 | 1250 | 1600 | 2000 | 2500 | 3150 | 3500 | 4000 | 4500 | 5000 | 5400 |

Diameter (mm) | 3 | 3.5 | 4 | 4.5 | 5 | 6 | 7.2 | 8.1 | 8.6 | 8.9 | 9.7 | 10.9 | 11.3 |

Pitch(mm) | 10±1.5 | 10±1.5 | 12±1.5 | 12±1.5 | 12±1.5 | 12±1.5 | 15±1.5 | 15±1.5 | 15±1.5 | 15±1.5 | 16±1.5 | 17±1.5 | 17±1.5 |

Cover Thickness (mm) | 5×5 | 5×5 | 6×6 | 6×6 | 6×6 | 8×8 | 8×8 | 8×8 | 8×8 | 8×8 | 8×8 | 8.5×8.5 | 9×9 |

Minimum Pulley Diameter(mm) | 500 | 500 | 630 | 800 | 1000 | 1000 | 1250 | 1400 | 1600 | 1600 | 1600 | 1800 | 1800 |

Number of Steel Cord

| Width (mm) | ST630 | ST800 | ST1000 | ST1250 | ST1600 | ST2000 | ST2500 | ST3150 | ST3500 | ST4000 | ST4500 | ST5000 | ST5400 |

| 800 | 75 | 75 | 63 | 63 | 63 | 63 | 50 | 50 | 50 | ||||

| 1000 | 95 | 95 | 79 | 79 | 79 | 79 | 64 | 64 | 64 | 64 | 59 | 55 | 55 |

| 1200 | 113 | 113 | 94 | 94 | 94 | 94 | 76 | 76 | 77 | 77 | 71 | 66 | 66 |

| 1400 | 133 | 133 | 111 | 111 | 111 | 111 | 89 | 89 | 90 | 90 | 84 | 78 | 78 |

| 1600 | 151 | 151 | 126 | 126 | 126 | 126 | 101 | 101 | 104 | 104 | 96 | 90 | 90 |

| 1800 | 171 | 143 | 143 | 143 | 143 | 114 | 114 | 117 | 117 | 109 | 102 | 102 | |

| 2000 | 159 | 159 | 159 | 159 | 128 | 128 | 130 | 130 | 121 | 113 | 113 | ||

| 2200 | 176 | 141 | 141 | 144 | 144 | 134 | 125 | 125 | |||||

| 2400 | 193 | 155 | 155 | 157 | 157 | 146 | 137 | 137 |

Adhesive

| Tensile Strength | ST630 | ST800 | ST1000 | ST1250 | ST1600 | ST2000 | ST2500 | ST3150 | ST3500 | ST4000 | ST4500 | ST5000 | ST5400 |

| Before Aging | 60 | 70 | 80 | 95 | 105 | 105 | 130 | 140 | 145 | 150 | 165 | 175 | 180 |

| After Aging | 55 | 65 | 75 | 90 | 95 | 95 | 120 | 130 | 140 | 145 | 160 | 170 | 175 |

ST Conveyor Belt Construction

- Top Cover:

Wear-resistant rubber layer for surface protection. - Bounding Rubber:

Ensures strong bonding between steel cords and covers. - Steel Cord:

High-strength galvanized wires for load bearing and low elongation. - Bottom Cover:

Protects the belt underside from friction and wear.

ST Conveyor Belt Tensile Strength

The principle of testing the tensile strength of a steel cord conveyor belt is similar to that of testing the tensile strength of an EP conveyor belt. However, since the steel cord can withstand greater tension, a larger clamp is required to clamp the conveyor belt, as shown in the figure, or another clamp fastened by screws.

NN Rubber Conveyor Belt

- Constructed with nylon-nylon fabric for high elasticity and flexibility.

- Runs smoothly on small pulleys without cracking or deformation.

- Excellent troughability for secure and stable material flow.

- Lightweight structure improves energy efficiency of the conveyor system.

- Strong impact absorption makes it ideal for drop loading conditions.

NN Conveyor Belt Specification

| Carcass | Carcass Structure | Carcas s Type | Carcass Thickness (mm/p) | Strength(N/mm) | Cover Thickness (mm) | Width (mm) | ||||||

| Warp | Weft | 2ply | 3ply | 4ply | 5ply | 6ply | top cover | bottom cover | ||||

NN | Nylon | Nylon | NN100 | 1 | 200 | 300 | 400 | 500 | 600 | 1.5-30 | 1.5-20 | 300-3500 |

| NN125 | 1 | 250 | 375 | 500 | 625 | 750 | ||||||

| NN150 | 1.1 | 300 | 450 | 600 | 750 | 900 | ||||||

| NN200 | 1.2 | 400 | 600 | 800 | 1000 | 1200 | ||||||

| NN250 | 1.4 | 500 | 750 | 1000 | 1250 | 1500 | ||||||

| NN300 | 1.6 | 600 | 900 | 1200 | 1500 | 1800 | 2-30 | 2-20 | ||||

| NN350 | 1.7 | 700 | 1050 | 1400 | 1750 | 2100 | ||||||

| NN400 | 1.9 | 800 | 1200 | 1600 | 2000 | 2400 | ||||||

| NN500 | 2.1 | 1000 | 1500 | 2000 | 2500 | 3000 | ||||||

| NN630 | 2.6 | 1260 | 1890 | 2520 | 3150 | 3780 | ||||||

| Adhesion Strength and Elongation | |||||||||||||

| Carcass Type (EP/NN) | Adhesion | Elongation | |||||||||||

| Between Plies N/MM | Between Rubber and Carcass N/MM | Longitudinal Elongation At Break At All Thckness of Belt %≥ | Longitudinal Reference Tensile Rate at All Thickness of Belt %≤ | ||||||||||

| Cover Thickness (0.8-1.5mm) | Cover Thickness >1.5mm | ||||||||||||

| Mean Value | ≥ 4.5 | ≥3.2 | ≥3.5 | 10 | 2 | ||||||||

| Lowest Data | ≥3.9 | ≥2.4 | ≥2.9 | 10 | 2 | ||||||||

NN Conveyor Belt Construction

- Top Cover Rubber:

Protects the belt surface from abrasion, impact, weather, and harsh material contact. - NN Fabric:

Reinforced nylon in both warp and weft ensures flexibility, strength, and good load-bearing capacity. - Adhesive Glue:

Strong bonding layer that tightly connects rubber and fabric, preventing internal separation or delamination. - Bottom Cover Rubber:

Provides underside protection from rollers, pulleys, and wear caused by constant running contact.

NN Conveyor Belt Tensile Strength

This test demonstrates the tensile strength of our NN Conveyor Belt.

A standard sample is cut and placed into a calibrated tensile testing machine.

Both ends are clamped securely to ensure accurate results.

The machine applies steady pulling force until the belt breaks.

At the point of failure, the system records the maximum load the belt can withstand.

This value reflects the actual tensile strength of the material.

The process helps confirm that our NN Conveyor Belts meet the mechanical requirements for demanding industrial use.

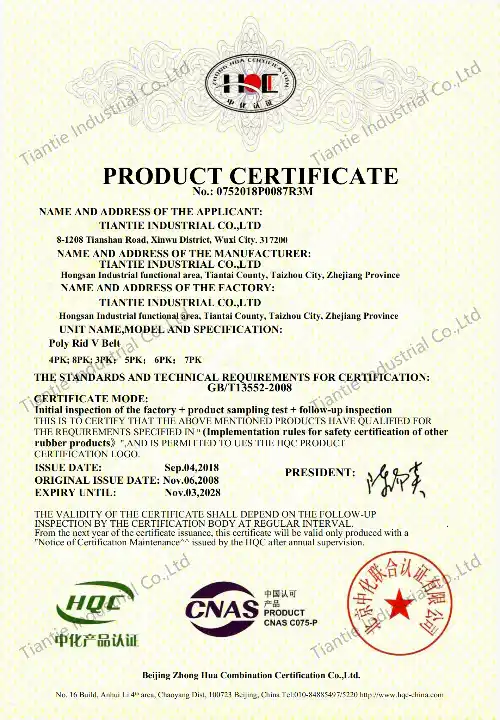

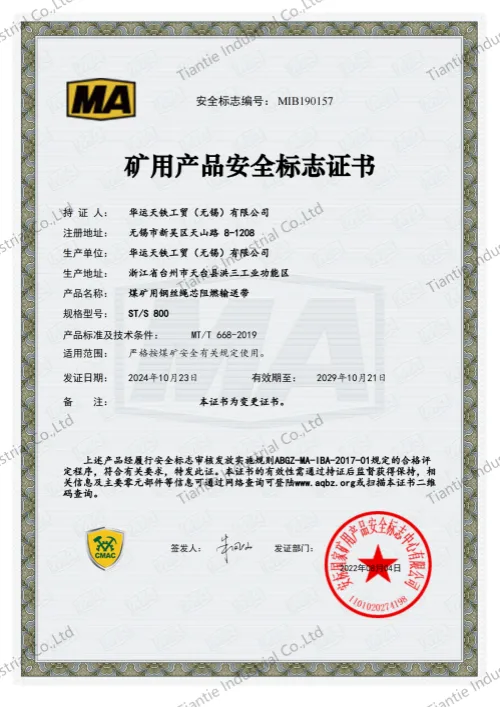

Quality Control

Bringing customers good service and good products is our pursuit.

Rubber Conveyor Belt Shipping And Packing

Packaging Forms:

Round roll

Glasses roll

Oval roll

Outer Wrapping:

PP tarpaulin (polypropylene waterproof cloth)

Customizable colors for tarpaulin wrapping

Support & Protection Options:

Wooden pallet

Metal pallet

Iron frame

Packaging Recommendation:

Tiantie Industrial will provide corresponding packaging suggestions based on the type of conveyor belt you order

REQUEST A QUOTE FOR MORE DETAILS

Rubber Conveyor Belt Engineering & Reliability

Our rubber conveyor belts are designed for strength, precision, and long-term reliability. Engineered with advanced materials, they ensure smooth operation under demanding industrial conditions.

How Does the Conveyor Belt Prevent Elongation?

Our belts feature steel cord or polyester-nylon reinforcements that prevent elongation. This ensures consistent tension and stable performance, reducing the need for frequent adjustments in long-haul applications.

How does the belt resist fire and static buildup?

Our flame-resistant rubber compounds meet ISO 340 standards, while the anti-static features help dissipate charge buildup, preventing safety hazards in environments like coal mines and grain storage areas.

How does the belt handle heavy loads?

Our belts use high-tensile steel cord made from multiple high-strength wires, providing superior load-bearing capacity and durability, allowing the belt to handle heavy loads without compromising performance.

What enhances belt flexibility in complex layouts?

The use of high-flexibility carcass materials allows our belts to handle tight turns and curves without cracking or causing stress. This design ensures better durability in challenging conveyor paths.

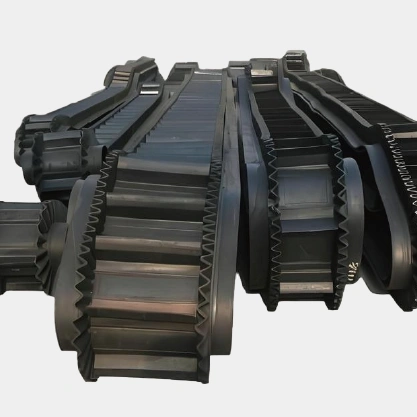

What prevents material spillage and edge wear?

Our belts are equipped with reinforced sidewalls and high-abrasion resistant rubber. This prevents material spillage and edge wear, ensuring a clean material transport process in mining, cement, and other bulk material applications.

How is belt traction on pulleys improved?

We use optimized rubber compounds with precision-engineered textures to increase traction, preventing slippage and improving efficiency in applications where consistent material flow is required.

Request A Free Quote

We'd like to work with you

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 12 hours .