High-Performance Mining Conveyor Belt Manufacturer

Delivered in as fast as 20 days with full after-sales support

—get your mining conveyor belts when you need them.

High-Volume Conveyor Belts

– Coal Mine Durability, Wholesale Pricing

Engineered to Cut Your Mining Conveyor Belt Costs – No Minimum Order, Fast Turnaround

- Price Match Guarantee – Found cheaper? We’ll beat it by 5%

- 20-Day Standard Lead Time – Custom-built belts shipped globally

- Bulk Order Savings – Order 500m+ & save 18% on abrasion-resistant cores

Who We Are ?-True Factory

As a leading Mining Conveyor Belt Manufacturer, Tiantie Industrial provides durable Mining rubber conveyor belts with reliable quality.

Our 20 production lines, 60,000㎡ facilities, and 1,000+ employees ensure consistent quality. We provide EP, NN, and steel cord belts engineered for strength, durability, and heavy-duty applications.

Trusted by clients in South America, Africa, Middle East, and Southeast Asia, Tiantie stands out for strict ISO/DIN standards, factory-direct pricing, and delivery as fast as 20 days.

Delivery Mining Conveyor Belt in 20 Days

- Fireproof compounds (MA-certified) for safer coal mine use

- Steel-cord reinforced layers built for 24/7 abrasion resistance

- Anti-static protection to reduce explosive dust ignition risk

- Fast custom delivery in 20 days, with 100m+ B2B MOQ support

Trusted Mining Conveyor Belt Supplier in 60+ Countries

“Need a mining conveyor belt that withstands heat, abrasion, and heavy loads? TIANTIE INDUSTRIAL supplies custom-engineered belts trusted in 60+ countries to reduce downtime and cut maintenance costs.”

“Every belt is built for your operation—whether in deep coal mines or remote sites. We deliver in as fast as 20 days and provide custom designs even for low MOQs, so your production never stops.”

“You get certified fire-resistant belts, proven longer service life, and reliable global supply from a manufacturer with 20+ years of experience.”

Why Choose Tiantie ?

Field results show our belts run 6–12 months longer than standard options. That means fewer belt replacements, reduced maintenance, and less costly downtime for your mine.

- Precision Production Capacity

Bulk mining belts (1500m+) shipped in as fast as 20 days.

- 24/7 Service Support

Our team is available 24/7 to answer your questions, confirm specs, and provide fast technical support worldwide.

- Proven Wear Resistance

Built to last longer in coal and rock, reducing replacement cycles.

- Custom Mining Solutions

Belts tailored to your mine—from steep inclines to high-moisture conditions.

Visit Our Professional Factory

Compounding Workshop

Compounded Rubber

Calendering

Forming

Vulcanization

Vulcanization Test

Tensile Strength test

Rubber Aging Test

Products Finished

You Deserve a Trusted Supplier

We know that customer trust and satisfaction are our greatest assets. Through our dedication and quality, we’ve earned high praise and fostered lasting partnerships in conveyor belts for sale.

From project initiation to completion, the whole process was unbelievably smooth. The team was professional, efficient and exceeded our expectations. Highly recommended!

Every step of the cooperation demonstrated their professional competence and dedication. We are very pleased with the results and look forward to working together in the future.

No matter the situation, they responded and solved the problem quickly. Very reliable partners. We would absolutely choose them again and recommend them to any company in need of quality service.

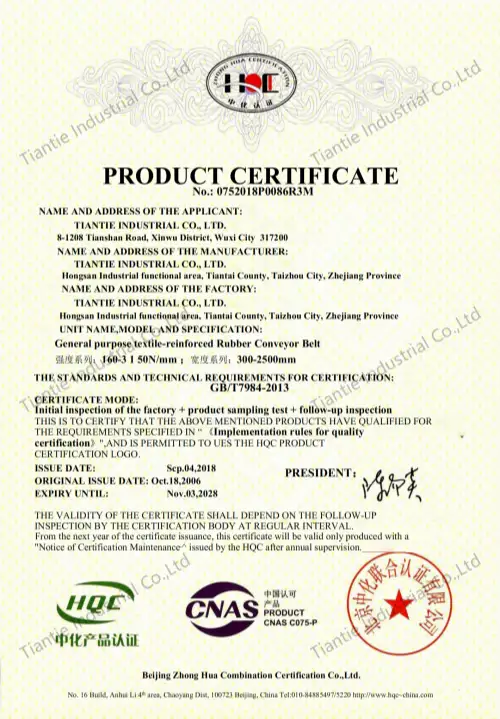

Our Certificates

Here is the certificate of the mining conveyor belt you need.

F.A.Q

Our mining conveyor belts comply with international standards such as ISO quality management system and DIN , and undergo rigorous in-house quality testing and third-party certification to ensure that key properties such as abrasion resistance, tensile strength, and resistance to high temperatures are at industry-leading levels.

We complete custom production within 20 days, thanks to our 10 production lines and advanced ERP system. With efficient global logistics, you get your belts on time—minimizing delays and keeping your operations moving.

Absolutely. You can customize ply count, tensile strength, cover thickness, width, and surface type. Our engineers will work with you to ensure the belts meet your specific working conditions and international standards.

Our belts are manufactured under ISO 9001, ISO 14001, and MA certifications, and comply with DIN and RMA standards. Every step of production is traceable via QR-coded process control, so you get consistent, high-performance belts—batch after batch.

We have a dedicated after-sales team with an average response time of 12 hours and provide initial solutions within 24 hours to ensure that your production process is not affected.

Our MOQ is total 100 meters + , making it easier for you to start orders, test products, or stock up in batches. We welcome both trial orders and long-term partnerships.