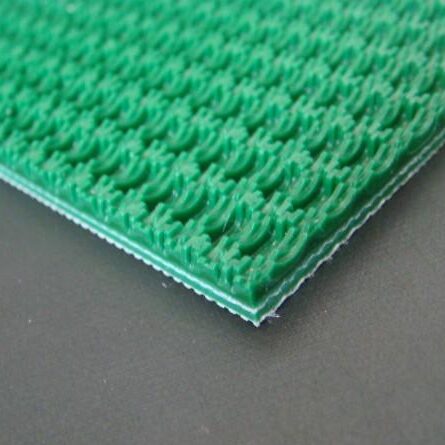

Anti-slip PVC Conveyor Belt

Anti-slip PVC conveyor belts provide efficient anti-slip performance through a special patterned surface treatment and are suitable for warehousing, logistics, food processing and other applications where material sliding needs to be prevented.With its excellent abrasion resistance and versatile surface design, this conveyor belt provides a durable, stable material handling solution under high-frequency operating conditions, and is particularly suitable for inclined conveying.

Details

Usage Scenario:

Anti-slip PVC conveyor belts are designed for the occasions where materials need to be prevented from sliding, and are widely used in warehousing and logistics, packaging, food processing, and material conveying with large inclined angles.The conveyor belt provides excellent anti-slip performance through special surface treatment technology, which ensures that the materials can remain stable without sliding or displacement under different conveying angles and working conditions.

Product Features:

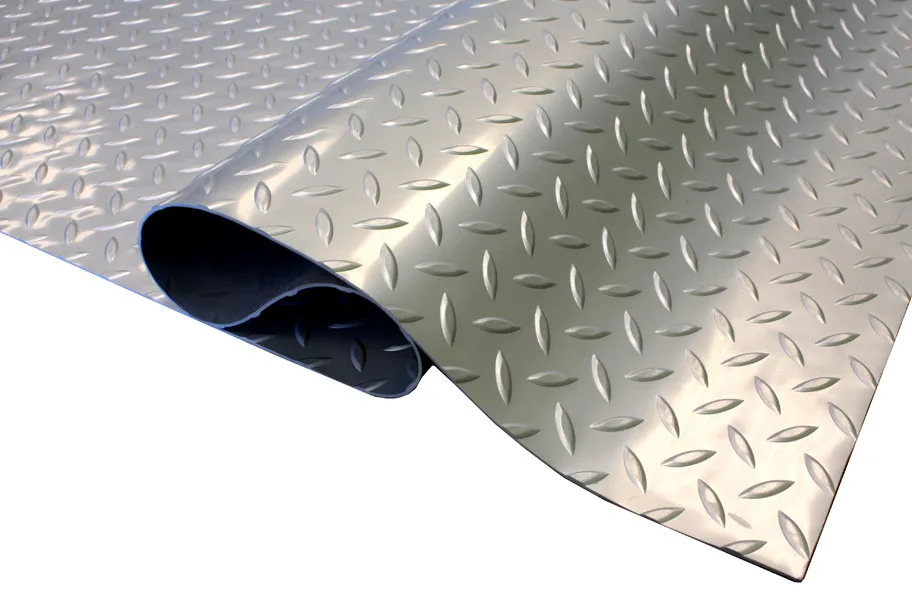

- Efficient anti-slip performance: the surface of the conveyor belt is designed with special anti-slip patterns, such as herringbone, checkerboard or rough surface treatment, which effectively improves the friction of the material in the conveying process, and is suitable for inclined transfer environments that require high friction.

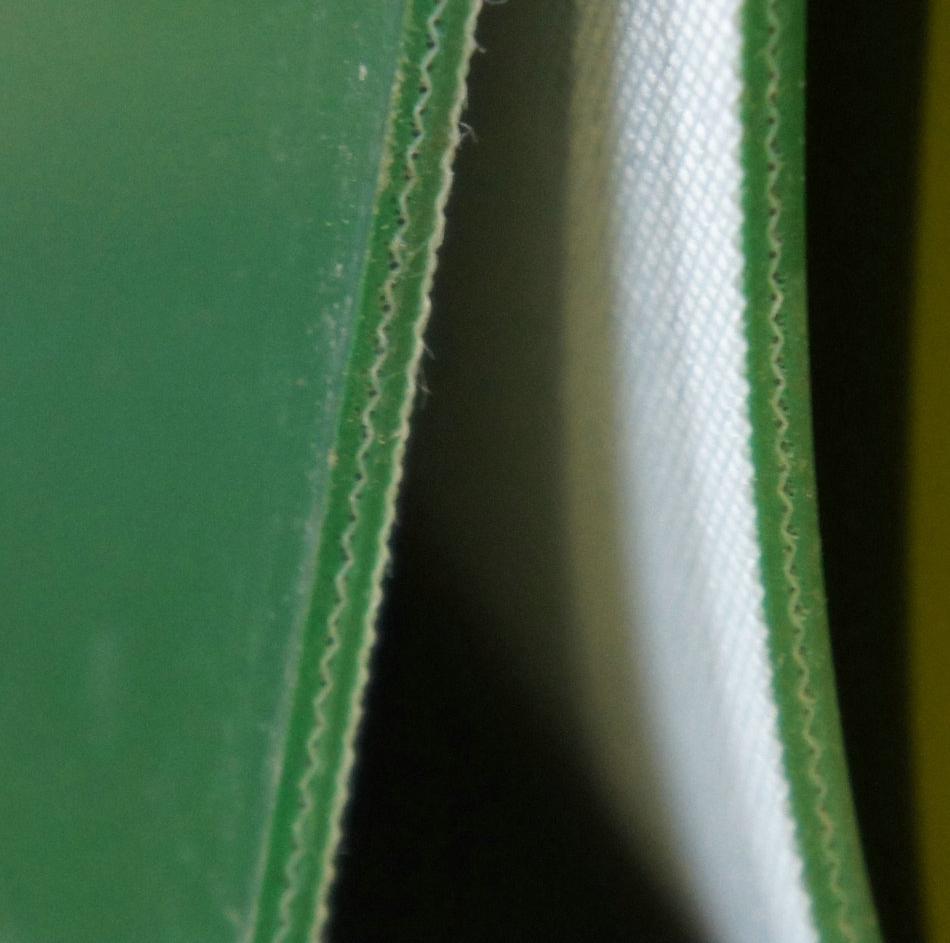

- Wear-resistant design: Anti-slip PVC conveyor belts are made of wear-resistant PVC material, which can maintain durability for a long time even under high-friction and high-frequency use conditions, reducing the need for frequent replacement.

- Multi-functional surface treatment: According to different working requirements, the conveyor belt provides a variety of surface structures, including herringbone pattern, mesh pattern, rough surface, etc., which ensures stable material transfer in various conveying scenarios.

- Flexibility and Tear Resistance: The conveyor belt has good flexibility to keep running smoothly in complex conveying paths, and the tear-resistant design is suitable for non-slip conveying of heavy materials.

Applicable environment:

- Warehousing and logistics industry: used in the process of conveying boxed, bagged or bulk materials, the non-slip pattern design ensures that the materials will not slip on the inclined conveyor belt, which is suitable for use in sorting, loading and unloading and automated logistics systems.

- Food processing industry: Especially suitable for inclined conveyor belts in food production, e.g. bakery, meat processing and packaging of fruits and vegetables, to prevent slippage of materials due to smooth surfaces or grease during transport.

- Packaging industry: In automated packaging lines, non-slip conveyor belts can ensure that packaging materials and finished products do not slide during rapid transmission, thus improving production efficiency.

Product Advantage:

- Excellent anti-slip effect: with a variety of patterns and surface treatment options, the conveyor belt can keep the material stable at any conveying angle, especially suitable for inclined conveying needs.

- Durable: The use of high-quality PVC material provides excellent abrasion and tear resistance, enabling long-time use in high-frequency operating environments, reducing belt replacement frequency and maintenance costs.

- Customized application scenarios: Surface treatments can be customized according to specific working conditions, ensuring stable transmission in different materials, environments and conveying paths.

| Parameters | Description | Range |

| Thickness | Total belt thickness (in mm) | 2.0mm – 5.0mm |

| Friction coefficient | Coefficient of friction between conveyor belt surface and material, suitable for anti-slip requirements. | 0.6 – 0.8 |

| Inclination angle | Inclination angle of the conveyor belt for material handling | 15° – 35 |

| Tear strength | Tear resistance of the conveyor belt material for non-slip conveying of heavy materials. | 200N/mm – 350N/mm |

| Applicable temperature range | Operating temperature range that the belt can withstand (in °C) | -10°C to +70°C |

| Abrasion resistance | Abrasion resistance of the belt surface material for frequent contact with rough or high friction environments. | 80mm³ – 120mm³ |

| Surface treatment | Conveyor belt surface treatments, including herringbone, mesh, rough surface and other non-slip patterns. | Herringbone, mesh, rough surface |

| Conveying speed | Recommended maximum conveying speed (unit: m/s) | 1.5m/s – 3.5m/s |

| Weight | Weight per square meter of conveyor belt (in kg/m²) | 3.5kg/m² – 6.5kg/m² |

Related Products

Why Choose Our Industrial Adhesive Solutions for Your Manufacturing Needs?

Discover how our innovative conveyor belt solutions enhance efficiency, reduce downtime, and provide reliable performance for all your industrial needs.

QUALITY ASSURANCE

Adopts high-strength double anilox rollers and tear-resistant materials to ensure product durability, safety and compliance with strict quality standards.Technological Innovation

Introduces lifetime replacement-free anilox roller coating technology and high-efficiency automated equipment to improve production efficiency and reduce maintenance costs.Professional Services

provides one-on-one technical support and quick response to customer needs to ensure smooth and worry-free use.Diversified Choices

provides a variety of industrial solutions and customized services to meet the specific needs of different customers.

Hello

Get Free Quote

Contact us today to receive a customized quote for your conveyor belt needs—fast, easy, and at no cost!

changjiang No.1 Office Building ,No.8 Tianshan Road, Xinwu District, Wuxi City, Jiangsu Province, China