EP and NN Conveyor Belts Tailored for Your Load and Budget

—Tiantie Industrial

Choose the Right Fabric Belt—Built to Handle Your Workload, Environment, and Expectations

EP Rubber Conveyor Belt

- Excellent dimensional stability thanks to low elongation polyester warp yarns

- Custom widths ranging from 300mm to 3500mm are available, depending on the required thickness and roll length.

- Various cover grades allow EP belts to perform reliably in harsh environments — from -60℃ freezing conditions to 300℃ heat, and in contact with oily, flammable, or abrasive materials.

- Its low stretch properties deliver exceptional stability and operational consistency.

- Strong interlayer bonding and superior adhesion between cover and fabric layers enhance belt integrity.

EP Conveyor Belt Specification

| Carcass | Carcass Structure | Carcas s Type | Carcass Thickness (mm/p) | Strength(N/mm) | Cover Thickness (mm) | Width (mm) | ||||||

| Warp | Weft | 2ply | 3ply | 4ply | 5ply | 6ply | top cover | bottom cover | ||||

| EP | Polyester | Nylon | EP100 | 1 | 200 | 300 | 400 | 500 | 600 | 1.5-30 | 1.5-20 | 300-3500 |

| EP125 | 1 | 250 | 375 | 500 | 625 | 750 | ||||||

| EP150 | 1.1 | 300 | 450 | 600 | 750 | 900 | ||||||

| EP200 | 1.2 | 400 | 600 | 800 | 1000 | 1200 | ||||||

| EP250 | 1.4 | 500 | 750 | 1000 | 1250 | 1500 | ||||||

| EP300 | 1.6 | 600 | 900 | 1200 | 1500 | 1800 | 2-30 | 2-20 | ||||

| EP350 | 1.7 | 700 | 1050 | 1400 | 1750 | 2100 | ||||||

| EP400 | 1.9 | 800 | 1200 | 1600 | 2000 | 2400 | ||||||

| EP500 | 2.1 | 1000 | 1500 | 2000 | 2500 | 3000 | ||||||

| EP630 | 2.6 | 1260 | 1890 | 2520 | 3150 | 3780 | ||||||

| Adhesion Strength and Elongation | |||||||||||||

| Carcass Type (EP/NN) | Adhesion | Elongation | |||||||||||

| Between Plies N/MM | Between Rubber and Carcass N/MM | Longitudinal Elongation At Break At All Thckness of Belt %≥ | Longitudinal Reference Tensile Rate at All Thickness of Belt %≤ | ||||||||||

| Cover Thickness (0.8-1.5mm) | Cover Thickness >1.5mm | ||||||||||||

| Mean Value | ≥ 4.5 | ≥3.2 | ≥3.5 | 10 | 2 | ||||||||

| Lowest Data | ≥3.9 | ≥2.4 | ≥2.9 | 10 | 2 | ||||||||

EP Conveyor Belt Construction

- Top Rubber Cover: Protects the belt surface from wear, impact, and chemicals; customizable for heat, oil, or abrasion resistance.

- EP Fabric: Core layer made of polyester and nylon, offering high strength and low stretch for stable.

- Skim Rubber: Bonding layer between plies that enhances adhesion and impact resistance.

- Bottom Rubber Cover: Shields the underside from pulley wear and external abrasion.

- Rubber Moulded Edge: Seals the edges to prevent moisture and dust ingress, extending belt lifespan.

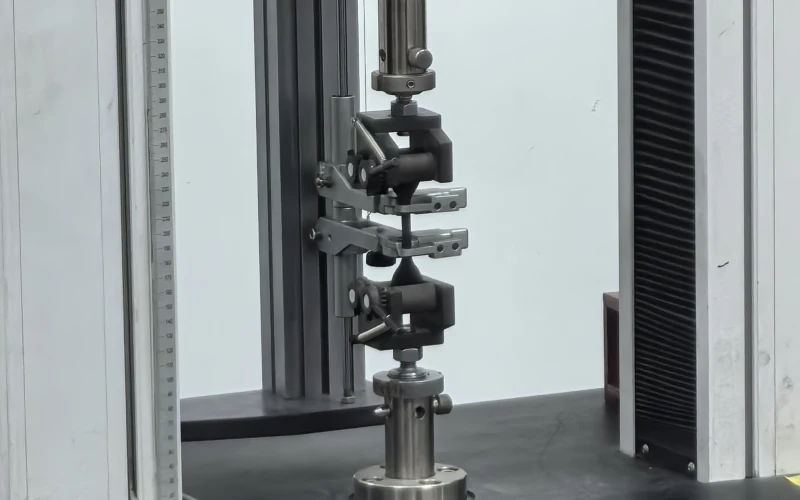

EP Conveyor Belt Tensile Strength Test

In this video, we put our Rubber Conveyor Belt to the test—literally.

To verify the tensile strength of the belt, we secure both ends of a prepared sample using a calibrated clamping fixture.

The testing machine gradually applies increasing force until the belt finally breaks.

At the moment of rupture, the computer records the peak load, giving us the precise tensile strength of the material.

This process ensures our conveyor belts meet the mechanical performance standards required for heavy-duty industrial applications.

NN Rubber Conveyor Belt

- Constructed with nylon-nylon fabric for high elasticity and flexibility.

- Runs smoothly on small pulleys without cracking or deformation.

- Excellent troughability for secure and stable material flow.

- Lightweight structure improves energy efficiency of the conveyor system.

- Strong impact absorption makes it ideal for drop loading conditions.

NN Conveyor Belt Specification

| Carcass | Carcass Structure | Carcas s Type | Carcass Thickness (mm/p) | Strength(N/mm) | Cover Thickness (mm) | Width (mm) | ||||||

| Warp | Weft | 2ply | 3ply | 4ply | 5ply | 6ply | top cover | bottom cover | ||||

NN | Nylon | Nylon | NN100 | 1 | 200 | 300 | 400 | 500 | 600 | 1.5-30 | 1.5-20 | 300-3500 |

| NN125 | 1 | 250 | 375 | 500 | 625 | 750 | ||||||

| NN150 | 1.1 | 300 | 450 | 600 | 750 | 900 | ||||||

| NN200 | 1.2 | 400 | 600 | 800 | 1000 | 1200 | ||||||

| NN250 | 1.4 | 500 | 750 | 1000 | 1250 | 1500 | ||||||

| NN300 | 1.6 | 600 | 900 | 1200 | 1500 | 1800 | 2-30 | 2-20 | ||||

| NN350 | 1.7 | 700 | 1050 | 1400 | 1750 | 2100 | ||||||

| NN400 | 1.9 | 800 | 1200 | 1600 | 2000 | 2400 | ||||||

| NN500 | 2.1 | 1000 | 1500 | 2000 | 2500 | 3000 | ||||||

| NN630 | 2.6 | 1260 | 1890 | 2520 | 3150 | 3780 | ||||||

| Adhesion Strength and Elongation | |||||||||||||

| Carcass Type (EP/NN) | Adhesion | Elongation | |||||||||||

| Between Plies N/MM | Between Rubber and Carcass N/MM | Longitudinal Elongation At Break At All Thckness of Belt %≥ | Longitudinal Reference Tensile Rate at All Thickness of Belt %≤ | ||||||||||

| Cover Thickness (0.8-1.5mm) | Cover Thickness >1.5mm | ||||||||||||

| Mean Value | ≥ 4.5 | ≥3.2 | ≥3.5 | 10 | 2 | ||||||||

| Lowest Data | ≥3.9 | ≥2.4 | ≥2.9 | 10 | 2 | ||||||||

NN Conveyor Belt Construction

- Top Cover Rubber:

Protects the belt surface from abrasion, impact, weather, and harsh material contact. - NN Fabric:

Reinforced nylon in both warp and weft ensures flexibility, strength, and good load-bearing capacity. - Adhesive Glue:

Strong bonding layer that tightly connects rubber and fabric, preventing internal separation or delamination. - Bottom Cover Rubber:

Provides underside protection from rollers, pulleys, and wear caused by constant running contact.

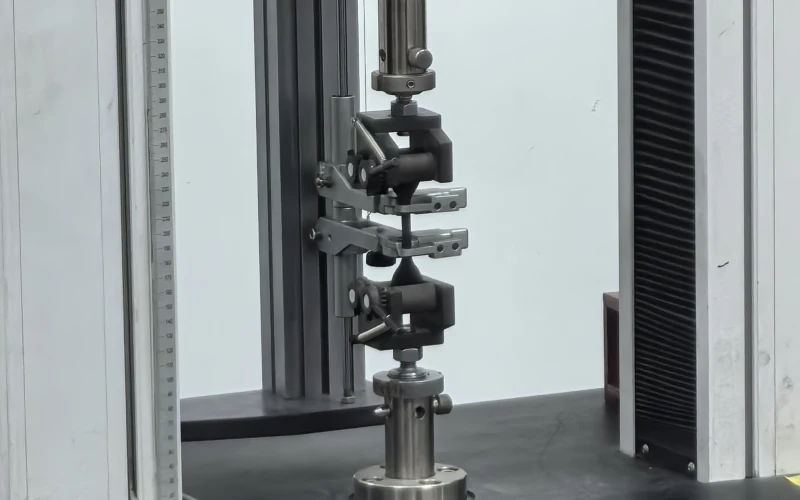

NN Conveyor Belt Tensile Strength

This test demonstrates the tensile strength of our NN Conveyor Belt.

A standard sample is cut and placed into a calibrated tensile testing machine.

Both ends are clamped securely to ensure accurate results.

The machine applies steady pulling force until the belt breaks.

At the point of failure, the system records the maximum load the belt can withstand.

This value reflects the actual tensile strength of the material.

The process helps confirm that our NN Conveyor Belts meet the mechanical requirements for demanding industrial use.

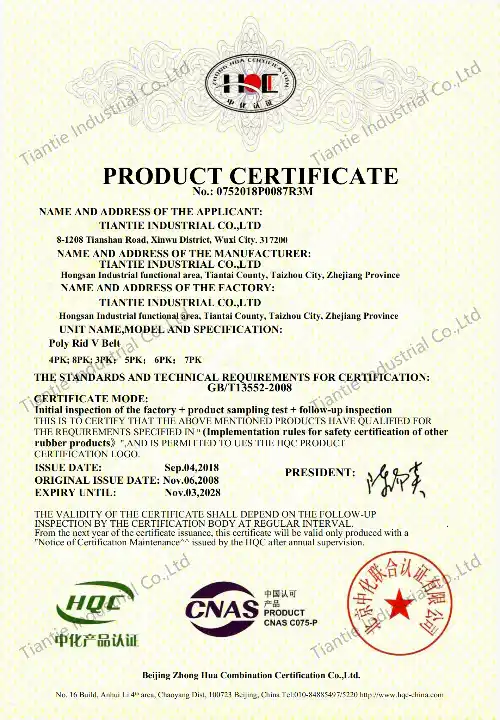

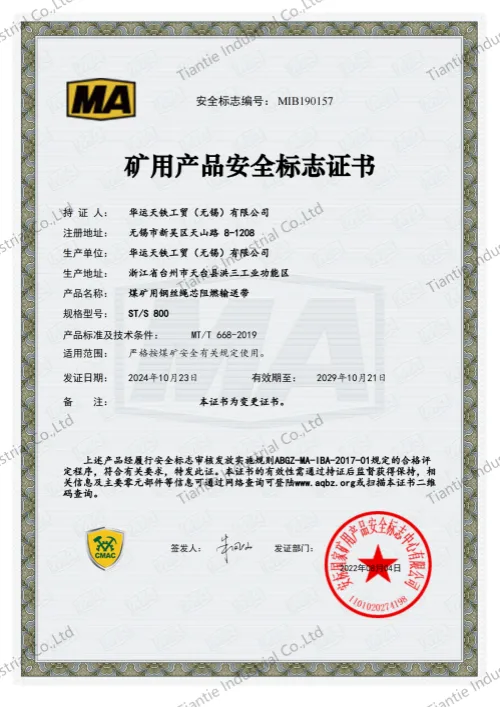

Quality Control

Bringing you good service and good products is our pursuit.

Rubber Conveyor Belt Shipping And Packing

Packaging Forms:

Round roll

Glasses roll

Oval roll

Outer Wrapping:

PP tarpaulin (polypropylene waterproof cloth)

Customizable colors for tarpaulin wrapping

Support & Protection Options:

Wooden pallet

Metal pallet

Iron frame

Packaging Recommendation:

Tiantie Industrial will provide corresponding packaging suggestions based on the type of conveyor belt you order

Why Choose Us

Experience the reliability of a leading Rubber conveyor belt manufacturer in China.

Trust us to deliver consistent, high-quality results.

We are proud to maintain an unparalleled level of client satisfaction, built on trust, reliability, and quality service in providing industrial conveyor belts.

As a professional conveyor belt company, we offer customized conveyor belt solutions, backed by 20+ years of experience, ensuring quality and operational efficiency.

Our proven track record speaks for itself, with thousands of industrial conveyor belt projects successfully delivered to satisfied clients worldwide.

You Partner with a Reputable Team

We know that customer trust and satisfaction are our greatest assets. Through our dedication and quality, we’ve earned high praise and fostered lasting partnerships in conveyor belts for sale.

From project initiation to completion, the whole process was unbelievably smooth. The team was professional, efficient and exceeded our expectations. Highly recommended!

Every step of the cooperation demonstrated their professional competence and dedication. We are very pleased with the results and look forward to working together in the future.

No matter the situation, they responded and solved the problem quickly. Very reliable partners. We would absolutely choose them again and recommend them to any company in need of quality service.

Our Clients

Our success is proven by the strength of our clients.

Join the growing list of businesses that trust us for quality and reliable service.

F.A.Q

Our conveyor belts comply with international standards such as ISO quality management system and DIN , and undergo rigorous in-house quality testing and third-party certification to ensure that key properties such as abrasion resistance, tensile strength, and resistance to high temperatures are at industry-leading levels.

Yes, we not only optimize the performance of our products according to specific application scenarios, but also customize the size of the conveyor belt, the thickness of the top and bottom rubber, etc., to ensure compliance with special specifications, and provide one-on-one technical support to ensure that the customized products accurately fit your needs.

We will take samples from the product after completion, and prioritize testing in the laboratory to ensure that the performance meets the standard before arranging shipment to ensure that you receive a reliable product quality to meet the requirements of actual use.

We offer a variety of high-quality packaging options such as PP bags, as well as steel pallet packaging options for added transportation security, ensuring that the conveyor belts are protected from damage during long-distance shipments and are delivered to the customer in perfect condition.

We have a dedicated after-sales team with an average response time of 12 hours and provide initial solutions within 24 hours to ensure that your production process is not affected.

We have over 20 years of international export experience and have handled export requirements from more than 50 countries around the world, and can help you complete customs clearance and logistics arrangements efficiently.