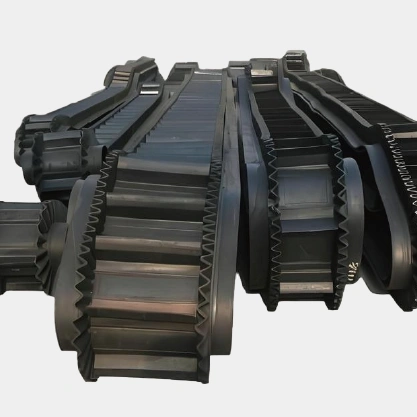

Acid and Alkali(Chemicals) Resistant Conveyor Belt

Acid and alkali resistant conveyor belts are specially designed for corrosive environments such as chemical industry, chemical fertilizer and paper making, with excellent acid and alkali resistance and corrosion resistance properties, suitable for material conveying needs of chemical plants, chemical fertilizer factories, paper mills and other factories and mining enterprises.

Details

- Uses:

- This conveyor belt is suitable for material conveying in corrosive environment, especially in chemical plants, fertilizer plants, paper mills and other places where acid and alkali resistance and corrosion resistance are required.

- Product Features:

- Excellent acid and alkali resistance: made of special materials, it can effectively resist various acid and alkali chemicals, ensuring the long-term use of the conveyor belt in highly corrosive environments.

- Excellent Corrosion Resistance: The surface coating has excellent corrosion resistance, which prevents deterioration and abrasion of the conveyor belt material caused by chemical reaction.

- HIGH DURABILITY: Conveyor belts are designed to meet industry standards to maintain stable performance under harsh operating conditions, extending service life and reducing downtime and maintenance costs.

- Applicable environment:

- Chemical plant: suitable for conveying various chemical raw materials and corrosive materials.

- Fertilizer factory: It can efficiently convey corrosive materials in the process of fertilizer production.

- Paper mills: to meet the special needs of the paper industry for acid and alkali resistance and corrosion resistance.

- Other factories and mines: Suitable for all industrial places that need acid and alkali resistant and corrosion resistant transportation.

- Uses:

| ITEM | Breaking strength,MPa | Elongation at break,% | abrasion,mm3 | hardness,(°) |

| Performance before agingg | ≥14.0 | ≥400 | ≤250 | 60±5 |

| Performance after aging | ≥12.0 | ≥340 | — | 65±10 |

| Note: When the thickness of the cover rubber is 0.8mm-1.6m, the sample thickness can be the maximum cut length, the tensile strength and the elongation at break are allowed to be 15% lower than those in the table. | ||||

| classes | solution | concentration | Covered condition | The change rate before and after covered | |

| Volume expansivity | Strength change rate | ||||

| A1 | (HCI) | 18% | 50℃×96h | +10%≥ | -10%≤ |

| A2 | (H2SO4) | 50% | 50℃×96h | +10%≥ | -10%≤ |

| A3 | (NaOH) | 48% | 50℃×96h | +10%≤ | -10%≤ |

Related Products

Why Choose Our Belts for Your Manufacturing Needs?

Discover how our innovative conveyor belt solutions enhance efficiency, reduce downtime, and provide reliable performance for all your industrial needs.

QUALITY ASSURANCE

Adopts high-strength double anilox rollers and tear-resistant materials to ensure product durability, safety and compliance with strict quality standards.Technological Innovation

Introduces lifetime replacement-free anilox roller coating technology and high-efficiency automated equipment to improve production efficiency and reduce maintenance costs.Professional Services

provides one-on-one technical support and quick response to customer needs to ensure smooth and worry-free use.Diversified Choices

provides a variety of industrial solutions and customized services to meet the specific needs of different customers.

Hello

Get Free Quote

Contact us today to receive a customized quote for your conveyor belt needs—fast, easy, and at no cost!

changjiang No.1 Office Building ,No.8 Tianshan Road, Xinwu District, Wuxi City, Jiangsu Province, China