High-Performance Rubber Conveyor Belts

Built for Your Industry

From mining to material handling, our belts deliver strength, safety, and stability—right from our factory to your site.

Types of Rubber Conveyor Belt

Steel Cord Conveyor Belt

Engineered for mining, cement, and power plants—built to handle ultra-heavy loads over long distances with superior strength and impact resistance.

EP Conveyor Belt

Ideal for stone crushing plants, ports, and coal handling. Offers high strength, wear resistance, and low elongation in medium to heavy-duty applications.

Nylon Conveyor Belt

Flexible and impact-resistant for logistics centers, brick factories, and grain processing. Perfect for high-speed, short-distance conveying under dynamic loads.

Straight Warp Conveyor Belt

Compact, cost-effective for recycling plants, crushers, and quarries. Ensures stable performance in tight, lightweight systems.

Pipe Conveyor Belt

Perfect for cement plants, ports, and environmentally sensitive zones. Fully enclosed design prevents spillage, ideal for curved and inclined material transport.

Sensor Conveyor belt

Used in smart factories, steel mills, and critical monitoring zones. Integrates sensors to track temperature, wear, and load—enabling predictive maintenance and automation.

Why Choose Us

Experience the reliability of a leading conveyor belt manufacturer in China.

Trust us to deliver consistent, high-quality results.

We are proud to maintain an unparalleled level of client satisfaction, built on trust, reliability, and quality service in providing industrial conveyor belts.

As a professional conveyor belt company, we offer customized conveyor belt solutions, backed by 20+ years of experience, ensuring quality and operational efficiency.

Our proven track record speaks for itself, with thousands of industrial conveyor belt projects successfully delivered to satisfied clients worldwide.

What Sets Us Apart

Superior Durability

Our conveyor belts offer stable performance and extended lifespan, thanks to advanced composite layer technology, ensuring reliability under varying loads.

Exclusive customization

We offer custom rubber conveyor belts tailored to specific needs, ensuring reliable performance and stability across various industrial environments.

International Cooperation

We collaborate with leading global enterprises to develop high-quality conveyor belts meeting international standards, ensuring top performance.

Extreme Resistance

Our Rubber conveyor belts feature excellent anti-static and oil-resistant properties, ensuring stable performance and reliability in food processing environments.

Low MOQ

We offer MOQs 30% lower than comparable companies, allowing businesses of all sizes to access our high-quality conveyor belts without large bulk commitments.

Excellent After-Sales Service

Our team responds 50% faster than competitors, offering comprehensive after-sales support to ensure a worry-free experience with our rubber conveyor belts.

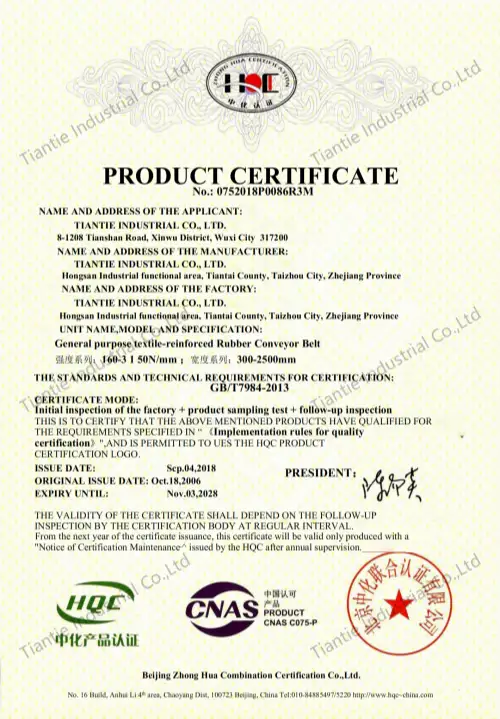

Our Certificates

We deliver top-quality products backed by ISO 9001, ISO 14001, and ISO 45001 certifications—ensuring reliability, environmental responsibility, and workplace safety.

Professional Processes for Best Quality

Unsure About Product Quality? Every Belt We Ship Is Fully Traceable

Visual appearance doesn’t reflect what’s inside. That’s why we ensure every conveyor belt you receive from us comes with:

- A unique serial number linked to production batch, raw material origin, and test data.

- Full factory inspection reports including tensile strength, abrasion resistance, and layer bonding

- Optional third-party certifications upon request

- Archived samples for future verification, supporting long-term supply consistency

Frequent Replacements? We Specialize in High-Durability, Heavy-Duty Belts

Frequent belt failures in harsh environments lead to costly downtime and lost efficiency:

- Wear-resistant, heat-resistant, tear-resistant rubber compounds

- High-strength EP fabrics for superior load capacity and impact resistance

- Custom structures for high-temperature, anti-adhesive, or oil-resistant applications

- Tailored recommendations based on actual material type and operational load

Poor After-Sales Support? We Provide Fast, Professional, and Traceable Service

When problems arise, we don’t disappear — we respond. Our after-sales support is structured and responsive:

- Every client is assigned a dedicated service contact

- 12-hour response commitment, with initial technical analysis within 24 hours

- Easy reporting process with photo, serial number, and on-site info submission

- Full batch data traceability to speed up root cause diagnosis and resolution

Delivery Delays? We Commit to Predictable Production and Shipping Timelines

On-time delivery is critical to your project’s success. We make sure our belts arrive when you need them:

- 15 advanced production lines ensure fast turnaround, even for large orders

- ERP-driven smart scheduling with real-time order tracking

- Urgent order “fast-track” channel available for critical project deadlines

- Pre-shipping photo archive and full logistics traceability

Cheap Belt = Expensive Problem? We Focus on Total Cost of Ownership (TCO)

Low-cost belts may seem attractive upfront — until they break early, require frequent replacements, and disrupt your workflow. Our approach focuses on long-term savings:

- Longer service life = fewer stoppages

- Better maintainability = lower labor costs

- More uptime = higher operational efficiency

- Faster response = minimized downtime risks

We are a professional and reputable company.

We know that customer trust and satisfaction are our greatest assets. Through our dedication and quality, we’ve earned high praise and fostered lasting partnerships in conveyor belts for sale.

From project initiation to completion, the whole process was unbelievably smooth. The team was professional, efficient and exceeded our expectations. Highly recommended!

Every step of the cooperation demonstrated their professional competence and dedication. We are very pleased with the results and look forward to working together in the future.

No matter the situation, they responded and solved the problem quickly. Very reliable partners. We would absolutely choose them again and recommend them to any company in need of quality service.

Our Clients

Our success is proven by the strength of our clients.

Join the growing list of businesses that trust us for quality and reliable service.

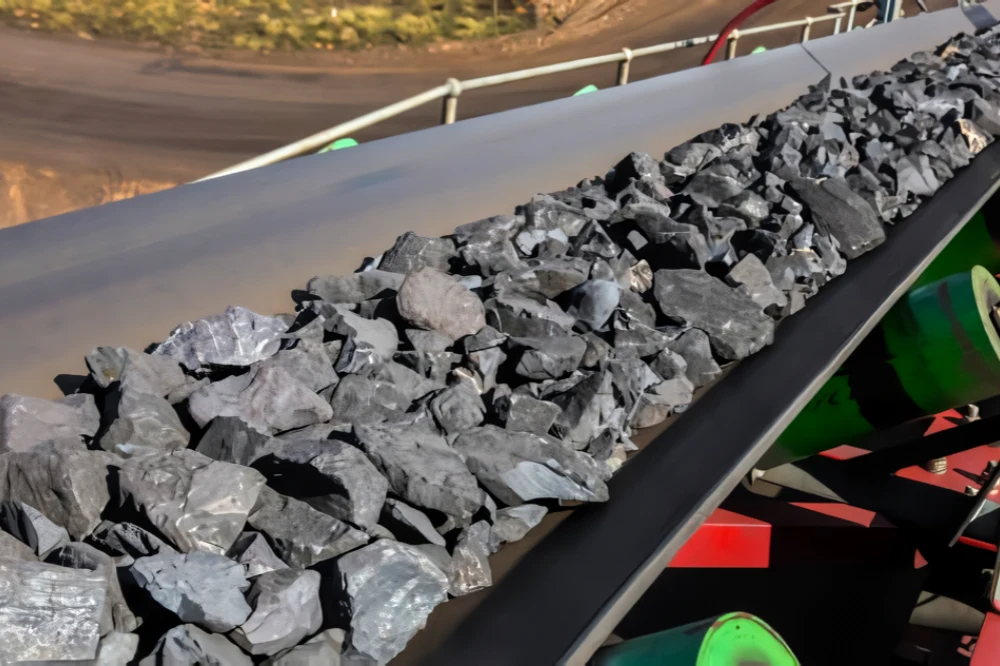

application

Lime Transportation

Ore Transportation

Cinder Transportation

Wood Transportation

Grain Transportation

Salt Transportation

F.A.Q

Our conveyor belts comply with international standards such as ISO quality management system and DIN , and undergo rigorous in-house quality testing and third-party certification to ensure that key properties such as abrasion resistance, tensile strength, and resistance to high temperatures are at industry-leading levels.

We complete custom production within 20 days, thanks to our 10 production lines and advanced ERP system. With efficient global logistics, you get your belts on time—minimizing delays and keeping your operations moving.

Absolutely. You can customize ply count, tensile strength, cover thickness, width, and surface type. Our engineers will work with you to ensure the belts meet your specific working conditions and international standards.

Our belts are manufactured under ISO 9001, ISO 14001, and MA certifications, and comply with DIN and RMA standards. Every step of production is traceable via QR-coded process control, so you get consistent, high-performance belts—batch after batch.

We have a dedicated after-sales team with an average response time of 12 hours and provide initial solutions within 24 hours to ensure that your production process is not affected.

Our MOQ is 30% lower than the industry average, making it easier for you to start orders, test products, or stock up in batches. We welcome both trial orders and long-term partnerships.