EP Rubber Conveyor Belt

- Excellent dimensional stability thanks to low elongation polyester warp yarns

- Custom widths ranging from 300mm to 3500mm are available, depending on the required thickness and roll length.

- Various cover grades allow EP belts to perform reliably in harsh environments — from -60℃ freezing conditions to 300℃ heat, and in contact with oily, flammable, or abrasive materials.

- Its low stretch properties deliver exceptional stability and operational consistency.

- Strong interlayer bonding and superior adhesion between cover and fabric layers enhance belt integrity.

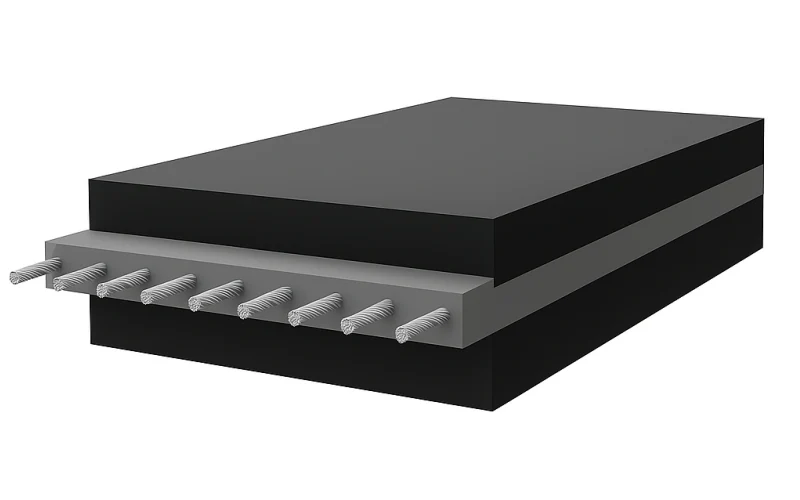

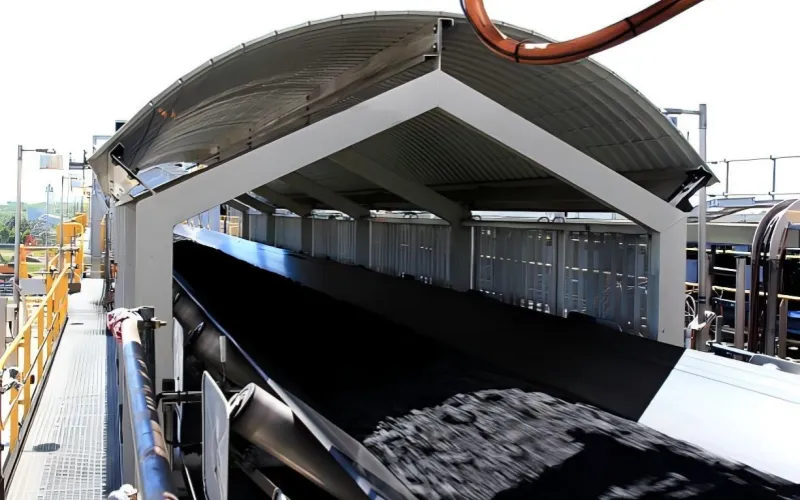

ST Rubber Conveyor Belt

- ST Rubber Conveyor Belt offers strength from ST630 to ST5400 for all-duty applications.

- Cord diameter ranges 3–11.3 mm, making ST Rubber Conveyor Belt highly customizable.

- ST Rubber Conveyor Belt features pitch options from 10 to 17±1.5 mm for stability.

- Cover thickness 5×5–9×9 mm enhances ST Rubber Conveyor Belt wear resistance.

- ST Rubber Conveyor Belt supports pulley diameters from 500 mm to 1800 mm.

- ST Rubber Conveyor Belt delivers strength and durability even under extreme load.

NN Rubber Conveyor Belt

- Constructed with nylon-nylon fabric for high elasticity and flexibility.

- Runs smoothly on small pulleys without cracking or deformation.

- Excellent troughability for secure and stable material flow.

- Lightweight structure improves energy efficiency of the conveyor system.

- Strong impact absorption makes it ideal for drop loading conditions.

Built for Your Business Needs

1.Longer Belt Life

In heavy-duty use, our belts last 6–12 months longer than standard options, backed by lab tests showing 30% better wear resistance—so you replace less often and cut downtime.

2. Faster Delivery

With 20 production lines and advanced vulcanizing presses, we ensure strong capacity for bulk orders. Standard belts are in stock, and custom belts can be delivered in as little as 15 days.

You get belts on time, so your project never misses a deadline.

3. Built for Any Condition

Whether you need belts that withstand heat up to 300°C, resist oil, or meet flame-retardant standards, we customize solutions that keep your system running without premature failure.

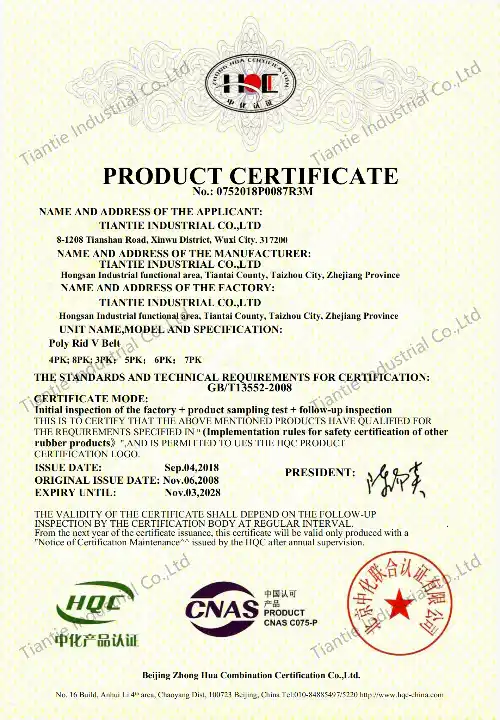

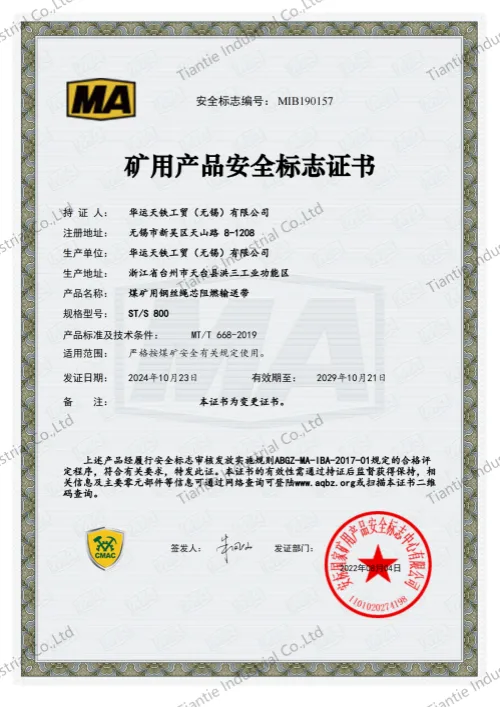

4. Global Standards Ready

Our belts are manufactured to ISO, DIN, RMA, JIS, and AS standards, ensuring compliance with international requirements and proven performance in 60+ countries.

5. Global Support & Responsive After-Sales

You can reach us 24/7, and we guarantee a reply within 12 hours or less, no matter where you are. Send us your request now—we’ll get back faster than you expect.

Who We Are ?-True Factory

As a leading china rubber conveyor belt manufacturer, Tiantie Industrial provides durable rubber conveyor belts with reliable quality.

Our 20 production lines, 60,000㎡ facilities, and 1,000+ employees ensure consistent quality. We provide EP, NN, and steel cord belts engineered for strength, durability, and heavy-duty applications.

Trusted by clients in South America, Africa, Middle East, and Southeast Asia, Tiantie stands out for strict ISO/DIN standards, factory-direct pricing, and delivery as fast as 15 days.

Why Global Clients Trust Tiantie Industrial

Direct from our factory in China, delivering ISO-certified rubber conveyor belts you can rely on.

Our clients choose us for reliable after-sales support and responsive service.

20+ years of factory expertise ensures customized belts with consistent quality.

From mining to power plants, 8,000+ projects prove our belts perform worldwide.

Rubber Conveyor Belt Shipping And Packing

Packaging Forms:

Round roll

Glasses roll

Oval roll

Outer Wrapping:

PP tarpaulin (polypropylene waterproof cloth)

Customizable colors for tarpaulin wrapping

Support & Protection Options:

Wooden pallet

Metal pallet

Iron frame

Quality Control

Bringing you good service and good products is our pursuit.

You Partner with a Reputable Team

We know that customer trust and satisfaction are our greatest assets. Through our dedication and quality, we’ve earned high praise and fostered lasting partnerships in conveyor belts for sale.

From project initiation to completion, the whole process was unbelievably smooth. The team was professional, efficient and exceeded our expectations. Highly recommended!

Every step of the cooperation demonstrated their professional competence and dedication. We are very pleased with the results and look forward to working together in the future.

No matter the situation, they responded and solved the problem quickly. Very reliable partners. We would absolutely choose them again and recommend them to any company in need of quality service.

Our Clients

Our success is proven by the strength of our clients.

Join the growing list of businesses that trust us for quality and reliable service.

F.A.Q

Our conveyor belts comply with international standards such as ISO quality management system and DIN , and undergo rigorous in-house quality testing and third-party certification to ensure that key properties such as abrasion resistance, tensile strength, and resistance to high temperatures are at industry-leading levels.

Yes, we not only optimize the performance of our products according to specific application scenarios, but also customize the size of the conveyor belt, the thickness of the top and bottom rubber, etc., to ensure compliance with special specifications, and provide one-on-one technical support to ensure that the customized products accurately fit your needs.

We will take samples from the product after completion, and prioritize testing in the laboratory to ensure that the performance meets the standard before arranging shipment to ensure that you receive a reliable product quality to meet the requirements of actual use.

We offer a variety of high-quality packaging options such as PP bags, as well as steel pallet packaging options for added transportation security, ensuring that the conveyor belts are protected from damage during long-distance shipments and are delivered to the customer in perfect condition.

We have a dedicated after-sales team with an average response time of 12 hours and provide initial solutions within 24 hours to ensure that your production process is not affected.

We have over 20 years of international export experience and have handled export requirements from more than 50 countries around the world, and can help you complete customs clearance and logistics arrangements efficiently.