Wear Resistant PVC Conveyor Belt

Wear Resistant PVC conveyor belts are made of high-strength wear-resistant PVC material with extremely high abrasion resistance and are suitable for use in mining, construction material transportation, wood processing and other industries.Its diverse surface treatment options enable it to demonstrate excellent friction and impact resistance in different working environments, making it an ideal choice for heavy-duty, high-abrasion working conditions.

Details

Application Scenario:

Wear Resistant PVC Conveyor Belt is designed for high friction, high impact and heavy duty material conveying needs, which is widely used in the mining industry, construction materials, wood processing and other fields, and is especially suitable for heavy-duty operating environments that require long hours of continuous conveying.Its excellent abrasion resistance effectively reduces wear and tear, extends service life, and reduces downtime, ensuring that the equipment maintains optimal operation under high-intensity working conditions.

Product Features:

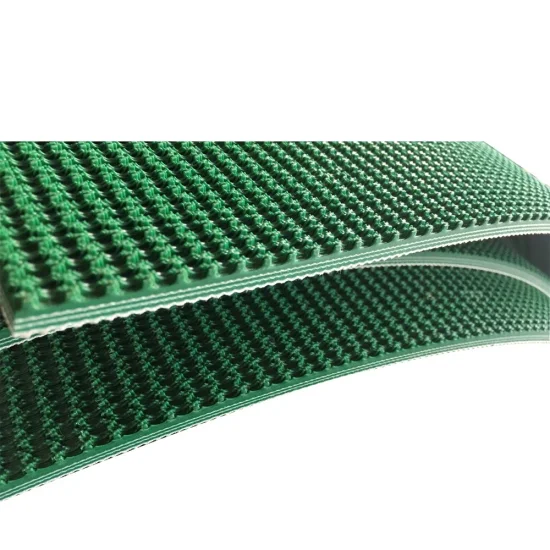

- Excellent abrasion resistance: the surface of this conveyor belt is formulated with special high abrasion-resistant PVC material, which is able to withstand high-frequency contact with rough and hard materials, and its abrasion-resistant grade ranges from 80mm³ to 150mm³, which greatly enhances the service life of the conveyor belt.

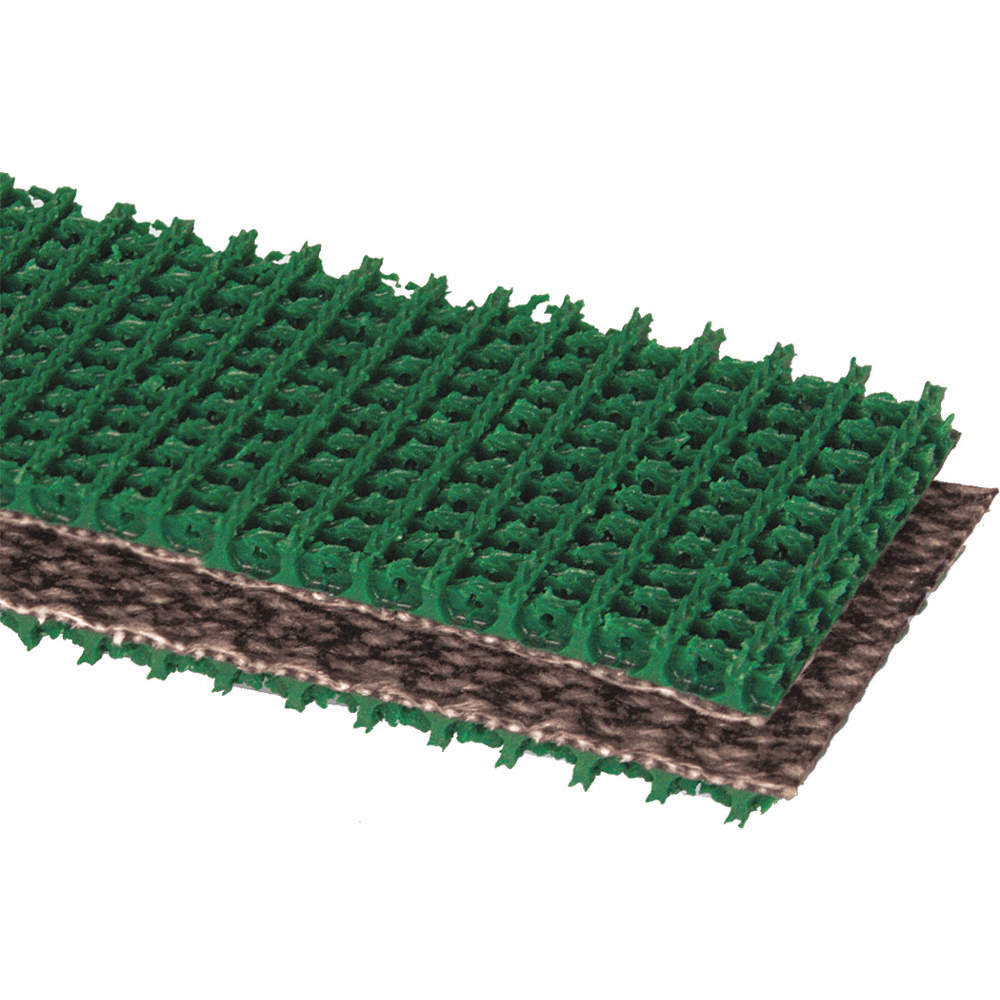

- Enhanced impact-resistant design: Specially designed to withstand heavy materials and high-impact scenarios, the conveyor belt can effectively absorb impacts during material loading and unloading, avoiding damage caused by excessive impact.

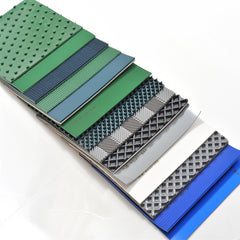

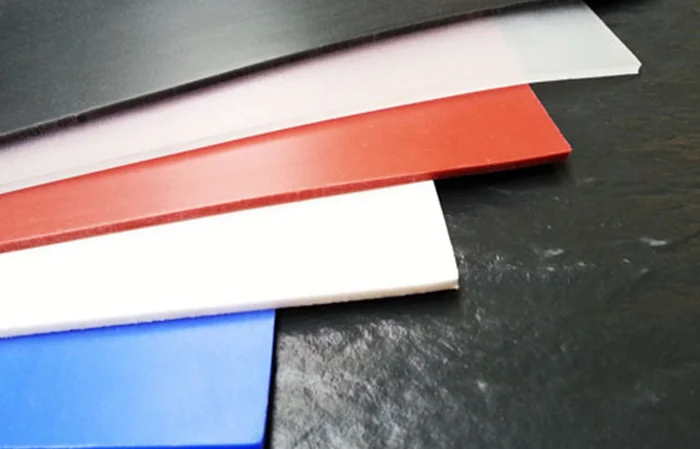

- Customized Surface Treatment: According to specific application scenarios, different surface treatments such as smooth, patterned or rough surface can be selected to adapt to different material requirements and ensure the stability of the material in high friction or inclined conveying environments.

- High and low temperature adaptability: the conveyor belt has good temperature adaptability and can maintain its performance in a wide range of temperatures from **-10°C to +70°C**, suitable for a variety of complex industrial operating environments.

Applicable environment:

- Mining industry: suitable for conveying hard materials such as ore, sand and gravel, it can resist high intensity friction and impact in mining scenarios to ensure long time and efficient operation.

- Construction Materials: Used for conveying construction materials such as cement, bricks, concrete, etc. The conveyor belts are able to withstand high abrasion and heavy-duty operations, which meets the construction industry’s stringent requirements for material handling.

- Wood processing: During wood processing, the conveyor belt reduces the friction loss of materials on the belt body through specific surface treatment, which is suitable for long time material transportation needs.

Product Advantage:

- Excellent anti-wear performance: when handling high friction materials, the conveyor belt shows excellent durability, which reduces the cost of frequent replacement and maintenance and guarantees the long-term operation of the equipment.

- Efficient impact resistance: Suitable for high-intensity loading and unloading and heavy-duty operation scenarios, the conveyor belt is able to effectively resist the impact of materials, preventing breakage and improving the reliability of equipment operation.

| Parameter | Descripción | Range |

| Thickness | Total belt thickness (in mm) | 3.0mm – 6.0mm |

| Wear-resistant grade | Abrasion resistance of the belt surface material for high friction conditions. | 80mm³ – 150mm³ |

| Impact resistance | Impact resistance of the conveyor belt when handling heavy or high impact materials | High impact design |

| Applicable temperature range | Operating temperature range that the belt can withstand (in °C) | -10°C to +70°C |

| Coefficient of friction | Coefficient of friction between conveyor belt surface and material for high friction demand environments | 0.6 – 0.8 |

| Load capacity | Maximum load capacity of the conveyor belt for heavy material transfer | High load capacity design |

| Surface Finishes | Conveyor belt surface treatment, including smooth, patterned and rough surface | Smooth, Patterned and Rough Surfaces |

| Conveying speed | Recommended maximum conveying speed (unit: m/s) | 1.5m/s – 3.5m/s |

| Weight | Weight per square meter of conveyor belt (in kg/m²) | 4.0kg/m² – 7.0kg/m² |

Related Products

Why Choose Our Industrial Adhesive Solutions for Your Manufacturing Needs?

Discover how our innovative conveyor belt solutions enhance efficiency, reduce downtime, and provide reliable performance for all your industrial needs.

QUALITY ASSURANCE

Adopts high-strength double anilox rollers and tear-resistant materials to ensure product durability, safety and compliance with strict quality standards.Technological Innovation

Introduces lifetime replacement-free anilox roller coating technology and high-efficiency automated equipment to improve production efficiency and reduce maintenance costs.Professional Services

provides one-on-one technical support and quick response to customer needs to ensure smooth and worry-free use.Diversified Choices

provides a variety of industrial solutions and customized services to meet the specific needs of different customers.

Hello

Get Free Quote

Contact us today to receive a customized quote for your conveyor belt needs—fast, easy, and at no cost!

changjiang No.1 Office Building ,No.8 Tianshan Road, Xinwu District, Wuxi City, Jiangsu Province, China